You are currently browsing the category archive for the ‘Observations’ category.

In the past few weeks, together with Share PLM, we recorded and prepared a few podcasts to be published soon. As you might have noticed, for Season 2, our target is to discuss the human side of PLM and PLM best practices and less the technology side. Meaning:

In the past few weeks, together with Share PLM, we recorded and prepared a few podcasts to be published soon. As you might have noticed, for Season 2, our target is to discuss the human side of PLM and PLM best practices and less the technology side. Meaning:

- How to align and motivate people around a PLM initiative?

- What are the best practices when running a PLM initiative?

- What are the crucial skills you need to have as a PLM lead?

And as there are always many success stories to learn on the internet, we also challenged our guests to share the moments where they got experienced.

As the famous quote says:

Experience is what you get when you don’t get what you expect!

We recently published our with Antonio Casaschi from Assa Abloy, a Swedish company you might have never noticed, although their products and services are a part of your daily life.

It was a discussion to my heart. We discussed the various aspects of PLM. What makes a person a PLM professional? And if you have no time to listen for these 35 minutes, read and scan the recording transcript on the transcription tab.

At 0:24:00, Antonio mentioned the concept of Proof of Concept as he had good experiences with them in the past. The remark triggered me to share some observations that a Proof of Concept (POC) is an old-fashioned way to drive change within organizations. Not discussed in this podcast but based on my experience, companies have been using the Proof Of Concepts to win time, as they were afraid to make a decision.

A POC to gain time?

Company A

When working with a well-known company in 2014, I learned they were planning approximately ten POC per year to explore new ways of working or new technologies. As it was a POC based on an annual time scheme, the evaluation at the end of the year was often very discouraging.

When working with a well-known company in 2014, I learned they were planning approximately ten POC per year to explore new ways of working or new technologies. As it was a POC based on an annual time scheme, the evaluation at the end of the year was often very discouraging.

Most of the time, the conclusion was: “Interesting, we should explore this further” /“What are the next POCs for the upcoming year?”

There was no commitment to follow-up; it was more of a learning exercise not connected to any follow-up.

Company B

During one of the PDT events, a company presented that two years POC with the three leading PLM vendors, exploring supplier collaboration. I understood the PLM vendors had invested much time and resources to support this POC, expecting a big deal. However, the team mentioned it was an interesting exercise, and they learned a lot about supplier collaboration.

During one of the PDT events, a company presented that two years POC with the three leading PLM vendors, exploring supplier collaboration. I understood the PLM vendors had invested much time and resources to support this POC, expecting a big deal. However, the team mentioned it was an interesting exercise, and they learned a lot about supplier collaboration.

And nothing happened afterward ………

In 2019

At the 2019 Product Innovation Conference in London, when discussing Digital Transformation within the PLM domain, I shared in my conclusion that the POC was mainly a waste of time as it does not push you to transform; it is an option to win time but is uncommitted.

My main reason for not pushing a POC is that it is more of a limited feasibility study.

- Often to push people and processes into the technical capabilities of the systems used. A focus starting from technology is the opposite of what I have been pushing for longer: First, focus on the value stream – people and processes- and then study which tools and technologies support these demands.

- Second, the POC approach often blocks innovation as the incumbent system providers will claim the desired capabilities will come (soon) within their systems—a safe bet.

The Minimum Viable Product approach (MVP)

With the awareness that we need to work differently and benefit from digital capabilities also came the term Minimum Viable Product or MVP.

The abbreviation MVP is not to be confused with the minimum valuable products or most valuable players.

There are two significant differences with the POC approach:

- You admit the solution does not exist anywhere – so it cannot be purchased or copied.

- You commit to the fact that this new approach will be the right direction to take and agree that a perfect fit solution is not blocking you from starting for real.

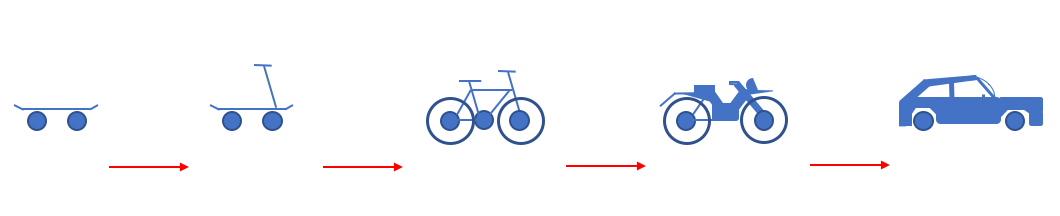

These two differences highlight the main challenges of digital transformation in the PLM domain. Digital Transformation is a learning process – it takes time for organizations to acquire and master the needed skills. And secondly, it cannot be a big bang, and I have often referred to the 2017 article from McKinsey: Toward an integrated technology operating model. Image below.

We will soon hear more about digital transformation within the PLM domain during the next episode of our SharePLM podcast. We spoke with Yousef Hooshmand, currently working for NIO, a Chinese multinational automobile manufacturer specializing in designing and developing electric vehicles, as their PLM data lead.

You might have discovered Yousef earlier when he published his paper: “From a Monolithic PLM Landscape to a Federated Domain and Data Mesh”. It is highly recommended that to read the paper if you are interested in a potential PLM future infrastructure. I wrote about this whitepaper in 2022: A new PLM paradigm discussing the upcoming Systems of Engagement on top of a Systems or Record infrastructure.

You might have discovered Yousef earlier when he published his paper: “From a Monolithic PLM Landscape to a Federated Domain and Data Mesh”. It is highly recommended that to read the paper if you are interested in a potential PLM future infrastructure. I wrote about this whitepaper in 2022: A new PLM paradigm discussing the upcoming Systems of Engagement on top of a Systems or Record infrastructure.

To align our terminology with Yousef’s wording, his domains align with the Systems of Engagement definition.

As we discovered and discussed with Yousef, technology is not the blocking issue to start. You must understand the target infrastructure well and where each domain’s activities fit. Yousef mentions that there is enough literature about this topic, and I can refer to the SAAB conference paper: Genesis -an Architectural Pattern for Federated PLM.

For a less academic impression, read my blog post, The week after PLM Roadmap / PDT Europe 2022, where I share the highlights of Erik Herzog’s presentation: Heterogeneous and Federated PLM – is it feasible?

For a less academic impression, read my blog post, The week after PLM Roadmap / PDT Europe 2022, where I share the highlights of Erik Herzog’s presentation: Heterogeneous and Federated PLM – is it feasible?

There is much to learn and discover which standards will be relevant, as both Yousef and Erik mention the importance of standards.

The podcast with Yousef (soon to be found HERE) was not so much about organizational change management and people.

However, Yousef mentioned the most crucial success factor for the transformation project he supported at Daimler. It was C-level support, trust and understanding of the approach, knowing it will be many years, an unavoidable journey if you want to remain competitive.

However, Yousef mentioned the most crucial success factor for the transformation project he supported at Daimler. It was C-level support, trust and understanding of the approach, knowing it will be many years, an unavoidable journey if you want to remain competitive.

And with the journey aspect comes the importance of the Minimal Viable Product. You are starting a journey with an end goal in mind (top-of-the-mountain), and step by step (from base camp to base camp), people will be better covered in their day-to-day activities thanks to digitization.

And with the journey aspect comes the importance of the Minimal Viable Product. You are starting a journey with an end goal in mind (top-of-the-mountain), and step by step (from base camp to base camp), people will be better covered in their day-to-day activities thanks to digitization.

A POC would not help you make the journey; perhaps a small POC would understand what it takes to cross a barrier.

Conclusion

The concept of POCs is outdated in a fast-changing environment where technology is not necessary the blocking issue. Developing practices, new architectures and using the best-fit standards is the future. Embrace the Minimal Viable Product approach. Are you?

In the past two weeks, I had several discussions with peers in the PLM domain about their experiences.

In the past two weeks, I had several discussions with peers in the PLM domain about their experiences.

