You are currently browsing the category archive for the ‘Supplier Collaboration’ category.

One year ago, I wrote the post: Time to Split PLM, which reflected a noticeable trend in 2022 and 2023.

One year ago, I wrote the post: Time to Split PLM, which reflected a noticeable trend in 2022 and 2023.

If you still pursue the Single Source of Truth or think that PLM should be supported by a single system, the best you can buy, then you are living in the past.

It is now the time to move from a Monolithic PLM Landscape to a Federated Domain and Data Mesh (Yousef Hooshmand) or the Heliple Federated PLM project (Erik Herzog) – you may have read about these concepts.

When moving from a traditional coordinated, document-driven business towards a modern, connected, and data-driven business, there is a paradigm shift. In many situations, we still need the document-driven approach to manage baselines for governance and traceability, where we create the required truth for manufacturing, compliance, and configuration management.

However, we also need an infrastructure for multidisciplinary collaboration nowadays. Working with systems, a combination of hardware and software, requires a model-based approach and multidisciplinary collaboration. This infrastructure needs to be data-driven to remain competitive despite more complexity, connecting stakeholders along value streams.

Traditional PLM vendors still push all functionality into one system, often leading to frustration among the end-users, complaining about lack of usability, bureaucracy, and the challenge of connecting to external stakeholders, like customers, suppliers, design or service partners.

Traditional PLM vendors still push all functionality into one system, often leading to frustration among the end-users, complaining about lack of usability, bureaucracy, and the challenge of connecting to external stakeholders, like customers, suppliers, design or service partners.

Systems of Engagement

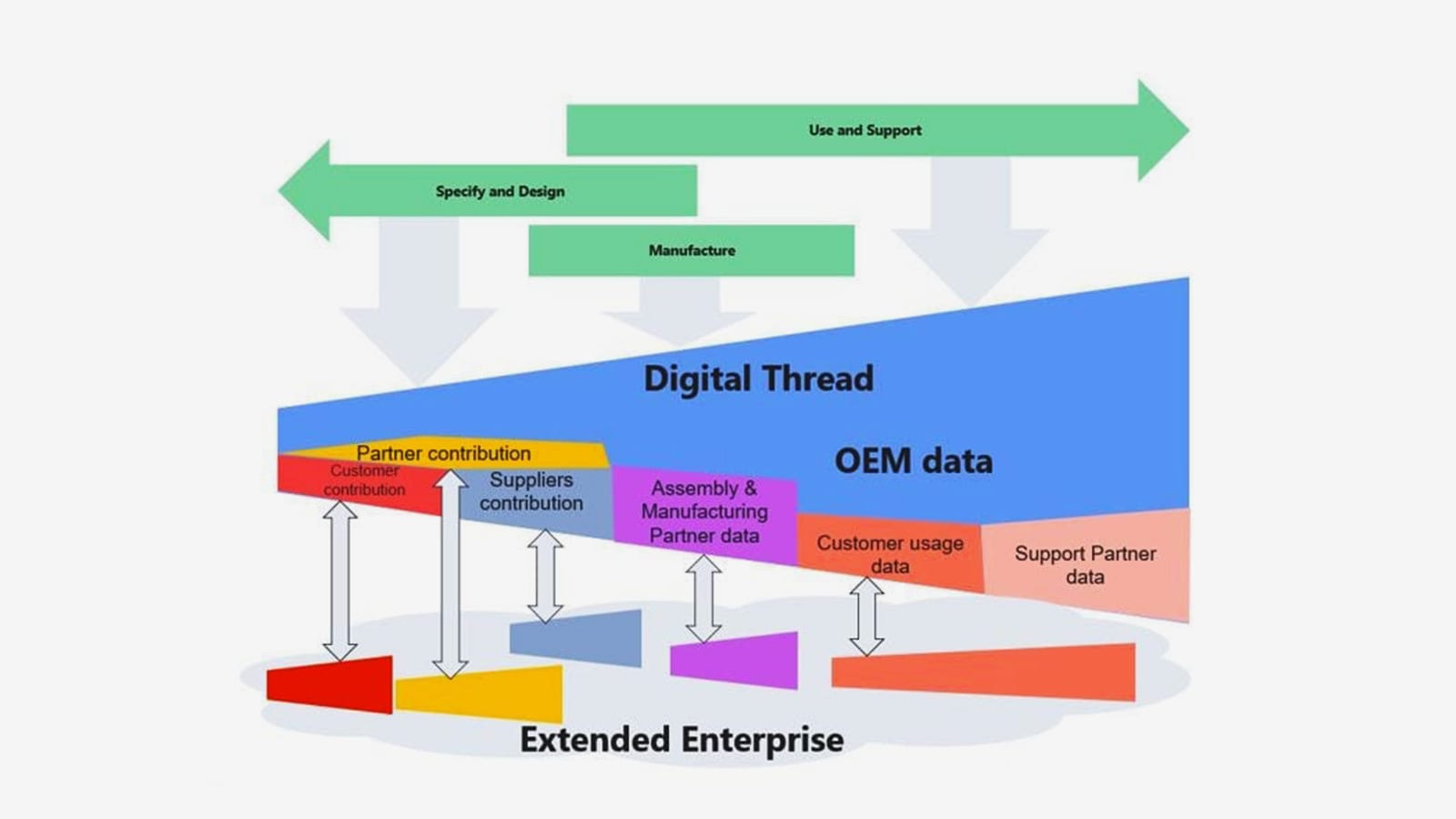

It is in modern PLM infrastructures where I started the positioning of Systems or Record (the traditional enterprise siloes – PDM/PLM, ERP, CM) and the Systems of Engagement (modern environments designed for close to real-time collaboration between stakeholders within a domain/value stream). In the Heliple project (image below), the Systems of Record are the vertical bars, and the Systems of Engagement are the horizontal bars.

The power of a System of Engagement is the data-driven connection between stakeholders even when working in different enterprises. Last year, I discussed with Andre Wegner from Authentise, MJ Smith from CoLab, and Oleg Shilovitsky from OpenBOM.

They all focus on modern, data-driven, multidisciplinary collaboration. You can find the discussion here: The new side of PLM? Systems of Engagement!

Where is the money?

Business leaders usually are not interested in a technology or architectural discussion – too many details and complexity, they look for the business case. Look at this recent post and comments on LinkedIn – “When you try to explain PLM to your C-suite, and they just don’t get it.”

Business leaders usually are not interested in a technology or architectural discussion – too many details and complexity, they look for the business case. Look at this recent post and comments on LinkedIn – “When you try to explain PLM to your C-suite, and they just don’t get it.”

It is hard to build evidence for the need for systems of engagement, as the concepts are relatively new and experiences from the field are bubbling up slowly. With the Heliple team, we are now working on building the business case for Federated PLM in the context of the Heliple project scope.

Therefore, I was excited to read the results of this survey: Quantifying the impact of design review methods on NPD, a survey among 250 global engineering leaders initiated by CoLab.

![]() CoLab is one of those companies that focus on providing a System of Engagement, and their scope is design collaboration. In this post, I am discussing the findings of this survey with Taylor Young, Chief Strategy Officer of CoLab.

CoLab is one of those companies that focus on providing a System of Engagement, and their scope is design collaboration. In this post, I am discussing the findings of this survey with Taylor Young, Chief Strategy Officer of CoLab.

CoLab – the company /the mission

Taylor, thanks for helping me explain the complementary value of CoLab based on some of the key findings from the survey. But first of all, can you briefly introduce CoLab as a company and the unique value you are offering to your clients?

Taylor, thanks for helping me explain the complementary value of CoLab based on some of the key findings from the survey. But first of all, can you briefly introduce CoLab as a company and the unique value you are offering to your clients?

Hi Jos, CoLab is a Design Engagement System – we exist to help engineering teams make design decisions.

Hi Jos, CoLab is a Design Engagement System – we exist to help engineering teams make design decisions.

Product decision-making has never been more challenging – or more essential – to get right – that’s why we built CoLab. In today’s world of product complexity, excellent decision-making requires specialized expertise. That means decision-making is no longer just about people engaging with product data – it’s about people engaging with other people.

PLM provides a strong foundation where product data is controlled (and therefore reliable). But PLM has a rigid architecture that’s optimized for data (and for human-to-data interaction). To deal with increased complexity in product design, engineers now need a system that’s built for human-to-human interaction complimentary to PLM.

