After the series about “Learning from the past,” it is time to start looking toward the future. I learned from several discussions that I probably work most of the time with advanced companies. I believe this would motivate companies that lag behind even to look into the future even more.

After the series about “Learning from the past,” it is time to start looking toward the future. I learned from several discussions that I probably work most of the time with advanced companies. I believe this would motivate companies that lag behind even to look into the future even more.

If you look into the future for your company, you need new or better business outcomes. That should be the driver for your company. A company does not need PLM or a Digital Twin. A company might want to reduce its time to market and improve collaboration between all stakeholders. These objectives can be realized by different ways of working and an IT infrastructure to allow these processes to become digital and connected.

That is the “game”. Coming back to the future of PLM. We do not need a discussion about definitions; I leave this to the academics and vendors. We will see the same applies to the concept of a Digital Twin.

That is the “game”. Coming back to the future of PLM. We do not need a discussion about definitions; I leave this to the academics and vendors. We will see the same applies to the concept of a Digital Twin.

My statement: The digital twin is not new. Everybody can have their own digital twin as long as you interpret the definition differently. Does this sound like the PLM definition?

The definition

I like to follow the Gartner definition:

A digital twin is a digital representation of a real-world entity or system. The implementation of a digital twin is an encapsulated software object or model that mirrors a unique physical object, process, organization, person, or other abstraction. Data from multiple digital twins can be aggregated for a composite view across a number of real-world entities, such as a power plant or a city, and their related processes.

As you see, not a narrow definition. Now we will look at the different types of interpretations.

Single-purpose siloed Digital Twins

- Simple – data only

One of the most straightforward applications of a digital twin is, for example, my Garmin Connect environment. My device registers performance parameters (speed, cadence, power, heartbeat, location) when cycling. Then, after every trip, I can analyze my performance. I can see changes in my overall performance; compare my performance with others in my category (weight, age, sex).

One of the most straightforward applications of a digital twin is, for example, my Garmin Connect environment. My device registers performance parameters (speed, cadence, power, heartbeat, location) when cycling. Then, after every trip, I can analyze my performance. I can see changes in my overall performance; compare my performance with others in my category (weight, age, sex).

Based on that, I can decide if I want to improve my performance. My personal business goal is to maintain and improve my overall performance, knowing I cannot stop aging by upgrading my body.

On November 4th, 2020, I am participating in the (almost virtual) Digital Twin conference organized by Bits&Chips in the Netherlands. In the context of human performance, I look forward to Natal van Riel’s presentation: Towards the metabolic digital twin – for sure, this direction is not simple. Natal is a full professor at the Technical University in Eindhoven, the “smart city” in the Netherlands.

On November 4th, 2020, I am participating in the (almost virtual) Digital Twin conference organized by Bits&Chips in the Netherlands. In the context of human performance, I look forward to Natal van Riel’s presentation: Towards the metabolic digital twin – for sure, this direction is not simple. Natal is a full professor at the Technical University in Eindhoven, the “smart city” in the Netherlands.

- Medium – data and operating models

Many connected devices in the world use the same principle. An airplane engine, an industrial robot, a wind turbine, a medical device, and a train carriage; all track the performance based on this connection between physical and virtual, based on some sort of digital connectivity.

Many connected devices in the world use the same principle. An airplane engine, an industrial robot, a wind turbine, a medical device, and a train carriage; all track the performance based on this connection between physical and virtual, based on some sort of digital connectivity.

The business case here is also monitoring performance, predicting maintenance, and upgrading the product when needed.

This is the domain of Asset Lifecycle Management, a practice that has existed for decades. Based on financial and performance models, the optimal balance between maintaining and overhauling has to be found. Repairs are disruptive and can be extremely costly. A manufacturing site that cannot produce can cost millions per day. Connecting data between the physical and the virtual model allows us to have real-time insights and be proactive. It becomes a digital twin.

This is the domain of Asset Lifecycle Management, a practice that has existed for decades. Based on financial and performance models, the optimal balance between maintaining and overhauling has to be found. Repairs are disruptive and can be extremely costly. A manufacturing site that cannot produce can cost millions per day. Connecting data between the physical and the virtual model allows us to have real-time insights and be proactive. It becomes a digital twin.

- Advanced – data and connected 3D model

The digital twin we see the most in marketing videos is a virtual twin, using a 3D representation for understanding and navigation. The 3D representation provides a Virtual Reality (VR) environment with connected data. When pointing at the virtual components, information might appear, or some animation might take place.

The digital twin we see the most in marketing videos is a virtual twin, using a 3D representation for understanding and navigation. The 3D representation provides a Virtual Reality (VR) environment with connected data. When pointing at the virtual components, information might appear, or some animation might take place.

Building such a virtual representation is a significant effort; therefore, there needs to be a serious business case.

The simplest business case is to use the virtual twin for training purposes. A flight simulator provides a virtual environment and behavior as-if you are flying in a physical airplane – the behavior model behind the simulator should match as well as possibly the real behavior. However, as it is a model, it will never be 100 % reality and requires updates when new findings or product changes appear.

