I was happy to present and participate at the 3DEXEPRIENCE User Conference held this year in Paris on 14-15 March. The conference was an evolution of the previous ENOVIA User conferences; this time, it was a joint event by both the ENOVIA and the NETVIBES brand.

I was happy to present and participate at the 3DEXEPRIENCE User Conference held this year in Paris on 14-15 March. The conference was an evolution of the previous ENOVIA User conferences; this time, it was a joint event by both the ENOVIA and the NETVIBES brand.

The conference was, for me, like a reunion. As I have worked for over 25 years in the SmarTeam, ENOVIA and 3DEXPERIENCE eco-system, now meeting people I have worked with and have not seen for over fifteen years.

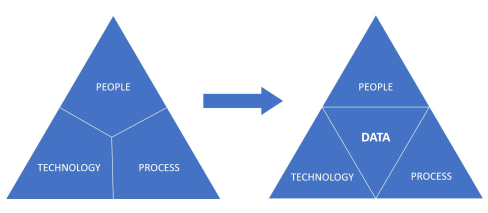

My presentation: Sustainability Demands Virtualization – and it should happen fast was based on explaining the transformation from a coordinated (document-driven) to a connected (data-driven) enterprise.

There were 100+ attendees at the conference, mainly from Europe, and most of the presentations were coming from customers, where the breakout sessions gave the attendees a chance to dive deeper into the Dassault Systèmes portfolio.

Here are some of my impressions.

The power of ENOVIA and NETVIBES

I had a traditional view of the 3DEXPERIENCE platform based on my knowledge of ENOVIA, CATIA and SIMULIA, as many of my engagements were in the domain of MBSE or a model-based approach.

I had a traditional view of the 3DEXPERIENCE platform based on my knowledge of ENOVIA, CATIA and SIMULIA, as many of my engagements were in the domain of MBSE or a model-based approach.

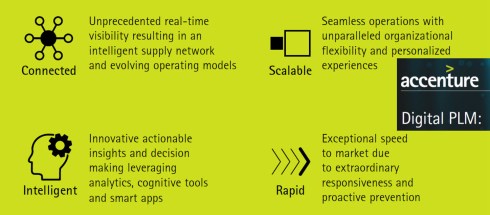

However, at this conference, I discovered the data intelligence side that Dassault Systèmes is bringing with its NETVIBES brand.

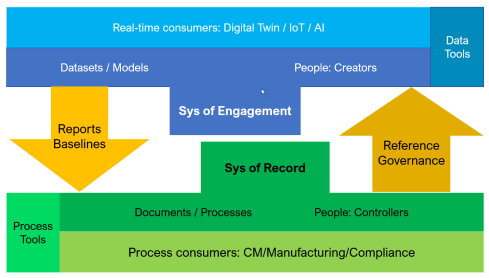

Where I would classify the ENOVIA part of the 3DEXPERIENCE platform as a traditional System of Record infrastructure (see Time to Split PLM?).

I discovered that by adding NETVIBES on top of the 3DEXPERIENCE platform and other data sources, the potential scope had changed significantly. See the image below:

As we can see, the ontologies and knowledge graph layer make it possible to make sense of all the indexed data below, including the data from the 3DEXPERIENCE Platform, which provides a modern data-driven layer for its consumers and apps.

The applications on top of this layer, standard or developed, can be considered Systems of Engagement.

My curiosity now: will Dassault Systèmes keep supporting the “old” system of record approach – often based on BOM structures (see also my post: The Rise and Fall of the BOM) combined with the new data-driven environment? In that case, you would have both approaches within one platform.

My curiosity now: will Dassault Systèmes keep supporting the “old” system of record approach – often based on BOM structures (see also my post: The Rise and Fall of the BOM) combined with the new data-driven environment? In that case, you would have both approaches within one platform.

The Virtual Twin versus the Digital Twin

It is interesting to notice that Dassault Systèmes consistently differentiates between the definition of the Virtual Twin and the Digital Twin.

According to the 3DS.com website:

Digital Twins are simply a digital form of an object, a virtual version.