Some of them I met after a long time again face-to-face at the LiveWorx 2023 event. See my review of the event here: The Weekend after LiveWorx 2023.

And there were several interactions on LinkedIn, leading to a more extended discussion thread (an example of a digital thread ?) or a Zoom discussion (a so-called 2D conversation).

To complete the story, I also participated in two PLM podcasts from Share PLM, where we interviewed Johan Mikkelä (currently working at FLSmidth) and, in the second episode Issam Darraj (presently working at ABB) about their PLM experiences. Less a discussion, more a dialogue, trying to grasp the non-documented aspects of PLM. We are looking for your feedback on these podcasts too.

To complete the story, I also participated in two PLM podcasts from Share PLM, where we interviewed Johan Mikkelä (currently working at FLSmidth) and, in the second episode Issam Darraj (presently working at ABB) about their PLM experiences. Less a discussion, more a dialogue, trying to grasp the non-documented aspects of PLM. We are looking for your feedback on these podcasts too.

All these discussions led to a reconfirmation that if you are a PLM practitioner, you need a broad skillset to address the business needs, translate them into people and process activities relevant to the industry and ultimately implement the proper collection of tools.

![]() As a sneaky preview for the podcast sessions, we asked both Johan and Issam about the importance of the tools. I will not disclose their answers here; you have to listen.

As a sneaky preview for the podcast sessions, we asked both Johan and Issam about the importance of the tools. I will not disclose their answers here; you have to listen.

Let’s look at some of the discussions.

NOTE: Just before pushing the Publish button, Oleg Shilovitsky published this blog article PLM Project Failures and Unstoppable PLM Playbook. I will comment on his points at the end of this post. It is all part of the extensive discussion.

NOTE: Just before pushing the Publish button, Oleg Shilovitsky published this blog article PLM Project Failures and Unstoppable PLM Playbook. I will comment on his points at the end of this post. It is all part of the extensive discussion.

PLM, LinkedIn and complexity

The most popular discussions on LinkedIn are often related to the various types of Bills of Materials (eBOM, mBOM, sBOM), Part numbering schemes (intelligent or not), version and revision management and the famous FFF discussions.

The most popular discussions on LinkedIn are often related to the various types of Bills of Materials (eBOM, mBOM, sBOM), Part numbering schemes (intelligent or not), version and revision management and the famous FFF discussions.

This post: PLM and Configuration Management Best Practices: Working with Revisions, from Andreas Lindenthal, was a recent example that triggered others to react.

I had some offline discussions on this topic last week, and I noticed Frédéric Zeller wrote his post with the title PLM, LinkedIn and complexity, starting his post with (quote):

I am stunned by the average level of posts on the PLM on LinkedIn.

I’m sorry, but in 2023 :

- Part Number management (significant, non-significant) should no longer be a problem.

- Revision management should no longer be a question.

- Configuration management theory should no longer be a question.

- Notions of EBOMs, MBOMs … should no longer be a question.

So why are there still problems on these topics?

You can see from the at least 40+ comments that this statement created a lot of reactions, including mine. Apparently, these topics are touching many people worldwide, and there is no simple, single answer to each of these topics. And there are so many other topics relevant to PLM.

Talking later with Frederic for one hour in a Zoom session, we discussed the importance of the right PLM data model.

Talking later with Frederic for one hour in a Zoom session, we discussed the importance of the right PLM data model.

I also wrote a series about the (traditional) PLM data model: The importance of a (PLM) data model.

Frederic is more of a PLM architect; we even discussed the wording related to the EBOM and the MBOM. A topic that I feel comfortable discussing after many years of experience seeing the attempts that failed and the dreams people had. And this was only one aspect of PLM.

You also find the discussion related to a PLM certification in the same thread. How would you certify a person as a PLM expert?

You also find the discussion related to a PLM certification in the same thread. How would you certify a person as a PLM expert?

There are so many dimensions to PLM. Even more important, the PLM from 10-15 years ago (more of a system discussion) is no longer the PLM nowadays (a strategy and an infrastructure) –

This is a crucial difference. Learning to use a PLM tool and implement it is not the same as building a PLM strategy for your company. It is Tools, Process, People versus Process, People, Tools and Data.

Time for Methodology workshops?

I recently discussed with several peers what we could do to assist people looking for best practices discussion and lessons learned. There is a need, but how to organize them as we cannot expect this to be voluntary work.

![]() In the past, I suggested MarketKey, the organizer of the PI DX events, extend its theme workshops. For example, instead of a 45-min Focus group with a short introduction to a theme (e.g., eBOM-mBOM, PLM-ERP interfaces), make these sessions last at least half a day and be independent of the PLM vendors.

In the past, I suggested MarketKey, the organizer of the PI DX events, extend its theme workshops. For example, instead of a 45-min Focus group with a short introduction to a theme (e.g., eBOM-mBOM, PLM-ERP interfaces), make these sessions last at least half a day and be independent of the PLM vendors.

Apparently, it did not fit in the PI DX programming; half a day would potentially stretch the duration of the conference and more and more, we see two days of meetings as the maximum. Longer becomes difficult to justify even if the content might have high value for the participants.

I observed a similar situation last year in combination with the PLM roadmap/PDT Europe conference in Gothenburg. Here we had a half-day workshop before the conference led by Erik Herzog(SAAB Aeronautics)/ Judith Crockford (Europstep) to discuss concepts related to federated PLM – read more in this post: The week after PLM Roadmap/PDT Europe 2022.

I observed a similar situation last year in combination with the PLM roadmap/PDT Europe conference in Gothenburg. Here we had a half-day workshop before the conference led by Erik Herzog(SAAB Aeronautics)/ Judith Crockford (Europstep) to discuss concepts related to federated PLM – read more in this post: The week after PLM Roadmap/PDT Europe 2022.

It reminded me of an MDM workshop before the 2015 Event, led by Marc Halpern from Gartner. Unfortunately, the federated PLM discussion remained a pretty Swedish initiative, and the follow-up did not reach a wider audience.

And then there are the Aerospace and Defense PLM action groups that discuss moderated by CIMdata. It is great that they published their findings (look here), although the best lessons learned are during the workshops.

And then there are the Aerospace and Defense PLM action groups that discuss moderated by CIMdata. It is great that they published their findings (look here), although the best lessons learned are during the workshops.

However, I also believe the A&D industry cannot be compared to a mid-market machinery manufacturing company. Therefore, it is helpful for a smaller audience only.

And here, I inserted a paragraph dedicated to Oleg’s recent post, PLM Project Failures and Unstoppable PLM Playbook – starting with a quote:

How to learn to implement PLM? I wrote about it in my earlier article – PLM playbook: how to learn about PLM? While I’m still happy to share my knowledge and experience, I think there is a bigger need in helping manufacturing companies and, especially PLM professionals, with the methodology of how to achieve the right goal when implementing PLM. Which made me think about the Unstoppable PLM playbook ©.

I found a similar passion for helping companies to adopt PLM while talking to Helena Gutierrez. Over many conversations during the last few months, we talked about how to help manufacturing companies with PLM adoption. The unstoppable PLM playbook is still a work in progress, but we want to start talking about it to get your feedback and start the conversation.

It is an excellent confirmation of the fact that there is a need for education and that the education related to PLM on the Internet is not good enough.

As a former teacher in Physics, I do not believe in the Unstoppable PLM Playbook, even if it is a branded name. Many books are written by specific authors, giving their perspectives based on their (academic) knowledge.

As a former teacher in Physics, I do not believe in the Unstoppable PLM Playbook, even if it is a branded name. Many books are written by specific authors, giving their perspectives based on their (academic) knowledge.

Are they useful? I believe only in the context of a classroom discussion where the applicability can be discussed,

Therefore my questions to vendor-neutral global players, like CIMdata, Eurostep, Prostep, SharePLM, TCS and others, are you willing to pick up this request? Or are there other entities that I missed? Please leave your thoughts in the comments. I will be happy to assist in organizing them.