A virtual model of a platform or plant can be used for training on Standard Operating Procedures (SOPs). In the physical world, there is no place or time to conduct such training. Here the complexity might be lower. There is a 3D Model; however, serious updates can only be expected after a major maintenance or overhaul activity.

A virtual model of a platform or plant can be used for training on Standard Operating Procedures (SOPs). In the physical world, there is no place or time to conduct such training. Here the complexity might be lower. There is a 3D Model; however, serious updates can only be expected after a major maintenance or overhaul activity.

These practices are not new either and are used in places where physical training cannot be done.

More challenging is the Augmented Reality (AR) use case. Here the virtual model, most of the time, a lightweight 3D Model, connects to real-time data coming from other sources. For example, AR can be used when an engineer has to service a machine. The AR environment might project actual data from the machine, indicate service points and service procedures.

More challenging is the Augmented Reality (AR) use case. Here the virtual model, most of the time, a lightweight 3D Model, connects to real-time data coming from other sources. For example, AR can be used when an engineer has to service a machine. The AR environment might project actual data from the machine, indicate service points and service procedures.

The positive side of the business case is clear for such an opportunity, ensuring service engineers always work with the right information in a real-time context. The main obstacle to implementing AR, in reality, is the access to data, the presentation of the data and keeping the data in the AR environment matching the reality.

And although there are 3D Models in use, they are, to my knowledge, always created in siloes, not yet connected to their design sources. Have a look at the Digital Twin conference from Bits&Chips, as mentioned before.

And although there are 3D Models in use, they are, to my knowledge, always created in siloes, not yet connected to their design sources. Have a look at the Digital Twin conference from Bits&Chips, as mentioned before.

Several of the cases mentioned above will be discussed here. The conference’s target is to share real cases concluded by Q & A sessions, crucial for a virtual event.

