You are currently browsing the category archive for the ‘PLCS’ category.

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

Now, I want to conclude on what I would call, in my terminology, the connected digital thread. This topic was already addressed when I reported on the federated PLM story from NIO (Yousef Hooshmand) and SAAB Aeronautics (Erik Herzog).

The Need for a Governance Digital Thread

This time, my presentation was a memory refresher related to digital transformation in the PLM domain – moving from coordinated ways of working towards connected ways of working.

A typology that is also valid for the digital thread definition.

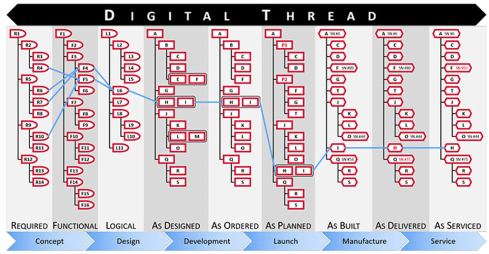

- A Coordinated Digital Thread is a digital thread that connects various artifacts in an enterprise. These relations are created and managed to support traceability and an impact analysis. The coordinated digital thread requires human interpretation to process the information. The image below from Aras is a perfect example of a coordinated digital thread.

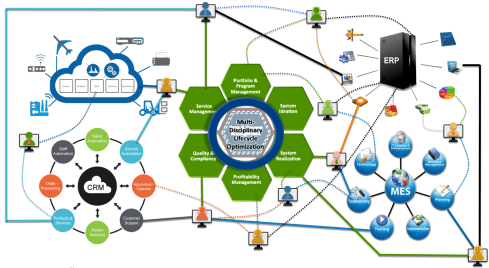

- The Connected Digital Thread is the digital thread where the artifacts are datasets stored in a federated infrastructure of databases. A connected digital thread provides real-time access to data through applications or dashboards for users. The real-time access makes the connected digital thread a solution for real-time, multidisciplinary collaboration activities.

The image above illustrates the connected digital thread as an infrastructure on top of five potential business platforms, i.e., the IoT platform, the CRM platform, the ERP platform, the MES platform and ultimately, the Product Innovation Platform.

Note: These platforms are usually a collection of systems that logically work together efficiently.

The importance of the Connected Digital Thread

When looking at the benefits of the Connected Digital Thread, the most essential feature is that it allows people in an organization to have all relevant data and its context available for making changes, analysis and design choices.

Due to the rich context, people can work proactively and reduce the number of iterations and fixes later.

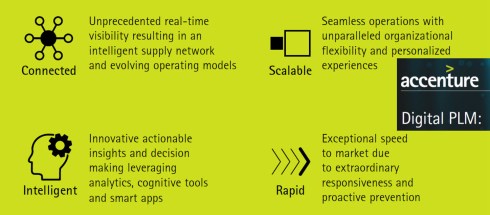

The above image from Accenture (2014) describing the business benefits can be divided into two categories:

- The top, Connected and Scalable describing capabilities

- The bottom, Intelligent and Rapid, describes the business impact

The connected digital thread for governance

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

The PLM system will be one of the sources; other sources can be fragmented in an organization. Bringing them together manually in one report is a significant human effort, time-consuming and not supporting the business.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

According to a recent KPMG report, only a quarter of companies are ready for ESG Reporting Requirements.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

The Connected Digital Thread and the Digital Product Passport

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

The DPP is based on the GS1 infrastructure, originating from the retail industry. Each product will have a unique ID (UID based on ISO/IEC 15459:2015), and this UID will provide digital access to product information, containing information about the product’s used materials, its environmental impact, and recycle/reuse–ability.

It will serve both for regulatory compliance and as an information source for consumers to make informed decisions about the products they buy. The DPP aims to stimulate and enforce a more circular economy.

![]() Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

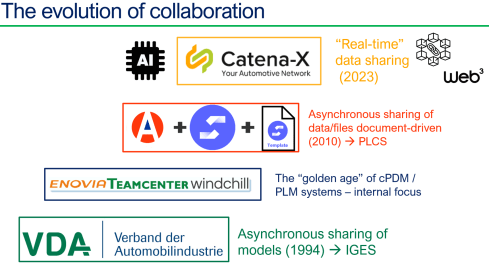

The Connected Digital Thread and Catena-X

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

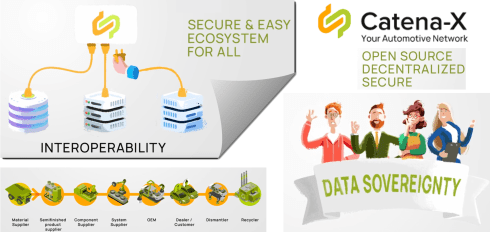

A new exciting trend is the potential rise of not-for-profit infrastructure for a particular industry. Where the GS1-based infrastructure is designed to provide visibility on sustainable targets and decisions, Catena-X is focusing on the automotive industry.

Catena-X is the establishment of a data-driven value chain for the German automotive industry and is now in the process of expanding to become a global network.

It is a significant building block in what I would call the connected or even adaptive enterprise, using a data-driven infrastructure to let information flow through the whole value chain.

It is one of the best examples of a Connected Digital Thread covering an end-to-end value chain.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

So Sustainability and Digitization go hand in hand.

Why a Digital Thread makes a lot of sense

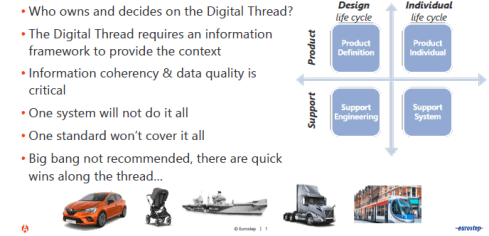

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

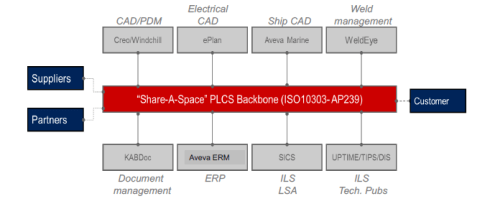

Eurostep, recently acquired by BAE Systems, is known for its collaboration hub or information backbone, ShareAspace. The interesting trend here is switching from a traditional PLM infrastructure to an asset-centric one.

This approach makes a lot of sense for complex assets with a long lifecycle, as the development phase is usually done with a consortium of companies. Still, the owner/operator wants to maintain a digital twin of the asset – for maintenance and upgrades.

A standards-based backbone makes much sense in such an environment due to the various data formats. This setup also means we are looking at a Coordinated Digital Thread at this stage, not a Connected Digital Thread.

Mattias concluded with the question of who owns and who decides on the coordinated digital thread – a discussion also valid in the construction industry when discussing Building Information Management (BIM) and a Common Data Environment(CDE).

I believe software vendors can provide the Coordinated Digital Thread option when they can demonstrate and provide a positive business case for their solution. Still, it will be seen as an overhead to connect the dots.

