You are currently browsing the category archive for the ‘Climate Change’ category.

In the last few weeks, I thought I had a writer’s block, as I usually write about PLM-related topics close to my engagements.

In the last few weeks, I thought I had a writer’s block, as I usually write about PLM-related topics close to my engagements.

Where are the always popular discussions related to EBOM or MBOM? Where is the Form-Fit-Function discussion or the traditional “meaningful numbers” discussions?

These topics always create a lot of interaction and discussion, as many of us have mature opinions.

However, last month I spent most of the time discussing the connection between digital PLM strategies and sustainability. With the Russian invasion of Ukraine, leading to high energy prices, combined with several climate disasters this year, people are aware that 2022 is not a year as usual. A year full of events that force us to rethink our current ways of living.

The notion of urgency

Sustainability for the planet and its people has all the focus currently. COP27 gives you the impression that governments are really serious. Are they? Read this post from Kimberley R. Miner, Climate Scientist at NASA, Polar Explorer& Professor.

Sustainability for the planet and its people has all the focus currently. COP27 gives you the impression that governments are really serious. Are they? Read this post from Kimberley R. Miner, Climate Scientist at NASA, Polar Explorer& Professor.

She doubts if we really grasp the urgency needed to address climate change. Or are we just playing to be on stage? I agree with her doubts.

So what to do with my favorite EBOM-MBOM discussions?

Last week I attended an event organized by Dassault Systems in the Netherlands for their Dutch/Belgium customers.

Last week I attended an event organized by Dassault Systems in the Netherlands for their Dutch/Belgium customers.

The title of the event was: Sustainable innovation for a digital future. I expected a techy event. Click on the image to see the details.

Asking my grandson, who had just started to his study Aerospace Engineering in Delft (NL), learning to work with CAD and PLM-tools, to join me – he replied:

“Too many software demos”

It turned out that my grandson was wrong. The keynote speech from Ruud Veltenaar made most of the audience feel uncomfortable. He really pointed to the fact that we are aware of climate change and our impact on the planet, but in a way, we are paralyzed. Nothing new, but confronting and unexpected when going to a customer event.

It turned out that my grandson was wrong. The keynote speech from Ruud Veltenaar made most of the audience feel uncomfortable. He really pointed to the fact that we are aware of climate change and our impact on the planet, but in a way, we are paralyzed. Nothing new, but confronting and unexpected when going to a customer event.

Ruud’s message: Accept that we are at the end of an existing world order, and we should prepare for a new world order with the right moral leadership. It starts within yourself. Reflect on who you really are, where you are in your life path, and finally, what you want.

It sounds simple, and I can see it helps to step aside and reflect on these points.

Otherwise, you might feel we are in a rat race as shown below (recommend to watch).

The keynote was the foundation for a day of group and panel discussions on sustainability. Learning from their customers their sustainability plans and experiences.

It showed Dassault Systems, with its 2012 purpose (click on the link to see its history), Harmonizing Products, Nature and Life is ahead of the curve (at least they were for me).

It showed Dassault Systems, with its 2012 purpose (click on the link to see its history), Harmonizing Products, Nature and Life is ahead of the curve (at least they were for me).

The event was energizing, and my grandson was wrong:

“No software – next time?”

The impact of legacies – data, processes & people

For those who haven’t read my previous post, The week after PLM Roadmap / PDT Europe 2022, I wrote about the importance of Heterogeneous and federated PLM, one of the discussions related to data-driven PLM.

For those who haven’t read my previous post, The week after PLM Roadmap / PDT Europe 2022, I wrote about the importance of Heterogeneous and federated PLM, one of the discussions related to data-driven PLM.

Looking back, I have been writing about data-driven PLM since 2014, and few companies have made progress here. Understandable, first of all, due to legacy data, which is not in the right format or quality to support data-driven processes.

However, also here, legacy processes and legacy people are blocking the change. There is no blame here; it is difficult to change. You might have a visionary management team, but then it comes down to the execution of the strategy. The organizational structure and the existing people skills are creating more resistance than progress.

For that reason, I wrote this post in 2015: PLM and Global Warming, where I compared the progress we made within our PLM community with the lack of progress we are making in solving global warming. We know the problem, but we are unable to act due to the lack of feeling the urgency.

For that reason, I wrote this post in 2015: PLM and Global Warming, where I compared the progress we made within our PLM community with the lack of progress we are making in solving global warming. We know the problem, but we are unable to act due to the lack of feeling the urgency.

This blog post triggered Rich McFall to start together in 2018 the PLM Global Green Alliance.

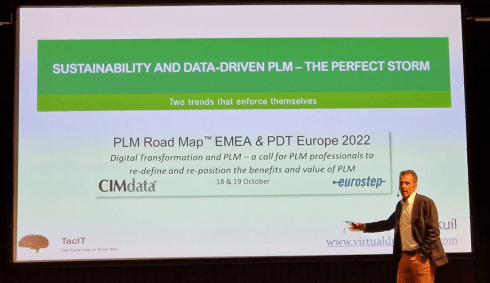

In my PLM Roadmap / PDT Europe session Sustainability and Data-driven PLM – the perfect storm, I raised the awareness that we need to speed up. We have 10 perhaps 15 years to implement radical changes, according to scientists, before we reach irreversible tipping points.

Why PLM and Sustainability?

Sustainability starts with the business strategy. How does your company want to contribute to a more sustainable future? The strategy to follow with probably the most impact is the concept of a circular economy – image below and more info here.

The idea behind the circular economy is to minimize the need for new finite materials (the right side) and to use for energy delivery only renewables. Implementing these principles clearly requires a more holistic design of products and services. Each loop should be analyzed and considered when delivering solutions to the market.

Therefore, a logical outcome of the circular economy would be transforming from selling products to the market towards a product-as-a-service model. In this case, the product manufacturer becomes responsible for the full product lifecycle and its environmental impact.

And here comes the importance of PLM. You can measure and tune your environmental impact during production in your ERP or MES environment. However, 80 % of the environmental impact is defined during the design phase, the domain of PLM. All these analysis together are called Life Cycle Analysis or Life Cycle Assessment (LCA). A practice that starts at the moment you start to think about a product or solution – a specialized systems thinking approach.

So how to define and select the right options for future products?

Virtual products / Digital Twins

This is where sustainability is pushing for digitization of the product lifecycle. Building and analyzing products in the virtual world is much cheaper than working with physical prototypes.

This is where sustainability is pushing for digitization of the product lifecycle. Building and analyzing products in the virtual world is much cheaper than working with physical prototypes.

The importance of a model-based approach here allows companies efficiently deal with trade-off studies for each solution.

In addition, the choice and the behavior of materials also have an impact. These material properties will come from various databases, some based on hazardous substances, others on environmental parameters. Connecting these databases to the virtual model is crucial to remain efficient.

Imagine you need manually collect and process in these properties whenever studying an alternative. The manual process will be too costly (fewer trade-offs and not finding the optimum) and too slow (time-to-market impact).

That’s why I am greatly interested in all the developments related to a federated PLM infrastructure. A monolithic system cannot be the solution for such a model-based environment. In my terminology, here we need an architecture with systems of engagement combined with system(s) of record.

That’s why I am greatly interested in all the developments related to a federated PLM infrastructure. A monolithic system cannot be the solution for such a model-based environment. In my terminology, here we need an architecture with systems of engagement combined with system(s) of record.

I will publish more on this topic in the future.

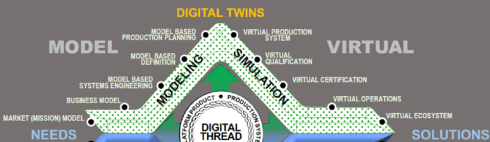

In the previous paragraphs, I wrote about the virtual product environment, which some companies call the virtual twin. However, besides the virtual twin, we also need several digital twins. These digital models allow us to monitor and optimize the production process, which can lead to design changes.