Connected Virtual Twins along the product lifecycle

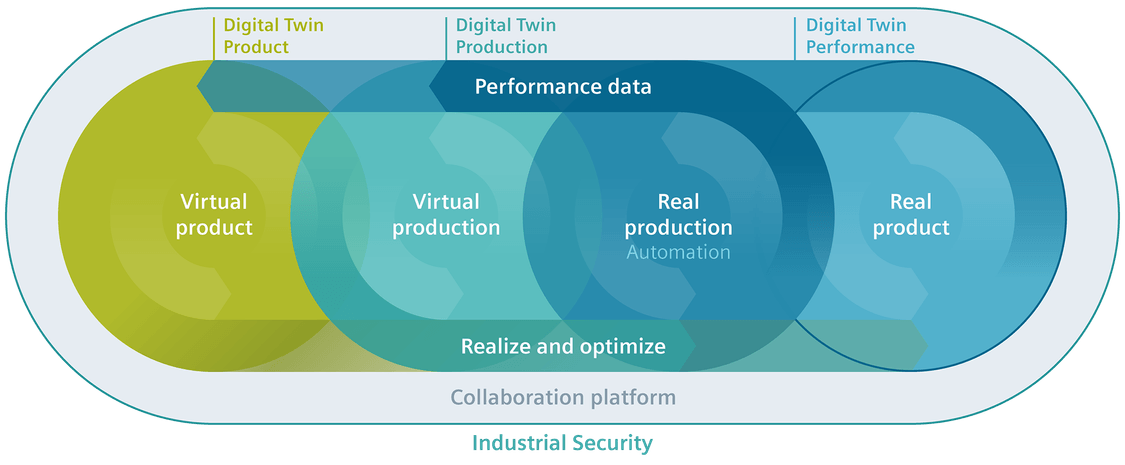

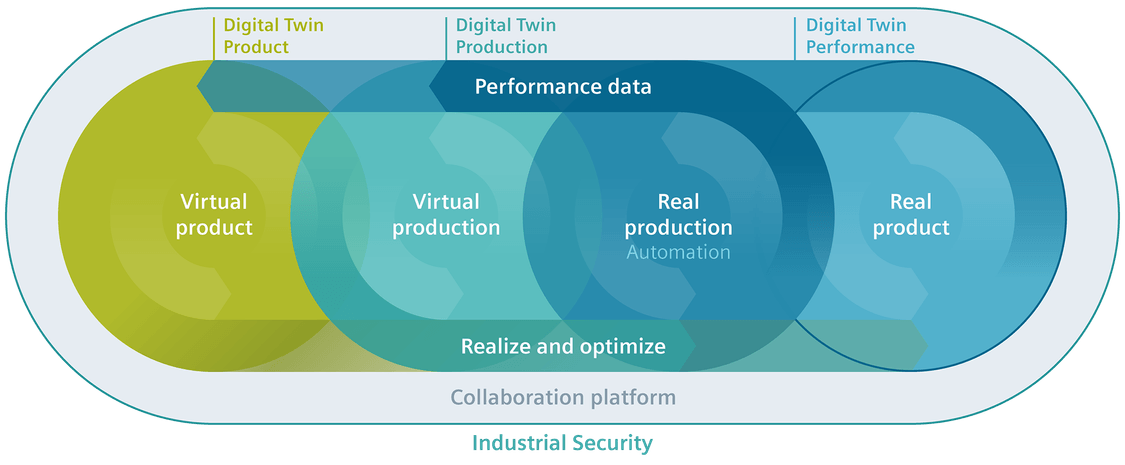

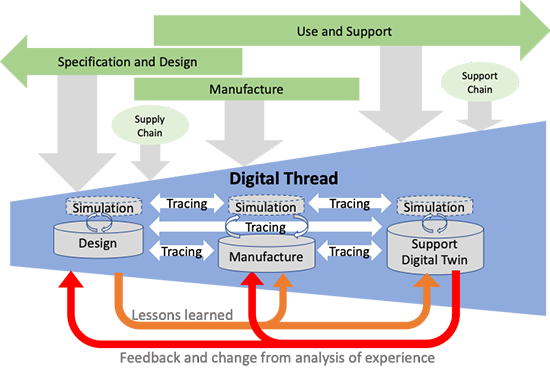

So far, we have been discussing the virtual twin concept, where we connect a product/system/person in the physical world to a virtual model. Now let us zoom in on the virtual twins relevant for the early parts of the product lifecycle, the manufacturing twin, and the development twin. This image from Siemens illustrates the concept:

On slides they imagine a complete integrated framework, which is the future vision. Let us first zoom in on the individual connected twins.