For a Connected Digital Thread, I think it might be provided as an infrastructure like the World Wide Web (W3C) organization. Here, the business case is much easier to demonstrate as it is really a digital highway.

Such an infrastructure could be provided by not-for-profit organizations like GS1 (Digital Product Passport/Retail), Catena-X (Automotive) and others (Gaia-X).

![]() For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

AI

And then there was AI. During the conference, people spoke more about AI than Sustainability topics, illustrating that our audience is more interested in understanding the next hype instead of feeling the short-term need to address climate change and planet sustainability.

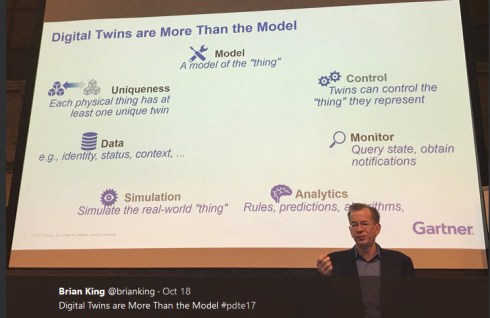

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

And we closed the conference with a roundtable discussion: AI, PLM and the Digital Thread: Why should we care about AI?

From the roundtable, I concluded that we are all convinced AI will have a significant impact in the upcoming years and are all in the early phases of the AI hype.

Will AI introduction go faster than digital transformation?

Conclusion

The conference gave me confidence that digital transformation in the PLM domain has reached the next level. Many sessions were related to collaboration concepts outside the traditional engineering domain – coordinated and connected digital threads.

The connected digital thread is the future, and as we saw it, it heralds the downfall of monolithic PLM. The change is needed for business efficiency AND compliance with more and more environmental regulations.

I am looking forward to seeing the pace of progress here next year.

Last week, I shared my first impressions from my favorite conference, in the post: The weekend after PLM Roadmap/PDT Europe 2023, where most impressions could be classified as traditional PLM and model-based.

Last week, I shared my first impressions from my favorite conference, in the post: The weekend after PLM Roadmap/PDT Europe 2023, where most impressions could be classified as traditional PLM and model-based.

There is nothing wrong with conventional PLM, as there is still much to do within this scope. A model-based approach for MBSE (Model-Based Systems Engineering) and MBD (Model-Based Definition) and efficient supplier collaboration are not topics you solve by implementing a new system.

Ultimately, to have a business-sustainable PLM infrastructure, you need to structure your company internally and connect to the outside world with a focus on standards to avoid a vendor lock-in or a dead end.

Ultimately, to have a business-sustainable PLM infrastructure, you need to structure your company internally and connect to the outside world with a focus on standards to avoid a vendor lock-in or a dead end.

In short, this is what I described so far in The weekend after ….part 1.

Now, let’s look at the relatively new topics for this audience.

Enabling the Marketing, Engineering & Manufacturing Digital Thread

Cyril Bouillard, the PLM & CAD Tools Referent at the Mersen Electrical Protection (EP) business unit, shared his experience implementing an end-to-end digital backbone from marketing through engineering and manufacturing.

Cyril Bouillard, the PLM & CAD Tools Referent at the Mersen Electrical Protection (EP) business unit, shared his experience implementing an end-to-end digital backbone from marketing through engineering and manufacturing.

Cyril showed the benefits of a modern PLM infrastructure that is not CAD-centric and focused on engineering only. The advantages of this approach are a seamless integrated flow of PLM and PIM (Product Information Management).

I wrote about this topic in 2019: PLM and PIM – the complementary value in a digital enterprise. Combining the concepts of PLM and PIM in an integrated, connected environment could also provide a serious benefit when collaborating with external parties.

Another benefit Cyril demonstrated was the integration of RoHS compliance to the BOM as an integrated environment. In my session, I also addressed integrated RoHS compliance as a stepping stone to efficiency in future compliance needs.

Another benefit Cyril demonstrated was the integration of RoHS compliance to the BOM as an integrated environment. In my session, I also addressed integrated RoHS compliance as a stepping stone to efficiency in future compliance needs.

Read more later or in this post: Material Compliance – as a stepping-stone towards Life Cycle Assessment (LCA)

Cyril concluded with some lessons learned.

Data quality is essential in such an environment, and there are significant time savings implementing the connected Digital Thread.

Meeting the Challenges of Sustainability in Critical Transport Infrastructures

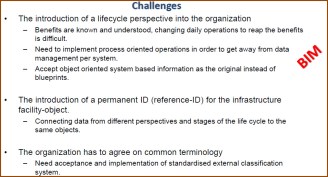

Etienne Pansart, head of digital engineering for construction at SYSTRA, explained how they address digital continuity with PLM throughout the built assets’ lifecycle.

Etienne Pansart, head of digital engineering for construction at SYSTRA, explained how they address digital continuity with PLM throughout the built assets’ lifecycle.

Etienne’s story was related to the complexity of managing a railway infrastructure, which is a linear and vertical distribution at multiple scales; it needs to be predictable and under constant monitoring; it is a typical system of systems network, and on top of that, maintenance and operational conditions need to be continued up to date.

Regarding railway assets – a railway needs renewal every two years, bridges are designed to last a hundred years, and train stations should support everyday use.

When complaining about disturbances, you might have a little more respect now (depending on your country). However, on top of these challenges, Etienne also talked about the additional difficulties expected due to climate change: floods, fire, earth movements, and droughts, all of which will influence the availability of the rail infrastructure.

In that context, Etienne talked about the MINERVE project – see image below:

As you can see from the main challenges, there is an effort of digitalization for both the assets and a need to provide digital continuity over the entire asset lifecycle. This is not typically done in an environment with many different partners and suppliers delivering a part of the information.

Etienne explained in more detail how they aim to establish digital twins and MBSE practices to build and maintain a data-driven, model-based environment.

Having digital twins allows much more granular monitoring and making accurate design decisions, mainly related to sustainability, without the need to study the physical world.

His presentation was again a proof point that through digitalization and digital twins, the traditional worlds of Product Lifecycle Management and Asset Information Management become part of the same infrastructure.

And it may be clear that in such a collaboration environment, standards are crucial to connect the various stakeholder’s data sources – Etienne mentioned ISO 16739 (IFC), IFC Rail, and ISO 19650 (BIM) as obvious standards but also ISO 10303 (PLCS) to support the digital thread leveraged by OSLC.

And it may be clear that in such a collaboration environment, standards are crucial to connect the various stakeholder’s data sources – Etienne mentioned ISO 16739 (IFC), IFC Rail, and ISO 19650 (BIM) as obvious standards but also ISO 10303 (PLCS) to support the digital thread leveraged by OSLC.

I am curious to learn more about the progress of such a challenging project – having worked with the high-speed railway project in the Netherlands in 1995 – no standards at that time (BIM did not exist) – mainly a location reference structure with documents. Nothing digital.

The connected Digital Thread

The theme of the conference was The Digital Thread in a Heterogeneous, Extended Enterprise Reality, and in the next section, I will zoom in on some of the inspiring sessions for the future, where collaboration or information sharing is all based on a connected Digital Thread – a term I will explain in more depth in my next blog post.