Unlike a digital twin prototype that focuses on one specific object, Virtual Twin Experiences let you visualize, model and simulate the entire environment of a sophisticated experience. As a result, they facilitate sustainable business innovation across the whole product lifecycle.

Understandably, Dassault Systemes makes this differentiation. With the implementation of the Unified Product Structure, they can connect CAD geometry as datasets to other non-CAD datasets, like eBOM and mBOM data.

The Unified Product Structure was not the topic of this event but is worthwhile to notice.

REE Automotive

![]() The presentation from Steve Atherton from REE Automotive was interesting because here we saw an example of an automotive startup that decided to go pure for the cloud.

The presentation from Steve Atherton from REE Automotive was interesting because here we saw an example of an automotive startup that decided to go pure for the cloud.

REE Automotive is an Israeli technology company that designs, develops, and produces electric vehicle platforms. Their mission is to provide a modular and scalable electric vehicle platform that can be used by a wide range of industries, including delivery and logistics, passenger cars, and autonomous vehicles.

Steve Atherton is the PLM 3DExperience lead for REE at the Engineering Centre in Coventry in the UK, where they have most designers. REE also has an R&D center in Tel Aviv with offshore support from India and satellite offices in the US

Steve Atherton is the PLM 3DExperience lead for REE at the Engineering Centre in Coventry in the UK, where they have most designers. REE also has an R&D center in Tel Aviv with offshore support from India and satellite offices in the US

REE decided from the start to implement its PLM backbone in the cloud, a logical choice for such a global spread company.

The cloud was also one of the conference’s central themes, and it was interesting to see that a startup company like REE is pushing for an end-to-end solution based on a cloud solution. So often, you see startups choosing traditional systems as the senior members of the startup to take their (legacy) PLM knowledge to their next company.

The cloud was also one of the conference’s central themes, and it was interesting to see that a startup company like REE is pushing for an end-to-end solution based on a cloud solution. So often, you see startups choosing traditional systems as the senior members of the startup to take their (legacy) PLM knowledge to their next company.

The current challenge for REE is implementing the manufacturing processes (EBOM- MBOM) and complying as much as possible with the out-of-the-box best practices to make their cloud implementation future-proof.

Groupe Renault

Olivier Mougin, Head of PLM at Groupe RENAULT, talked about their Renaulution Virtual Twin (RVT) program. Renault has always been a strategic partner of Dassault Systèmes.

Olivier Mougin, Head of PLM at Groupe RENAULT, talked about their Renaulution Virtual Twin (RVT) program. Renault has always been a strategic partner of Dassault Systèmes.

I remember them as one of the first references for the ENOVIA V6 backbone.

The Renaulution Virtual Twin ambition: from engineering to enterprise platform, is enormous, as you can see below:

Each of the three pillars has transformational aspects beyond traditional ways of working. For each pillar, Olivier explained the business drivers, expected benefits, and why a new approach is needed. I will not go into the details in this post.

However, you can see the transformation from an engineering backbone to an enterprise collaboration platform – The Renaulution!.

Ahmed Lguaouzi, head of marketing at NETVIBES, enforced the extended power of data intelligence on top of an engineering landscape as the target architecture.

Renault’s ambition is enormous – the ultimate dream of digital transformation for a company with a great legacy. The mission will challenge Renault and Dassault Systèmes to implement this vision, which can become a lighthouse for others.

3DS PLM Journey at MIELE

An exciting session close to my heart was the digital transformation story from MIELE, explained by André Lietz, head of the IT Products PLM @ Miele. As an old MIELE dishwasher owner, I was curious to learn about their future.

An exciting session close to my heart was the digital transformation story from MIELE, explained by André Lietz, head of the IT Products PLM @ Miele. As an old MIELE dishwasher owner, I was curious to learn about their future.

Miele has been a family-owned business since 1899, making high-end domestic and commercial equipment. They are a typical example of the power of German mid-market companies. Moreover, family-owned gives them stability and the opportunity to develop a multi-year transformation roadmap without being distracted by investor demands every few years.