Also, monitoring the product in operation using a digital twin allows us to optimize the performance and execution of the solutions in the field.

The feedback from these digital twins will then help the company to improve the design and calibrate their simulation models. It should be a closed loop. You can find a more recent discussion related to the above image here.

Our mission

At this moment, sustainability is at the top of my personal agenda, and I hope for many of you. However, besides the choices we can make in our personal lives, there is also an area where we, as PLM interested parties, should contribute: The digitization of the product lifecycle as an enabler for a sustainable business.

At this moment, sustainability is at the top of my personal agenda, and I hope for many of you. However, besides the choices we can make in our personal lives, there is also an area where we, as PLM interested parties, should contribute: The digitization of the product lifecycle as an enabler for a sustainable business.

Without mature concepts for a connected enterprise, implementing sustainable products and business processes will be a wish, not a strategy. So add digitization to your skillset and use it in the context of sustainability.

Conclusion

It might look like this PLM blog has become an environmental blog. This might be right, as the environmental impact of products and solutions is directly related to product lifecycle management. However, do not worry. In the upcoming time, I will focus on the aspects and experiences of a connected enterprise. I will leave the easier discussions (EBOM/MBOM/FFF/Smart Numbers) from a coordinated enterprise as they are. There is work to do shortly. Your thoughts?

I hope you all remained curious after last week’s report from day 1 of the PLM Roadmap / PDT Europe 2022 conference in Gothenburg. The networking dinner after day 1 and the Share PLM after-party allowed us to discuss and compare our businesses. Now the highlights of day 2

I hope you all remained curious after last week’s report from day 1 of the PLM Roadmap / PDT Europe 2022 conference in Gothenburg. The networking dinner after day 1 and the Share PLM after-party allowed us to discuss and compare our businesses. Now the highlights of day 2

The Power of Curiosity

We started with a keynote speech from Stefaan van Hooydonk, Founder of the Global Curiosity Institute. It was a well-received opener of the day and an interesting theme concerning PLM.

According to Stefaan, in the previous century, curiosity had a negative connotation. Curiosity killing the cat is one of these expressions confirming the mindset. It was all about conformity to the majority, the company, and curiosity was non-conformant.

According to Stefaan, in the previous century, curiosity had a negative connotation. Curiosity killing the cat is one of these expressions confirming the mindset. It was all about conformity to the majority, the company, and curiosity was non-conformant.

The same mindset I would say we have with traditional PLM; we all have to work the same way with the same processes.

In the 21st century, modern enterprises stimulate curiosity as we understand that throughout history, curiosity has been the engine of individual, organizational, and societal progress. And in particular, in modern, unpredictable times, curiosity becomes important, for the world, the others around us and ourselves.

As Stefaan describes in his book, the Curiosity Manifesto, organizations and individuals can develop curiosity. Stefaan pushed us to reflect on our personal curiosity behavior.

- Are we really interested in the person, the topic I do not know or do not like?

- Are we avoiding curious steps out of fear? Fear for failing, judgment?

After Stefaan’s curiosity storm, you could see that the audience was inspired to apply it to themselves and their PLM mission(s).

I hope the latter – as here there is a lot to discover.

Digital Transformation – Time to roll up your sleeves

In his presentation, Torbjörn Holm, co-founder of Eurostep, addressed one of the bigger elephants in the modern enterprise: how to deal with data?

Thanks to digitization, companies are gathering ad storing data, and there seem to be no limits. However, data centers compete for electricity from the grid with civilians.

Torbjörn also introduced the term “Dark data – the dirty secret of the ICT sector. We store too much data; some research mentions that only 12 % of the data stored is critical, and the rest clogs up on some file servers. Storing unstructured and unused data generates millions of greenhouse gasses yearly.

Torbjörn also introduced the term “Dark data – the dirty secret of the ICT sector. We store too much data; some research mentions that only 12 % of the data stored is critical, and the rest clogs up on some file servers. Storing unstructured and unused data generates millions of greenhouse gasses yearly.

It is time for a data cleanup day, and inspired by Torbjörn’s story, I have already started to clean up my cloud storage. However, I did not touch my backup hard disks as they do not use energy when switched off.

Further, Torbjörn elaborated that companies need to have end-to-end data policies. Which data is required? And in the case of contracted work or suppliers, data is crucial.

Ultimately companies that want to benefit from a virtual twin of their asset in operation need to have processes in place to acquire the correct data and maintain the valid data. Digital twins do not run on documents; as mentioned in some of my blog posts, they need accurate data.

Torbjörn once more reminded us that the PLCS objective is designed for that.

Heterogeneous and federated PLM – is it feasible?

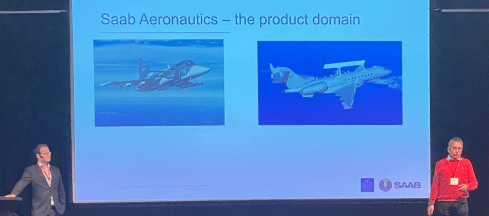

One of the sessions that upfront had most of my attention was the presentation from Erik Herzog, Technical Fellow at Saab Aeronautics and Jad El-Khoury, Researcher at the KTH/Royal Institute of Technology.

Their presentation was closely related to the pre-conference workshop we had organized by Erik and Eurostep. More about this topic in the future.

Saab, Eurostep and KTH conducted a research project named Helipe to analyze and test a federated PLM architecture. The concept was strongly driven by engineering. The idea is shown in the images below.

First are the four main modular engineering environments; in the image, we see mechanical, electrical, software and engineering environments. The target is to keep these environments as standard as possible towards the outside world so that later, an environment could be swapped for a better environment. Inside an environment, automation should provide optimal performance for the users.

In my terminology, these environments serve as systems of engagement.

The second dimension of this architecture is the traceability layer(s) – the requirements management layer, the configuration item structures, change control and realization structures.

These traceability structures look much like what we have been doing with traditional PLM, CM and ERP systems. In my terminology, they are the systems or record, not mentioned to directly serve end-users but to provide traceability, baselines for configuration, compliance and more.

The team chose the OSLC standard to realize these capabilities. One of the main reasons because OSLC is an existing open standard based on linked data, not replicating data. In this way, a federated environment would be created with designated connections between datasets.

Jad El-Koury demonstrated how to link an existing requirement in Siemens Polarion to a Defect in IBM ELM and then create a new requirement in Polarion and link this requirement to the same defect. I never get excited from technical demos; more important to learn is the effort to build such integration and its stability over time. Click on the image for the details

Jad El-Koury demonstrated how to link an existing requirement in Siemens Polarion to a Defect in IBM ELM and then create a new requirement in Polarion and link this requirement to the same defect. I never get excited from technical demos; more important to learn is the effort to build such integration and its stability over time. Click on the image for the details

The conclusions from the team below give the right indicators where the last two points seem feasible.

Still, we need more benchmarking in other environments to learn.

Still, we need more benchmarking in other environments to learn.

I remain curious about this approach as I believe it is heading toward what is necessary for the future, the mix of systems of record and systems of engagement connected through a digital web.

The bold part of the last sentence may be used by marketers.

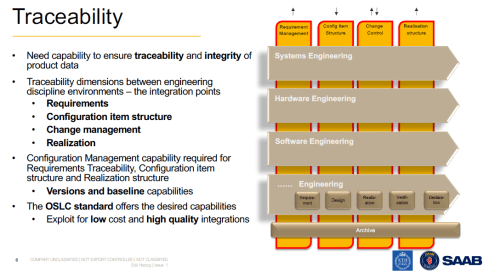

Sustainability and Data-driven PLM – the perfect storm

For those familiar with my blog (virtualdutchman.com) and my contribution to the PLM Global Green Alliance, it will be no surprise that I am currently combining new ways of working for the PLM domain (digitization) with an even more hot topic, sustainability.