Transforming the PLM Landscape:

The Gateway to Business Transformation

Yousef Hooshmand‘s presentation was the highlight of this conference for me.

Yousef Hooshmand‘s presentation was the highlight of this conference for me.

Yousef is the PLM Architect and Lead for the Modernization of the PLM Landscape at NIO, and he has been active before in the IT-landscape transformation at Daimler, on which he published the paper: From a monolithic PLM landscape to a federated domain and data mesh.

If you read my blog or follow Share PLM, you might seen the reference to Yousef’s work before, or recently, you can hear the full story at the Share PLM Podcast: Episode 6: Revolutionizing PLM: Insights.

If you read my blog or follow Share PLM, you might seen the reference to Yousef’s work before, or recently, you can hear the full story at the Share PLM Podcast: Episode 6: Revolutionizing PLM: Insights.

It was the first time I met Yousef in 3D after several virtual meetings, and his passion for the topic made it hard to fit in the assigned 30 minutes.

There is so much to share on this topic, and part of it we already did before the conference in a half-day workshop related to Federated PLM (more on this in the following review).

First, Yousef started with the five steps of the business transformation at NIO, where long-term executive commitment is a must.

His statement: “If you don’t report directly to the board, your project is not important”, caused some discomfort in the audience.

As the image shows, a business transformation should start with a systematic description and analysis of which business values and objectives should be targeted, where they fit in the business and IT landscape, what are the measures and how they can be tracked or assessed and ultimately, what we need as tools and technology.

In his paper From a Monolithic PLM Landscape to a Federated Domain and Data Mesh, Yousef described the targeted federated landscape in the image below.

And now some vendors might say, we have all these domains in our product portfolio (or we have slides for that) – so buy our software, and you are good.

And here Yousef added his essential message, illustrated by the image below.

Start by delivering the best user-centric solutions (in an MVP manner – days/weeks – not months/years). Next, be data-centric in all your choices and ultimately build an environment ready for change. As Yousef mentioned: “Make sure you own the data – people and tools can leave!”

And to conclude reporting about his passionate plea for Federated PLM:

“Stop talking about the Single Source of Truth, start Thinking of the Nearest Source of Truth based on the Single Source of Change”.

Heliple-2 PLM Federation:

A Call for Action & Contributions

A great follow-up on Yousef’s session was Erik Herzog‘s presentation about the final findings of the Heliple 2 project, where SAAB Aeronautics, together with Volvo, Eurostep, KTH, IBM and Lynxwork, are investigating a new way of federated PLM, by using an OSLC-based, heterogeneous linked product lifecycle environment.

A great follow-up on Yousef’s session was Erik Herzog‘s presentation about the final findings of the Heliple 2 project, where SAAB Aeronautics, together with Volvo, Eurostep, KTH, IBM and Lynxwork, are investigating a new way of federated PLM, by using an OSLC-based, heterogeneous linked product lifecycle environment.

Heliple stands for HEterogeneous LInked Product Lifecycle Environment

The image below, which I shared several times before, illustrates the mindset of the project.

Last year, during the previous conference in Gothenburg, Erik introduced the concept of federated PLM – read more in my post: The week after PLM Roadmap / PDT Europe 2022, mentioning two open issues to be investigated: Operational feasibility (is it maintainable over time) and Realisation effectivity (is it affordable and maintainable at a reasonable cost)

As you can see from the slide below, the results were positive and encouraged SAAB to continue on this path.

One of the points to mention was that during this project, Lynxwork was used to speed up the development of the OSLC adapter, reducing costs, time and needed skills.

After this successful effort, Erik and several others who joined us at the pre-conference workshop agreed that this initiative is valid to be tested, discussed and exposed outside Sweden.

After this successful effort, Erik and several others who joined us at the pre-conference workshop agreed that this initiative is valid to be tested, discussed and exposed outside Sweden.

Therefore, the Federated PLM Interest Group was launched to join people worldwide who want to contribute to this concept with their experiences and tools.

A first webinar from the group is already scheduled for December 12th at 4 PM CET – you can join and register here.

More to come

Given the length of this blog post, I want to stop here.

Topics to share in the next post are related to my contribution at the conference The Need for a Governance Digital Thread, where I addressed the need for federated PLM capabilities with the upcoming regulations and practices related to sustainability, which require a connected Digital.

Topics to share in the next post are related to my contribution at the conference The Need for a Governance Digital Thread, where I addressed the need for federated PLM capabilities with the upcoming regulations and practices related to sustainability, which require a connected Digital.

I want to combine this post with the findings that Mattias Johansson, CEO of Eurostep, shared in his session: Why a Digital Thread makes a lot of sense, goes beyond manufacturing, and should be standards-based.

I want to combine this post with the findings that Mattias Johansson, CEO of Eurostep, shared in his session: Why a Digital Thread makes a lot of sense, goes beyond manufacturing, and should be standards-based.

There are some interesting findings in these two presentations.

And there was the introduction of AI at the conference, with some experts’ talks and thoughts. Perhaps at this stage, it is too high on Gartner’s hype cycle to go into details. It will surely be THE topic of discussion or interest you must have noticed.

And there was the introduction of AI at the conference, with some experts’ talks and thoughts. Perhaps at this stage, it is too high on Gartner’s hype cycle to go into details. It will surely be THE topic of discussion or interest you must have noticed.

The recent turmoil at OpenAI is an example of that. More to come for sure in the future.

Conclusion

The PLM Roadmap/PDT Europe conference was significant for me because I discovered that companies are working on concepts for a data-driven infrastructure for PLM and are (working on) implementing them. The end of monolithic PLM is visible, and companies need to learn to master data using ontologies, standards and connected digital threads.

This week I attended the SCAF conference in Jonkoping. SCAF is an abbreviation of the Swedish CATIA User Group. First of all, I was happy to be there as it was a “physical” conference, having the opportunity to discuss topics with the attendees outside the presentation time slot.

This week I attended the SCAF conference in Jonkoping. SCAF is an abbreviation of the Swedish CATIA User Group. First of all, I was happy to be there as it was a “physical” conference, having the opportunity to discuss topics with the attendees outside the presentation time slot.

It is crucial for me as I have no technical message. Instead, I am trying to make sense of the future through dialogues. What is sure is that the future will be based on new digital concepts, completely different from the traditional approach that we currently practice.

My presentation, which you can find here on SlideShare, was again zooming in on the difference between a coordinated approach (current) and a connected approach (the future).

My presentation, which you can find here on SlideShare, was again zooming in on the difference between a coordinated approach (current) and a connected approach (the future).

The presentation explains the concepts of datasets, which I discussed in my previous blog post. Now, I focussed on how this concept can be discovered in the Dassault Systemes 3DExperience platform, combined with the must-go path for all companies to more systems thinking and sustainable products.

It was interesting to learn that the concept of connected datasets like the spider’s web in the image reflected the future concept for many of the attendees.