Therefore my questions to vendor-neutral global players, like CIMdata, Eurostep, Prostep, SharePLM, TCS and others, are you willing to pick up this request? Or are there other entities that I missed? Please leave your thoughts in the comments. I will be happy to assist in organizing them.

There are many more future topics to discuss and document too.

- What about the potential split of a PLM infrastructure between Systems of Record & Systems of Engagement?

- What about the Digital Thread, a more and more accepted theme in discussions, but what is the standard definition?

- Is it traceability as some vendors promote it, or is it the continuity of data, direct usable in various contexts – the DevOps approach?

Who likes to discuss methodology?

When asking myself this question, I see the analogy with standards. So let’s look at the various players in the PLM domain – sorry for the immense generalization.

When asking myself this question, I see the analogy with standards. So let’s look at the various players in the PLM domain – sorry for the immense generalization.

Strategic consultants: standards are essential, but spare me the details.

Vendors: standards are limiting the unique capabilities of my products

Implementers: two types – Those who understand and use standards as they see the long-term benefits. Those who avoid standards as it introduces complexity.

Companies: they love standards if they can be implemented seamlessly.

Universities: they love to explore standards and help to set the standards even if they are not scalable

Just replace standards with methodology, and you see the analogy.

We like to discuss the methodology.

As I mentioned in the introduction, I started to work with Share PLM on a series of podcasts where we interview PLM experts in the field that have experience with the people, the process, the tools and the data side. Through these interviews, you will realize PLM is complex and has become even more complicated when you consider PLM a strategy instead of a tool.

As I mentioned in the introduction, I started to work with Share PLM on a series of podcasts where we interview PLM experts in the field that have experience with the people, the process, the tools and the data side. Through these interviews, you will realize PLM is complex and has become even more complicated when you consider PLM a strategy instead of a tool.

We hope these podcasts might be a starting point for further discussion – either through direct interactions or through contributions to the podcast. If you have PLM experts in your network that can explain the complexity of PLM from various angles and have the experience. Please let us know – it is time to share.

Conclusion

By switching gears, I noticed that PLM has become complex. Too complex for a single person to master. With an aging traditional PLM workforce (like me), it is time to consolidate the best practices of the past and discuss the best practices for the future. There are no simple answers, as every industry is different. Help us to energize the PLM community – your thoughts/contributions?

After the first episode of “The PLM Doctor is IN“, this time a question from Helena Gutierrez. Helena is one of the founders of SharePLM, a young and dynamic company focusing on providing education services based on your company’s needs, instead of leaving it to function-feature training.

I might come back on this topic later this year in the context of PLM and complementary domains/services.

Now sit back and enjoy.

Note: Due to a technical mistake Helena’s mimic might give you a “CNN-like” impression as the recording of her doctor visit was too short to cover the full response.

PLM and Startups – is this a good match?

Relevant links discussed in this video

![]() Marc Halpern (Gartner): The PLM maturity table

Marc Halpern (Gartner): The PLM maturity table

VirtualDutchman: Digital PLM requires a Model-Based Enterprise

Conclusion

I hope you enjoyed the answer and look forward to your questions and comments. Let me know if you want to be an actor in one of the episodes.

The main rule: A single open question that is puzzling you related to PLM.

For those living in the Northern Hemisphere: This week, we had the shortest day, or if you like the dark, the longest night. This period has always been a moment of reflection. What have we done this year?

For those living in the Northern Hemisphere: This week, we had the shortest day, or if you like the dark, the longest night. This period has always been a moment of reflection. What have we done this year?

Rob Ferrone (Quick Release), the Santa on the left (the leftist), and Jos Voskuil (TacIT), the Santa on the right (the rightist), share in a dialogue their highlights from 2020

Wishing you all a great moment of reflection and a smooth path into a Corona-proof future.

It will be different; let’s make it better.

In the last two weeks, three events were leading to this post.

First, I read John Stark’s recent book Products2019. A must-read for anyone who wants to understand the full reach of product lifecycle related activities. See my recent post: Products2019, a must-read if you are new to PLM

First, I read John Stark’s recent book Products2019. A must-read for anyone who wants to understand the full reach of product lifecycle related activities. See my recent post: Products2019, a must-read if you are new to PLM

Afterwards, I talked with John, discussing the lack of knowledge and teaching of PLM, not to be confused by PLM capabilities and features.

Second, I participated in an exciting PI DX USA 2020 event. Some of the sessions and most of the roundtables provided insights to me and, hopefully, many other participants. You can get an impression in the post: The Weekend after PI DX 2020 USA.

Second, I participated in an exciting PI DX USA 2020 event. Some of the sessions and most of the roundtables provided insights to me and, hopefully, many other participants. You can get an impression in the post: The Weekend after PI DX 2020 USA.

A small disappointment in that event was the closing session with six vendors, as I wrote. I know it is evident when you put a group of vendors in the arena, it will be about scoring points instead of finding alignment. Still, having criticism does not mean blaming, and I am always open to having a dialogue. For that reason, I am grateful for their sponsorship and contribution.

Oleg Shilovitsky mentioned cleverly that this statement is a contradiction.

“How can you accuse PLM vendors of having a limited view on PLM and thanking them for their contribution?”

I hope the above explanation says it all, combined with the fact that I grew up in a Dutch culture of not hiding friction, meanwhile being respectful to others.

We cannot simplify PLM by just a better tool or technology or by 3D for everybody. There are so many more people and processes related to product lifecycle management involved in this domain if you want a real conference, however many of them will not sponsor events.

It is well illustrated in John Stark’s book. Many disciplines are involved in the product lifecycle. Therefore, if you only focus on what you can do with your tool, it will lead to an incomplete understanding.

It is well illustrated in John Stark’s book. Many disciplines are involved in the product lifecycle. Therefore, if you only focus on what you can do with your tool, it will lead to an incomplete understanding.

If your tool is a hammer, you hope to see nails everywhere around you to demonstrate your value

The thirds event was a LinkedIn post from John Stark – 16 groups needing Product Lifecycle Knowledge, which for me was a logical follow-up on the previous two events. I promised John to go through these 16 groups and provide my thoughts.

The thirds event was a LinkedIn post from John Stark – 16 groups needing Product Lifecycle Knowledge, which for me was a logical follow-up on the previous two events. I promised John to go through these 16 groups and provide my thoughts.

Please read his post first as I will not rewrite what has been said by John already.

CEOs and CTOs

John suggested that they should read his book, which might take more than eight hours. CEOs and CTOs, most of the time, do not read this type of book with so many details, so probably mission impossible.

John suggested that they should read his book, which might take more than eight hours. CEOs and CTOs, most of the time, do not read this type of book with so many details, so probably mission impossible.

They want to keep up with the significant trends and need to think about future business (model).

New digital and technical capabilities allow companies to move from a linear, coordinated business towards a resilient, connected business. This requires exploring future business models and working methods by experimenting in real-life, not Proof of Concept. Creating a learning culture and allowing experiments to fail is crucial, as you only learn by failing.

CDO, CIOs and Digital Transformation Executives

They are the crucial people to help the business to imagine what digital technologies can do. They should educate the board and the business teams about the power of having reliable, real-time data available for everyone connected. Instead of standardizing on systems and optimizing the siloes, they should assist and lead in new infrastructure for connected services, end-to-end flows delivered on connected platforms.

They are the crucial people to help the business to imagine what digital technologies can do. They should educate the board and the business teams about the power of having reliable, real-time data available for everyone connected. Instead of standardizing on systems and optimizing the siloes, they should assist and lead in new infrastructure for connected services, end-to-end flows delivered on connected platforms.

These concepts won’t be realized soon. However, doing nothing is a big risk, as the traditional business will decline in a competitive environment. Time to act.

Departmental Managers

These are the people that should worry about their job in the long term. Their current mission might be to optimize their department within its own Profit & Loss budget. The future is about optimizing the information flow for the whole value chain, including suppliers and customers.