For those familiar with my blog (virtualdutchman.com) and my contribution to the PLM Global Green Alliance, it will be no surprise that I am currently combining new ways of working for the PLM domain (digitization) with an even more hot topic, sustainability.

More hot is perhaps a cynical remark.

In my presentation, I explained that a model-based, data-driven enterprise will be able to use digital twins during the design phase, the manufacturing process planning and twins of products in operation. Each twin has a different purpose.

The virtual product during the design phase does not have a real physical twin yet, so some might say it is not a twin at this stage. The virtual product/twin allows companies to perform trade-offs, verification and validation relatively fast and inexpensively. The power of analyzing this virtual twin will enable companies to design products not only at the best price/performance range but even as important, with the lowest environmental impact during manufacturing and usage in the field.

As the Boeing diamond nicely shows, there is a whole virtual world for digital twins. The manufacturing digital twin allows companies to analyze their manufacturing process and virtually analyze the most effective manufacturing process, preferably with the lowest environmental impact.

For digital twins from a product in the field, we can analyze its behavior and optimize performance, hopefully with environmental performance indicators in mind.

For a sustainable future, it is clear that we need to implement concepts of the circular economy as the earth does not have enough resources and renewables to support our current consumption behavior and ways of living.

Note: not for everybody on the globe, a quote from the European Environment Agency below:

Europe consumes more resources than most other regions. An average European citizen uses approximately four times more resources than one in Africa and three times more than one in Asia, but half of that of a citizen of the USA, Canada, or Australia

To reduce consumption, one of the recommendations is to switch the business model from owning products to products as a service. In the case of products as a service, the manufacturer becomes the owner of the full product lifecycle. Therefore, the manufacturer will have business reasons to make the products repairable, upgradeable, recyclable and using energy efficiently, preferably with renewables. If not, the product might become too expensive; fossil energy will be too expensive as carbon taxes will increase, and virgin materials might become too expensive.

It is a business change; however, sustainability will push organizations to change faster than we are used to. For example, we learned this week that the peeking energy prices and Russia’s current war in Ukraine have led to strong investments in renewables.

It is a business change; however, sustainability will push organizations to change faster than we are used to. For example, we learned this week that the peeking energy prices and Russia’s current war in Ukraine have led to strong investments in renewables.

As a result, many countries no longer want to depend on Russian energy. The peak of carbon emissions for the world is now expected in 2025.

(Although we had a very bad year so far)

Therefore, my presentation concluded that we should use sustainability as an additional driver for our digital transformation in the PLM domain. The planet cannot wait until we slowly change our traditional working methods.

Therefore, my presentation concluded that we should use sustainability as an additional driver for our digital transformation in the PLM domain. The planet cannot wait until we slowly change our traditional working methods.

Therefore, the need for digital twins to support sustainability and systems thinking are the perfect storm to speed up our digitization projects.

You can find my presentation as usual, here on SlideShare and a “spoken” version on our PGGA YouTube channel here

Digitalization for the Development and Industrialization of Innovative and Sustainable Solutions

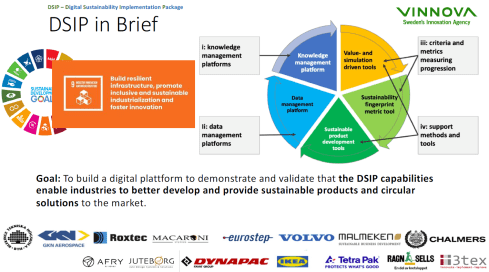

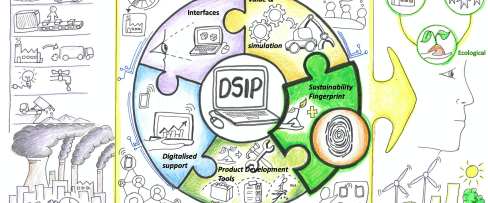

This session, given by Ola Isaksson, Professor, Product Development & Systems Engineering Design Research Group Leader at Chalmers University, was a great continuation on my part of sustainability. Ola went deeper into the aspects of sustainable products and sustainable business models.

The DSIP project (Digital Sustainability Implementation Package – image above) aims to help companies understand all aspects of sustainable development. Ola mentioned that today’s products’ evolution is insufficient to ensure a sustainable outcome. Currently, not products nor product development practices are adequate enough as we do not understand all the aspects.

For example, Ola used the electrification process, taking the Lithium raw material needed for the batteries. If we take the Nissan Leaf car as the point of measure, we would have used all Lithium resources within 50 years.

Therefore, other business models are also required, where the product ownership is transferred to the manufacturer. This is one of the 9Rs (or 10), as the image shows moving from a linear economy towards a circular economy.

Also, as I mentioned in my session, Ola referred to the upcoming regulations forcing manufacturers to change their business model or product design. All these aspects are discussed in the DSIP project, and I look forward to learning the impact this project had on educating and supporting companies in their sustainability journey.

A day 2 summary

We had Bernd Feldvoss, Value Stream Leader PLM Interoperability Standards at Airbus, reporting on the progress of the A&D action group focusing on Collaboration. At this stage, the project team has developed an open-service Collaboration Management System (CMS) web application, providing navigation through the eight-step guidelines and offering the potential to improve OEM-supplier collaboration consistency and efficiency within the A&D community.

We had Bernd Feldvoss, Value Stream Leader PLM Interoperability Standards at Airbus, reporting on the progress of the A&D action group focusing on Collaboration. At this stage, the project team has developed an open-service Collaboration Management System (CMS) web application, providing navigation through the eight-step guidelines and offering the potential to improve OEM-supplier collaboration consistency and efficiency within the A&D community.

We had Henrik Lindblad, Group Leader PLM & Process Support at the European Spallation Source, building and soon operating the world’s most powerful neutron source, enabling scientific breakthroughs in research related to materials, energy, health and the environment. Besides a scientific breakthrough, this project is also an example of starting with building a virtual twin of the facility from the start providing a multidisciplinary collaboration space.

We had Henrik Lindblad, Group Leader PLM & Process Support at the European Spallation Source, building and soon operating the world’s most powerful neutron source, enabling scientific breakthroughs in research related to materials, energy, health and the environment. Besides a scientific breakthrough, this project is also an example of starting with building a virtual twin of the facility from the start providing a multidisciplinary collaboration space.

Conclusion

I left the conference with a lot of positive energy. The Curiosity session from Stefaan van Hooydonk energized us all, but as important for our PLM domain, I saw the trend towards more federated PLM environments, more discussions related to sustainability, and people in 3D again. So far, my takeaways this time. Enough to explore till the next event.

The summer holidays are over, and with the PLM Global Green Alliance, we are glad to continue with our series: PLM and Sustainability, where we interview PLM-related software vendors, talking about their sustainability mission and offering.

The summer holidays are over, and with the PLM Global Green Alliance, we are glad to continue with our series: PLM and Sustainability, where we interview PLM-related software vendors, talking about their sustainability mission and offering.

We talked with SAP, Autodesk, and Dassault Systèmes. This week we spoke with Sustaira, and soon we will talk with Aras. Sustaira, an independent Siemens partner, is the provider of a sustainability platform based on Mendix.

SUSTAIRA

The interview with Vincent de la Mar, founder and CEO of Sustaira, was quite different from the previous interviews. In the earlier interviews, we talked with people driving sustainability in their company and software portfolio. Now with Sustaira, we were talking with a relatively new company with a single focus on sustainability.