It was interesting to learn that the concept of connected datasets like the spider’s web in the image reflected the future concept for many of the attendees.

One of the demos during the conference illustrated that it is no longer about managing the product lifecycle through structures (EBOM/MBOM/SBOM).

Still, it is based on a collection of connected datasets – the path in the spider’s web.

It was interesting to talk with the present companies about their roadmap. How to become a digital enterprise is strongly influenced by their legacy culture and ways of working. Where to start to be connected is the main challenge for all.

A final positive remark. The SCAF had renamed itself to SCAF (3DX), showing that even CATIA practices no longer can be considered as a niche – the future of business is to be connected.

A final positive remark. The SCAF had renamed itself to SCAF (3DX), showing that even CATIA practices no longer can be considered as a niche – the future of business is to be connected.

Now back to the thread that I am following on the series The road to model-based. Perhaps I should change the title to “The road to connected datasets, using models”. The statement for this week to discuss is:

Data-driven means that you need to have an enterprise architecture, data governance and a master data management (MDM) approach. So far, the traditional PLM vendors have not been active in the MDM domain as they believe their proprietary data model is leading. Read also this interesting McKinsey article: How enterprise architects need to evolve to survive in a digital world

Reliable data

If you have been following my story related to PLM transition: From a connected to a coordinated infrastructure might have seen the image below:

The challenge of a connected enterprise is that you want to connect different datasets, defined in various platforms, to support any type of context. We called this a digital thread or perhaps even better framed a digital web.

This is new for most organizations because each discipline has been working most of the time in its own silo. They are producing readable information in neutral files – pdf drawings/documents. In cases where a discipline needs to deliver datasets, like in a PDM-ERP integration, we see IT-energy levels rising as integrations are an IT thing, right?

This is new for most organizations because each discipline has been working most of the time in its own silo. They are producing readable information in neutral files – pdf drawings/documents. In cases where a discipline needs to deliver datasets, like in a PDM-ERP integration, we see IT-energy levels rising as integrations are an IT thing, right?

Too much focus on IT

In particular, SAP has always played the IT card (and is still playing it through their Siemens partnership). Historically, SAP claimed that all parts/items should be in their system. Thus, there was no need for a PDM interface, neglecting that the interface moment was now shifted to the designer in CAD.

In particular, SAP has always played the IT card (and is still playing it through their Siemens partnership). Historically, SAP claimed that all parts/items should be in their system. Thus, there was no need for a PDM interface, neglecting that the interface moment was now shifted to the designer in CAD.

And by using the name Material for what is considered a Part in the engineering world, they illustrated their lack of understanding of the actual engineering world.

There is more to “blame” to SAP when it comes to the PLM domain, or you can state PLM vendors did not yet understand what enterprise data means. Historically ERP systems were the first enterprise systems introduced in a company; they have been leading in a transactional “digital” world. The world of product development never has been a transactional process.

SAP introduced the Master Data Management for their customers to manage data in heterogeneous environments. As you can imagine, the focus of SAP MDM was more on the transactional side of the product (also PIM) than on the engineering characteristics of a product.

SAP introduced the Master Data Management for their customers to manage data in heterogeneous environments. As you can imagine, the focus of SAP MDM was more on the transactional side of the product (also PIM) than on the engineering characteristics of a product.

I have no problem that each vendor wants to see their solution as the center of the world. This is expected behavior. However, when it comes to a single system approach, there is a considerable danger of vendor lock-in, a lack of freedom to optimize your business.

In a modern digital enterprise (to be), the business processes and value streams should be driving the requirements for which systems to use. I was tempted to write “not the IT capabilities”; however, that would be a mistake. We need systems or platforms that are open and able to connect to other systems or platforms. The technology should be there, and more and more, we realize the future is based on connectivity between cloud solutions.

In a modern digital enterprise (to be), the business processes and value streams should be driving the requirements for which systems to use. I was tempted to write “not the IT capabilities”; however, that would be a mistake. We need systems or platforms that are open and able to connect to other systems or platforms. The technology should be there, and more and more, we realize the future is based on connectivity between cloud solutions.

In one of my first posts (part 2), I referred to five potential platforms for a connected enterprise. Each platform will have its own data model based on its legacy design, allowing it to service its core users in an optimized environment.

When it comes to interactions between two or more platforms, for example, between PLM and ERP, between PLM and IoT, but also between IoT and ERP or IoT and CRM, these interactions should first be based on identified business processes and value streams.

When it comes to interactions between two or more platforms, for example, between PLM and ERP, between PLM and IoT, but also between IoT and ERP or IoT and CRM, these interactions should first be based on identified business processes and value streams.

The need for Master Data Management

Defining horizontal business processes and value streams independent of the existing IT systems is the biggest challenge in many enterprises. Historically, we have been thinking around a coordinated way of working, meaning people shifting pieces of information between systems – either as files or through interfaces.

Defining horizontal business processes and value streams independent of the existing IT systems is the biggest challenge in many enterprises. Historically, we have been thinking around a coordinated way of working, meaning people shifting pieces of information between systems – either as files or through interfaces.

In the digital enterprise, the flow should be leading based on the stakeholders involved. Once people agree on the ideal flow, the implementation process can start.

Which systems are involved, and where do we need a connection between the two systems. Is the relationship bidirectional, or is it a push?

The interfaces need to be data-driven in a digital enterprise; we do not want human interference here, slowing down or modifying the flow. This is the moment Master Data Management and Data Governance comes in.

The interfaces need to be data-driven in a digital enterprise; we do not want human interference here, slowing down or modifying the flow. This is the moment Master Data Management and Data Governance comes in.

When exchanging data, we need to trust the data in its context, and we should be able to use the data in another context. But, unfortunately, trust is hard to gain.

I can share an example of trust when implementing a PDM system linked to a Microsoft-friendly ERP system. Both systems we able to have Excel as an interface medium – the Excel columns took care of the data mapping between these two systems.

In the first year, engineers produced the Excel with BOM information and manufacturing engineering imported the Excel into their ERP system. After a year, the manufacturing engineers proposed to automatically upload the Excel as they discovered the exchange process did not need their attention anymore – they learned to trust the data.

In the first year, engineers produced the Excel with BOM information and manufacturing engineering imported the Excel into their ERP system. After a year, the manufacturing engineers proposed to automatically upload the Excel as they discovered the exchange process did not need their attention anymore – they learned to trust the data.

How often have you seen similar cases in your company where we insist on a readable exchange format?

When you trust the process(es), you can trust the data. In a digital enterprise, you must assume that specific datasets are used or consumed in different systems. Therefore a single data mapping as in the Excel example won’t be sufficient

When you trust the process(es), you can trust the data. In a digital enterprise, you must assume that specific datasets are used or consumed in different systems. Therefore a single data mapping as in the Excel example won’t be sufficient

Master Data Management and standards?

Some traditional standards, like the ISO 15926 or ISO 10303, have been designed to exchange process and engineering data – they are domain-specific. Therefore, they could simplify your master data management approach if your digitalization efforts are in that domain.