The digital production twin

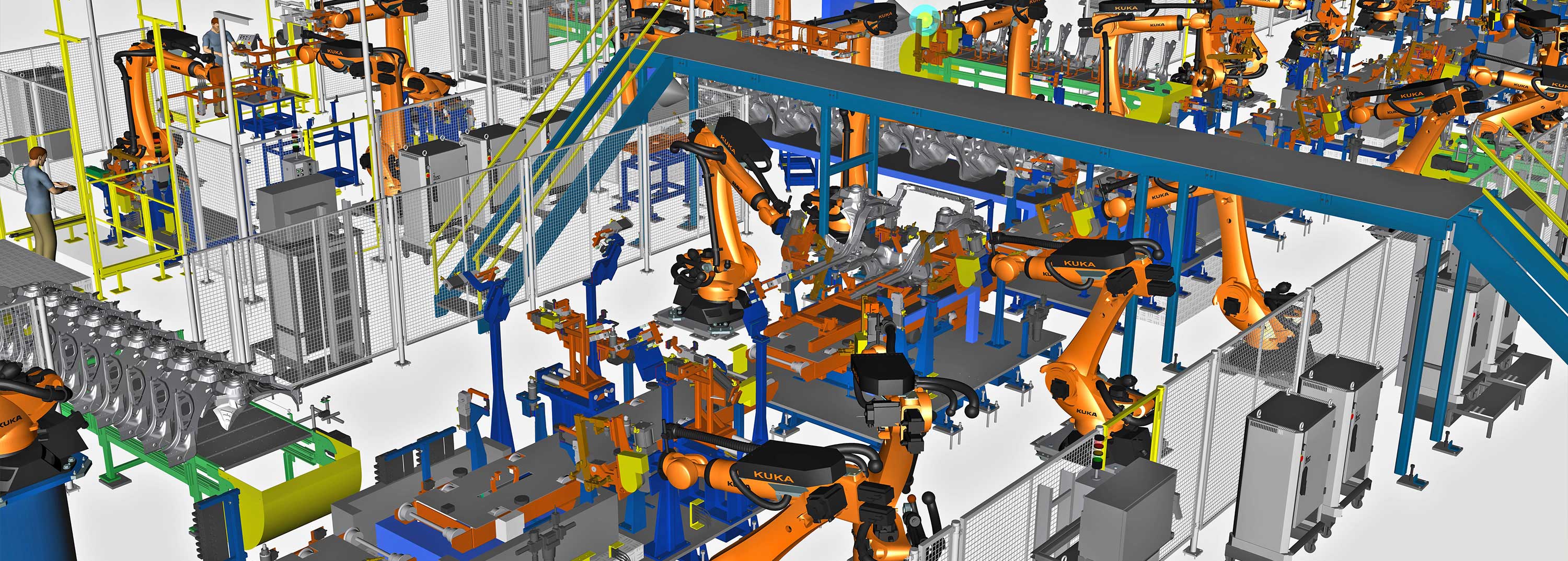

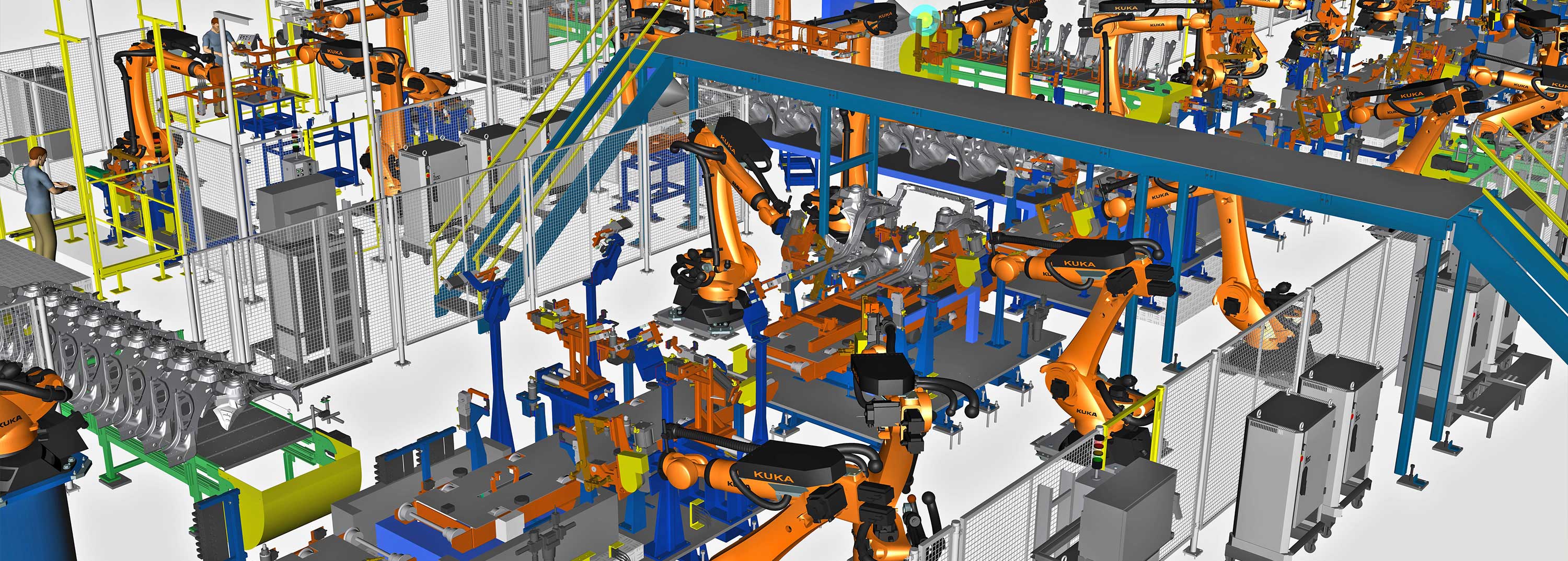

This is the area of virtual manufacturing and creating a virtual model of the manufacturing plant. Virtual manufacturing planning is not a new topic. DELMIA (Dassault Systèmes) and Tecnomatix (Siemens) are already for a long time offering virtual manufacturing planning solutions.

This is the area of virtual manufacturing and creating a virtual model of the manufacturing plant. Virtual manufacturing planning is not a new topic. DELMIA (Dassault Systèmes) and Tecnomatix (Siemens) are already for a long time offering virtual manufacturing planning solutions.

At that time, the business case was based on the fact that the definition of a manufacturing plant and process done virtually allows you to optimize the plant before investing in physical assets.

Saving money as there is no costly prototype phase to optimize production. In a virtual world, you can perform many trade-off studies without extra costs. That was the past (and, for many companies, still the current situation).

Saving money as there is no costly prototype phase to optimize production. In a virtual world, you can perform many trade-off studies without extra costs. That was the past (and, for many companies, still the current situation).

With the need to be more flexible in manufacturing to address individual customer orders without increasing the overhead of delivering these customer-specific solutions, there is a need for a configurable plant that can produce these individual products (batch size 1).

This is where the virtual plant model comes into the picture again. Instead of having a virtual model to define the ultimate physical plant, now the virtual model remains an active model to propose and configure the production process for each of these individual products in the physical plant.

This is where the virtual plant model comes into the picture again. Instead of having a virtual model to define the ultimate physical plant, now the virtual model remains an active model to propose and configure the production process for each of these individual products in the physical plant.

This is partly what Industry 4.0 is about. Using a model-based approach to configure the plant and its assets in a connected manner. The digital production twin drives the execution of the physical plant. The factory has to change from a static factory to a dynamic “smart” factory.

In the domain of Industry 4.0, companies are reporting progress. However, in my experience, the main challenge is still that the product source data is not yet built in a model-based, configurable manner. Therefore, requires manual rework. This is the area of Model-Based Definition, and I have been writing about this aspect several times. Latest post: Model-Based: Connecting Engineering and Manufacturing

The business case for this type of digital twin, of course, is to be able to customer-specific products with extremely competitive speed and reduced cost compared to standard. It could be your company’s survival strategy. As it is hard to predict the future, as we see from COVID-19, it is still crucial to anticipate the future instead of waiting.

The business case for this type of digital twin, of course, is to be able to customer-specific products with extremely competitive speed and reduced cost compared to standard. It could be your company’s survival strategy. As it is hard to predict the future, as we see from COVID-19, it is still crucial to anticipate the future instead of waiting.