The interview with Vincent de la Mar, founder and CEO of Sustaira, was quite different from the previous interviews. In the earlier interviews, we talked with people driving sustainability in their company and software portfolio. Now with Sustaira, we were talking with a relatively new company with a single focus on sustainability.

Sustaira provides an open platform targeting purely sustainability by offering relevant apps and infrastructure based on Mendix.

Listen to the interview and discover the differences and the potential for you.

Slides shown during the interview and additional company information: Sustaira Overview 2022.

What we have learned

Using the proven technology of the Mendix platform allows you to build a data-driven platform focused on sustainability for your company.

Using the proven technology of the Mendix platform allows you to build a data-driven platform focused on sustainability for your company.

As I wrote in my post: PLM and Sustainability, there is the need to be data-driven and connected with federated data sources for accurate data.

This is a technology challenge. Sustaira, as a young company, has taken up this challenge and provides various apps related to sustainability topics on its platform. Still, they remain adaptable to your organization.

Secondly, I like the concept that although Mendix is part of the Siemens portfolio, you do not need to have Siemens PLM installed. The openness of the Sustaira platform allows you to implement it in your organization independent of your PLM infrastructure.

Secondly, I like the concept that although Mendix is part of the Siemens portfolio, you do not need to have Siemens PLM installed. The openness of the Sustaira platform allows you to implement it in your organization independent of your PLM infrastructure.

The final observation – the rule of people, process, and technology – is still valid. To implement Sustaira in an efficient and valuable manner, you need to be clear in your objectives and sustainability targets within the organization. And these targets should be more detailed than the corporate statement in the annual report.

Want to Learn more

To learn more about Sustaira and the wide variety of offerings, you can explore any of these helpful links:

- First, here is a short video introducing Sustaira

- With this link, anyone can sign up for the free version of the Sustaira platform and begin exploring today!

- Lastly, for additional information, demos, downloadable content, and more, head over to the Sustiara Content Hub.

Conclusion

It was interesting to learn about Sustaira and how they started with a proven technology platform (Mendix) to build their sustainability platform. Being sustainable involves using trusted data and calculations to understand the environmental impact at every lifecycle stage.

Again we can state that the technology is there. Now it is up to companies to act and connect the relevant data sources to underpin and improve their sustainability efforts.

July and August are the quiet summer months here in Europe when companies slow down to allow people to recharge themselves.

July and August are the quiet summer months here in Europe when companies slow down to allow people to recharge themselves.

However, the speed and hectic are not the same overall, nor is the recharging time. I will be entering a six-week thinking break, assembling thoughts to explore after the summer break. Here are some topics – and you may note – they are all connected.

The MBOM discussion

Although my German is not as good as my English, I got intrigued by a post from Prof. Dr. Jörg W. Fischer.

Although my German is not as good as my English, I got intrigued by a post from Prof. Dr. Jörg W. Fischer.

He claims there is no meaning to the MBOM and, therefore, the “expensive” PLM concept of the MBOM has to disappear – read the original post here.

Jörg claims there are three reasons why the MBOM why we should not speak about the MBOM – here are the google translated quotes – and I left out some details to keep a place for the thoughts – not the answer yet:

- The MBOM as the structure for deriving the assembly drawings. No BOM! (here, I fully agree)

- The structure that comes out as a result when planning the assembly. Again, no BOM. (here, I tend to agree – however, we could extend this structure to an MBOM)

- The MBOM as the classic parts list in the ERP, the one with which the MRP run is performed. Is that an MBOM? Until recently, I thought so. But it isn’t. So again, no MBOM. (here, I tend to agree – however, we could extend this structure to an MBOM)

The topic on LinkedIn here initiated an interesting sharing of viewpoints. I am quite aligned with Martin Eigner’s comment. It is a pity that this type of discussion is hidden in a LinkedIn environment and in the German language. It would be great to discuss such a topic at a PLM conference. For example, the CIMdata PLM roadmap conference had several Multiview BOM discussions coming from Aerospace and Defense action groups.

The topic on LinkedIn here initiated an interesting sharing of viewpoints. I am quite aligned with Martin Eigner’s comment. It is a pity that this type of discussion is hidden in a LinkedIn environment and in the German language. It would be great to discuss such a topic at a PLM conference. For example, the CIMdata PLM roadmap conference had several Multiview BOM discussions coming from Aerospace and Defense action groups.

Perhaps comparing these two viewpoints – preferably in English – could lead to a better understanding for all of us. Now communication language and system dependencies might blur the methodology discussion.

![]() Cheryl Peck (CIMdata PLM Roadmap organizer)/ Jörg W. Fischer, are you open to this suggestion? BOM discussions have always been popular.

Cheryl Peck (CIMdata PLM Roadmap organizer)/ Jörg W. Fischer, are you open to this suggestion? BOM discussions have always been popular.

PLM Roadmap & PDT 2022

The good news is the upcoming PLM Roadmap & PDT 2022 event is scheduled as an in-person event on the 18th and 19th of October in Gothenburg, Sweden. Let’s hope no new corona-variant will destroy this plan. I am confident to be there as the Swedish COVID-19 approach has kept society open as much as possible.

The good news is the upcoming PLM Roadmap & PDT 2022 event is scheduled as an in-person event on the 18th and 19th of October in Gothenburg, Sweden. Let’s hope no new corona-variant will destroy this plan. I am confident to be there as the Swedish COVID-19 approach has kept society open as much as possible.

Therefore, I am collecting my topics to discuss and preparing my luggage and presentation to be there.

The theme of the conference: Digital Transformation and PLM – a call for PLM Professionals to redefine and re-position the benefits and value of PLM, is close to my experience.

New PLM paradigms are coming up, while at the same time, we are working on solidifying existing concepts, like the Multiview BOM. The PDT part of the conference always brought interesting sessions related to sustainability and, often, the circular economy.

New PLM paradigms are coming up, while at the same time, we are working on solidifying existing concepts, like the Multiview BOM. The PDT part of the conference always brought interesting sessions related to sustainability and, often, the circular economy.

I am curious to see the final agenda. Hakan Karden already gave us some insights into why it is good to be curious – read it here.

Sustainability

Talking and learning about sustainability at PDT Europe is not a luxury. In particular, we experienced an unforeseen heatwave in western Europe, reminding us that the climate is not slowing down. More the contrary, rapid climate change caused by human influence becomes more and more visible.

Talking and learning about sustainability at PDT Europe is not a luxury. In particular, we experienced an unforeseen heatwave in western Europe, reminding us that the climate is not slowing down. More the contrary, rapid climate change caused by human influence becomes more and more visible.

Unfortunately, the people that suffer from droughts, bushfires, and famine are not the ones that can be held responsible for these effects. It is a global crisis, and the strongest shoulders must carry the weight to address these issues.

In that context, we had an internal meeting with the PLM Global Green Alliance core team members to plan our activities for the rest of the year.

In that context, we had an internal meeting with the PLM Global Green Alliance core team members to plan our activities for the rest of the year.

Besides interviews with PLM vendors and technology solution providers, we want to create opportunities for PGGA members to discuss PLM technology, methodology or change topics of interest, moderated by one of our core team members.

One of our observations is that awareness of the need for a more sustainable society exists. In polls all around the world, the majority of people mention their concerns.

However, where to start? What does matter, and how to influence companies as individuals? We also need to learn what is real and what is greenwashing. Therefore we want to schedule open discussions with PGGA members (are you already a member?) to share knowledge and thoughts about a topic. More about the agenda after the summer break.

However, where to start? What does matter, and how to influence companies as individuals? We also need to learn what is real and what is greenwashing. Therefore we want to schedule open discussions with PGGA members (are you already a member?) to share knowledge and thoughts about a topic. More about the agenda after the summer break.