Some traditional standards, like the ISO 15926 or ISO 10303, have been designed to exchange process and engineering data – they are domain-specific. Therefore, they could simplify your master data management approach if your digitalization efforts are in that domain.

To connect other types of data, it is hard to find a global standard that also encompasses different kinds of data or consumers. Think about the GS1 standard, which has more of a focus on the consumer-side of data management. When PLM meets PIM, this standard and Master Data Management will be relevant.

To connect other types of data, it is hard to find a global standard that also encompasses different kinds of data or consumers. Think about the GS1 standard, which has more of a focus on the consumer-side of data management. When PLM meets PIM, this standard and Master Data Management will be relevant.

Therefore I want to point to these two articles in this context:

How enterprise architects need to evolve to survive in a digital world focusing on the transition of a coordinated enterprise towards a connected enterprise from the IT point of view. And a recent LinkedIn post, Web Ontology Language as a common standard language for Engineering Networks? by Matthias Ahrens exploring the concepts I have been discussing in this post.

How enterprise architects need to evolve to survive in a digital world focusing on the transition of a coordinated enterprise towards a connected enterprise from the IT point of view. And a recent LinkedIn post, Web Ontology Language as a common standard language for Engineering Networks? by Matthias Ahrens exploring the concepts I have been discussing in this post.

To me, it seems that standards are helpful when working in a coordinated environment. However, in a connected environment, we have to rely on master data management and data governance processes, potentially based on a clever IT infrastructure using graph databases to be able to connect anything meaningful and possibly artificial intelligence to provide quality monitoring.

Conclusion

Standards have great value in exchange processes, which happen in a coordinated business environment. To benefit from a connected business environment, we need an open and flexible IT infrastructure supported by algorithms (AI) to guarantee quality. Before installing the IT infrastructure, we should first have defined the value streams it should support.

What are your experiences with this transition?

One of my favorite conferences is the PLM Road Map & PDT conference. Probably because in the pre-COVID days, it was the best PLM conference to network with peers focusing on PLM practices, standards, and sustainability topics. Now the conference is virtual, and hopefully, after the pandemic, we will meet again in the conference space to elaborate on our experiences further.

One of my favorite conferences is the PLM Road Map & PDT conference. Probably because in the pre-COVID days, it was the best PLM conference to network with peers focusing on PLM practices, standards, and sustainability topics. Now the conference is virtual, and hopefully, after the pandemic, we will meet again in the conference space to elaborate on our experiences further.

Last year’s fall conference was special because we had three days filled with a generic PLM update and several A&D (Aerospace & Defense) working groups updates, reporting their progress and findings. Sessions related to the Multiview BOM research, Global Collaboration, and several aspects of Model-Based practices: Model-Based Definition, Model-Based Engineering & Model-Based Systems engineering.

All topics that I will elaborate on soon. You can refresh your memory through these two links:

- The weekend after PLM Roadmap / PDT 2020 – part 1

- The next weekend after PLM Roadmap / PDT 2020 – part 2

This year, it was a two-day conference with approximately 200 attendees discussing how emerging technologies can disrupt the current PLM landscape and reshape the PLM Value Equation. During the first day of the conference, we focused on technology.

This year, it was a two-day conference with approximately 200 attendees discussing how emerging technologies can disrupt the current PLM landscape and reshape the PLM Value Equation. During the first day of the conference, we focused on technology.

On the second day, we looked in addition to the impact new technology has on people and organizations.

Today’s Emerging Trends & Disrupters

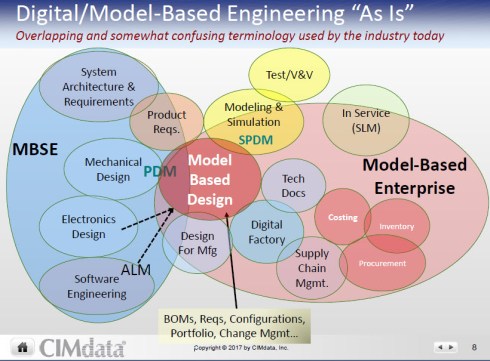

Peter Bilello, CIMdata’s President & CEO, kicked off the conference by providing CIMdata observations of the market. An increasing number of technology capabilities, like cloud, additive manufacturing, platforms, digital thread, and digital twin, all with the potential of realizing a connected vision. Meanwhile, companies evolve at their own pace, illustrating that the gap between the leaders and followers becomes bigger and bigger.

Where is your company? Can you afford to be a follower? Is your PLM ready for the future? Probably not, Peter states.

Next, Peter walked us through some technology trends and their applicability for a future PLM, like topological data analytics (TDA), the Graph Database, Low-Code/No-Code platforms, Additive Manufacturing, DevOps, and Agile ways of working during product development. All capabilities should be related to new ways of working and updated individual skills.

Next, Peter walked us through some technology trends and their applicability for a future PLM, like topological data analytics (TDA), the Graph Database, Low-Code/No-Code platforms, Additive Manufacturing, DevOps, and Agile ways of working during product development. All capabilities should be related to new ways of working and updated individual skills.

I fully agreed with Peter’s final slide – we have to actively rethink and reshape PLM – not by calling it different but by learning, experimenting, and discussing in the field.

Digital Transformation Supporting Army Modernization

An interesting viewpoint related to modern PLM came from Dr. Raj Iyer, Chief Information Officer for IT Reform from the US Army. Rai walked us through some of the US Army’s challenges, and he gave us some fantastic statements to think about. Although an Army cannot be compared with a commercial business, its target remains to be always ahead of the competition and be aware of the competition.

Where we would say “data is the new oil”, Rai Iyer said: “Data is the ammunition of the future fight – as fights will more and more take place in cyberspace.”

The US Army is using a lot of modern technology – as the image below shows. The big difference here with regular businesses is that it is not about ROI but about winning fights.

Also, for the US Army, the cloud becomes the platform of the future. Due to the wide range of assets, the US Army has to manage, the importance of product data standards is evident. – Rai mentioned their contribution and adherence to the ISO 10303 STEP standard crucial for interoperability. It was an exciting insight into the US Army’s current and future challenges. Their primary mission remains to stay ahead of the competition.

Joining up Engineering Data without losing the M in PLM

![]() Nigel Shaw’s (Eurostep) presentation was somehow philosophical but precisely to the point what is the current dilemma in the PLM domain. Through an analogy of the internet, explaining that we live in a world of HTTP(s) linking, we create new ways of connecting information. The link becomes an essential artifact in our information model.

Nigel Shaw’s (Eurostep) presentation was somehow philosophical but precisely to the point what is the current dilemma in the PLM domain. Through an analogy of the internet, explaining that we live in a world of HTTP(s) linking, we create new ways of connecting information. The link becomes an essential artifact in our information model.

Where it is apparent links are crucial for managing engineering data, Nigel pointed out some of the significant challenges of this approach, as you can see from his (compiled) image below.

I will not discuss this topic further here as I am planning to come back to this topic when explaining the challenges of the future of PLM.