André, with his team, is responsible for developing the value chain inside the product development process (PDP), the operation of nearly 90 IT applications, and the strategic transformation of the overarching PLM Mission 2027+.

André, with his team, is responsible for developing the value chain inside the product development process (PDP), the operation of nearly 90 IT applications, and the strategic transformation of the overarching PLM Mission 2027+.

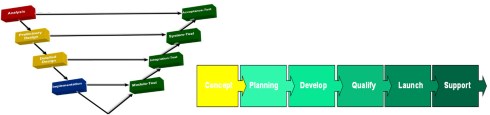

As the slide below illustrates, the team is working on four typical transformation drivers:

- Providing customers with connected, advanced products (increasing R&D complexity)

- Providing employees with a modern, digital environment (the war for digital talent)

- Providing sustainable solutions (addressing the whole product lifecycle)

- Improving internal end-to-end collaboration and information visibility (PLM digital transformation)

André talked about their DELMIA pilot plant/project and its benefits to connect the EBOM and MBOM in the 3DEXPERIENCE platform. From my experience, this is a challenging topic, particularly in German companies, where SAP dominated the BOM for over twenty years.

I am curious to learn more about the progress in the upcoming years. The vision is there; the transformation is significant, but they have the time to succeed! This can be another digital transformation example.

I am curious to learn more about the progress in the upcoming years. The vision is there; the transformation is significant, but they have the time to succeed! This can be another digital transformation example.

And more …

Besides some educational sessions by Dassault Systemes (Laurent Bertaud – NETVIBES data science), there were also other interesting customer testimonies from Fernando Petre (IAR80 – Fly Again project), Christian Barlach (ISC Sustainable Construction) and Thelma Bonello (Methode Electronics – end-to-end BOM infrastructure). All sessions helped to get a better understanding about what is possible and what is done in the domain of PLM.

Conclusion

I learned a lot during these days, particularly the virtual twin strategy and the related capabilities of data intelligence. As the event was also a reunion for me with many people from my network, I discovered that we all aim at a digital transformation. We have a mission and a vision. The upcoming years will be crucial to implement the mission and realizing the vision. It will be the early adopters like Renault pushing Dassault Systèmes to deliver. I hope to stay tuned. You too?

NOTE: Dassault Systèmes covered some of the expenses associated with my participation in this event but did not in any way influence the content of this post.

I am writing this post because one of my PLM peers recently asked me this question: “Is the BOM losing its position? He was in discussion with another colleague who told him:

I am writing this post because one of my PLM peers recently asked me this question: “Is the BOM losing its position? He was in discussion with another colleague who told him: S

S

The ERP system became the most significant IT system, the execution system of the company. As it was the first enterprise system implemented, it was the first moment we learned about implementation challenges – people change and budget overruns. However, as the ERP system brought visibility to the company’s execution, it became a “must-have” system for management.

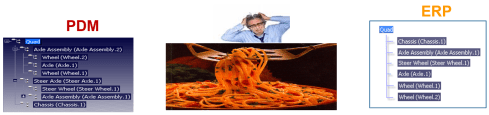

The ERP system became the most significant IT system, the execution system of the company. As it was the first enterprise system implemented, it was the first moment we learned about implementation challenges – people change and budget overruns. However, as the ERP system brought visibility to the company’s execution, it became a “must-have” system for management. Sometimes the interaction with the MRP/ERP system was enhanced by an interface – sending the drawing BOM to ERP. The advantage of the interface: no manual transfer of data reducing typos and BOM errors. The disadvantages at that time: relatively expensive (connectivity between systems was a challenge) and mostly one direction.

Sometimes the interaction with the MRP/ERP system was enhanced by an interface – sending the drawing BOM to ERP. The advantage of the interface: no manual transfer of data reducing typos and BOM errors. The disadvantages at that time: relatively expensive (connectivity between systems was a challenge) and mostly one direction.