Discussions & Podcasts

While I remain open for discussions and those who contacted me with a direct message on LinkedIn will acknowledge there is always a follow-up.

While I remain open for discussions and those who contacted me with a direct message on LinkedIn will acknowledge there is always a follow-up.

Whenever I have time – most of the time, I target Fridays for ad-hoc discussions – I am happy to schedule a zoom session to learn and discuss a particular topic without obligations. It will be a discussion, not a consult.

During Covid-lockdowns, I learned to appreciate podcasts. While making the daily walk through the same environment, the entertainment came from listening to an interesting podcast.

I learned a lot about history, mysteries, and human behavior. Of course, I was also looking for PLM-related podcasts. Of course, the major vendors found their way to podcasts too. However, I think they are often too slick, only highlighting a vision and not enough discussing what really happens in the field.

I learned a lot about history, mysteries, and human behavior. Of course, I was also looking for PLM-related podcasts. Of course, the major vendors found their way to podcasts too. However, I think they are often too slick, only highlighting a vision and not enough discussing what really happens in the field.

Starting a PLM-related podcast, and I want to highlight three of them

The Share PLM podcast, with 11 episodes, started promising in 2020. After a first start, it becomes difficult to deliver continuous new content.

The Share PLM podcast, with 11 episodes, started promising in 2020. After a first start, it becomes difficult to deliver continuous new content.

Currently, I am talking with the Share PLM team to see how we can build this continuity and extend the content. There are so many interesting persons in our network that have valuable opinions about PLM to share. More after the summer

The Peer Check podcast from CoLab is not a typical PLM podcast. More a focus on what engineering leaders should know. They started in 2022 and have already published ten episodes. I am in the process of listening to all of them, and I found them very refreshing.

The Peer Check podcast from CoLab is not a typical PLM podcast. More a focus on what engineering leaders should know. They started in 2022 and have already published ten episodes. I am in the process of listening to all of them, and I found them very refreshing.

This week I was happy to join Adam Keating, founder of CoLab, in a discussion related to Systems of Record and Systems of Engagement. More new after the summer.

The Change Troubleshooter podcast from Nina Dar, with already 34 episodes, is a podcast not focusing on PLM purely. Although Nina has a background in coaching PLM implementations, her episodes are around A Human Approach to Innovation and Change. You can imagine it is quite aligned with my area of interest.

The Change Troubleshooter podcast from Nina Dar, with already 34 episodes, is a podcast not focusing on PLM purely. Although Nina has a background in coaching PLM implementations, her episodes are around A Human Approach to Innovation and Change. You can imagine it is quite aligned with my area of interest.

In particular, Nina and I are having some side discussions about sustainability and (the lack of) human behavior to address climate change. You might hear more from Nina through our PGGA community.

More podcasts?

![]() I am curious to learn if similar podcasts exist to the topics I mentioned in this post. If so, provide a link in the comments. With enough feedback, I will publish a top-ten list this year’s end.

I am curious to learn if similar podcasts exist to the topics I mentioned in this post. If so, provide a link in the comments. With enough feedback, I will publish a top-ten list this year’s end.

Conclusion

In a society that seems to behave as if everything is black and white, to be solved by a tweet, we need people that can build a colorful opinion. Conferences, discussions and podcasts can help you remain curious and learn. As it must be extremely boring if you know already everything.

Have a great summertime.

In the last weeks, I had several discussions related to sustainability. What can companies do to become sustainable and prove it? But, unfortunately, there is so much greenwashing at this moment.

In the last weeks, I had several discussions related to sustainability. What can companies do to become sustainable and prove it? But, unfortunately, there is so much greenwashing at this moment.

Look at this post: 10 Companies and Corporations Called Out For Greenwashing.

Therefore I thought about which practical steps a company should take to prepare for a sustainable future, as the change will not happen overnight. It reminds me of the path towards a digital, model-based enterprise (my other passion). In my post Why Model-Based definition is important for all, I mentioned that MBD (Model-Based Definition) could be considered the first stepping-stone toward a Model-Based enterprise.

Therefore I thought about which practical steps a company should take to prepare for a sustainable future, as the change will not happen overnight. It reminds me of the path towards a digital, model-based enterprise (my other passion). In my post Why Model-Based definition is important for all, I mentioned that MBD (Model-Based Definition) could be considered the first stepping-stone toward a Model-Based enterprise.

The analogy for Material Compliance came after an Aras seminar I watched a month ago. The webinar How PLM Paves the Way for Sustainability with Insensia (an Aras implementer) demonstrates how material compliance is the first step toward sustainable product development.

The analogy for Material Compliance came after an Aras seminar I watched a month ago. The webinar How PLM Paves the Way for Sustainability with Insensia (an Aras implementer) demonstrates how material compliance is the first step toward sustainable product development.

Let’s understand why

The first steps

Companies that currently deliver solutions mostly only focus on economic gains. The projects or products they sell need to be profitable and competitive, which makes sense if you want a future.

Companies that currently deliver solutions mostly only focus on economic gains. The projects or products they sell need to be profitable and competitive, which makes sense if you want a future.

And this would not have changed if the awareness of climate impact has not become apparent.

First, CFKs and hazardous materials lead to new regulations. Next global agreements to fight climate change – the Paris agreement and more to come – have led and will lead to regulations that will change how products will be developed. All companies will have to change their product development and delivery models when it becomes a global mandate.

A required change is likely going to happen. In Europe, the Green Deal is making stable progress. However, what will happen in the US will be a mystery as even their supreme court becomes a political entity against sustainability (money first).

A required change is likely going to happen. In Europe, the Green Deal is making stable progress. However, what will happen in the US will be a mystery as even their supreme court becomes a political entity against sustainability (money first).

Still, compliance with regulations will be required if a company wants to operate in a global market.

What is Material Compliance?

In 2002, the European Union published a directive to restrict hazardous substances in materials. The directive, known as RoHS (Restriction of Hazardous Substances), was mainly related to electronic components. In the first directive, six hazardous materials were restricted.

In 2002, the European Union published a directive to restrict hazardous substances in materials. The directive, known as RoHS (Restriction of Hazardous Substances), was mainly related to electronic components. In the first directive, six hazardous materials were restricted.

The most infamous are Cadmium(Cd), Lead(Pb), and Mercury (Hg). In 2006 all products on the EU market must pass RoHS compliance, and in 2011 was now connected the CE marking of products sold in the European market was.

In 2015 four additional chemical substances were added, most softening PVC but also affecting the immune system. Meanwhile, other countries have introduced similar RoHS regulations; therefore, we can see it as a global restricting. Read more here: The RoHS guide.

In 2015 four additional chemical substances were added, most softening PVC but also affecting the immune system. Meanwhile, other countries have introduced similar RoHS regulations; therefore, we can see it as a global restricting. Read more here: The RoHS guide.

Consumers buying RoHS-compliant products now can be assured that none of the threshold values of the substances is reached in the product. The challenge for the manufacturer is to go through each of the components of the MBOM. To understand if it contains one of the ten restricted substances and, if yes, in which quantity.

Therefore, they need to get that information from each relevant supplier a RoHS declaration.

Besides RoHS, additional regulations protect the environment and the consumer. For example, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance deals with the regulations created to improve the environment and protect human health. In addition, REACH addresses the risks associated with chemicals and promotes alternative methods for the hazard assessment of substances.

Besides RoHS, additional regulations protect the environment and the consumer. For example, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance deals with the regulations created to improve the environment and protect human health. In addition, REACH addresses the risks associated with chemicals and promotes alternative methods for the hazard assessment of substances.

The compliance process in four steps

Material compliance is most of all the job of engineers. Therefore around 2005, some of my customers started to add RoHS support to their PLM environment.

Step 1

The image below shows the simple implementation – the PDF-from from the supplier was linked to the (M)BOM part.