As Nigel said, they have a debate with one of their customers to replace the existing PLM tools or enhance the existing PLM tools. The challenge of moving from coordinated information towards connected data is a topic that we as a community should study.

Integration is about more than Model Format.

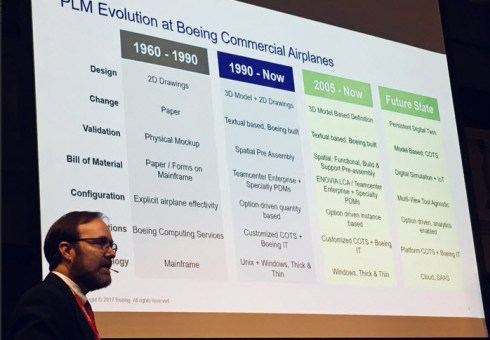

This was the presentation I have been waiting for. Mark Williams from Boeing had built the story together with Adrian Burton from Airbus. Nigel Shaw, in the previous session, already pointed to the challenge of managing linked information. Mark elaborated further about the model-based approach for system definition.

This was the presentation I have been waiting for. Mark Williams from Boeing had built the story together with Adrian Burton from Airbus. Nigel Shaw, in the previous session, already pointed to the challenge of managing linked information. Mark elaborated further about the model-based approach for system definition.

All content was related to the understanding that we need a model-based information infrastructure for the future because storing information in documents (the coordinated approach) is no longer viable for complex systems. Mark ‘slide below says it all.

Mark stressed the importance of managing model information in context, and it has become a challenge.

Mark mentioned that 20 years ago, the IDC (International Data Corporation) measured Boeing’s performance and estimated that each employee spent 2 ½ hours per day. In 2018, the IDC estimated that this number has grown to 30 % of the employee’s time and could go up to 50 % when adding the effort of reusing and duplicating data.

Mark mentioned that 20 years ago, the IDC (International Data Corporation) measured Boeing’s performance and estimated that each employee spent 2 ½ hours per day. In 2018, the IDC estimated that this number has grown to 30 % of the employee’s time and could go up to 50 % when adding the effort of reusing and duplicating data.

The consequence of this would be that a full-service enterprise, having engineering, manufacturing and services connected, probably loses 70 % of its information because they cannot find it—an impressive number asking for “clever” ways to find the correct information in context.

It is not about just a full indexed search of the data, as some technology geeks might think. It is also about describing and standardizing metadata that describes the models. In that context, Mark walked through a list of existing standards, all with their pros and cons, ending up with the recommendation to use the ISO 10303-243 – MoSSEC standard.

It is not about just a full indexed search of the data, as some technology geeks might think. It is also about describing and standardizing metadata that describes the models. In that context, Mark walked through a list of existing standards, all with their pros and cons, ending up with the recommendation to use the ISO 10303-243 – MoSSEC standard.

MoSSEC standing for Modelling and Simulation information in a collaborative Systems Engineering Context to manage and connect the relationships between models.

MoSSEC and its implication for future digital enterprises are interesting, considering the importance of a model-based future. I am curious how PLM Vendors and tools will support and enable the standard for future interoperability and collaboration.

Additive Manufacturing

– not as simple as paper printing – yet

Andreas Graichen from Siemens Energy closed the day, coming back to the new technologies’ topic: Additive Manufacturing or in common language 3D Printing. Andreas shared their Additive Manufacturing experiences, matching the famous Gartner Hype Cycle. His image shows that real work needs to be done to understand the technology and its use cases after the first excitement of the hype is over.

Material knowledge was one of the important topics to study when applying additive manufacturing. It is probably a new area for most companies to understand the material behaviors and properties in an Additive Manufacturing process.

The ultimate goal for Siemens Energy is to reach an “autonomous” workshop anywhere in the world where gas turbines could order their spare parts by themselves through digital warehouses. It is a grand vision, and Andreas confirmed that the scalability of Additive Manufacturing is still a challenge.

For rapid prototyping or small series of spare parts, Additive Manufacturing might be the right solution. The success of your Additive Manufacturing process depends a lot on how your company’s management has realistic expectations and the budget available to explore this direction.

Conclusion

Day 1 was enjoyable and educational, starting and ending with a focus on disruptive technologies. The middle part related to data the data management concepts needed for a digital enterprise were the most exciting topics to follow up in my opinion.

Next week I will follow up with reviewing day 2 and share my conclusions. The PLM Road Map & PDT Spring 2021 conference confirmed that there is work to do to understand the future (of PLM).

After “The PLM Doctor is IN #2,” now again a written post in the category of PLM and complementary practices/domains.

After PLM and Configuration Lifecycle ManagementCLM (January 2021) and PLM and Configuration Management CM (February 2021), now it is time to address the third interesting topic:

PLM and Supply Chain collaboration.

In this post, I am speaking with Magnus Färneland from Eurostep, a company well known in my PLM ecosystem, through their involvement in standards (STEP and PLCS), the PDT conferences, and their PLM collaboration hub, ShareAspace.