CoLab allows you to interrogate a rich dataset, even an extended team, outside your company borders in real-time or asynchronously. With CoLab, decisions are made with context, input from the right people, and as early as possible in the process. Reviews and decision-making get tracked automatically and can be synced back to PLM. Engineers can do what they do best, and CoLab will support them by documenting everything in the background.

Design Review Quality

It is known that late-stage design errors are very costly, both impacting product launches and profitability. The report shows design review quality has been rated as the #1 most important factor affecting an engineering team’s ability to deliver projects on time.

It is known that late-stage design errors are very costly, both impacting product launches and profitability. The report shows design review quality has been rated as the #1 most important factor affecting an engineering team’s ability to deliver projects on time.

Is it a severe problem for companies, and what are they trying to do to improve the quality of design reviews? Can you quantify the problem?

Our survey report demonstrated that late-stage design errors delay product launches for 90% of companies. The impact varies significantly from organization to organization, but we know that for large manufacturing companies, just one late-stage design error can be a six to seven-figure problem.

Our survey report demonstrated that late-stage design errors delay product launches for 90% of companies. The impact varies significantly from organization to organization, but we know that for large manufacturing companies, just one late-stage design error can be a six to seven-figure problem.

There are a few factors that lead to a “quality” design review – some of the most important ones we see leading manufacturing companies doing differently are:

- Who they include – the highest performing teams include manufacturing, suppliers, and customers within the proper context.

- When they happen – the highest performing teams focus on getting CAD to these stakeholders early in the process (during detailed design) and paralleling these processes (i.e., they don’t wait for one group to sign off before getting early info to the next)

- Rethinking the Design Review meeting – the highest performing teams aren’t having issue-generation meetings – they have problem-solving meetings. Feedback is collected from a broad audience upfront, and meetings are used to solve nuanced problems – not to get familiar with the project for the first time.

Multidisciplinary collaboration

An interesting observation is that providing feedback to engineers mainly comes from peers or within the company. Having suppliers or customers involved seems to be very difficult. Why do you think this is happening, and how can we improve their contribution?

An interesting observation is that providing feedback to engineers mainly comes from peers or within the company. Having suppliers or customers involved seems to be very difficult. Why do you think this is happening, and how can we improve their contribution?

When we talk to manufacturing companies about “collaboration” or how engineers engage with other engineers – however good or bad the processes are internally, it almost always is significantly more challenging/less effective when they go external. External teams often use different CAD systems, work in different time zones, speak other first languages, and have varying levels of access to core engineering information.

When we talk to manufacturing companies about “collaboration” or how engineers engage with other engineers – however good or bad the processes are internally, it almost always is significantly more challenging/less effective when they go external. External teams often use different CAD systems, work in different time zones, speak other first languages, and have varying levels of access to core engineering information.

However, as we can read from the HBR article What the Most Productive Companies Do Differently, we know that the most productive manufacturing companies “collaborate with suppliers and customers to form new ecosystems that benefit from agglomeration effects and create shared pools of value”.

They leverage the expertise of their suppliers and customers to do things more effectively. But manufacturing companies struggle to create engaging, high-value, external collaboration and ‘co-design’ without the tools purpose-built for person-to-person external communication.

Traceability and PLM

One of the findings is that keeping track of the feedback and design issues is failing in companies. One of my recommendations from the past was to integrate Issue management into your PLM systems – why is this not working?

One of the findings is that keeping track of the feedback and design issues is failing in companies. One of my recommendations from the past was to integrate Issue management into your PLM systems – why is this not working?

We believe that the task of completing a design review and the task of documenting the output of that review should not be two separate efforts. Suppose we are to reduce the amount of time engineers spend on admin work and decrease the number of issues that are never tracked or documented (43%, according to our survey).

We believe that the task of completing a design review and the task of documenting the output of that review should not be two separate efforts. Suppose we are to reduce the amount of time engineers spend on admin work and decrease the number of issues that are never tracked or documented (43%, according to our survey).

In that case, we need to introduce a purpose-built, engaging design review system that is self-documenting. It is crucial for the quality of design reviews that issues aren’t tracked in a separate system from where they are raised/developed, but that instead, they are automatically tracked just by doing the work.

Learn More?

Below is the recording of a recent webinar, where Taylor said that your PLM alone isn’t enough: Why you need a Design Engagement System during product development.

- A traditional PLM system is the system of record for product data – from ideation through sustaining engineering.

- However one set of critical data never makes it to the PLM. For many manufacturing companies today, design feedback and decisions live almost exclusively in emails, spreadsheets, and PowerPoint decks. At the same time, 90% of engineering teams state that product launches are delayed due to late-stage changes.

- Engineering teams need to implement a true Design Engagement System (DES) for more effective product development and a more holistic digital thread.

Conclusion

Traditional PLM systems have always been used to provide quality and data governance along the product lifecycle. However, most end users dislike the PLM system as it is a bureaucratic overhead to their ways of working. CoLab, with its DES solution, provides a System of Engagement focusing on design reviews, speed, and quality of multidisciplinary collaboration complementary to the PLM System of Record – a modern example of how digitization is transforming the PLM domain.

Again, a “The weekend after …” post related to my favorite event to which I have contributed since 2014.

Expectations were high this time from my side, in particular because we would have a serious discussion related to connected digital threads and federated PLM.

More about these topics in my post next week as all content is not yet available for sharing.

The conference was sold out this time, and during the breaks, you had to navigate through the people to find your network opportunities. Also, the participation of the main PLM players as sponsors illustrated that everyone wanted to benefit from this opportunity to meet and learn from their industry peers.

The conference was sold out this time, and during the breaks, you had to navigate through the people to find your network opportunities. Also, the participation of the main PLM players as sponsors illustrated that everyone wanted to benefit from this opportunity to meet and learn from their industry peers.

Looking back to the conference, there were two noticeable streams.

- The stream where people share their current PLM experiences, traditionally the A&D action groups moderated by CIMdata, is part of this stream. This part I will cover in this post.

- There were forward-looking presentations related to standards, ontologies, and federated PLM—all with an AI flavor. This part I will cover in my next post(s).

The connection between all these sessions was the Digital Thread. The conference’s theme was: The Digital Thread in a Heterogeneous, Extended Enterprise Reality. Let’s start the review with the highlights from the first stream.

Digital Thread: Why Should We Care?

As usual, Peter Bilello from CIMdata kicked off the conference by setting the scene. Peter started by clarifying the two definitions of the Digital Thread.

- The first is a communication framework that allows a connected data flow and integrated view of an asset’s data (i.e., its Digital Twin) throughout its lifecycle across traditionally siloed functional perspectives.

In my terminology, the connected digital thread. - The second is a network of connected information sources around the product lifecycle supporting traceability and decision-making.

In my terminology, the coordinated digital thread is the most straightforward digital thread to achieve.

Peter recommends starting a digital thread by connecting at the beginning of product conceptualization, creating an environment where one can analyze the performance of the product portfolio and the product features and capabilities that need to be planned or how they perform in the field.

In addition, when defining the products, connect them with regulatory requirement databases as they have must-have requirements. A topic I addressed in my session too, besides the existing regulatory requirements, it is expected that in the upcoming years, due to environmental regulations, these requirements will increase, and it will be necessary to have them integrated with your digital thread.

Digital Threads require data governance and are the basis for the various digital twins. Peter discussed the multiple applications of the digital twin, primarily a relation between a virtual asset and a physical asset, except in the early concept phase.

The digital thread is still in the early phase of implementation at companies. A CIMdata survey showed that companies still focus primarily on implementing traditional PDM capabilities, although as the image above shows, there is a growing interest in short-term digital twin/thread implementations.

People, Process & Technology:

The Pillars of Digital Transformation Success

The second keynote was from Christine McMonagle, Director of Digital Engineering Systems at Textron Systems a services and products supplier for the Aerospace and Defense industry. Christine leads the digital evolution in Textron Systems and presents nicely how a digital transformation should start from the people.Traditionally this industry has enough budget on the OEM level and therefore companies will not take a revolutionary approach when it comes to digital transformation.

The second keynote was from Christine McMonagle, Director of Digital Engineering Systems at Textron Systems a services and products supplier for the Aerospace and Defense industry. Christine leads the digital evolution in Textron Systems and presents nicely how a digital transformation should start from the people.Traditionally this industry has enough budget on the OEM level and therefore companies will not take a revolutionary approach when it comes to digital transformation.

Having your people at all levels involved and make them understand the need for change is crucial. A change does not happen top-down. You must educate people and understand what is possible and achievable to change – in the right direction. One of her concluding slides highlights the main points.