An employee had to manually add the substances into a table and ensure the threshold values were not reached. But, of course, there was already a selection of preferred manufacturer parts during the engineering phase. Therefore RoHS compliance was almost guaranteed when releasing the EBOM.

An employee had to manually add the substances into a table and ensure the threshold values were not reached. But, of course, there was already a selection of preferred manufacturer parts during the engineering phase. Therefore RoHS compliance was almost guaranteed when releasing the EBOM.

But this process could be done more cleverly.

Step 2

So the next step was that manufacturers started to extend their PLM data model with the additional attributes for RoHS compliance. Again, this could be done cleverly or extremely generic, adding the attributes to all parts.

So now, when receiving the material declaration, a person just has to add the substance values to the part attributes. Then, through either standard functionality or customization, a compliance report could be generated for the (M)BOM. So this already saves some work.

So now, when receiving the material declaration, a person just has to add the substance values to the part attributes. Then, through either standard functionality or customization, a compliance report could be generated for the (M)BOM. So this already saves some work.

Step 3

The next step was to provide direct access to these attributes to the supplier and push the supplier to do the work.

Now the overhead for the manufacturer has been reduced again. This is because only the supplier needs to do the job for his customer.

Now the overhead for the manufacturer has been reduced again. This is because only the supplier needs to do the job for his customer.

Step 4

In step 4, we see a real connected environment, where information is stored only once, referenced by manufacturers, and kept actual by the part suppliers.

Who will host the RoHS databank? From some of my customer projects, I recall IHS as a data provider – it seems they are into this business when you look at their website HERE.

Who will host the RoHS databank? From some of my customer projects, I recall IHS as a data provider – it seems they are into this business when you look at their website HERE.

Where is your company at this moment?

Having seen the four stepping-stones leading towards efficient RoHS compliance, you see the challenge of moving from a document-driven approach to a data-driven approach.

Now let’s look into the future. Concepts like Life Cycle Assessment (LCA) or a Digital Product Passport (DPP) will require a fully connected approach.

Now let’s look into the future. Concepts like Life Cycle Assessment (LCA) or a Digital Product Passport (DPP) will require a fully connected approach.

Where is your company at this moment – have you reached RoHS compliance step 3 or 4? A first step to learn and work connected and data-driven.

Life Cycle Assessment – the ultimate target

A lifecycle assessment, or lifecycle analysis (two times LCA again), is a methodology to assess the environmental impact of a product (or solution) through its whole lifecycle. From materials sourcing, manufacturing, transportation, usage, service, and decommissioning. And by assessing, we mean a clear, verifiable, and shareable manner, not just guessing.

A lifecycle assessment, or lifecycle analysis (two times LCA again), is a methodology to assess the environmental impact of a product (or solution) through its whole lifecycle. From materials sourcing, manufacturing, transportation, usage, service, and decommissioning. And by assessing, we mean a clear, verifiable, and shareable manner, not just guessing.

Traditional engineering education is not bringing these skills, although LCA is not new, as this 10-years old YouTube movie from Autodesk illustrates:

What is new is that due to global understanding, we are reaching the limits of what our planet can endure; we must act now. Upcoming international regulations will enforce life cycle analysis reporting for manufacturers or service providers. This will happen gradually.

Meanwhile, we all should work on a circular economy, the major framework for a sustainable planet- click on the image on the left.

Meanwhile, we all should work on a circular economy, the major framework for a sustainable planet- click on the image on the left.

In my post, I wrote about these combined topics: SYSTEMS THINKING – a must-have skill in the 21st century.

Life Cycle Analysis – Digital Twin – Digitization

The big elephant in the room is that when we talk about introducing LCA in your company, it has a lot to do with the digitization of your company. Assessment data in a document can require too much human effort to maintain the data at the right quality. The costs are not affordable if your competitor is more efficient.

When coming to the Analysis part, here, a model-based, data-driven infrastructure is the most efficient way to run virtual analysis, using digital twin concepts at each stage of the product lifecycle.

When coming to the Analysis part, here, a model-based, data-driven infrastructure is the most efficient way to run virtual analysis, using digital twin concepts at each stage of the product lifecycle.

Virtual models for design, manufacturing and operations allow your company to make trade-off studies with low cost before committing to the physical world. 80 % of the environmental impact of a product comes from decisions in the virtual world.

Once you have your digital twins for each phase of the product lifecycle, you can benchmark your models with data reported from the physical world. All these interactions can be found in the beautiful Boeing diamond below, which I discussed before – Read A digital twin for everybody.

Conclusion

Efficient and sustainable life cycle assessment and analysis will come from connected information sources. The old document-driven paradigm is too costly and too slow to maintain. In particular, when the scope is not only a subset of your product, it is your full product and its full lifecycle with LCA. Another stepping stone towards the near future. Where are you?

Stepping-stone 1: From Model-Based Definition to an efficient Model-Based, Data-driven Enterprise

Stepping-stone 2: For RoHS compliance to an efficient and sustainable Model-Based, data-driven enterprise.

Yes, it is not a typo. Clayton Christensen famous book written in 1995 discussed the Innovator’s Dilemma when new technologies cause great firms to fail. This was the challenge two decades ago. Existing prominent companies could become obsolete quickly as they were bypassed by new technologies.

Yes, it is not a typo. Clayton Christensen famous book written in 1995 discussed the Innovator’s Dilemma when new technologies cause great firms to fail. This was the challenge two decades ago. Existing prominent companies could become obsolete quickly as they were bypassed by new technologies.

The examples are well known. To mention a few: DEC (Digital Equipment Corporation), Kodak, and Nokia.

Why the innovation dilemma?

This decade the challenge has become different. All companies are forced to become more sustainable in the next ten years. Either pushed by global regulations or because of their customer demands. The challenge is this time different. Besides the priority of reducing greenhouse gas emissions, there is also the need to transform our society from a linear, continuous growth economy into a circular doughnut economy.

The circular economy makes the creation, the usage and the reuse of our products more complex as the challenge is to reduce the need for raw materials and avoid landfills.

The doughnut economy makes the values of an economy more complex as it is not only about money and growth, human and environmental factors should also be considered.

To manage this complexity, I wrote SYSTEMS THINKING – a must-have skill in the 21st century, focusing on the logical part of the brain. In my follow-up post, Systems Thinking: a second thought, I looked at the human challenge. Our brain is not rational and wants to think fast to solve direct threats. Therefore, we have to overcome our old brains to make progress.

To manage this complexity, I wrote SYSTEMS THINKING – a must-have skill in the 21st century, focusing on the logical part of the brain. In my follow-up post, Systems Thinking: a second thought, I looked at the human challenge. Our brain is not rational and wants to think fast to solve direct threats. Therefore, we have to overcome our old brains to make progress.

An interesting and thought-provoking was shared by Nina Dar in this discussion, sharing the video below. The 17 Sustainability Development Goals (SDGs) describe what needs to be done. However, we also need the Inner Development Goals (IDGs) and the human side to connect. Watch the movie:

Our society needs to change and innovate; however, we cannot. The Innovation Dilemma.The future is data-driven and digital.

What is clear to me is that companies developing products and services have only one way to move forward: becoming data-driven and digital.

Why data-driven and digital?

Let’s look at something companies might already practice, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). This European directive, introduced in 2007, had the aim to protect human health and protect the environment by communicating information on chemicals up and down the supply chain. This would ensure that manufacturers, importers, and their customers are aware of information relating to the health and safety of the products supplied.

Let’s look at something companies might already practice, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). This European directive, introduced in 2007, had the aim to protect human health and protect the environment by communicating information on chemicals up and down the supply chain. This would ensure that manufacturers, importers, and their customers are aware of information relating to the health and safety of the products supplied.