Supply Chain collaboration

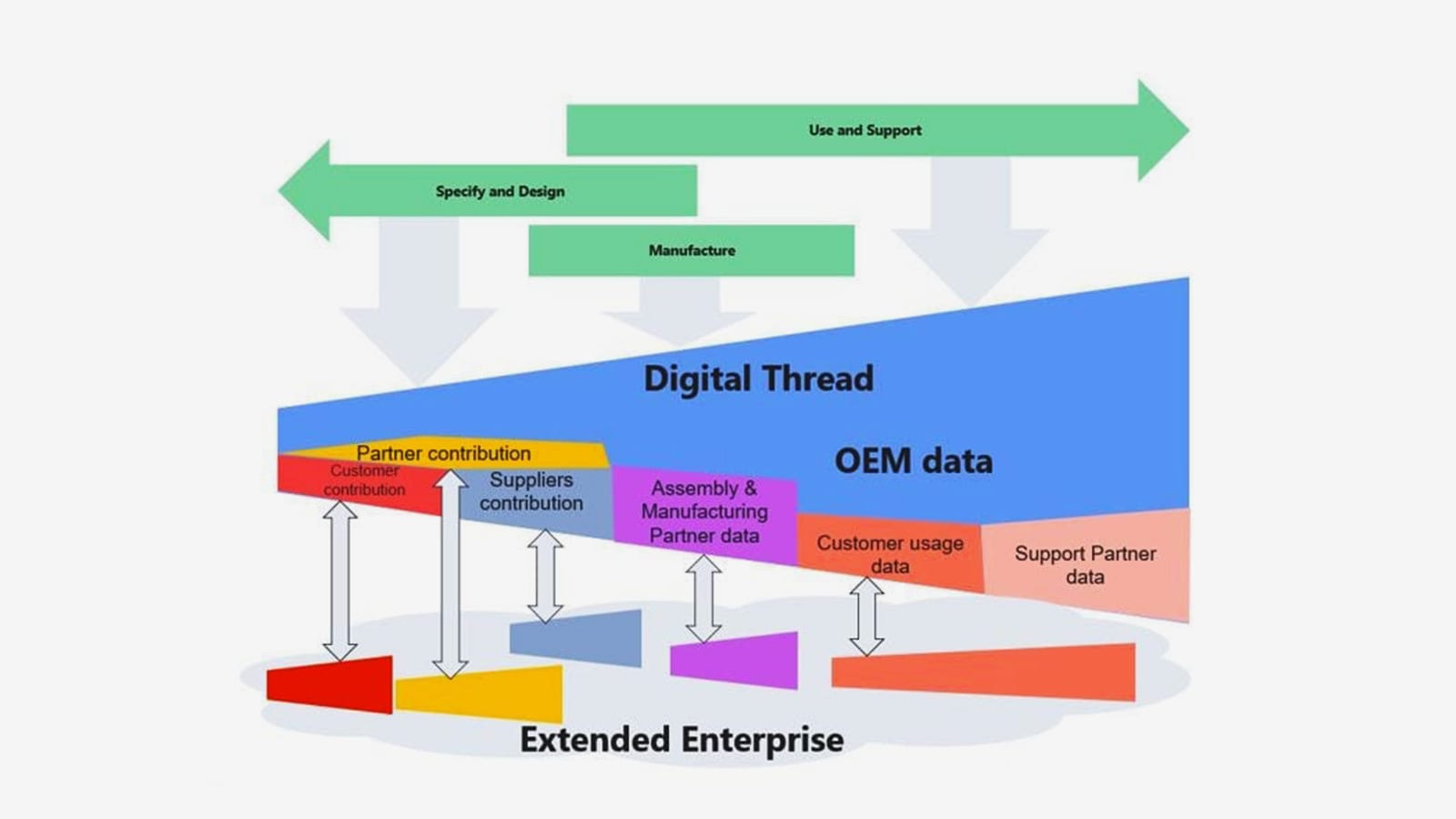

The interaction between OEMs and their suppliers has been a topic of particular interest to me. As a warming-up, read my post after CIMdata/PDT Roadmap 2020: PLM and the Supply Chain. In this post, I briefly touched on the Eurostep approach – having a Supply Chain Collaboration Hub. Below an image from that post – in this case, the Collaboration Hub is positioned between two OEMs.

Recently Eurostep shared a blog post in the same context: 3 Steps to remove data silos from your supply chain addressing the dreams of many companies: moving from disconnected information silos towards a logical flow of data. This topic is well suited for all companies in the digital transformation process with their supply chain. So, let us hear it from Eurostep.

Eurostep – the company / the mission

First of all, can you give a short introduction to Eurostep as a company and the unique value you are offering to your clients?

First of all, can you give a short introduction to Eurostep as a company and the unique value you are offering to your clients?

Eurostep was founded in 1994 by several world-class experts on product data and information management. In the year 2000, we started developing ShareAspace. We took all the experience we had from working with collaboration in the extended enterprise, mixed it with our standards knowledge, and selected Microsoft as the technology for our software platform.

Eurostep was founded in 1994 by several world-class experts on product data and information management. In the year 2000, we started developing ShareAspace. We took all the experience we had from working with collaboration in the extended enterprise, mixed it with our standards knowledge, and selected Microsoft as the technology for our software platform.

We now offer ShareAspace as a solution for product information collaboration in all three industry verticals where we are active: Manufacturing, Defense and AEC & Plant.

ShareAspace is based on an information standard called PLCS (ISO 10300-239). This means we have a data model covering the complete life cycle of a product from requirements and conceptual design to an existing installed base. We have added things needed, such as consolidation and security. Our partnership with Microsoft has also resulted in ShareAspace being available in Azure as a service (our Design to Manufacturing software).

ShareAspace is based on an information standard called PLCS (ISO 10300-239). This means we have a data model covering the complete life cycle of a product from requirements and conceptual design to an existing installed base. We have added things needed, such as consolidation and security. Our partnership with Microsoft has also resulted in ShareAspace being available in Azure as a service (our Design to Manufacturing software).

Why a supply chain collaboration hub?

Currently, most suppliers work in a disconnected manner with their clients – sending files up and down or the need to work inside the OEM environment. What are the reasons to consider a supply chain collaboration hub or, as you call it, a product information collaboration solution?

Currently, most suppliers work in a disconnected manner with their clients – sending files up and down or the need to work inside the OEM environment. What are the reasons to consider a supply chain collaboration hub or, as you call it, a product information collaboration solution?

The hub concept is not new per se. There are plenty of examples of file sharing hubs. Once you realize that sending files back and forth by email is a disaster for keeping control of your information being shared with suppliers, you would probably try out one of the available file-sharing alternatives.

The hub concept is not new per se. There are plenty of examples of file sharing hubs. Once you realize that sending files back and forth by email is a disaster for keeping control of your information being shared with suppliers, you would probably try out one of the available file-sharing alternatives.

However, after a while, you begin to realize that a file share can be quite time consuming to keep up to date. Files are being changed. Files are being removed! Some files are enormous, and you realize that you only need a fraction of what is in the file. References within one file to another file becomes corrupt because the other file is of a new version. Etc. Etc.

![]() This is about the time when you realize that you need similar control of the data you share with suppliers as you have in your internal systems. If not better.

This is about the time when you realize that you need similar control of the data you share with suppliers as you have in your internal systems. If not better.

A hub allows all partners to continue to use their internal tools and processes. It is also a more secure way of collaboration as the suppliers and partners are not let into the internal systems of the OEM.

Another significant side effect of this is that you only expose the data in the hub intended for external sharing and avoid sharing too much or exposing internal sensitive data.

A hub is also suitable for business flexibility as partners are not hardwired with the OEM. Partners can change, and IT systems in the value chain can change without impacting more than the single system’s connecting to the hub.

Should every company implement a supply chain collaboration hub?

Based on your experience, what types of companies should implement a supply chain collaboration hub and what are the expected benefits?

Based on your experience, what types of companies should implement a supply chain collaboration hub and what are the expected benefits?

The large OEMs and 1st tier suppliers certainly benefit from this since they can incorporate hundreds, if not thousands, of suppliers. Sharing technical data across the supply chain from a dedicated hub will remove confusions, improve control of the shared data, and build trust with their partners.

The large OEMs and 1st tier suppliers certainly benefit from this since they can incorporate hundreds, if not thousands, of suppliers. Sharing technical data across the supply chain from a dedicated hub will remove confusions, improve control of the shared data, and build trust with their partners.

With our cloud-based offering, we now also make it possible for at least mid-sized companies (like 200+ employees) to use ShareAspace. They may not have a well-adopted PLM system or the issues of communicating complex specifications originating from several internal sources. However still, they need to be professional in dealing with suppliers.

![]() The smallest client we have is a manufacturer of pool cleaners, a complex product with many suppliers. The company Weda [www.weda.se] has less than 10 employees, and they use ShareAspace as SaaS. With ShareAspace, they have improved their collaboration process with suppliers and cut costs and lowered inventory levels.