In the Q&A there to Christine’s sessions there was an interesting question related to the involvement of Human Resources (HR) in this project. There was a laugh that said it all – like in most companies HR is not focusing on organizational change, they focus more on operational issues – the Human is considered a Resource.

In the Q&A there to Christine’s sessions there was an interesting question related to the involvement of Human Resources (HR) in this project. There was a laugh that said it all – like in most companies HR is not focusing on organizational change, they focus more on operational issues – the Human is considered a Resource.

Between the regular sessions there were short sessions from sponsors: Altium, Contact Software, Dassault Systemes, ESI, inensia, Modular Management , PTC, SAP, Share PLM and Sinequa could pitch their value offering.

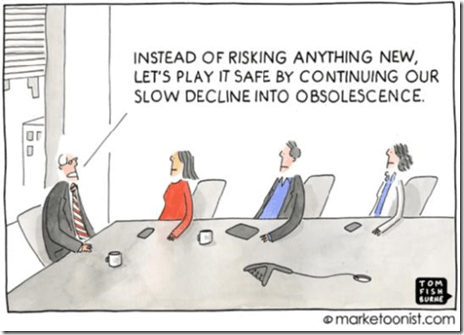

The Share PLM session, shortly after Christine’s presentation was a nice continuation of the focus on people. I loved the Share PLM image to the left explaining why people do not engage with our dreams.

Learn how LEONI is achieving Digital Continuity in the Automotive Industry.

Tobias Bauer, head of Product Data Standardization at LEONI talked about their FLOW project. FLOW is an acronym for Future Leoni Operating World. LEONI, well-known in the automotive industry produces cable and network solutions, including cable harnesses.

Tobias Bauer, head of Product Data Standardization at LEONI talked about their FLOW project. FLOW is an acronym for Future Leoni Operating World. LEONI, well-known in the automotive industry produces cable and network solutions, including cable harnesses.

Recently it has gone through a serious financial crisis and the need for restructuring. This makes it always challenging for a “visionary” PLM project. Tobias mentioned that after disappointing engagements with consultancy firms, they decided on a bottom-up approach to analyze existing processes using BPML. They agreed on a to-be state, fixing bottlenecks and streamlining the flow of information.

Tobias presented a smooth product data flow between their PLM system (PTC Windchill) and ERP (SAP S/4 HANA), clearly stating that the PLM system has become the controlled source of managing product changes.

Their key achievements reported so far were:

- related to BOM creation and routing (approx. 10x faster – from 2-3 days to ¼ day),

- better data consistency (fewer manual steps)

- complete traceability between the systems with PLM as the change management backbone.

The last point I would call the coordinated Digital Thread. The image below shows their current IT landscape in a simplified manner.

This solution might seem obvious for neutral PLM academics or experts, but it is an achievement to do this in an environment with SAP implemented. The eBOM-mBOM discussion is one of the most frequent held discussions – sometimes a battle.

Often, companies use their IT systems first and listen to the vendor’s experts to build integrations instead of starting from the natural business flow of information.

Aerospace & Defense Action groups outcomes

As usual, several Aerospace & Defense (A&D) action groups reported their progress during this conference. The A&D action groups are facilitated by CIMdata, and per topic, various OEMs and suppliers in the A&D industry study and analyze a particular topic, often inviting software vendors to demonstrate and discuss their capabilities with them.

Their activities and reports can be found on the A&D PLM Action page here; In the remainder of this post I will share briefly the ones presented. For a real deep dive in the topics I recommend to find the proceedings per topic on the A&D action page.

The Promise and Reality of the Digital Thread

James Roche CIMdata presented insights from industry research on The Promise and Reality of the Digital Thread. A total of 90 persons completed an in-depth survey about the status and implementation of digital thread concepts in their company. It is clear that the digital thread is still in its early days in this industry, and it is mainly about the coordinated digital thread. The image below reflects the highlights of the survey.

A&D Industry Digital Twin and Digital Thread Standards

Robert Rencher from Boeing explained the progress of their Digital Twin/Digital Thread project, where they had investigated the applicable standards to support a Digital Twin/Digital Thread (Phase 4 out of 7 currently planned). The image below shows that various standards may apply depending on business perspectives.

Their current findings are:

- Digital twin standards overlap, which is most likely a function of standards bodies representing their respective standards as an ongoing development from a historical perspective.

- The limited availability of mature digital twin/thread standards requires greater attention by standards organizations.

- The concept of the digital twin continues to evolve. This dynamic will be a challenge to standards bodies.

- The digital twin and the digital thread are distinct aspects of digital transformation. The corresponding digital twin and digital thread standards will be distinctly different.

- Coordinating the development of the respective standards between the digital twin/thread is needed.

- The digital twin’s organization, definition, and enablement depend on data and information provided by the digital thread.

Roadmap for Enabling Global Collaboration

Robert Gutwein (Pratt & Whitney Canada) and Agnes Gourillon-Jandot (Safran Aircraft Engines) reported their progress on the Global Collaboration project. Collaboration is challenged as exchange methods can vary, as well as dealing with the validation of exchanged information and governing the exchange of information in the context of IP protection.

One of the focal points was to introduce an approach to define standardized supplier agreements that anticipate modern model-based exchanges and collaboration methods.

Robert & Agnes presented the 8-step guideline for the aerospace industry in specific terms, explicitly mentioning the ISO44001 standard as being generic for all industries. An impression of the eight steps and sub-steps can be found below:

The 8-step approach will be supported by a 3rd-party Collaboration Management System (CMS app), which is not mandatory but recommended for use. When an interaction depends on a specific tool, it cannot become an ISO standard. The purpose of the methodology and app is to assist participants to ensure the collaboration aspect between stakeholders contains all the necessary steps & and people.

Model-based OEM/Supplier Collaboration Needs in Aviation Industry

Hartmut Hintze, working at Airbus Operations, presented the latest findings of the MBSE Data Interoperability working group and presented the model-based OEM/Supplier collaboration requirements and standards that need to be supported by the PLM/MBSE solution providers in the future. This collaboration goes beyond sharing CAD models, as you can see from the supplier engagement framework below:

As there are no standards-based tools, their first focus was looking into methodologies for model and behavior exchanges based on use cases. The use cases are then used to verify the state-of-the-art abilities of the various tools. At this moment, there is a focus on SysML V2 as a potential game-changer due to its new API support. As a relative novice on SysML, I cannot explain this topic in more simple words. I recommend that experts visit their presentations on the AD PAG publications page here.

Conclusions

The theme of the conference was related to the Digital Thread – and as you will discover it is valid for everyone. Learn to see the difference between the coordinated Digital Thread and the connected Digital Tread.This time, a lot of information about the Aerospace and Defense Action Groups (AD PAG), which are a fundamental part of this conference. The A&D industry has always been leading in advanced PLM concepts. However, more advanced concepts will come in my next post when touching the connected Digital Thread in the context of federated PLM and let’s not forget AI.

Imagine you are a supplier working for several customers, such as big OEMs or smaller companies. In Dec 2020, I wrote about PLM and the Supply Chain because it was an underexposed topic in many companies. Suppliers need their own PLM and IP protection and work as efficiently as possible with their customers, often the OEMs.

Imagine you are a supplier working for several customers, such as big OEMs or smaller companies. In Dec 2020, I wrote about PLM and the Supply Chain because it was an underexposed topic in many companies. Suppliers need their own PLM and IP protection and work as efficiently as possible with their customers, often the OEMs.

Most PLM implementations always start by creating the ideal internal collaboration between functions in the enterprise. Historically starting with R&D and Engineering, next expanding to Manufacturing, Services and Marketing. Most of the time in this logical order.

In these implementations, people are not paying much attention to the total value chain, customers and suppliers. And that was one of the interesting findings at that time, supported by surveys from Gartner and McKinsey:

- Gartner: Companies reported improvements in the accuracy of product data and product development as the main benefit of their PLM implementation. They did not see so much of a reduced time to market or reduced product development costs. After analysis, Gartner believes the real issue is related to collaboration processes and supply chain practices. Here the lead times did not change, nor did the number of changes.

- McKinsey: In their article, The Case for Digital Reinvention, digital supply chains were mentioned as the area with the potential highest ROI; however, as the image shows below, it was the area with the lowest investment at that time.

In 2020 we were in the middle of broken supply chains and wishful thinking related to digital transformation, all due to COVID-19.

In 2020 we were in the middle of broken supply chains and wishful thinking related to digital transformation, all due to COVID-19.