The digital development twin

Before a product gets manufactured, there is a product development process. In the past, this was pure mechanical with some electronic components. Nowadays, many companies are actually manufacturing systems as the software controlling the product plays a significant role. In this context, the model-based systems engineering approach is the upcoming approach to defining and testing a system virtually before committing to the physical world.

Before a product gets manufactured, there is a product development process. In the past, this was pure mechanical with some electronic components. Nowadays, many companies are actually manufacturing systems as the software controlling the product plays a significant role. In this context, the model-based systems engineering approach is the upcoming approach to defining and testing a system virtually before committing to the physical world.

Model-Based Systems Engineering can define a single complex product and perform all kinds of analyses on the system even before there is a physical system in place. I will explain more about model-based systems engineering in future posts. In this context, I want to stress that having a model-based system engineering environment combined with modularity (do not confuse it with model-based) is a solid foundation for dealing with unique custom products. Solutions can be configured and validated against their requirements already during the engineering phase.

Model-Based Systems Engineering can define a single complex product and perform all kinds of analyses on the system even before there is a physical system in place. I will explain more about model-based systems engineering in future posts. In this context, I want to stress that having a model-based system engineering environment combined with modularity (do not confuse it with model-based) is a solid foundation for dealing with unique custom products. Solutions can be configured and validated against their requirements already during the engineering phase.

The business case for the digital development twin is easy to make. Shorter time to market, improved and validated quality, and reduced engineering hours and costs compared to traditional ways of working. To achieve these results, for sure, you need to change your ways of working and the tools you are using. So it won’t be that easy!

The business case for the digital development twin is easy to make. Shorter time to market, improved and validated quality, and reduced engineering hours and costs compared to traditional ways of working. To achieve these results, for sure, you need to change your ways of working and the tools you are using. So it won’t be that easy!

For those interested in Industry 4.0 and the Model-Based System Engineering approach, join me at the upcoming PLM Road Map 2020 and PDT 2020 conference on 17-18-19 November. As you can see from the agenda, a lot of attention to the Digital Twin and Model-Based approaches.

For those interested in Industry 4.0 and the Model-Based System Engineering approach, join me at the upcoming PLM Road Map 2020 and PDT 2020 conference on 17-18-19 November. As you can see from the agenda, a lot of attention to the Digital Twin and Model-Based approaches.

Three digital half-days with hopefully a lot to learn and stay with our feet on the ground. In particular, I am looking forward to Marc Halpern’s keynote speech: Digital Thread: Be Careful What you Wish For, It Just Might Come True

Conclusion

It has been very noisy on the internet related to product features and technologies, probably due to COVID-19 and therefore disrupted interactions between all of us – vendors, implementers and companies trying to adjust their future. The Digital Twin concept is an excellent framing for a concept that everyone can relate to. Choose your business case and then look for the best matching twin.

About a year ago we started the PLM Global Green Alliance, further abbreviated as the PGGA. Rich McFall, the main driver behind the PGGA started the website, The PLM Green Alliance, to have a persistent place to share information.

About a year ago we started the PLM Global Green Alliance, further abbreviated as the PGGA. Rich McFall, the main driver behind the PGGA started the website, The PLM Green Alliance, to have a persistent place to share information. My personal motivation to support and join the PGGA was driven by the wish to combine my PLM-world with interest to create a more sustainable society for anyone around the world. It is a challenging combination. For example, PLM is born in the Aerospace and Defense industries, probably not the most sustainable industries.

My personal motivation to support and join the PGGA was driven by the wish to combine my PLM-world with interest to create a more sustainable society for anyone around the world. It is a challenging combination. For example, PLM is born in the Aerospace and Defense industries, probably not the most sustainable industries. Many readers of this post have probably never heard of the Ragn-Sells group or followed up on a call for action. I have the same challenge. Being motivated beyond your day-to-day business (the old ways of working) and giving these activities priority above exploring and learning more about applying sustainability in my PLM practices.

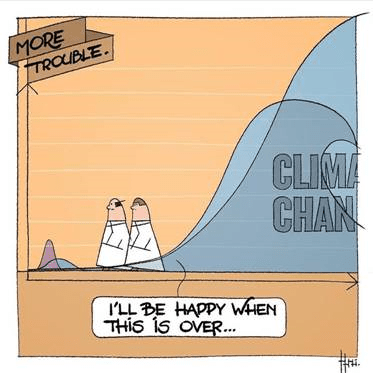

Many readers of this post have probably never heard of the Ragn-Sells group or followed up on a call for action. I have the same challenge. Being motivated beyond your day-to-day business (the old ways of working) and giving these activities priority above exploring and learning more about applying sustainability in my PLM practices. I think most of you have seen the image on the left, which started as a joke. However, looking back, we all have seen that COVID-19 has led to a tremendous push for using digital technologies to modernize existing businesses.