Many companies still have based their processes on this approach. ERP (read SAP nowadays) is the central execution system, and PDM is an external system. You might remember the story and image from

Many companies still have based their processes on this approach. ERP (read SAP nowadays) is the central execution system, and PDM is an external system. You might remember the story and image from

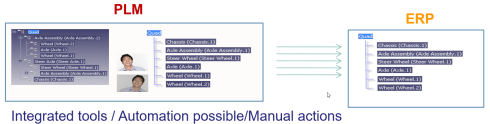

The MBOM structure in PLM could then be the information structure to transfer to the ERP system; however, there is more, as

The MBOM structure in PLM could then be the information structure to transfer to the ERP system; however, there is more, as

Historically ERP was the first enterprise system that most companies implemented. For product development, there was the PDM system, an engineering tool, and for execution, there was the ERP system. Since ERP focuses on the company’s execution, the system became the management’s favorite.

Historically ERP was the first enterprise system that most companies implemented. For product development, there was the PDM system, an engineering tool, and for execution, there was the ERP system. Since ERP focuses on the company’s execution, the system became the management’s favorite. Next, as the ERP system could only deal with 7 digits, what about part number reuse? In conclusion, it is a considerable risk that reused part numbers can lead to errors. With the introduction of the PLM systems, there was the opportunity to bridge the gap between engineering and manufacturing. Now it is clear for most companies that the engineer should create the initial part number.

Next, as the ERP system could only deal with 7 digits, what about part number reuse? In conclusion, it is a considerable risk that reused part numbers can lead to errors. With the introduction of the PLM systems, there was the opportunity to bridge the gap between engineering and manufacturing. Now it is clear for most companies that the engineer should create the initial part number. Meanwhile, in the PLM world, we have evolved on this topic. The part and the BOM are no longer simple entities. Instead, we often differentiate between EBOM and MBOM, and the parts in those BOMs are not necessarily the same.

Meanwhile, in the PLM world, we have evolved on this topic. The part and the BOM are no longer simple entities. Instead, we often differentiate between EBOM and MBOM, and the parts in those BOMs are not necessarily the same.

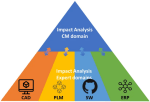

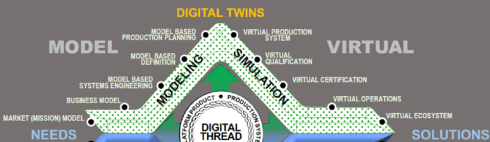

Once we start to include sustainability in our product’s mission, we need a systems engineering approach, as several factors will push for different considerations. The most obvious considerations are the choice of materials and the optimizing the production process (reducing carbon emissions).

Once we start to include sustainability in our product’s mission, we need a systems engineering approach, as several factors will push for different considerations. The most obvious considerations are the choice of materials and the optimizing the production process (reducing carbon emissions). Probably Yes, when your customer has a long-term vision, as the overall lifecycle costs of the product will be lower.

Probably Yes, when your customer has a long-term vision, as the overall lifecycle costs of the product will be lower. However, the change has already started. Higher energy prices will impact the production of specific resources and raise costs. In addition, energy-intensive manufacturing processes will lead to more expensive materials. Combined with raising carbon taxes, this will be a significant driver for companies to reconsider their product offering and manufacturing processes.

However, the change has already started. Higher energy prices will impact the production of specific resources and raise costs. In addition, energy-intensive manufacturing processes will lead to more expensive materials. Combined with raising carbon taxes, this will be a significant driver for companies to reconsider their product offering and manufacturing processes.

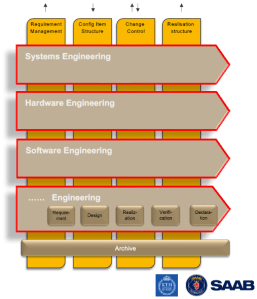

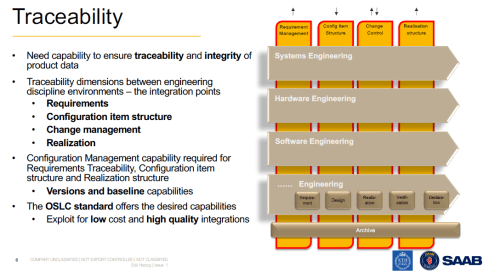

This year started for me with a discussion related to federated PLM. A topic that I highlighted as one of the imminent trends of 2022. A topic relevant for PLM consultants and implementers. If you are working in a company struggling with PLM, this topic might be hard to introduce in your company.