These are the people that should worry about their job in the long term. Their current mission might be to optimize their department within its own Profit & Loss budget. The future is about optimizing the information flow for the whole value chain, including suppliers and customers.

I wrote about it in “The Middle Management Dilemma.” Departmental Managers should become more team leaders inspiring and supporting the team members instead of controlling the numbers.

Products Managers

This is a crucial role for the future, assuming a product manager is not only responsible for the marketing or development side of the product but also gets responsibility for understanding what happens with the product during production and sales performance. Understanding the full lifecycle performance and cost should be their mission, supported by a digital infrastructure.

This is a crucial role for the future, assuming a product manager is not only responsible for the marketing or development side of the product but also gets responsibility for understanding what happens with the product during production and sales performance. Understanding the full lifecycle performance and cost should be their mission, supported by a digital infrastructure.

Product Developers

They should read the book Products2019 to be aware there is so much related to their work. From this understanding, a product developer should ask the question:

“What can I do better to serve my internal and external customers ?”

This question will no arise in a hierarchical organization where people are controlled by managers that have a mission to optimize their silo. Product Developers should be trained and coached to operate in a broader context, which should be part of your company’s mission. Too many people complain about usability in their authoring and data management systems without having a holistic understanding of why you need change processes and configuration management.

This question will no arise in a hierarchical organization where people are controlled by managers that have a mission to optimize their silo. Product Developers should be trained and coached to operate in a broader context, which should be part of your company’s mission. Too many people complain about usability in their authoring and data management systems without having a holistic understanding of why you need change processes and configuration management.

Product Lifecycle Management (PLM) deployers

Here I have a little bit of the challenge that this might be read as PLM-system users. However, it should be clear that we mean here people using product data at any moment along the product lifecycle, not necessarily in a single system.

This is again related to your company’s management culture. In the ideal world, people work with a purpose and get informed on how their contribution fits the company’s strategy and execution.

Unfortunately, in most hierarchical organizations, the strategy and total overview get lost, and people become measured resources.

New Hires and others

John continues with five other groups within the organization. I will not comment on them, as the answers are similar to the ones above – it is about organization and culture.

Educators and Students

This topic is very close to my heart, and one of the reasons I continue blogging about PLM practices. There is not enough attention to product development methodology or processes. Engineers can get many years of education in specific domains, like product design principles, available tools and technologies, performing physical and logical simulations.

This topic is very close to my heart, and one of the reasons I continue blogging about PLM practices. There is not enough attention to product development methodology or processes. Engineers can get many years of education in specific domains, like product design principles, available tools and technologies, performing physical and logical simulations.

Not so much time is spent on educating current best practices, business models for product lifecycle management.

Check in your country how many vendor-independent methodology-oriented training you can find. Perhaps the only consistent organization I know is CIMdata, where the challenge is that they deliver training to companies after students have graduated. It would be great if education institutes would embed serious time for product lifecycle management topics in their curriculum. The challenge, of course, the time and budget needed to create materials and, coming next, prioritizing this topic on the overall agenda.

Check in your country how many vendor-independent methodology-oriented training you can find. Perhaps the only consistent organization I know is CIMdata, where the challenge is that they deliver training to companies after students have graduated. It would be great if education institutes would embed serious time for product lifecycle management topics in their curriculum. The challenge, of course, the time and budget needed to create materials and, coming next, prioritizing this topic on the overall agenda.

I am happy to participate to a Specialized Master education program aiming at the Products and Buildings Digital Engineering Manager (INGENUM). This program organized by Arts Et Metiers in France helps create the overview for understanding PLM and BIM – in the French language as before COVID-19 this was an on-site training course in Paris.

I am happy to participate to a Specialized Master education program aiming at the Products and Buildings Digital Engineering Manager (INGENUM). This program organized by Arts Et Metiers in France helps create the overview for understanding PLM and BIM – in the French language as before COVID-19 this was an on-site training course in Paris.

Hopefully, there are more institutes offering PLM eductation – feel free to add them in the comments of this post.

Consultants, Integrators and Software Company Employees

Of course, it would be nice if everyone in these groups understands the total flow and processes within an organization and how they relate to each other. Too often, I have seen experts in a specific domain, for example, a 3D CAD-system having no clue about revisioning, the relation of CAD to the BOM, or the fundamentals of configuration management.

Of course, it would be nice if everyone in these groups understands the total flow and processes within an organization and how they relate to each other. Too often, I have seen experts in a specific domain, for example, a 3D CAD-system having no clue about revisioning, the relation of CAD to the BOM, or the fundamentals of configuration management.

Consultants, Integrators and Software Company Employees have their own challenges as their business model is often looking for specialized skills they can sell to their clients, where a broader and general knowledge will come from experience on-the-job.

And if you are three years working full-time on a single project or perhaps work in three projects, your broader knowledge does not grow fast. You might become the hammer that sees nails everywhere.

For that reason, I recommend everyone in my ecosystem to invest your personal time to read related topics of interest. Read LinkedIn-posts from others and learn to differentiate between marketing messages and people willing to share experiences. Don’t waste your time on the marketing messages and react and participate in the other discussions. A “Like” is not enough. Ask questions or add your insights.

For that reason, I recommend everyone in my ecosystem to invest your personal time to read related topics of interest. Read LinkedIn-posts from others and learn to differentiate between marketing messages and people willing to share experiences. Don’t waste your time on the marketing messages and react and participate in the other discussions. A “Like” is not enough. Ask questions or add your insights.

In the context of my personal learning, I mentioned that I participated in the DigitalTwin-conference in the Netherlands this week. Unfortunately, due to the partial lockdown, mainly a virtual event.

In the context of my personal learning, I mentioned that I participated in the DigitalTwin-conference in the Netherlands this week. Unfortunately, due to the partial lockdown, mainly a virtual event.

I got several new insights that I will share with you soon. An event that illustrated Digital Twin as a buzzword might be hype, however several of the participants illustrated examples of where they applied or plan to apply Digital Twin concepts. A great touch with reality.

Another upcoming conference that will start next week in the PLM Roadmap 2020 – PDT conference. The theme: Digital Thread—the PLM Professionals’ Path to Delivering Innovation, Efficiency, and Quality is not a marketing theme as you can learn from the agenda. Step by step we are learning here from each other.

Another upcoming conference that will start next week in the PLM Roadmap 2020 – PDT conference. The theme: Digital Thread—the PLM Professionals’ Path to Delivering Innovation, Efficiency, and Quality is not a marketing theme as you can learn from the agenda. Step by step we are learning here from each other.

Conclusion

John Stark started with the question of who should need Product Lifecycle Knowledge. In general, Knowledge is power, and it does not come for free. Either by consultancy, reading or training. Related to Product Lifecycle Management, everyone must understand the bigger picture. For executives as they will need to steer the company in the right direction. For everyone else to streamline the company and enjoy working in a profitable environment where you contribute and can even inspire others.

An organization is like a human body; you cannot have individual cells or organs that optimize themselves only – we have a name for that disease. Want to learn more? Read this poem: Who should be the boss?

In the previous seven posts, learning from the past to understand the future, we have seen the evolution from manual 2D drawing handling. Next, the emerge of ERP and CAD followed by data management systems (PDM/PLM) and methodology (EBOM/MBOM) to create an infrastructure for product data from concept towards manufacturing.

In the previous seven posts, learning from the past to understand the future, we have seen the evolution from manual 2D drawing handling. Next, the emerge of ERP and CAD followed by data management systems (PDM/PLM) and methodology (EBOM/MBOM) to create an infrastructure for product data from concept towards manufacturing.

Before discussing the extension to the SBOM-concept, I first want to discuss Engineering Change Management and Configuration Management.

ECM and CM – are they the same?

Often when you talk with people in my PLM bubble, the terms Change Management and Configuration Management are mixed or not well understood.