I think most of you have seen the image on the left, which started as a joke. However, looking back, we all have seen that COVID-19 has led to a tremendous push for using digital technologies to modernize existing businesses. In the PGGA LinkedIn community, we had people joining from all over the world. We started to organize video meetings to discuss their expectations and interest in this group with some active members.

In the PGGA LinkedIn community, we had people joining from all over the world. We started to organize video meetings to discuss their expectations and interest in this group with some active members.

Finally, we will organize video discussion sessions to ask the participants to prepare themselves for a discussion. Any member of the PGGA can bring in the discussion topics.

Finally, we will organize video discussion sessions to ask the participants to prepare themselves for a discussion. Any member of the PGGA can bring in the discussion topics. For December 4th, we have planned a discussion meeting related to the Exponential Roadmap 2019 report, where 36 solutions to halve carbon emission by 2030 are discussed. In our video discussion, we want to focus on the chapter: Digital Industries.

For December 4th, we have planned a discussion meeting related to the Exponential Roadmap 2019 report, where 36 solutions to halve carbon emission by 2030 are discussed. In our video discussion, we want to focus on the chapter: Digital Industries. You can download the Exponential Roadmap here or by clicking on the image. More details about the PLM Global Green Alliance you will find in the LinkedIn group. If you want to participate, let us know.

You can download the Exponential Roadmap here or by clicking on the image. More details about the PLM Global Green Alliance you will find in the LinkedIn group. If you want to participate, let us know.

This question will no arise in a hierarchical organization where people are controlled by managers that have a mission to optimize their silo. Product Developers should be trained and coached to operate in a broader context, which should be part of your company’s mission. Too many people complain about usability in their authoring and data management systems without having a holistic understanding of why you need change processes and configuration management.

This question will no arise in a hierarchical organization where people are controlled by managers that have a mission to optimize their silo. Product Developers should be trained and coached to operate in a broader context, which should be part of your company’s mission. Too many people complain about usability in their authoring and data management systems without having a holistic understanding of why you need change processes and configuration management.

Of course, it would be nice if everyone in these groups understands the total flow and processes within an organization and how they relate to each other. Too often, I have seen experts in a specific domain, for example, a 3D CAD-system having no clue about revisioning, the relation of CAD to the BOM, or the fundamentals of configuration management.

Of course, it would be nice if everyone in these groups understands the total flow and processes within an organization and how they relate to each other. Too often, I have seen experts in a specific domain, for example, a 3D CAD-system having no clue about revisioning, the relation of CAD to the BOM, or the fundamentals of configuration management.

How to deal with legacy data, a challenge in the aerospace industry. Store data in neutral formats or select a preferred vendor-related format and stick to it.

How to deal with legacy data, a challenge in the aerospace industry. Store data in neutral formats or select a preferred vendor-related format and stick to it.

Poor Jane, in seven weeks, she is interviewing people on three sites. Two sites in Germany and one in France, and she is doing over a hundred interviews on her own. I realized that thanks to relation to SmarTeam at that time, it took me probably seven years to get in front of all these stakeholders in a company.

Poor Jane, in seven weeks, she is interviewing people on three sites. Two sites in Germany and one in France, and she is doing over a hundred interviews on her own. I realized that thanks to relation to SmarTeam at that time, it took me probably seven years to get in front of all these stakeholders in a company.

You will learn that 3D CAD is not the most important topic, as perhaps many traditional vendor-related PDM consultants might think.

You will learn that 3D CAD is not the most important topic, as perhaps many traditional vendor-related PDM consultants might think.

How to deal with more data-driven, more agile in their go-to-market strategy, as software, will be more and more defining the product’s capabilities?

How to deal with more data-driven, more agile in their go-to-market strategy, as software, will be more and more defining the product’s capabilities?

After the series about

After the series about  That is the “game”. Coming back to the future of PLM. We do not need a discussion about definitions; I leave this to the academics and vendors. We will see the same applies to the concept of a Digital Twin.

That is the “game”. Coming back to the future of PLM. We do not need a discussion about definitions; I leave this to the academics and vendors. We will see the same applies to the concept of a Digital Twin.

Many connected devices in the world use the same principle. An airplane engine, an industrial robot, a wind turbine, a medical device, and a train carriage; all track the performance based on this connection between physical and virtual, based on some sort of digital connectivity.

Many connected devices in the world use the same principle. An airplane engine, an industrial robot, a wind turbine, a medical device, and a train carriage; all track the performance based on this connection between physical and virtual, based on some sort of digital connectivity. This is the domain of Asset Lifecycle Management, a practice that has existed for decades. Based on financial and performance models, the optimal balance between maintaining and overhauling has to be found. Repairs are disruptive and can be extremely costly. A manufacturing site that cannot produce can cost millions per day. Connecting data between the physical and the virtual model allows us to have real-time insights and be proactive. It becomes a digital twin.