Meanwhile, the further digitization in PLM (systems of engagement) and the new topic, Sustainability of the supply chain, became visible.

Therefore it is time to make a status again, also driven by discussions in the past few weeks.

The old “connected” approach (loose-loose).

A preferred way for OEMs in the past was to have the Supplier or partner directly work in their PLM environment. The OEM could keep control of the product development process and the incremental maturity of the BOM, where the Supplier could connect their part data and designs to the OEM environment. T

A preferred way for OEMs in the past was to have the Supplier or partner directly work in their PLM environment. The OEM could keep control of the product development process and the incremental maturity of the BOM, where the Supplier could connect their part data and designs to the OEM environment. T

The advantage for the OEM is clear – direct visibility of the supplier data when available. The benefit for the Supplier could also be immediate visibility of the broader context of the part they are responsible for.

However, the disadvantages for a supplier are more significant. Working in the OEM environment exposes all your IP and hinders knowledge capitalization from the Supplier. Not a big thing for perhaps a tier 3 supplier; however, the more advanced the products from the Supplier are, the higher the need to have its own PLM environment.

However, the disadvantages for a supplier are more significant. Working in the OEM environment exposes all your IP and hinders knowledge capitalization from the Supplier. Not a big thing for perhaps a tier 3 supplier; however, the more advanced the products from the Supplier are, the higher the need to have its own PLM environment.

Therefore the old connected approach is a loose-loose relationship in particular for the Supplier and even for the OEM (having less knowledgeable suppliers)

The modern “connected” approach (wins t.b.d.)

In this situation, the target infrastructure is a digital infrastructure, where datasets are connected in real-time, providing the various stakeholders in engagement access to a filtered set of data relevant to their roles.

In this situation, the target infrastructure is a digital infrastructure, where datasets are connected in real-time, providing the various stakeholders in engagement access to a filtered set of data relevant to their roles.

In my terminology, I refer to them as Systems of Engagement, as the target is that all stakeholders work in this environment.

The counterpart of Systems of Engagement is the Systems of Record, which provides a product baseline, manufacturing baseline, and configuration baseline of information consumed by other disciplines.

These baselines are often called Bills of Information, and the traditional PLM system has been designed as a System of Record. Major Bills of Information are the eBOM, the mBOM and sometimes people talk about the sBOM(service BOM).

These baselines are often called Bills of Information, and the traditional PLM system has been designed as a System of Record. Major Bills of Information are the eBOM, the mBOM and sometimes people talk about the sBOM(service BOM).

Typical examples of Systems of Engagement I have seen in alphabetical order are:

- Arena Solutions has a long-term experience in BOM collaboration between engineering teams, suppliers and contract manufacturers.

- CATENA-X might be a strange player in this list, as CATENA-X is more a German Automotive consortium targeting digital collaboration between stakeholders, ensuring security and IP protection.

- Colab is a provider of cloud-based collaboration software allowing design teams and suppliers to work in real time together.

- OnShape – a cloud-based collaborative product design environment for dispersed engineering teams and partners.

- OpenBOM – a SaaS solution focusing on BOM collaboration connected to various CAD systems along with design teams and their connected suppliers

These are some of the Systems of Engagement I am aware of. They focus on specific value streams that can improve the targeted time to market and product introduction efficiency. In companies with no extensive additional PLM infrastructure, they can become crucial systems of engagement.

The main challenge for these systems of engagement is how they will connect to traditional Systems or Records – the classical PLM systems that we know in the market (Aras, Dassault, PTC, Siemens).

The main challenge for these systems of engagement is how they will connect to traditional Systems or Records – the classical PLM systems that we know in the market (Aras, Dassault, PTC, Siemens).

Image on the left from a presentation done by Eric Herzog from SAAB at last year’s CIMdata/PDT conference.

You can read more about this here.

When establishing a mix of Systems of Engagement and Systems of Record in your organization digitally connected, we will see overall benefits. My earlier thoughts, in general, are here: Time to split PLM?

The almost Connected approach

As I mentioned, in most companies, it is already challenging to manage their internal System of Record, which is needed for current operations and the traceability of information. In addition, most of the data stored in these systems is document-driven, not designed for real-time collaboration. So how would these companies collaborate with their suppliers?

The Model-Based Enterprise

In the bigger image below, I am referring to an image published by Jennifer Herron from her book Re-use Your CAD, where she describes the various stages of interaction between engineering, manufacturing and the extended enterprise.

In the bigger image below, I am referring to an image published by Jennifer Herron from her book Re-use Your CAD, where she describes the various stages of interaction between engineering, manufacturing and the extended enterprise.

Her mission is to promote and educate organizations in moving to a Model-Based Definition and, in the long term, to a Model-Base Enterprise.

The ultimate target of information exchange in this diagram is that the OEM and the Supplier are separate entities. However, they can exchange Digital Product Definition Packages and TDPs over the web (electronically). In this exchange, we have a mix of systems of engagement and systems of record on the OEM and Supplier sides.

Depending on the type of industry, in my ecosystem of companies, many suppliers are still at level 2, dreaming or pushed to become level 3, illustrating there is a difficult job to do – learning new practices. And why would you move to the next level?

Depending on the type of industry, in my ecosystem of companies, many suppliers are still at level 2, dreaming or pushed to become level 3, illustrating there is a difficult job to do – learning new practices. And why would you move to the next level?

Every step can have significant benefits, as reported by companies that did this.

So what’s stopping your company from moving ahead? People, Processes, Skills, Work Pressure? It is one of the most common excuses: “We are too busy, no time to improve”.

A supply chain collaboration hub

On March 21, I discussed with Magnus Färneland from Eurostep their cloud-based PLM collaboration hub, ShareAspace. You can read the interview here: PLM and Supply Chain Collaboration

I believe this concept can be compelling for a connected enterprise. The OEM and the Supplier share (or connect) only the data they want to share, preferably based on the PLCS data schema (ISO 10303-239).

In a primitive approach, this can be BOM structures with related files; however, it could become a real model-based connection hub in the advanced mode. “

Now you ask yourself why this solution is not booming.

In my opinion, there are several points to consider:

- Who designs, operates and maintains the collaboration hub?

It is likely not the suppliers, and when the OEM takes ownership, they might believe there is no need for the extra hub; just use the existing PLM infrastructure. - Could a third party find a niche market for this? Eurostep has already been working on this for many years, but adopting the concept seems higher in de BIM or Asset Management domains. Here the owner/operator sees the importance of a collaboration hub.

A final remark, we are still far from a connected enterprise; concepts like Catena-X and others need to become mature to serve as a foundation – there is a lot of technology out there -now we need the skilled people and tested practices to use the right technology and tune solutions concepts.

A final remark, we are still far from a connected enterprise; concepts like Catena-X and others need to become mature to serve as a foundation – there is a lot of technology out there -now we need the skilled people and tested practices to use the right technology and tune solutions concepts.

Sustainability demands a connected enterprise.

I focused on the Supplier dilemma this time because it is one of the crucial aspects of a circular economy and sustainable product development.

I focused on the Supplier dilemma this time because it is one of the crucial aspects of a circular economy and sustainable product development.

Only by using virtual models of the To-Be products/systems can we seriously optimize them. Virtual models and Digital Twins do not run on documents; they require accurate data from anywhere connected.

You can read more details in my post earlier this year: MBSE and Sustainability or look at the PLM and Sustainability recording on our PLM Global Green Alliance YouTube channel.

Conclusion

Due to various discussions I recently had in the field, it became clear that the topic of supplier integration in a best-connected manner is one of the most important topics to address in the near future. We cannot focus longer on our company as an isolated entity – value streams implemented in a connected manner become a must.

And now I am going to enjoy Liveworx in Boston, learning, discussing and understanding more about what PTC is doing and planning in the context of digital transformation and sustainability. More about that in my next post: The week(end) after Liveworx 2023 (to come)

I hope you all remained curious after last week’s report from day 1 of the PLM Roadmap / PDT Europe 2022 conference in Gothenburg. The networking dinner after day 1 and the Share PLM after-party allowed us to discuss and compare our businesses. Now the highlights of day 2

I hope you all remained curious after last week’s report from day 1 of the PLM Roadmap / PDT Europe 2022 conference in Gothenburg. The networking dinner after day 1 and the Share PLM after-party allowed us to discuss and compare our businesses. Now the highlights of day 2

The Power of Curiosity

We started with a keynote speech from Stefaan van Hooydonk, Founder of the Global Curiosity Institute. It was a well-received opener of the day and an interesting theme concerning PLM.