The regulation is currently still suffering in execution as most of the reporting and evaluation of chemicals is done manually. Suppliers report their chemicals in documents, and companies report the total of chemicals in their summary reports. Then, finally, authorities have to go through these reports.

The regulation is currently still suffering in execution as most of the reporting and evaluation of chemicals is done manually. Suppliers report their chemicals in documents, and companies report the total of chemicals in their summary reports. Then, finally, authorities have to go through these reports.

Where the scale of REACH is limited, the manual effort to have end-to-end reporting is relatively high. In addition, skilled workers are needed to do the job because reporting is done in a document-based manner.

Life Cycle Assessments (LCA)

Where you might think REACH is relatively simple, the real new challenges for companies are the need to perform Life Cycle Assessments for their products. In a Life Cycle Assessment. The Wiki definition of LCA says:

Life cycle assessment or LCA (also known as life cycle analysis) is a methodology for assessing environmental impacts associated with all the stages of the life cycle of a commercial product, process, or service. For instance, in the case of a manufactured product, environmental impacts are assessed from raw material extraction and processing (cradle), through the product’s manufacture, distribution and use, to the recycling or final disposal of the materials composing it (grave)

This will be a shift in the way companies need to define products. Much more thinking and analysis are required in the early design phases. Before committing to a physical solution, engineers and manufacturing engineers need to simulate and calculate the impact of their design decisions in the virtual world.

This is where the digital twin of the design and the digital twin of the manufacturing process becomes relevant. And remember: Digital Twins do not run on documents – you need connected data and various types of models to calculate and estimate the environmental impact.

This is where the digital twin of the design and the digital twin of the manufacturing process becomes relevant. And remember: Digital Twins do not run on documents – you need connected data and various types of models to calculate and estimate the environmental impact.

LCA done in a document-based manner will make your company too slow and expensive.

I described this needed transformation in my series from last year: The road to model-based and connected PLM – nine posts exploring the technology and concept of a model-based, data-driven PLM infrastructure.

Digital Product Passport (DPP)

The European Commission has published an action plan for the circular economy, one of the most important building blocks of the European Green Deal. One of the defined measures is the gradual introduction of a Digital Product Passport (DPP). As the quality of an LCA depends on the quality and trustworthy information about products and materials, the DPP is targeting to ensure circular economy metrics become reliable.

The European Commission has published an action plan for the circular economy, one of the most important building blocks of the European Green Deal. One of the defined measures is the gradual introduction of a Digital Product Passport (DPP). As the quality of an LCA depends on the quality and trustworthy information about products and materials, the DPP is targeting to ensure circular economy metrics become reliable.

This will be a long journey. If you want to catch a glimpse of the complexity, read this Medium article: The digital product passport and its technical implementation related to the DPP for batteries.

The innovation dilemma

Suppose you agree with my conclusion that companies need to change their current product or service development into a data-driven and model-based manner. In that case, the question will come up: where to start?

Becoming data-driven and model-based, of course, is not the business driver. However, this change is needed to be able to perform Life Cycle Assessments and comply with current and future regulations by remaining competitive.

Becoming data-driven and model-based, of course, is not the business driver. However, this change is needed to be able to perform Life Cycle Assessments and comply with current and future regulations by remaining competitive.

A document-driven approach is a dead-end.

Now let’s look at the real dilemmas by comparing a startup (clean sheet / no legacy) and an existing enterprise (experience with the past/legacy). Is there a winning approach?

The Startup

Having lived in Israel – the nation where almost everyone is a startup – and working with startups afterward in the past 10 years, I always get inspired by these people’s energy in startup companies. They have a unique value proposition most of the time, and they want to be visible on the market as soon as possible.

Having lived in Israel – the nation where almost everyone is a startup – and working with startups afterward in the past 10 years, I always get inspired by these people’s energy in startup companies. They have a unique value proposition most of the time, and they want to be visible on the market as soon as possible.

This approach is the opposite of systems thinking. It is often a very linear process to deliver this value proposition without exploring the side effects of such an approach.

For example, the new “green” transportation hype. Many cities now have been flooded with “green” scooters and electric bikes to promote transportation as a service. The idea behind this concept is that citizens do not require to own polluting motorbikes or cars anymore, and transportation means will be shared. Therefore, the city will be cleaner and greener.

For example, the new “green” transportation hype. Many cities now have been flooded with “green” scooters and electric bikes to promote transportation as a service. The idea behind this concept is that citizens do not require to own polluting motorbikes or cars anymore, and transportation means will be shared. Therefore, the city will be cleaner and greener.

However, these “green” vehicles are often designed in the traditional linear way. Is there a repair plan or a plan to recycle the batteries? Reuse of materials used.? Most of the time, not. Please, if you have examples contradicting my observations, let me know. I like to hear good news.

When startup companies start to scale, they need experts to help them grow the company. Often these experts are seasoned people, perhaps close to retirement. They will share their experience and what they know best from the past: traditional linear thinking.

As a result, even though startup companies can start with a clean sheet, their focus on delivering the product or service blocks further thinking. Instead, the seasoned experts will drive the company towards ways of working they know from the past.

Out of curiosity: Do you know or work in a startup that has started with a data-driven and model-based vision from scratch? Please add the name of this company in the comments, and let’s learn how they did it.

Out of curiosity: Do you know or work in a startup that has started with a data-driven and model-based vision from scratch? Please add the name of this company in the comments, and let’s learn how they did it.

The Existing company

Working in an established company is like being on board a big tanker. Changing its direction takes a clear eye on the target and navigation skills to come there. Unfortunately, most of the time, these changes take years as it is impossible to switch the PLM infrastructure and the people skills within a short time.

From the bimodal approach in 2015 to the hybrid approach for companies, inspired by this 2017 McKinsey article: Toward an integrated technology operating model, I discovered that this is probably the best approach to ensure a change will happen. In this approach – see image – the organization keeps running on its document-driven PLM infrastructure. This type of infrastructure becomes the system of record. Nothing different from what PLM currently is in most companies.

In parallel, you have to start with small groups of people who independently focus on a new product, a new service. Using the model-based approach, they work completely independently from the big enterprise in a data-driven approach. Their environment can be considered the future system of engagement.

The data-driven approach allows all disciplines to work in a connected, real-time manner. Mastering the new ways of working is usually the task of younger employees that are digital natives. These teams can be completed by experienced workers who behave as coaches. However, they will not work in the new environment; these coaches bring business knowledge to the team.

People cannot work in two modes, but organizations can. As you can see from the McKinsey chart, the digital teams will get bigger and more important for the core business over time. In parallel, when their data usage grows, more and more data integration will occur between the two operation modes. Therefore, the old PLM infrastructure can remain a System of Record and serve as a support backbone for the new systems of engagement.

The Innovation Dilemma conclusion

The upcoming ten years will push organizations to innovate their ways of working to become sustainable and competitive. As discussed before, they must learn to work in a data-driven, connected manner. Both startups and existing enterprises have challenges – they need to overcome the “thinking fast and acting slow” mindset. Do you see the change in your company?

Note: Before publishing this post, I read this interesting and complementary post from Jan Bosch Boost your digitalization: instrumentation.

Note: Before publishing this post, I read this interesting and complementary post from Jan Bosch Boost your digitalization: instrumentation.

It is in the air – grab it.

Two weeks ago, I wrote a generic post related to System Thinking, in my opinion, a must-have skill for the 21st century (and beyond). Have a look at the post on LinkedIn; in particular interesting to see the discussion related to Systems Thinking: a must-have skill for the 21st century.

Two weeks ago, I wrote a generic post related to System Thinking, in my opinion, a must-have skill for the 21st century (and beyond). Have a look at the post on LinkedIn; in particular interesting to see the discussion related to Systems Thinking: a must-have skill for the 21st century.