![]() When talking about Change Management, we should clearly distinguish between OCM (Organizational Change Management) and ECM (Engineering Change Management). In this post, I will focus on Engineering Change Management (ECM).

When talking about Change Management, we should clearly distinguish between OCM (Organizational Change Management) and ECM (Engineering Change Management). In this post, I will focus on Engineering Change Management (ECM).

When talking about Configuration Management also here we find two interpretations of it.

![]() The first one is a methodology describing technically how, in your PLM/CAD-environment, you can build the most efficient way connected data structures, representing all product variations. This technology varies per PLM/CAD-vendor, and therefore I will not discuss it here. The other interpretation of Configuration Management is described on Wiki as follows:

The first one is a methodology describing technically how, in your PLM/CAD-environment, you can build the most efficient way connected data structures, representing all product variations. This technology varies per PLM/CAD-vendor, and therefore I will not discuss it here. The other interpretation of Configuration Management is described on Wiki as follows:

Configuration management (CM) is a systems engineering process for establishing and maintaining consistency of a product’s performance, functional, and physical attributes with its requirements, design, and operational information throughout its life.

This is also the area where I will focus on this time.

And as-if great minds think alike and are synchronized, I was happy to see Martijn Dullaart’s recent blog post, referring to a poll and follow-up article on CM.

Here Martijn precisely touches the topic I address in this post. I recommend you to read his post: Configuration Management done right = Product-Centric first and then follow with the rest of this article.

Engineering Change Management

Initially, engineering change management was a departmental activity performed by engineering to manage the changes in a product’s definition. Other stakeholders are often consulted when preparing a change, which can be minor (affecting, for example, only engineering) or major (affecting engineering and manufacturing).

Initially, engineering change management was a departmental activity performed by engineering to manage the changes in a product’s definition. Other stakeholders are often consulted when preparing a change, which can be minor (affecting, for example, only engineering) or major (affecting engineering and manufacturing).

The way engineering change management has been implemented varies a lot. Over time companies all around the world have defined their change methodology, and there is a lot of commonality between these approaches. However, terminology as revision, version, major change, minor change all might vary.

I described the generic approach for engineering change processes in my blog post: ECR / ECO for Dummies from 2010.

The fact that companies have defined their own engineering change processes is not an issue when it works and is done manually. The real challenge came with PDM/PLM-systems that need to provide support for engineering change management.

Do you leave the methodology 100 % open, or do you provide business logic?

I have seen implementations where an engineer with a right-click could release an assembly without any constraints. Related drawings might not exist, parts in the assembly are not released, and more. To obtain a reliable engineering change management process, the company had to customize the PLM-system to its desired behavior.

I have seen implementations where an engineer with a right-click could release an assembly without any constraints. Related drawings might not exist, parts in the assembly are not released, and more. To obtain a reliable engineering change management process, the company had to customize the PLM-system to its desired behavior.

An exercise excellent for a system integrator as there was always a discussion with end-users that do not want to be restricted in case of an emergency (“we will complete the definition later” / “too many clicks” / “do I have to approve 100 parts ?”). In many cases, the system integrator kept on customizing the system to adapt to all wishes. Often the engineering change methodology on paper was not complete or contained contradictions when trying to digitize the processes.

For that reason, the PLM-vendors that aim to provide Out-Of-The-Box solutions have been trying to predefine certain behaviors in their system. For example, you cannot release a part, when its specifications (drawings/documents) are not released. Or, you cannot update a released assembly without creating a new revision.

For that reason, the PLM-vendors that aim to provide Out-Of-The-Box solutions have been trying to predefine certain behaviors in their system. For example, you cannot release a part, when its specifications (drawings/documents) are not released. Or, you cannot update a released assembly without creating a new revision.

These rules speed-up the implementation; however, they require more OCM (Organizational Change Management) as probably naming and methodology has to change within the company. This is the continuous battle in PLM-implementations. In particular where the company has a strong legacy or lack of business understanding, when implementing PLM.

There is an excellent webcast in this context on Minerva PLM TV – How to Increase IT Project Success with Organizational Change Management.

Click on the image or link to watch this recording.

Configuration Management

When we talk about configuration management, we have to think about managing the consistency of product data along the whole product lifecycle, as we have seen from the Wiki-definition before.

Configuration management existed long before we had IT-systems. Therefore, configuration management is more a collection of activities (see diagram above) to ensure the consistency of information is correct for any given product. Consistent during design, where requirements match product capabilities. Consistent with manufacturing, where the manufacturing process is based on the correct engineering specifications. And consistent with operations, meaning that we have the full definition of product in the field, the As-Built, in correct relation to its engineering and manufacturing definition.

This consistency is crucial for products where the cost of an error can have a massive impact on the manufacturer. The first industries that invested heavily in configuration management were the Aerospace and Defense industries. Configuration management is needed in these industries as the products are usually complex, and failure can have a fatal impact on the company. Combined with many regulatory constraints, managing the configuration of a product and the impact of changes is a discipline on its own.

Other industries have also introduced configuration management nowadays. The nuclear power industry and the pharmaceutical industry use configuration management as part of their regulatory compliance. The automotive industry requires configuration management partly for compliance, mainly driven by quality targets. An accident or a recall can be costly for a car manufacturer. Other manufacturing companies all have their own configuration management strategies, mainly depending on their own risk assessment. Configuration management is a pro-active discipline – it costs money – time, people and potential tools to implement it. In my experience, many of these companies try to do “some” configuration management, always hoping that a real disaster will not happen (or can happen). Proper configuration management allows you to perform reliable impact analysis for any change (image above)

What happens in the field?

When introducing PLM in mid-market companies, often, the dream was that with the new PLM-system configuration, management would be there too.

When introducing PLM in mid-market companies, often, the dream was that with the new PLM-system configuration, management would be there too.

Management believes the tools will fix the issue.

Partly because configuration management deals with a structured approach on how to manage changes, there was always confusion with engineering change management. Modern PLM-systems all have an impact analysis capability. However, most of the time, this impact analysis only reaches the content that is in the PLM-system. Configuration Management goes further.

If you think that configuration management is crucial for your company, start educating yourselves first before implementing anything in a tool. There are several places where you can learn all about configuration management.

- Probably the best-known organization is IpX (Institute for Process Excellence), teaching the CM2 methodology. Have a look here: CM2 certification and courses

- Closely related to IpX, Martijn Dullaart shares his thoughts coming from the field as Lead Architect for Enterprise Configuration Management at ASML (one of the Dutch crown jewels) in his blog: MDUX

- CMstat, a configuration and data management solution provider, provides educational posts from their perspective. Have a look at their posts, for example, PLM or PDM or CM

- If you want to have a quick overview of Configuration Management in general, targeted for the mid-market, have a look at this (outdated) course: Training for Small and Medium Enterprises on CONFIGURATION MANAGEMENT. Good for self-study to get an understanding of the domain.

To summarize

In regulated industries, Configuration Management and PLM are a must to ensure compliance and quality. Configuration management and (engineering) change management are, first of all, required methodologies that guarantee the quality of your products. The more complex your products are, the higher the need for change and configuration management.

In regulated industries, Configuration Management and PLM are a must to ensure compliance and quality. Configuration management and (engineering) change management are, first of all, required methodologies that guarantee the quality of your products. The more complex your products are, the higher the need for change and configuration management.

PLM-systems require embedded engineering change management – part of the PDM domain. Performing Engineering Change Management in a system is something many users do not like, as it feels like overhead. Too much administration or too many mouse clicks.

So far, there is no golden egg that performs engineering change management automatically. Perhaps in a data-driven environment, algorithms can speed-up change management processes. Still, there is a need for human decisions.

Similar to configuration management. If you have a PLM-system that connects all the data from concept, design, and manufacturing in a single environment, it does not mean you are performing configuration management. You need to have processes in place, and depending on your product and industry, the importance will vary.