According to Stefaan, in the previous century, curiosity had a negative connotation. Curiosity killing the cat is one of these expressions confirming the mindset. It was all about conformity to the majority, the company, and curiosity was non-conformant.

According to Stefaan, in the previous century, curiosity had a negative connotation. Curiosity killing the cat is one of these expressions confirming the mindset. It was all about conformity to the majority, the company, and curiosity was non-conformant.

The same mindset I would say we have with traditional PLM; we all have to work the same way with the same processes.

In the 21st century, modern enterprises stimulate curiosity as we understand that throughout history, curiosity has been the engine of individual, organizational, and societal progress. And in particular, in modern, unpredictable times, curiosity becomes important, for the world, the others around us and ourselves.

As Stefaan describes in his book, the Curiosity Manifesto, organizations and individuals can develop curiosity. Stefaan pushed us to reflect on our personal curiosity behavior.

- Are we really interested in the person, the topic I do not know or do not like?

- Are we avoiding curious steps out of fear? Fear for failing, judgment?

After Stefaan’s curiosity storm, you could see that the audience was inspired to apply it to themselves and their PLM mission(s).

I hope the latter – as here there is a lot to discover.

Digital Transformation – Time to roll up your sleeves

In his presentation, Torbjörn Holm, co-founder of Eurostep, addressed one of the bigger elephants in the modern enterprise: how to deal with data?

Thanks to digitization, companies are gathering ad storing data, and there seem to be no limits. However, data centers compete for electricity from the grid with civilians.

Torbjörn also introduced the term “Dark data – the dirty secret of the ICT sector. We store too much data; some research mentions that only 12 % of the data stored is critical, and the rest clogs up on some file servers. Storing unstructured and unused data generates millions of greenhouse gasses yearly.

Torbjörn also introduced the term “Dark data – the dirty secret of the ICT sector. We store too much data; some research mentions that only 12 % of the data stored is critical, and the rest clogs up on some file servers. Storing unstructured and unused data generates millions of greenhouse gasses yearly.

It is time for a data cleanup day, and inspired by Torbjörn’s story, I have already started to clean up my cloud storage. However, I did not touch my backup hard disks as they do not use energy when switched off.

Further, Torbjörn elaborated that companies need to have end-to-end data policies. Which data is required? And in the case of contracted work or suppliers, data is crucial.

Ultimately companies that want to benefit from a virtual twin of their asset in operation need to have processes in place to acquire the correct data and maintain the valid data. Digital twins do not run on documents; as mentioned in some of my blog posts, they need accurate data.

Torbjörn once more reminded us that the PLCS objective is designed for that.

Heterogeneous and federated PLM – is it feasible?

One of the sessions that upfront had most of my attention was the presentation from Erik Herzog, Technical Fellow at Saab Aeronautics and Jad El-Khoury, Researcher at the KTH/Royal Institute of Technology.

Their presentation was closely related to the pre-conference workshop we had organized by Erik and Eurostep. More about this topic in the future.

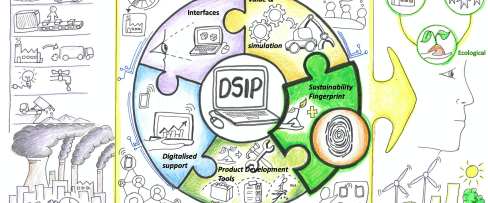

Saab, Eurostep and KTH conducted a research project named Helipe to analyze and test a federated PLM architecture. The concept was strongly driven by engineering. The idea is shown in the images below.

First are the four main modular engineering environments; in the image, we see mechanical, electrical, software and engineering environments. The target is to keep these environments as standard as possible towards the outside world so that later, an environment could be swapped for a better environment. Inside an environment, automation should provide optimal performance for the users.

In my terminology, these environments serve as systems of engagement.

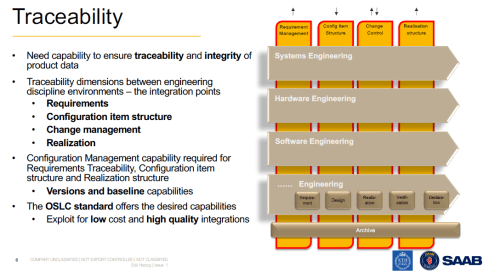

The second dimension of this architecture is the traceability layer(s) – the requirements management layer, the configuration item structures, change control and realization structures.

These traceability structures look much like what we have been doing with traditional PLM, CM and ERP systems. In my terminology, they are the systems or record, not mentioned to directly serve end-users but to provide traceability, baselines for configuration, compliance and more.

The team chose the OSLC standard to realize these capabilities. One of the main reasons because OSLC is an existing open standard based on linked data, not replicating data. In this way, a federated environment would be created with designated connections between datasets.

Jad El-Koury demonstrated how to link an existing requirement in Siemens Polarion to a Defect in IBM ELM and then create a new requirement in Polarion and link this requirement to the same defect. I never get excited from technical demos; more important to learn is the effort to build such integration and its stability over time. Click on the image for the details

Jad El-Koury demonstrated how to link an existing requirement in Siemens Polarion to a Defect in IBM ELM and then create a new requirement in Polarion and link this requirement to the same defect. I never get excited from technical demos; more important to learn is the effort to build such integration and its stability over time. Click on the image for the details

The conclusions from the team below give the right indicators where the last two points seem feasible.

Still, we need more benchmarking in other environments to learn.

Still, we need more benchmarking in other environments to learn.

I remain curious about this approach as I believe it is heading toward what is necessary for the future, the mix of systems of record and systems of engagement connected through a digital web.

The bold part of the last sentence may be used by marketers.

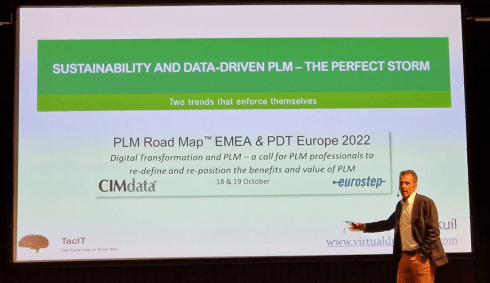

Sustainability and Data-driven PLM – the perfect storm

For those familiar with my blog (virtualdutchman.com) and my contribution to the PLM Global Green Alliance, it will be no surprise that I am currently combining new ways of working for the PLM domain (digitization) with an even more hot topic, sustainability.

For those familiar with my blog (virtualdutchman.com) and my contribution to the PLM Global Green Alliance, it will be no surprise that I am currently combining new ways of working for the PLM domain (digitization) with an even more hot topic, sustainability.

More hot is perhaps a cynical remark.

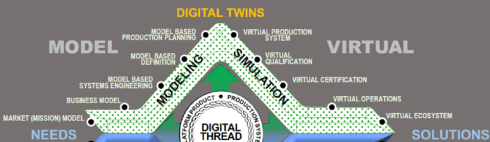

In my presentation, I explained that a model-based, data-driven enterprise will be able to use digital twins during the design phase, the manufacturing process planning and twins of products in operation. Each twin has a different purpose.

The virtual product during the design phase does not have a real physical twin yet, so some might say it is not a twin at this stage. The virtual product/twin allows companies to perform trade-offs, verification and validation relatively fast and inexpensively. The power of analyzing this virtual twin will enable companies to design products not only at the best price/performance range but even as important, with the lowest environmental impact during manufacturing and usage in the field.

As the Boeing diamond nicely shows, there is a whole virtual world for digital twins. The manufacturing digital twin allows companies to analyze their manufacturing process and virtually analyze the most effective manufacturing process, preferably with the lowest environmental impact.

For digital twins from a product in the field, we can analyze its behavior and optimize performance, hopefully with environmental performance indicators in mind.

For a sustainable future, it is clear that we need to implement concepts of the circular economy as the earth does not have enough resources and renewables to support our current consumption behavior and ways of living.

Note: not for everybody on the globe, a quote from the European Environment Agency below:

Europe consumes more resources than most other regions. An average European citizen uses approximately four times more resources than one in Africa and three times more than one in Asia, but half of that of a citizen of the USA, Canada, or Australia

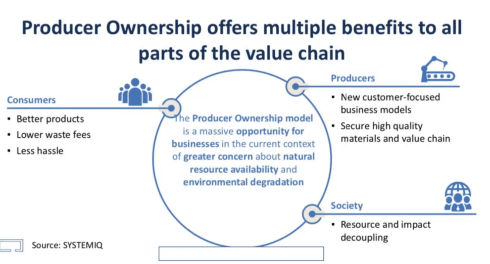

To reduce consumption, one of the recommendations is to switch the business model from owning products to products as a service. In the case of products as a service, the manufacturer becomes the owner of the full product lifecycle. Therefore, the manufacturer will have business reasons to make the products repairable, upgradeable, recyclable and using energy efficiently, preferably with renewables. If not, the product might become too expensive; fossil energy will be too expensive as carbon taxes will increase, and virgin materials might become too expensive.