I liked Remy Fannader’s remark that thinking about complexity was not something new.

This remark is understandable from his personal context. Many people enjoy thinking – it was a respected 20th-century skill.

However, I believe, as Daniel Kahneman describes in his famous book: Thinking Fast and Slow, our brain is trying to avoid thinking.

However, I believe, as Daniel Kahneman describes in his famous book: Thinking Fast and Slow, our brain is trying to avoid thinking.

This is because thinking consumes energy, the energy the body wants to save in the case of an emergency.

So let’s do a simple test (coming from Daniel):

xx

A bat and a ball cost together $ 1.10 – the bat costs one dollar more than the ball. So how much does the ball cost?

Look at the answer at the bottom of this post. If you have it wrong, you are a fast thinker. And this brings me to my next point. Our brain does not want to think deeply; we want fast and simple solutions. This is a challenge in a complex society as now we hear real-time information coming from all around the world. What is true and what is fake is hard to judge.

However, according to Kahneman, we do not want to waste energy on thinking. We create or adhere to simple solutions allowing our brains to feel relaxed.

This human behavior has always been exploited by populists and dictators: avoid complexity because, in this way, you lose people. Yuval Harari builds upon this with his claim that to align many people, you need a myth. I wrote about the need for myths in the PLM space a few times, e.g., PLM as a myth? and The myth perception

And this is where my second thoughts related to Systems Thinking started. Is the majority of people able and willing to digest complex problems?

And this is where my second thoughts related to Systems Thinking started. Is the majority of people able and willing to digest complex problems?

My doubts grew bigger when I had several discussions about fighting climate change and sustainability.

Both Brains required

By coincidence, I bumped on this interesting article Market-led Sustainability is a ‘Fix that Fails’…

By coincidence, I bumped on this interesting article Market-led Sustainability is a ‘Fix that Fails’…

I provided a link to the post indirectly through LinkedIn. If you are a LinkedIn PLM Global Green Alliance member, you can see below the article an interesting analysis related to market-led sustainability, system thinking and economics.

Join the PLM Global Green Alliance group to be part of the full discussion; otherwise, I recommend you visit Both Brains Required, where you can find the source article and other related content.

Join the PLM Global Green Alliance group to be part of the full discussion; otherwise, I recommend you visit Both Brains Required, where you can find the source article and other related content.

It is a great article with great images illustrating the need for systems thinking and sustainability. All information is there to help you realize that sustainability is not just a left-brain exercise.

The left brain is supposed to be logical and analytical. That’s systems thinking, you might say quickly. However, the other part of our brain is about our human behavior, and this side is mostly overlooked. My favorite quote from the article:

Voluntary Market-Led activities are not so much a solution to the sustainability crisis as a symptom of more profoundly unsustainable foundations of human behavior.

The article triggered my second thoughts related to systems thinking. Behavioral change is not part of systems thinking. It is another dimension harder to address and even harder to focus on sustainability.

The LinkedIn discussion below the article Market-led Sustainability is a ‘Fix that Fails’… is a great example of the talks we would like to have in our PLM Global Green Alliance group. Nina Dar, Patrick Hillberg and Richard McFall brought in several points worth discussing. Too many to discuss them all here – let’s take two fundamental issues:

1. More than economics

An interesting viewpoint in this discussion was the relation to economics. We don’t believe that economic growth is the main point to measure. Even a statement like: “Sustainable businesses will be more profitable than traditional ones” is misleading when companies are measured by shareholder value or EBIT (Earnings Before Interest or Taxes). We briefly touched on Kate Raworth’s doughnut economics.

This HBR article mentioned in the discussion: Business Schools Must Do More to Address the Climate Crisis also shows it is not just about systems thinking.

We have seen this in the Apparel industry with the horrible collapse of a factory in Bangladesh (2013). Still, the inhumane accidents happen in southeast Asia. I like to quote Chris Calverley in his LinkedIn article: Making ethical apparel supply chains achievable on a global scale.

No one gets into business because they want to behave unethically. On the contrary, a lack of ethics is usually driven by a common desire to operate more efficiently and increase profit margins.

In my last post, I shared a similar example from an automotive tier 2 supplier. Unfortunately, suppliers are not measured or rewarded for sustainability efforts; only efficiency and costs are relevant.

The seventeen Sustainability Development Goals (SDG), as defined by the United Nations, are the best guidance for sustainable drivers beyond money. Supporting the SDGs enforce systems thinking when developing a part, a product, or a solution. Many other stakeholders need to be taken care of, at least if you truly support sustainability as a company.

The seventeen Sustainability Development Goals (SDG), as defined by the United Nations, are the best guidance for sustainable drivers beyond money. Supporting the SDGs enforce systems thinking when developing a part, a product, or a solution. Many other stakeholders need to be taken care of, at least if you truly support sustainability as a company.

2. The downside of social media

The LinkedIn discussion related to Market-led Sustainability is a ‘Fix that Fails’… The thread shows that LinkedIn, like other social media, is not really interested in supporting in-depth discussions – try to navigate what has been said in chronological order. With Patrick, Nina and Richard, we agreed to organize a follow-up discussion in our PLM Global Green Alliance Group.

The LinkedIn discussion related to Market-led Sustainability is a ‘Fix that Fails’… The thread shows that LinkedIn, like other social media, is not really interested in supporting in-depth discussions – try to navigate what has been said in chronological order. With Patrick, Nina and Richard, we agreed to organize a follow-up discussion in our PLM Global Green Alliance Group.

And although we are happy with social media as it allows each of us to reach a global audience, there seems to be a worrying contra-productive impact. If you read the book Stolen Focus. A quote:

And although we are happy with social media as it allows each of us to reach a global audience, there seems to be a worrying contra-productive impact. If you read the book Stolen Focus. A quote:

All over the world, our ability to pay attention is collapsing. In the US, college students now focus on one task for only 65 seconds, and office workers, on average, manage only three minutes

This is worrying, returning to Remy Fannader’s remark: thinking about complexity was not something new. The main difference is that it is not new. However, our society is changing towards thinking too fast, not rewarding systems thinking.

Even scarier, if you have time, read this article from The Atlantic: about the impact of social media on the US Society. It is about trust in science and data. Are we facing the new (Trump) Tower of Babel in our modern society? As the writers state: Babel is a metaphor for what some forms of social media have done to nearly all of the groups and institutions most important to the country’s future—and to us as a people.

Even scarier, if you have time, read this article from The Atlantic: about the impact of social media on the US Society. It is about trust in science and data. Are we facing the new (Trump) Tower of Babel in our modern society? As the writers state: Babel is a metaphor for what some forms of social media have done to nearly all of the groups and institutions most important to the country’s future—and to us as a people.

xx

Congratulations

support

The fact that you reached this part of the post means your attention span has been larger than 3 minutes, showing there is hope for people like you and me. As an experiment to discover how many people read the post till here, please answer with the “support” icon if you have reached this part of the post.

I am curious to learn how many of us who saw the post came here.

Conclusion

Systems Thinking is a must-have skill for the 21st century. Many of us working in the PLM domain focus on providing support for systems thinking, particularly Life Cycle Assessment capabilities. However, the discussion with Patrick Hillberg, Nina Darr and Richard McFall made me realize there is more: economics and human behavior. For example, can we change our economic models, measuring companies not only for the money profit they deliver? What do?

Answering this type of question will be the extended mission for PLM consultants of the future – are you ready?

The answer to the question with the ball and the bat:

A fast answer would say the price of the ball is 10 cents. However, this would make the price of the bat $1.10, giving a total cost of $1.20. So the right answer should be 5 cents. To be honest, I got tricked the first time too. Never too late to confirm you make mistakes, as only people who do not do anything make no mistakes.