Similar to configuration management. If you have a PLM-system that connects all the data from concept, design, and manufacturing in a single environment, it does not mean you are performing configuration management. You need to have processes in place, and depending on your product and industry, the importance will vary.

Conclusion

In the first seven posts, we discussed the design and engineering practices, from CAD to EBOM, ending with the MBOM. Engineering Change Management and, in particular, Configuration Management are methodologies to ensure the consistency of data along the product lifecycle. These methodologies are connected and need to be fit for the future – more on this when we move to modern model-based approaches.

Closing note:

While finishing this blog post today I read Jan Bosch’s post: Why you should not align. Jan touches the same topic that I try to describe in my series Learning from the Past ….., as my intention is to make us aware that by holding on to practices from the past we are blocking our future. Highly recommended to read his post – a quote:

While finishing this blog post today I read Jan Bosch’s post: Why you should not align. Jan touches the same topic that I try to describe in my series Learning from the Past ….., as my intention is to make us aware that by holding on to practices from the past we are blocking our future. Highly recommended to read his post – a quote:

The problem is, of course, that every time you resist change, you get a bit behind. You accumulate some business, process and technical debt. You become a little less “fitting” to the environment in which you’re operating

In the series learning from the past to understand the future, we have almost reached the current state of PLM before digitization became visible. In the last post, I introduced the value of having the MBOM preparation inside a PLM-system, so manufacturing engineering can benefit from early visibility and richer product context when preparing the manufacturing process.

In the series learning from the past to understand the future, we have almost reached the current state of PLM before digitization became visible. In the last post, I introduced the value of having the MBOM preparation inside a PLM-system, so manufacturing engineering can benefit from early visibility and richer product context when preparing the manufacturing process.

Does everyone need an MBOM?

It is essential to realize that you do not need an EBOM and a separate MBOM in case of an Engineering To Order primary process. The target of ETO is to deliver a unique customer product with no time to lose. Therefore, engineering can design with a manufacturing process in mind.

It is essential to realize that you do not need an EBOM and a separate MBOM in case of an Engineering To Order primary process. The target of ETO is to deliver a unique customer product with no time to lose. Therefore, engineering can design with a manufacturing process in mind.

The need for an MBOM comes when:

- You are selling a specific product over a more extended period of time. The engineering definition, in that case, needs to be as little as possible dependent on supplier-specific parts.

- You are delivering your portfolio based on modules. Modules need to be as long as possible stable, therefore independent of where they are manufactured and supplier-specific parts. The better you can define your modules, the more customers you can reach over time.

- You are having multiple manufacturing locations around the world, allowing you to source locally and manufacture based on local plant-specific resources. I described these options in the previous post

The challenge for all companies that want to move from ETO to BTO/CTO is the fact that they need to change their methodology – building for the future while supporting the past. This is typically something to be analyzed per company on how to deal with the existing legacy and installed base.

The challenge for all companies that want to move from ETO to BTO/CTO is the fact that they need to change their methodology – building for the future while supporting the past. This is typically something to be analyzed per company on how to deal with the existing legacy and installed base.

Configurable EBOM and MBOM

In some previous posts, I mentioned that it is efficient to have a configurable EBOM. This means that various options and variants are managed in the same EBOM-structure that can be filtered based on configuration parameters (date effectivity/version identifier/time baseline). A configurable EBOM is often called a 150 % EBOM

The MBOM can also be configurable as a manufacturing plant might have almost common manufacturing steps for different product variants. By using the same process and filtered MBOM, you will manufacture the specific product version. In that case, we can talk about a 120 % MBOM

The MBOM can also be configurable as a manufacturing plant might have almost common manufacturing steps for different product variants. By using the same process and filtered MBOM, you will manufacture the specific product version. In that case, we can talk about a 120 % MBOM

Note: the freedom of configuration in the EBOM is generally higher than the options in the configurable MBOM.

The real business change for EBOM/MBOM

So far, we have discussed the EBOM/MBOM methodology. It is essential to realize this methodology only brings value when the organization will be adapted to benefit from the new possibilities.

One of the recurring errors in PLM implementations is that users of the system get an extended job scope, without giving them the extra time to perform these activities. Meanwhile, other persons downstream might benefit from these activities. However, they will not complain. I realized that already in 2009, I mentioned such a case: Where is my PLM ROI, Mr. Voskuil?

Now let us look at the recommended business changes when implementing an EBOM/MBOM-strategy

- Working in a single, shared environment for engineering and manufacturing preparation is the first step to take.

Working in a PLM-system is not a problem for engineers who are used to the complexity of a PDM-system. For manufacturing engineers, a PLM-environment will be completely new. Manufacturing engineers might prepare their bill of process first in Excel and ultimately enter the complete details in their ERP-system. ERP-systems are not known for their user-friendliness. However, their interfaces are often so rigid that it is not difficult to master the process. Excel, on the other side, is extremely flexible but not connected to anything else.

And now, this new PLM-system requires people to work in a more user-friendly environment with limited freedom. This is a significant shift in working methodology. This means manufacturing engineers need to be trained and supported over several months. Changing habits and keep people motivated takes energy and time. In reality, where is the budget for these activities? See my 2016 post: PLM and Cultural Change Management – too expensive?

And now, this new PLM-system requires people to work in a more user-friendly environment with limited freedom. This is a significant shift in working methodology. This means manufacturing engineers need to be trained and supported over several months. Changing habits and keep people motivated takes energy and time. In reality, where is the budget for these activities? See my 2016 post: PLM and Cultural Change Management – too expensive?

- From sequential to concurrent

Once your manufacturing engineers are able to work in a PLM-environment, they are able to start the manufacturing definition before the engineering definition is released. Manufacturing engineers can participate in design reviews having the information in their environment available. They can validate critical manufacturing steps and discuss with engineers potential changes that will reduce the complexity or cost for manufacturing. As these changes will be done before the product is released, the cost of change is much lower. After all, having engineering and manufacturing working partially in parallel will reduce time to market.

One of the leading business drivers for many companies is introducing products or enhancements to the market. Bringing engineering and manufacturing preparation together also means that the PLM-system can no longer be an engineering tool under the responsibility of the engineering department.

The responsibility for PLM needs to be at a level higher in the organization to ensure well-balanced choices. A higher level in the organization automatically means more attention for business benefits and less attention for functions and features.

The responsibility for PLM needs to be at a level higher in the organization to ensure well-balanced choices. A higher level in the organization automatically means more attention for business benefits and less attention for functions and features.

From technology to methodology – interface issues?

The whole EBOM/MBOM-discussion often has become a discussion related to a PLM-system and an ERP-system. Next, the discussion diverted to how these two systems could work together, changing the mindset to the complexity of interfaces instead of focusing on the logical flow of information.

In an earlier PI Event in München 2016, I lead a focus group related to the PLM and ERP interaction. The discussion was not about technology, all about focusing on what is the logical flow of information. From initial creation towards formal usage in a product definition (EBOM/MBOM).

In an earlier PI Event in München 2016, I lead a focus group related to the PLM and ERP interaction. The discussion was not about technology, all about focusing on what is the logical flow of information. From initial creation towards formal usage in a product definition (EBOM/MBOM).

What became clear from this workshop and other customer engagements is that people are often locked in their siloed way of thinking. Proposed information flows are based on system capabilities, not on the ideal flow of information. This is often the reason why a PLM/ERP-interface becomes complicated and expensive. System integrators do not want to push for organizational change, they prefer to develop an interface that adheres to the current customer expectations.

SAP has always been promoting that they do not need an interface between engineering and manufacturing as their data management starts from the EBOM. They forgot to mention that they have a difficult time (and almost no intention) to manage the early ideation and design phase. As a Dutch SAP country manager once told me: “Engineers are resources that do not want to be managed.” This remark says all about the mindset of ERP.

After overlooking successful PLM-implementations, I can tell the PLM-ERP interface has never been a technical issue once the methodology is transparent. A company needs to agree on logical data flow from ideation through engineering towards design is the foundation.