This year started for me with a discussion related to federated PLM. A topic that I highlighted as one of the imminent trends of 2022. A topic relevant for PLM consultants and implementers. If you are working in a company struggling with PLM, this topic might be hard to introduce in your company.

The actual engineering work is done with specialized tools, MCAD/ECAD, CAE, Simulation, Planning tools and more. Therefore, each person could work in their discipline-specific environment and synchronize their data to the PLM system in a coordinated manner.

The actual engineering work is done with specialized tools, MCAD/ECAD, CAE, Simulation, Planning tools and more. Therefore, each person could work in their discipline-specific environment and synchronize their data to the PLM system in a coordinated manner. Many of my implementation discussions with customers were in this context. For example, suppose your products are relatively simple, or your company is relatively small. In that case, the opinion is that the System or Record approach is overkill.

Many of my implementation discussions with customers were in this context. For example, suppose your products are relatively simple, or your company is relatively small. In that case, the opinion is that the System or Record approach is overkill. Customers, partners, and regulators all expect more accurate and fast responses on specific issues, preferably instantly. In addition, sustainability regulations might push your company to implement a System of Record.

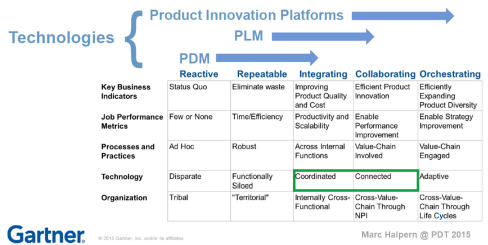

Customers, partners, and regulators all expect more accurate and fast responses on specific issues, preferably instantly. In addition, sustainability regulations might push your company to implement a System of Record. For the past fifteen years, we have discussed PLM more as a business strategy implemented with business systems and an infrastructure designed for sharing. Therefore, I choose these words carefully to avoid overhanging the expression: PLM as a business strategy.

For the past fifteen years, we have discussed PLM more as a business strategy implemented with business systems and an infrastructure designed for sharing. Therefore, I choose these words carefully to avoid overhanging the expression: PLM as a business strategy.

Connecting all stakeholders in an engagement has been a game changer in the world. With the introduction of platforms and the smartphone as a connected device, consumers could suddenly benefit from direct responses to desired service requests (Spotify, iTunes, Uber, Amazon, Airbnb, Booking, Netflix, …).

Connecting all stakeholders in an engagement has been a game changer in the world. With the introduction of platforms and the smartphone as a connected device, consumers could suddenly benefit from direct responses to desired service requests (Spotify, iTunes, Uber, Amazon, Airbnb, Booking, Netflix, …).

One of the main arguments behind this conclusion was that legacy product data and processes were not designed to ensure data accuracy and quality on such a level that it could become connected data. As a result, converting documents into reliable datasets would be a costly, impossible exercise with no real ROI.

One of the main arguments behind this conclusion was that legacy product data and processes were not designed to ensure data accuracy and quality on such a level that it could become connected data. As a result, converting documents into reliable datasets would be a costly, impossible exercise with no real ROI.

Systems of Engagement do not need to come from the same vendor, as they serve different purposes. But how to explain this to your management, who wants simplicity. I can imagine the IT organization has a better understanding of this concept as, at the end of 2015, Gartner introduced the concept of the bimodal approach.

Systems of Engagement do not need to come from the same vendor, as they serve different purposes. But how to explain this to your management, who wants simplicity. I can imagine the IT organization has a better understanding of this concept as, at the end of 2015, Gartner introduced the concept of the bimodal approach. Happy New Year to all of you, and may this year be a year of progress in understanding and addressing the challenges ahead of us.

Happy New Year to all of you, and may this year be a year of progress in understanding and addressing the challenges ahead of us.