It is a business change; however, sustainability will push organizations to change faster than we are used to. For example, we learned this week that the peeking energy prices and Russia’s current war in Ukraine have led to strong investments in renewables.

It is a business change; however, sustainability will push organizations to change faster than we are used to. For example, we learned this week that the peeking energy prices and Russia’s current war in Ukraine have led to strong investments in renewables.

As a result, many countries no longer want to depend on Russian energy. The peak of carbon emissions for the world is now expected in 2025.

(Although we had a very bad year so far)

Therefore, my presentation concluded that we should use sustainability as an additional driver for our digital transformation in the PLM domain. The planet cannot wait until we slowly change our traditional working methods.

Therefore, my presentation concluded that we should use sustainability as an additional driver for our digital transformation in the PLM domain. The planet cannot wait until we slowly change our traditional working methods.

Therefore, the need for digital twins to support sustainability and systems thinking are the perfect storm to speed up our digitization projects.

You can find my presentation as usual, here on SlideShare and a “spoken” version on our PGGA YouTube channel here

Digitalization for the Development and Industrialization of Innovative and Sustainable Solutions

This session, given by Ola Isaksson, Professor, Product Development & Systems Engineering Design Research Group Leader at Chalmers University, was a great continuation on my part of sustainability. Ola went deeper into the aspects of sustainable products and sustainable business models.

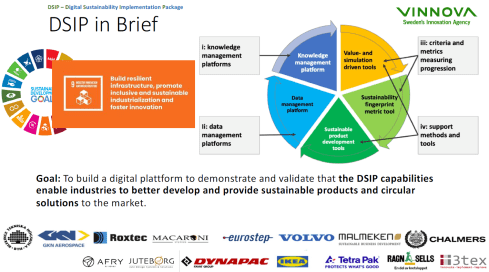

The DSIP project (Digital Sustainability Implementation Package – image above) aims to help companies understand all aspects of sustainable development. Ola mentioned that today’s products’ evolution is insufficient to ensure a sustainable outcome. Currently, not products nor product development practices are adequate enough as we do not understand all the aspects.

For example, Ola used the electrification process, taking the Lithium raw material needed for the batteries. If we take the Nissan Leaf car as the point of measure, we would have used all Lithium resources within 50 years.

Therefore, other business models are also required, where the product ownership is transferred to the manufacturer. This is one of the 9Rs (or 10), as the image shows moving from a linear economy towards a circular economy.

Also, as I mentioned in my session, Ola referred to the upcoming regulations forcing manufacturers to change their business model or product design. All these aspects are discussed in the DSIP project, and I look forward to learning the impact this project had on educating and supporting companies in their sustainability journey.

A day 2 summary

We had Bernd Feldvoss, Value Stream Leader PLM Interoperability Standards at Airbus, reporting on the progress of the A&D action group focusing on Collaboration. At this stage, the project team has developed an open-service Collaboration Management System (CMS) web application, providing navigation through the eight-step guidelines and offering the potential to improve OEM-supplier collaboration consistency and efficiency within the A&D community.

We had Bernd Feldvoss, Value Stream Leader PLM Interoperability Standards at Airbus, reporting on the progress of the A&D action group focusing on Collaboration. At this stage, the project team has developed an open-service Collaboration Management System (CMS) web application, providing navigation through the eight-step guidelines and offering the potential to improve OEM-supplier collaboration consistency and efficiency within the A&D community.

We had Henrik Lindblad, Group Leader PLM & Process Support at the European Spallation Source, building and soon operating the world’s most powerful neutron source, enabling scientific breakthroughs in research related to materials, energy, health and the environment. Besides a scientific breakthrough, this project is also an example of starting with building a virtual twin of the facility from the start providing a multidisciplinary collaboration space.

We had Henrik Lindblad, Group Leader PLM & Process Support at the European Spallation Source, building and soon operating the world’s most powerful neutron source, enabling scientific breakthroughs in research related to materials, energy, health and the environment. Besides a scientific breakthrough, this project is also an example of starting with building a virtual twin of the facility from the start providing a multidisciplinary collaboration space.

Conclusion

I left the conference with a lot of positive energy. The Curiosity session from Stefaan van Hooydonk energized us all, but as important for our PLM domain, I saw the trend towards more federated PLM environments, more discussions related to sustainability, and people in 3D again. So far, my takeaways this time. Enough to explore till the next event.

While preparing my presentation for the Dutch Model-Based Definition solutions event, I had some reflections and experiences discussing Model-Based Definition. Particularly in traditional industries. In the Aerospace & Defense, and Automotive industry, Model-Based Definition has become the standard. However, other industries have big challenges in adopting this approach. In this post, I want to share my observations and bring clarifications about the importance.

While preparing my presentation for the Dutch Model-Based Definition solutions event, I had some reflections and experiences discussing Model-Based Definition. Particularly in traditional industries. In the Aerospace & Defense, and Automotive industry, Model-Based Definition has become the standard. However, other industries have big challenges in adopting this approach. In this post, I want to share my observations and bring clarifications about the importance.

What is a Model-Based Definition?

The Wiki-definition for Model-Based Definition is not bad:

Model-based definition (MBD), sometimes called digital product definition (DPD), is the practice of using 3D models (such as solid models, 3D PMI and associated metadata) within 3D CAD software to define (provide specifications for) individual components and product assemblies. The types of information included are geometric dimensioning and tolerancing (GD&T), component level materials, assembly level bills of materials, engineering configurations, design intent, etc.

Model-based definition (MBD), sometimes called digital product definition (DPD), is the practice of using 3D models (such as solid models, 3D PMI and associated metadata) within 3D CAD software to define (provide specifications for) individual components and product assemblies. The types of information included are geometric dimensioning and tolerancing (GD&T), component level materials, assembly level bills of materials, engineering configurations, design intent, etc.

By contrast, other methodologies have historically required the accompanying use of 2D engineering drawings to provide such details.

When I started to write about Model-Based definition in 2016, the concept of a connected enterprise was not discussed. MBD mainly enhanced data sharing between engineering, manufacturing, and suppliers at that time. The 3D PMI is a data package for information exchange between these stakeholders.

When I started to write about Model-Based definition in 2016, the concept of a connected enterprise was not discussed. MBD mainly enhanced data sharing between engineering, manufacturing, and suppliers at that time. The 3D PMI is a data package for information exchange between these stakeholders.

The main difference is that the 3D Model is the main information carrier, connected to 2D manufacturing views and other relevant data, all connected in this package.

MBD – the benefits

![]() There is no need to write a blog post related to the benefits of MBD. With some research, you find enough reasons. The most important benefits of MBD are:

There is no need to write a blog post related to the benefits of MBD. With some research, you find enough reasons. The most important benefits of MBD are:

- the information is and human-readable and machine-readable. Allowing the implementation of Smart Manufacturing / Industry 4.0 concepts

- the information relies on processes and data and is no longer dependent on human interpretation. This leads to better quality and error-fixing late in the process.

- MBD information is a building block for the digital enterprise. If you cannot master this concept, forget the benefits of MBSE and Virtual Twins. These concepts don’t run on documents.

To help you discover the benefits of MBD described by others – have a look here:

- What is MBD, and what are its benefits?

- MBD Efficiencies for Small Manufacturers

- 5 reasons to use MBD

- 10 reasons why everyone is moving away from traditional 2D drawings

MBD as a stepping stone to the future

When you are able to implement model-based definition practices in your organization and connect with your eco-system, you are learning what it means to work in a connected matter. Where the scope is limited, you already discover that working in a connected manner is not the same as mandating everyone to work with the same systems or tools. Instead, it is about new ways of working (skills & people), combined with exchange standards (which to follow).

When you are able to implement model-based definition practices in your organization and connect with your eco-system, you are learning what it means to work in a connected matter. Where the scope is limited, you already discover that working in a connected manner is not the same as mandating everyone to work with the same systems or tools. Instead, it is about new ways of working (skills & people), combined with exchange standards (which to follow).