It is not about owning data and where to store it in a single system. It is about federated data sets that exist in different systems and that are complementary but connected, requiring data governance and master data management.

It is not about owning data and where to store it in a single system. It is about federated data sets that exist in different systems and that are complementary but connected, requiring data governance and master data management.

The SAP-Siemens partnership

In the context of the previous paragraph, the messaging around the recently announced partnership between SAP and Siemens made me curious. Almost everyone has shared an opinion about the partnership. There is a lot of speculation, and many questions were imaginarily answered by as many blog posts in the field. Last week Stan Przybylinski shared CIMdata’s interpretations in a webinar Putting the SAP-Siemens Partnership In Context, which was, in my opinion, the most in-depth analysis I have seen.

For what it is worth, my analysis:

- First of all, the partnership is a merger of slide decks at this moment, aiming to show to a potential customer that in the SAP/Siemens-combination, you find everything you need. A merger of slides does not mean everything works together.

- It is a merger of two different worlds. You can call SAP a real data platform with connected data, where Siemens offering is based on the Teamcenter backbone providing a foundation for a coordinated approach. In the coordinated approach, the data flexibility is lower. For that reason, Mendix is crucial to make Siemens portfolio behave like a connected platform too.

You can read my doubts about having a coordinated and connected system working together (see image above). It was my #1 identified challenge for this decade: PLM 2020 – PLM the next decade (before COVID-19 became a pandemic and illustrated we need to work connected) - The fact that SAP will sell TC PLM and Siemens will sell SAP PPM seems like loser’s statement, meaning our SAP PLM is probably not good enough, or our TC PPM capabilities are not good enough. In reality, I believe they both should remain, and the partnership should work on logical data flows with data residing in two locations – the federated approach. This is how platforms reside next to each other instead of the single black hole.

- The fact that standard interfaces will be developed between the two systems is a subtle sales argument with relatively low value. As I wrote in the “from technology to methodology”-paragraph, the challenges are in the organizational change within companies. Technology is not the issue, although system integrators also need to make a living.

- What I believe makes sense is that both SAP and Siemens, have to realize their Industry 4.0 end-to-end capabilities. It is a German vision now for several years and it is an excellent vision to strive for. Now it is time to build the two platforms working together. This will be a significant technical challenge mainly for Siemens as its foundation is based on a coordinated backbone.

- The biggest challenge, not only for this partnership, is the organizational change within companies that want to build an end-to-end connected solution. In particular, in companies with a vast legacy, the targeted industries by the partnership, the chasm between coordinated legacy data and intended connected data is enormous. Technology will not fix it, perhaps smoothen the pain a little.

Conclusion

With this post, we have reached the foundation of the item-centric approach for PLM, where the EBOM and MBOM are managed in a real-time context. Organizational change is the biggest inhibitor to move forward. The SAP-Siemens partnership is a sales/marketing approach to create a simplified view for the future at C-level discussions.

Let us watch carefully what happens in reality.

Next time potentially the dimension of change management and configuration management in an item-centric approach.

Or perhaps Martijn Dullaart will show us the way before, following up on his tricky poll question

Life goes on, and I hope you are all staying safe while thinking about the future. Interesting in the context of the future, there was a recent post from Lionel Grealou with the title: Towards PLM 4.0: Hyperconnected Asset Performance Management Framework.

Lionel gave a kind of evolutionary path for PLM. The path from PLM 1.0 (PDM) ending in a PLM 4.0 definition. Read the article or click on the image to see an enlarged version to understand the logical order. Interesting to mention that PLM 4.0 is the end target, for sure there is a wishful mind-mapping with Industry 4.0.

When seeing this diagram, it reminded me of Marc Halpern’s diagram that he presented during the PDT 2015 conference. Without much fantasy, you can map your company to one of the given stages and understand what the logical next step would be. To map Lionel’s model with Marc’s model, I would state PLM 4.0 aligns with Marc’s column Collaborating.

In the discussion related to Lionel’s post, I stated two points. First, an observation that most of the companies that I know remain in PLM 1.0 or 2.0, or in Marc’s diagram, they are still trying to reach the level of Integrating.

Why is it so difficult to move to the next stage?

Oleg Shilovitsky, in a reaction to Lionel’s post, confirmed this. In Why did manufacturing stuck in PLM 1.0 and PLM 2.0? Oleg points to several integration challenges, functional and technical. His take is that new technologies might be the answer to move to PLM 3.0, as you can read from his conclusion.

What is my conclusion?

There are many promising technologies, but integration is remaining the biggest problem for manufacturing companies in adopting PLM 3.0. The companies are struggling to expand upstream and downstream. Existing vendors are careful about the changes. At the same time, very few alternatives can be seen around. Cloud structure, new data management, and cloud infrastructure can simplify many integration challenges and unlock PLM 3.0 for future business upstream and especially downstream. Just my thoughts…

Completely disconnected from Lionel’s post, Angad Sorte from Plural Nordic AS wrote a LinkedIn post: Why PLM does not get attention from your CEO. Click on the image to see an enlarged version, that also neatly aligns with Industry 4.0. Coincidence, or do great minds think alike? Phil Collins would sing: It is in the air tonight

Completely disconnected from Lionel’s post, Angad Sorte from Plural Nordic AS wrote a LinkedIn post: Why PLM does not get attention from your CEO. Click on the image to see an enlarged version, that also neatly aligns with Industry 4.0. Coincidence, or do great minds think alike? Phil Collins would sing: It is in the air tonight

Angad’s post is about the historical framing of PLM as a system, an engineering tool versus a business strategy. Angrad believes once you have a clear definition, it will be easier to explain the next steps for the business. The challenge here is: Do we need, or do we have a clear definition of PLM? It is a topic that I do not want to discuss anymore due to a variety of opinions and interpretations. An exact definition will never lead to a CEO stating, “Now I know why we need PLM.”

I believe there are enough business proof points WHY companies require a PLM-infrastructure as part of a profitable business. Depending on the organization, it might be just a collection of tools, and people do the work. Perhaps this is the practice in small enterprises?

In larger enterprises, the go-to-market strategy, the information needs, and related processes will drive the justification for PLM. But always in the context of a business transformation. Strategic consultancy firms are excellent in providing strategic roadmaps for their customers, indicating the need for a PLM-infrastructure as part of that.

In larger enterprises, the go-to-market strategy, the information needs, and related processes will drive the justification for PLM. But always in the context of a business transformation. Strategic consultancy firms are excellent in providing strategic roadmaps for their customers, indicating the need for a PLM-infrastructure as part of that.

Most of the time, they do not dive more in-depth as when it comes to implementation, other resources are needed.

What needs to be done in PLM 1.0 to 4.0 per level/stage is well described in all the diagrams on a high-level. The WHAT-domain is the domain of the PLM-vendors and implementers. They know what their tools and skillsets can do, and they will help the customer to implement such an environment.

What needs to be done in PLM 1.0 to 4.0 per level/stage is well described in all the diagrams on a high-level. The WHAT-domain is the domain of the PLM-vendors and implementers. They know what their tools and skillsets can do, and they will help the customer to implement such an environment.

The big illusion of all the evolutionary diagrams is that it gives a false impression of evolution. Moving to the next level is not just switching on new or more technology and involve more people.

So the big question is HOW and WHEN to make progress.

HOW to make progress

In the past four years, I have learned that digital transformation in the domain of PLM is NOT an evolution. It is disruptive as the whole foundation for PLM changes. If you zoom in on the picture on the left, you will see the data model on the left, and the data model on the right is entirely different.

In the past four years, I have learned that digital transformation in the domain of PLM is NOT an evolution. It is disruptive as the whole foundation for PLM changes. If you zoom in on the picture on the left, you will see the data model on the left, and the data model on the right is entirely different.

On the left side of the chasm, we have a coordinated environment based on data-structures (items, folders, tasks) to link documents.

On the right side of the chasm, we have a connected environment based on federated data elements and models (3D, Logical, and Simulation models).