This is the domain of Asset Lifecycle Management, a practice that has existed for decades. Based on financial and performance models, the optimal balance between maintaining and overhauling has to be found. Repairs are disruptive and can be extremely costly. A manufacturing site that cannot produce can cost millions per day. Connecting data between the physical and the virtual model allows us to have real-time insights and be proactive. It becomes a digital twin.

Saving money as there is no costly prototype phase to optimize production. In a virtual world, you can perform many trade-off studies without extra costs. That was the past (and, for many companies, still the current situation).

Saving money as there is no costly prototype phase to optimize production. In a virtual world, you can perform many trade-off studies without extra costs. That was the past (and, for many companies, still the current situation).

The business case for this type of digital twin, of course, is to be able to customer-specific products with extremely competitive speed and reduced cost compared to standard. It could be your company’s survival strategy. As it is hard to predict the future, as we see from COVID-19, it is still crucial to anticipate the future instead of waiting.

The business case for this type of digital twin, of course, is to be able to customer-specific products with extremely competitive speed and reduced cost compared to standard. It could be your company’s survival strategy. As it is hard to predict the future, as we see from COVID-19, it is still crucial to anticipate the future instead of waiting.

The business case for the digital development twin is easy to make. Shorter time to market, improved and validated quality, and reduced engineering hours and costs compared to traditional ways of working. To achieve these results, for sure, you need to change your ways of working and the tools you are using. So it won’t be that easy!

The business case for the digital development twin is easy to make. Shorter time to market, improved and validated quality, and reduced engineering hours and costs compared to traditional ways of working. To achieve these results, for sure, you need to change your ways of working and the tools you are using. So it won’t be that easy!

I discovered I am getting tired as I am missing face-to-face interaction with people. Working from home, having video calls, is probably a very sustainable way of working. However, non-planned social interaction, meeting each other at the coffee machine, or during the breaks at a conference or workshop, is also crucial for informal interaction.

I discovered I am getting tired as I am missing face-to-face interaction with people. Working from home, having video calls, is probably a very sustainable way of working. However, non-planned social interaction, meeting each other at the coffee machine, or during the breaks at a conference or workshop, is also crucial for informal interaction.

The real problem in such situations was to come to a logical flow of events. Many times the company insisted that every change should start from the ERP-system as we like to standardize. This means that even an engineering change had to be registered first in the ERP-system

The real problem in such situations was to come to a logical flow of events. Many times the company insisted that every change should start from the ERP-system as we like to standardize. This means that even an engineering change had to be registered first in the ERP-system

In the previous seven posts,

In the previous seven posts,

Initially, engineering change management was a departmental activity performed by engineering to manage the changes in a product’s definition. Other stakeholders are often consulted when preparing a change, which can be minor (affecting, for example, only engineering) or major (affecting engineering and manufacturing).

Initially, engineering change management was a departmental activity performed by engineering to manage the changes in a product’s definition. Other stakeholders are often consulted when preparing a change, which can be minor (affecting, for example, only engineering) or major (affecting engineering and manufacturing).

I have seen implementations where an engineer with a right-click could release an assembly without any constraints. Related drawings might not exist, parts in the assembly are not released, and more. To obtain a reliable engineering change management process, the company had to customize the PLM-system to its desired behavior.

I have seen implementations where an engineer with a right-click could release an assembly without any constraints. Related drawings might not exist, parts in the assembly are not released, and more. To obtain a reliable engineering change management process, the company had to customize the PLM-system to its desired behavior.

When introducing PLM in mid-market companies, often, the dream was that with the new PLM-system configuration, management would be there too.

When introducing PLM in mid-market companies, often, the dream was that with the new PLM-system configuration, management would be there too. In regulated industries, Configuration Management and PLM are a must to ensure compliance and quality. Configuration management and (engineering) change management are, first of all, required methodologies that guarantee the quality of your products. The more complex your products are, the higher the need for change and configuration management.

In regulated industries, Configuration Management and PLM are a must to ensure compliance and quality. Configuration management and (engineering) change management are, first of all, required methodologies that guarantee the quality of your products. The more complex your products are, the higher the need for change and configuration management.

In the series

In the series

The challenge for all companies that want to move from ETO to BTO/CTO is the fact that they need to change their methodology – building for the future while supporting the past. This is typically something to be analyzed per company on how to deal with the existing legacy and installed base.

The challenge for all companies that want to move from ETO to BTO/CTO is the fact that they need to change their methodology – building for the future while supporting the past. This is typically something to be analyzed per company on how to deal with the existing legacy and installed base. The MBOM can also be configurable as a manufacturing plant might have almost common manufacturing steps for different product variants. By using the same process and filtered MBOM, you will manufacture the specific product version. In that case, we can talk about a 120 % MBOM

The MBOM can also be configurable as a manufacturing plant might have almost common manufacturing steps for different product variants. By using the same process and filtered MBOM, you will manufacture the specific product version. In that case, we can talk about a 120 % MBOM

The responsibility for PLM needs to be at a level higher in the organization to ensure well-balanced choices. A higher level in the organization automatically means more attention for business benefits and less attention for functions and features.