Where MBD is part of the bigger model-based enterprise, the same principles apply for connecting upstream information (Model-Based Systems Engineering) and downstream information(IoT-based operation and service models).

Oleg Shilovitsky addresses the same need from a data point of view in his recent blog: PLM Strategy For Post COVID Time. He makes an important point about the Digital Thread:

Digital Thread is one of my favorite topics because it is leading directly to the topic of connected data and services in global manufacturing networks.

I agree with that statement as the digital thread is like MBD, another steppingstone to organize information in a connected manner, even beyond the scope of engineering-manufacturing interaction. However, Digital Thread is an intermediate step toward a full data-driven and model-based enterprise.

To master all these new ways is working, it is crucial for the management of manufacturing companies, both OEM and their suppliers, to initiate learning programs. Not as a Proof of Concept but as a real-life, growing activity.

To master all these new ways is working, it is crucial for the management of manufacturing companies, both OEM and their suppliers, to initiate learning programs. Not as a Proof of Concept but as a real-life, growing activity.

Why MBD is not yet a common practice?

If you look at the success of MBD in Aerospace & Defense and Automotive, one of the main reasons was the push from the OEMs to align their suppliers. They even dictated CAD systems and versions to enable smooth and efficient collaboration.

If you look at the success of MBD in Aerospace & Defense and Automotive, one of the main reasons was the push from the OEMs to align their suppliers. They even dictated CAD systems and versions to enable smooth and efficient collaboration.

In other industries, there we not so many giant OEMs that could dictate their supply chain. Often also, the OEM was not even ready for MBD. Therefore, the excuse was often we cannot push our suppliers to work different, let’s remain working as best as possible (the old way and some automation)

Besides the technical changes, MBD also had a business impact. Where the traditional 2D-Drawing was the contractual and leading information carrier, now the annotated 3D Model has to become the contractual agreement. This is much more complex than browsing through (paper) documents; now, you need an application to open up the content and select the right view(s) or datasets.

Besides the technical changes, MBD also had a business impact. Where the traditional 2D-Drawing was the contractual and leading information carrier, now the annotated 3D Model has to become the contractual agreement. This is much more complex than browsing through (paper) documents; now, you need an application to open up the content and select the right view(s) or datasets.

In the interaction between engineering and manufacturing, you could hear statements like:

you can use the 3D Model for your NC programming, but be aware the 2D drawing is leading. We cannot guarantee consistency between them.

In particular, this is a business change affecting the relationship between an OEM and its suppliers. And we know business changes do not happen overnight.

Smaller suppliers might even refuse to work on a Model-Based definition, as it is considered an extra overhead they do not benefit from.

In particular, when working with various OEMs that might have their own preferred MBD package content based on their preferred usage. There are standards; however, OEMs often push for their preferred proprietary format.

It is about an orchestrated change.

Implementing MBD in your company, like PLM, is challenging because people need to be aligned and trained on new ways of working. In particular, this creates resistance at the end-user level.

Similar to the introduction of mainstream CAD (AutoCAD in the eighties) and mainstream 3D CAD (Solidworks in the late nineties), it requires new processes, trained people, and matching tools.

Similar to the introduction of mainstream CAD (AutoCAD in the eighties) and mainstream 3D CAD (Solidworks in the late nineties), it requires new processes, trained people, and matching tools.

I am aware of learning materials coming from the US, not so much about European or Asian thought leaders. Feel free to add other relevant resources for the readers in this post’s comments. Have a look and talk with:

![]() Action Engineering with their OSCAR initiative: Bringing MBD Within Reach. I spoke with Jennifer Herron, founder of Action Engineering, a year ago about MBD and OSCAR in my blog post: PLM and Model-Based Definition.

Action Engineering with their OSCAR initiative: Bringing MBD Within Reach. I spoke with Jennifer Herron, founder of Action Engineering, a year ago about MBD and OSCAR in my blog post: PLM and Model-Based Definition.

Another interesting company to follow is Capvidia. Read their blog post to start with is MBD model-based definition in the 21st century.

The future

What you will discover from these two companies is that they focus on the connected flow of information between companies while anticipating that each stakeholder might have their preferred (traditional) PLM environment. It is about data federation.

The future of a connected enterprise is even more complex. So I was excited to see and download Yousef Hooshmand’s paper: ”From a Monolithic PLM Landscape to a Federated Domain and Data Mesh”.

The future of a connected enterprise is even more complex. So I was excited to see and download Yousef Hooshmand’s paper: ”From a Monolithic PLM Landscape to a Federated Domain and Data Mesh”.

Yousef and some of his colleagues report about their PLM modernization project @Mercedes-Benz AG, aiming at transforming a monolithic PLM landscape into a federated Domain and Data Mesh.

This paper provides a lot of structured thinking related to the concepts I try to explain to my audience in everyday language. See my The road to model-based and connected PLM thoughts.

This paper has much more depth and is a must-read and must-discuss writing for those interested – perhaps an opportunity for new startups and a threat to traditional PLM vendors.

Conclusion

Vellum drawings are almost gone now – we have electronic 2D Drawings. The model-based definition has confirmed the benefits of improving the interaction between engineering, manufacturing & suppliers. Still, many industries are struggling with this approach due to process & people changes needed. If you are not able or willing to implement a model-based definition approach, be worried about the future. The eco-systems will only run efficiently (and survive) when their information exchange is based on data and models. Start learning now.

p.s. just out of curiosity:

If you are model-based advocate support this post with a

This week I attended the PLM Roadmap & PDT Fall 2021 with great expectations based on my enthusiasm last year. Unfortunately, the excitement was less this time, and I will explain in my conclusions why. This time it was unfortunate again a virtual event which makes it hard to be interactive, something I realize I am missing a lot.

This week I attended the PLM Roadmap & PDT Fall 2021 with great expectations based on my enthusiasm last year. Unfortunately, the excitement was less this time, and I will explain in my conclusions why. This time it was unfortunate again a virtual event which makes it hard to be interactive, something I realize I am missing a lot.

Over two hundred attendees connected for the two days, and you can find the agenda here. Typically I would discuss the relevant sessions; now, I want to group some of them related to a theme, as there was complementary information in these sessions.

Over two hundred attendees connected for the two days, and you can find the agenda here. Typically I would discuss the relevant sessions; now, I want to group some of them related to a theme, as there was complementary information in these sessions.

Disruption

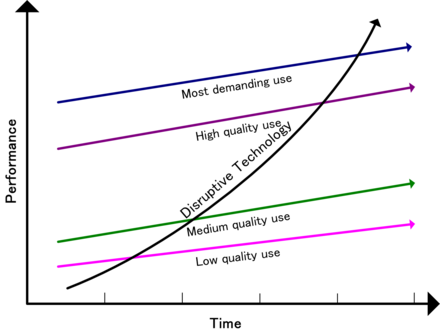

Again like in the spring, the theme was focusing on DISRUPTION. The word disruption can give you an uncomfortable feeling when you are not in power. It is more fun to disrupt than to be disrupted, as I mentioned in my spring presentation. Read The week after PLM Roadmap & PDT Spring 2021

Again like in the spring, the theme was focusing on DISRUPTION. The word disruption can give you an uncomfortable feeling when you are not in power. It is more fun to disrupt than to be disrupted, as I mentioned in my spring presentation. Read The week after PLM Roadmap & PDT Spring 2021

In his keynote speech Peter Bilello (CIMdata) kicked off with: The Critical Dozen: 12 familiar, evolving trends and enablers of digital transformation that you cannot or should not live without.

You can see them on the slide below:

I believe many of them should be familiar to you as these themes have been “in the air” already for quite some time. Vendors first and slowly companies start to investigate them when relevant. You will find many of them back in my recent series: The road to model-based and connected PLM, where I explored the topics that would cross your path on that journey.

I believe many of them should be familiar to you as these themes have been “in the air” already for quite some time. Vendors first and slowly companies start to investigate them when relevant. You will find many of them back in my recent series: The road to model-based and connected PLM, where I explored the topics that would cross your path on that journey.

Like Peter said: “For most of the topics you cannot pick and choose as they are all connected.”

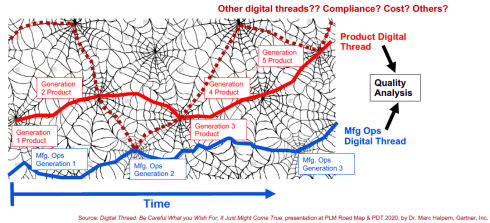

Another interesting observation was that we are more and more moving away from the concept of related structures (digital thread) but more to connected datasets (digital web). Marc Halpern first introduced this topic last year at the 2020 conference and has become an excellent image to frame what we should imagine in a connected world.