And even here, I would say this definition is challenging as the scope is extensive and could touch a lot of activities inside an enterprise. As I wrote last year in my

And even here, I would say this definition is challenging as the scope is extensive and could touch a lot of activities inside an enterprise. As I wrote last year in my

This week there was an interesting discussion on LinkedIn initiated by

This week there was an interesting discussion on LinkedIn initiated by  This time Alex shared an observation from an event organized by the

This time Alex shared an observation from an event organized by the

Again statistics show it is not likely that advanced tools like NX or CATIA will be chosen for the design part. More likely mid-market products like SolidWorks or Autodesk products. And for data management and reporting, the logical tools are the office tools, Excel, Word and Visio.

Again statistics show it is not likely that advanced tools like NX or CATIA will be chosen for the design part. More likely mid-market products like SolidWorks or Autodesk products. And for data management and reporting, the logical tools are the office tools, Excel, Word and Visio.

This is the same dilemma that very small and medium enterprises face. They function reasonably well in a

This is the same dilemma that very small and medium enterprises face. They function reasonably well in a  However, in path #2, the startup should have a longer-term vision. Instead of choosing the obvious tools, they should focus on their company’s most important value streams. They have the opportunity to select integrated domains that are based on a connected, often model-based approach. Some examples of these integrated domains:

However, in path #2, the startup should have a longer-term vision. Instead of choosing the obvious tools, they should focus on their company’s most important value streams. They have the opportunity to select integrated domains that are based on a connected, often model-based approach. Some examples of these integrated domains:

It turned out that my grandson was wrong. The keynote speech from

It turned out that my grandson was wrong. The keynote speech from  It showed Dassault Systems, with its 2012 purpose (click on the link to see its history),

It showed Dassault Systems, with its 2012 purpose (click on the link to see its history),

That’s why I am greatly interested in all the developments related to a federated PLM infrastructure. A monolithic system cannot be the solution for such a model-based environment. In my terminology, here we need an architecture with systems of engagement combined with system(s) of record.

That’s why I am greatly interested in all the developments related to a federated PLM infrastructure. A monolithic system cannot be the solution for such a model-based environment. In my terminology, here we need an architecture with systems of engagement combined with system(s) of record.

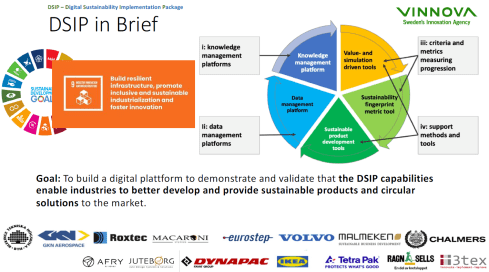

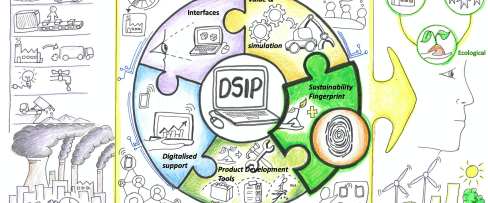

At this moment, sustainability is at the top of my personal agenda, and I hope for many of you. However, besides the choices we can make in our personal lives, there is also an area where we, as PLM interested parties, should contribute: The digitization of the product lifecycle as an enabler for a sustainable business.

At this moment, sustainability is at the top of my personal agenda, and I hope for many of you. However, besides the choices we can make in our personal lives, there is also an area where we, as PLM interested parties, should contribute: The digitization of the product lifecycle as an enabler for a sustainable business.

I hope you all remained curious

I hope you all remained curious

According to Stefaan, in the previous century, curiosity had a negative connotation. Curiosity killing the cat is one of these expressions confirming the mindset. It was all about conformity to the majority, the company, and curiosity was non-conformant.

According to Stefaan, in the previous century, curiosity had a negative connotation. Curiosity killing the cat is one of these expressions confirming the mindset. It was all about conformity to the majority, the company, and curiosity was non-conformant.

It is a business change; however, sustainability will push organizations to change faster than we are used to. For example,

It is a business change; however, sustainability will push organizations to change faster than we are used to. For example,

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…