I have been discussing this topic in the past two years at various PLM conferences and a year ago in my blog: The Challenges of a connected ecosystem for PLM

If you are interested in learning more about this topic, register for the upcoming virtual PLM Innovation Forum organized by TECHNIA. Registration is for free, and you will be able to watch the presentation, either live or recorded for 30 days.

If you are interested in learning more about this topic, register for the upcoming virtual PLM Innovation Forum organized by TECHNIA. Registration is for free, and you will be able to watch the presentation, either live or recorded for 30 days.

At this moment, the detailed agenda has not been published, and I will update the link once the session is visible. My presentation will not only focus on the HOW to execute a digital transformation, including PLM can be done, but also explain why NOW is the moment.

NOW to make progress

When the COVID19-related lockdown started, must of us thought that after the lockdown, we will be back in business as soon as possible. Now understanding the impact of the virus on our society, it is clear that we need to re-invent ourselves for a sustainable future, be more resilient.

It is now time to act and think differently as due to the lockdown, most of us have time to think. Are you and your company looking forward to creating a better future? Or will you and your company try to do the same non-sustainable rat race of the past and being caught by the next crises.

It is now time to act and think differently as due to the lockdown, most of us have time to think. Are you and your company looking forward to creating a better future? Or will you and your company try to do the same non-sustainable rat race of the past and being caught by the next crises.

McKinsey has been publishing several articles related to the impact of COVID19 and the article: Beyond coronavirus: The path to the next normal very insightful

As McKinsey never talks about PLM, therefore I want to guide you to think about more sustainable business.

Use a modern PLM-infrastructure, practices, and tools to remain competitive, meanwhile creating new or additional business models. Realizing concepts as digital twins, AR/VR-based business models require an internal transition in your company, the jump from coordinated to connected. Therefore, start investigating, experimenting in these new ways of working, and learn fast. This is why we created the PLM Green Alliance as a platform to share and discuss.

If you believe there is no need to be fast, I recommend you watch Rebecka Carlsson’s presentation at the PLMIF event. The title of her presentation: Exponential Tech in Sustainability. Rebecca will share insights for business development about how companies can upgrade to new business models based on the new opportunities that come with sustainability and exponential tech.

If you believe there is no need to be fast, I recommend you watch Rebecka Carlsson’s presentation at the PLMIF event. The title of her presentation: Exponential Tech in Sustainability. Rebecca will share insights for business development about how companies can upgrade to new business models based on the new opportunities that come with sustainability and exponential tech.

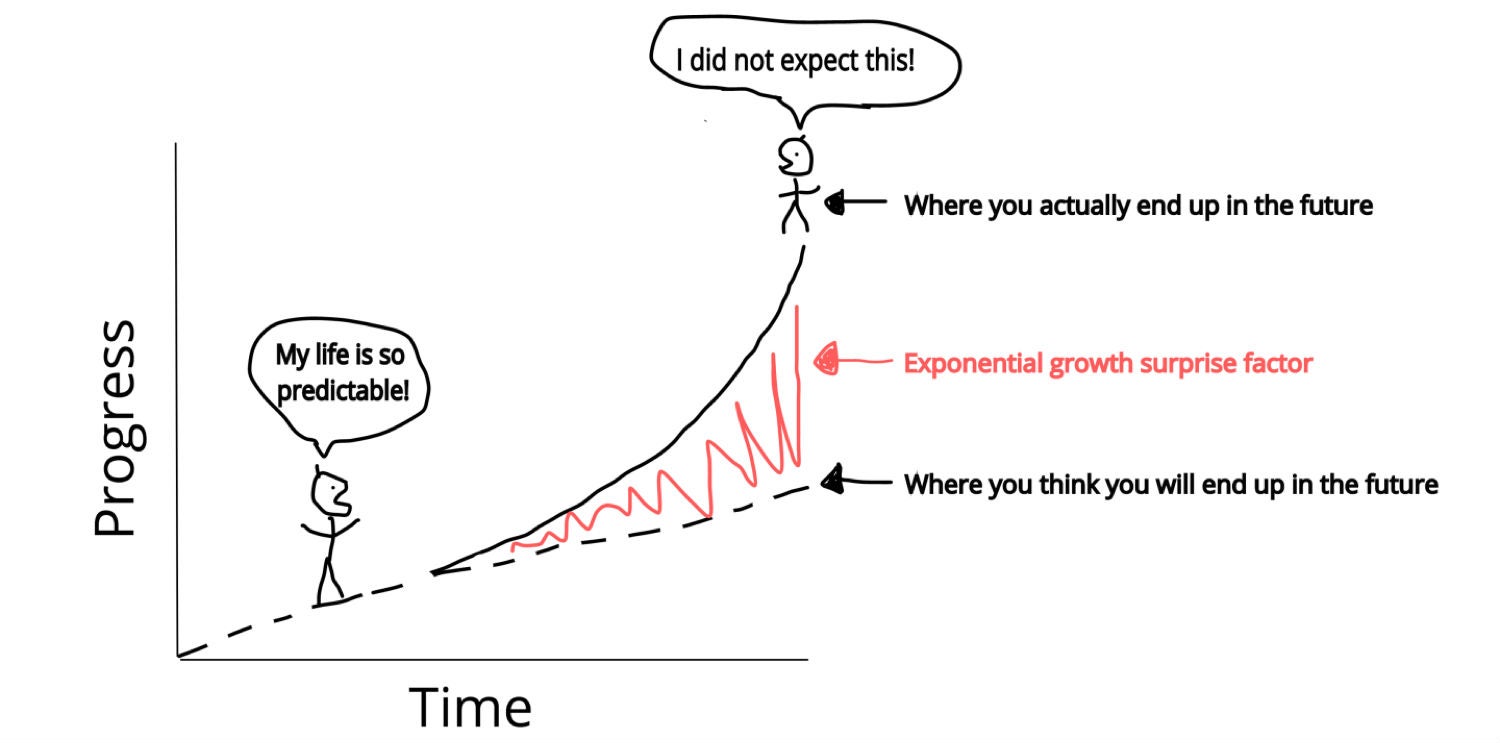

The reason I recommend her presentation because she addresses the aspect of exponential thinking nicely. Rebecka states we are “programmed” to think local-linear as mankind. Exponential thinking goes beyond our experience. Something we are not used doing until with the COVID19-virus we discovered exponential growth of the number of infections.

Finally, and this I read this morning, Jan Bosch wrote an interesting post: Why Agile Matters, talking about the fact that during the design and delivery of the product to the market, the environment and therefore the requirements might change. Read his post, unless as Jan states:

Concluding, if you’re able to perfectly predict the optimal set of requirements for a system or product years ahead of the start of production or deployment and if you’re able to accurately predict the effect of each requirement on the user, the customer and the quality attributes of the system, then you don’t need Agile.

What I like about Jan’s post is the fact that we should anticipate changing requirements. This statement combined with Rebecka’s call for being ready for exponential change, with an emerging need for sustainability, might help you discuss in your company how a modern New Product Introduction process might look like, including requirements for a sustainable future that might come in later (per current situation) or can become a practice for the future

Conclusion

Now is the disruptive moment to break with the old ways of working. Develop plans for the new Beyond-COVID19-society. Force yourselves to work in more sustainable modes (digital/virtual), develop sustainable products or services (a circular economy), and keep on learning. Perhaps we will meet virtually during the upcoming PLM Innovation Forum?

Note: You have reached the end of this post, which means you took the time to read it all. Now if you LIKE or DISLIKE the content, share it in a comment. Digital communication is the future. Just chasing for Likes is a skin-deep society. We need arguments.

Looking forward to your feedback.

Meanwhile, two weeks of a partial lockdown have passed here in the Netherlands, and we have at least another 3 weeks to go according to the Dutch government. The good thing in our country, decisions, and measures are made based on the advice of experts as we cannot rely on politicians as experts.