Digital web also has to do with the uprise of the graph database mentioned by Peter Bilello as a potentially disruptive technology during the fireside chat. Relational databases can be seen as rigid, associated with PLM structures. On the other hand, graph databases can be associated with flexible relations between different types of data – the image of the digital web.

Where Peter was mainly telling WHAT was happening, two presentations caught my attention because of the HOW.

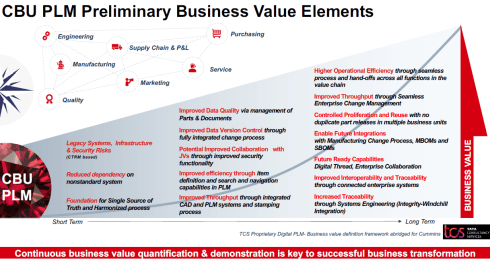

First of all, Dr. Rodney Ewing (Cummins) ‘s session: A Balanced Strategy to Reap Continuous Business Value from Digital PLM was a great story of a transformational project. It contained both having a continuous delivery of business value in mind while moving to the connected enterprise.

First of all, Dr. Rodney Ewing (Cummins) ‘s session: A Balanced Strategy to Reap Continuous Business Value from Digital PLM was a great story of a transformational project. It contained both having a continuous delivery of business value in mind while moving to the connected enterprise.

As Rodney mentioned, the contribution of TCS was crucial here, which I can imagine. It is hard for a company to understand what is happening in the outside (PLM) world when applying it to your company. Their transformation roadmap is an excellent example of having the long-term vision in mind, meanwhile delivering value during the transformation.

Talking about the right partner and synergy, the second presentation I liked in this context of disruption was Ian Quest’s presentation (Quick Release): Open-source Disruption in Support of Audacious Goals. As a sponsor of the conference, they had ten minutes to pitch their area of expertise.

After Ian’s presentation, focused on audacious goals (for non-English natives translated as “brave” goals), there was only one word that stuck to my mind: pragmatic.

After Ian’s presentation, focused on audacious goals (for non-English natives translated as “brave” goals), there was only one word that stuck to my mind: pragmatic.

Instead of discussions about the complexity, Ian gave examples of where a pragmatic data-centric approach could lead to great benefits, as you can see from one of the illustrated benefits below:

Standards

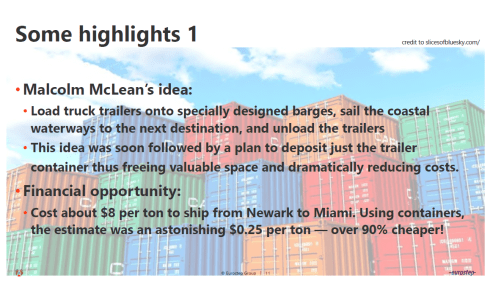

A characteristic topic of this conference is that we always talk about standards. Torbjörn Holm (Eurostep) gave an excellent overview of where standards have led to significant benefits. For example, the containerization of goods has dramatically improved transportation of goods (we all benefit) while killing proprietary means of transport (trains, type of ships, type of unloading). See the image below:

Torbjörn rightfully expanded this story to the current situation in the construction industry or the challenges for asset operators. Unfortunately, in these practices, many content suppliers remain focusing on their unique capabilities, reluctantly neglecting the demand for interoperability among the whole value chain.

It is a topic Marc Halpern also mentioned last year as an outcome of their Gartner PLM benefits survey. Gartner’s findings:

It is a topic Marc Halpern also mentioned last year as an outcome of their Gartner PLM benefits survey. Gartner’s findings:

Time to Market is not so much improved by using PLM as the inefficient interaction with suppliers is the impediment.

Like transport before containerization, the exchange of information is not standardized and designed for digital exchange. Torbjorn believes that more and more companies will insist on exchange standards – like CHIFOS – an ISO1596-derived exchange standard in the process industry. It is a user-driven standard, the best standard.

Like transport before containerization, the exchange of information is not standardized and designed for digital exchange. Torbjorn believes that more and more companies will insist on exchange standards – like CHIFOS – an ISO1596-derived exchange standard in the process industry. It is a user-driven standard, the best standard.

In this context, the presentation from Kenny Swope (Boeing) and Jean Yves Delaunay (Airbus) The Business Value of Standards-based Information Interoperability for Aerospace & Defense illustrated this fact.

In this context, the presentation from Kenny Swope (Boeing) and Jean Yves Delaunay (Airbus) The Business Value of Standards-based Information Interoperability for Aerospace & Defense illustrated this fact.

While working for competitors, the Aerospace industry understands the criticality of standards to become more efficient and less vendor-dependent. In the aerospace & defense group, they discuss these themes. The last year’s 2020 Fall sessions showed the results. You can read their publications here

The A&D PLM action group uses the following framework when evaluating standards – as you can see on the image below:

The result – and this is a combined exercise of many participating experts from the field; this is their recommendation:

To conclude:

People often complain about standards, framed by proprietary data format vendors, that they lead to a rigid environment, blocking agility.

In reality, standards allow companies to be more agile as the (proprietary) data flow is less an issue. Remember the containerization example.

Sustainability and System Thinking

This conference has always been known for its attention to the circular economy and green thinking. In the past, these topics might have been considered disconnected from our PLM practices; now, they have become a part of everyone’s mission.

This conference has always been known for its attention to the circular economy and green thinking. In the past, these topics might have been considered disconnected from our PLM practices; now, they have become a part of everyone’s mission.

Two presentations stood out on this topic for me. First, Ken Webster, with his keynote speech: In the future, you will own nothing and you will be happy was a significant oversight of how we as consumers currently are disconnected from the circular economy. His plea, as shown below, for making manufacturers responsible for the legal ownership of the materials in the products they deliver would impact consumer behavior.

Product as a Service (PaaS) and new ways to provide a service is becoming essential. For example, buildings as power stations, as they are a place to collect solar or wind energy?

His thoughts are aligned with what is happening in Europe related to the European Green Deal (not in his presentation). There is a push for a PaaS model for all products as this would be an excellent stimulant for the circular economy. PaaS combined with a Digital Product Passport – more on that next year.

His thoughts are aligned with what is happening in Europe related to the European Green Deal (not in his presentation). There is a push for a PaaS model for all products as this would be an excellent stimulant for the circular economy. PaaS combined with a Digital Product Passport – more on that next year.

Making upgrades to your products has less impact on the environment than creating new products to sell (and creating waste of the old product). Ken Webster was an interesting statement about changing the economy – do we want to own products or do we want to benefit from the product and leave the legal ownership to the manufacturer.

A topic I discussed in the PLM Roadmap & PDT Conference Spring 2021 – look here at slide 11

Patrick Hillberg‘s presentation Rising to the challenge of engineering and optimizing . . . what? was the one closest to my heart. We discussed Sustainability and Systems Thinking with Patrick in our PLM Global Green Alliance, being pretty aligned on this topic. Patrick started by explaining the difference between Systems Engineering and Systems Thinking. Looking at the product go-to-market of an organization is more than the traditional V-model. Economic pressure and culture will push people to deviate from the ideal technological plan due to other priorities.

Expanding on this observation, Partick stated that there are limits to growth, a topic discussed by many people involved in the sustainable economy. Economic growth is impossible on a limited planet, and we have to take more dimensions into account. Patrick gave some examples of that, including issues related to the infamous Boeing 737 Max example.

For Patrick, the COVID-pandemic is the end of the old 2nd Industrial Revolution and a push for a new Fourth Industrial Revolution, which is not only technical, as the slide below indicates.

With Patrick, I believe we are at a decisive moment to disrupt ourselves, reconsider many things we do and are used to doing. Even for PLM practitioners, this is a new path to go.

Data

There were two presentations related to digitization and the shift from document-based to a data-driven approach.

First, there was Greg Weaver (Gulfstream) with his presentation Indexing Content – Finding Your Needle in the Haystack. Greg explained that by using indexation of existing document-based information combined with a specific dashboard, they could provide fast access to information that otherwise would have been hidden in so many document or even paper archives.

First, there was Greg Weaver (Gulfstream) with his presentation Indexing Content – Finding Your Needle in the Haystack. Greg explained that by using indexation of existing document-based information combined with a specific dashboard, they could provide fast access to information that otherwise would have been hidden in so many document or even paper archives.