The responsibility for PLM needs to be at a level higher in the organization to ensure well-balanced choices. A higher level in the organization automatically means more attention for business benefits and less attention for functions and features. In an earlier

In an earlier

It is not about owning data and where to store it in a single system. It is about federated data sets that exist in different systems and that are complementary but connected, requiring data governance and master data management.

It is not about owning data and where to store it in a single system. It is about federated data sets that exist in different systems and that are complementary but connected, requiring data governance and master data management.

Already

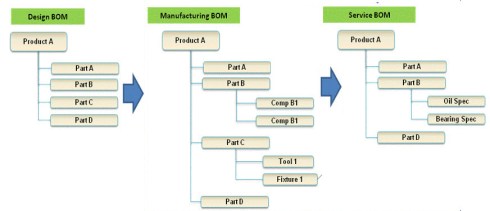

Already  In part five, I introduced the need to have a split between a logical product definition and a technical EBOM definition. The logical product definition is more the system or modular structure to be used when configuring solutions for a customer. The technical EBOM definition is, most of the time, a stable engineering specification independent of how and where the product is manufactured. The manufacturing BOM (the MBOM) should represent how the product will be manufactured, which can vary per location and vary over time. Let us look in some of the essential elements of this data model

In part five, I introduced the need to have a split between a logical product definition and a technical EBOM definition. The logical product definition is more the system or modular structure to be used when configuring solutions for a customer. The technical EBOM definition is, most of the time, a stable engineering specification independent of how and where the product is manufactured. The manufacturing BOM (the MBOM) should represent how the product will be manufactured, which can vary per location and vary over time. Let us look in some of the essential elements of this data model

Note: not all systems will support such a data model, and often the marketing sides in managed disconnected from the engineering side. Either in Excel or in a specialized

Note: not all systems will support such a data model, and often the marketing sides in managed disconnected from the engineering side. Either in Excel or in a specialized

Note: An EBOM is the place where multidisciplinary collaboration comes together. This post mainly deals with the mechanical part (as we are looking at the past)

Note: An EBOM is the place where multidisciplinary collaboration comes together. This post mainly deals with the mechanical part (as we are looking at the past) The MBOM represents the way the unique product is going to be manufactured. This means the MBOM-structure will represent the manufacturing steps. For each EBOM-purchase-part, the approved manufacturer for that plant needs to be selected. For each make-part in the EBOM, if made in this plant per customer order, the EBOM parts need to be resolved by one or more manufacturing steps combined with purchased materials.

The MBOM represents the way the unique product is going to be manufactured. This means the MBOM-structure will represent the manufacturing steps. For each EBOM-purchase-part, the approved manufacturer for that plant needs to be selected. For each make-part in the EBOM, if made in this plant per customer order, the EBOM parts need to be resolved by one or more manufacturing steps combined with purchased materials.

In the previous example, all components for the Squad were manufactured by the same company with the option to produce in Plant A or in Plant B. Now imagine the company also has a plant C in a location where they cannot produce the wheels and axle assembly. Therefore plant C has to “purchase” the Wheel-Axle assembly, and lucky for them plant B is selling the Wheel+Axle assembly to the market as a product.

In the previous example, all components for the Squad were manufactured by the same company with the option to produce in Plant A or in Plant B. Now imagine the company also has a plant C in a location where they cannot produce the wheels and axle assembly. Therefore plant C has to “purchase” the Wheel-Axle assembly, and lucky for them plant B is selling the Wheel+Axle assembly to the market as a product.

For those always that have been active in the engineering domain, a better understanding of the information flow downstream to manufacturing is crucial. Historically this flow of information has been linear – and in many companies, it is still the fact. The main reason for that lies in the fact that engineering had their own system (PDM or PLM), and manufacturing has their own system (ERP).

For those always that have been active in the engineering domain, a better understanding of the information flow downstream to manufacturing is crucial. Historically this flow of information has been linear – and in many companies, it is still the fact. The main reason for that lies in the fact that engineering had their own system (PDM or PLM), and manufacturing has their own system (ERP). Next, manufacturing engineering uses the engineering specifications to define the manufacturing BOM in the ERP system. Based on the drawings and parts list, they create a preferred manufacturing process (MBOM and BOP) – most of the time, a manual process. Despite the effort done by engineering, there might be a need to change the product. A different shape or dimension make manufacturing more efficient or done with existing tooling. This means an iteration, which causes delays and higher engineering costs.

Next, manufacturing engineering uses the engineering specifications to define the manufacturing BOM in the ERP system. Based on the drawings and parts list, they create a preferred manufacturing process (MBOM and BOP) – most of the time, a manual process. Despite the effort done by engineering, there might be a need to change the product. A different shape or dimension make manufacturing more efficient or done with existing tooling. This means an iteration, which causes delays and higher engineering costs.

The result, however, was that the interface was never covering all situations and became the most expensive part of the implementation.

The result, however, was that the interface was never covering all situations and became the most expensive part of the implementation.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…