The smallest client we have is a manufacturer of pool cleaners, a complex product with many suppliers. The company Weda [www.weda.se] has less than 10 employees, and they use ShareAspace as SaaS. With ShareAspace, they have improved their collaboration process with suppliers and cut costs and lowered inventory levels.

ShareAspace can really scale big. It serves as a collaboration solution for the two new Aircraft carriers in the UK, the QUEEN ELIZABETH class. The aircraft carriers were built by a consortium that was closed in early 2020.

ShareAspace can really scale big. It serves as a collaboration solution for the two new Aircraft carriers in the UK, the QUEEN ELIZABETH class. The aircraft carriers were built by a consortium that was closed in early 2020.

ShareAspace is being used to hold the design data and other documentation from the consortium to be available to the multiple organizations (both inside and outside of the Ministry of Defence) that need controlled access.

What is the dependency on standards?

I always associate Eurostep with the PLCS (ISO 10303-239) standard, providing an information model for “hardware” products along the lifecycle. How important is this standard for you in the context of your ShareAspace offering?

I always associate Eurostep with the PLCS (ISO 10303-239) standard, providing an information model for “hardware” products along the lifecycle. How important is this standard for you in the context of your ShareAspace offering?

Should everyone adapt to this standard?

We have used PLCS to define the internal data schema in ShareAspace. This is an excellent starting point for capturing information from different systems and domains and still getting it to fit together. Why invent something new?

We have used PLCS to define the internal data schema in ShareAspace. This is an excellent starting point for capturing information from different systems and domains and still getting it to fit together. Why invent something new?

However, we can import data in most formats, and it does not have to be according to a standard. When connecting to Teamcenter, Windchill, Enovia, SAP, Oracle, Maximo etc., it is more often in a proprietary format than according to any standards.

On the other hand, in some industries like Defense, standards-based data exchange is required and put into contracts. Sometimes it prescribes PLCS. For the plant industry, it could be CFIHOS or ISO15926.

Supply Chain Collaboration and digital transformation

As stated at the beginning of this post, digital transformation is about connecting the information siloes through a digital thread. How important is this related to the supply chain?

As stated at the beginning of this post, digital transformation is about connecting the information siloes through a digital thread. How important is this related to the supply chain?

Many companies have come a long way in improving their internal management of product data. But still, the exchange and sharing of data with the external world has considerable potential for improvement. Just look at the chaos everyone has experienced with emails, still used a lot, in finding the latest Word document or PowerPoint file. Imagine if you collaborate on a ship, a truck, a power plant, or a piece of complex infrastructure. FTP is not the answer, and for product data, Dropbox is not doing the trick.

Many companies have come a long way in improving their internal management of product data. But still, the exchange and sharing of data with the external world has considerable potential for improvement. Just look at the chaos everyone has experienced with emails, still used a lot, in finding the latest Word document or PowerPoint file. Imagine if you collaborate on a ship, a truck, a power plant, or a piece of complex infrastructure. FTP is not the answer, and for product data, Dropbox is not doing the trick.

A Digital Thread must support versions and changes in all directions, as changes are natural with reasonably advanced products. Much of the information created about or around a product is generated within the supply chain, like production parameters, test and inspection protocols, certifications, and more. Without an intelligent way of capturing this data, companies will continue to spend a fortune on administration trying to manage this manually.

As the Digital Thread extends across the value chain, a useful sharing tool is needed to allow for configuration management across the complete chain – ShareAspace is designed for this. The great thing with PLCS is that it gives a standard model for the Digital Thread covering several Digital Twins. PLCS adds the life cycle component, which is essential, and there is no alternative. Therefore, we are welcome with ShareAspace and PLCS to add capabilities to snapshot standards like IFC etc., that are outside the STEP series of standards.

Learning more

We discussed that a supply chain collaboration hub can have specific value to a company. Where can readers learn more?

There is a lot of information available. Of course, on our Eurostep website, you will find information under the tab Resources or on the ShareAspace website under the tab News.

Other sources are:

What I have learned

- I am surprised to see that the type of Supplier Collaboration Platform delivered by Eurostep is not a booming market. Where Time to Market is significantly impacted by how companies work with their suppliers, most companies still rely on the exchange of data packages.

- The most advanced exchanges are using a model-based definition if relevant. Traditional PLM Vendors will not develop such platforms as the platform needs to be agnostic in both directions.

- Having a recommended data model based on PLCS or a custom-data model in case of a large OEM can provide such a collaboration hub. Relative easy to implement (as you do not change your own PLM) and relatively easy to scale (adding a new supplier is easy). For me, the supplier collaboration platform is a must in a modern, digital connected enterprise.

Conclusion

A lot of marketing money is spent on “Digital Thread” or “Digital Continuity”. If you are looking at the full value chain of product development and operational support, there are still many manual hand-over processes with suppliers. A supplier collaboration hub might be the missing piece of the puzzle to realize a real digital thread or continuity.

Last week I shared the first impression from my favorite conference, the PLM Roadmap / PDT conference organized by CIMdata and Eurostep. You can read some of the highlights here: The weekend after PLM Roadmap / PDT 2019 Day 1.

Last week I shared the first impression from my favorite conference, the PLM Roadmap / PDT conference organized by CIMdata and Eurostep. You can read some of the highlights here: The weekend after PLM Roadmap / PDT 2019 Day 1.

Click on the logo to see what was the full agenda. In this post, I will focus on some of the highlights of day 2.

Chernobyl, The megaproject with the New Arch

Christophe Portenseigne from the Bouygues Construction Group shared with us his personal story about this megaproject, called Novarka. 33 years ago, reactor #4 exploded and has been confined with an object shelter within six months in 1986. This was done with heroic speed, and it was anticipated that the shelter would only last for 20 – 30 years. You can read about this project here.

Christophe Portenseigne from the Bouygues Construction Group shared with us his personal story about this megaproject, called Novarka. 33 years ago, reactor #4 exploded and has been confined with an object shelter within six months in 1986. This was done with heroic speed, and it was anticipated that the shelter would only last for 20 – 30 years. You can read about this project here.

The Novarka project was about creating a shelter for Confinement of the radioactive dust and protection of the existing against external actions (wind, water, snow…) for the next 100 years!

And even necessary, the inside the arch would be a plant where people could work safely on the process of decommissioning the existing contaminated structures. You can read about the full project here at the Novarka website.

What impressed me the most the personal stories of Christophe taking us through some of the massive challenges that need to be solved with innovative thinking. High complexity, a vast number of requirements, many parties, stakeholders involved closed in June 2019. As Christophe mentioned, this was a project to be proud of as it creates a kind of optimism that no matter how big the challenges are, with human ingenuity and effort, we can solve them.

A Model Factory for the Efficient Development of High Performing Vehicles

Eric Landel, expert leader for Numerical Modeling and Simulation at Renault, gave us an interesting insight into an aspect of digitalization that has become very valuable, the connection between design and simulation to develop products, in this case, the Renault CLIO V, as much as possible in the virtual world. You need excellent simulation models to match future reality (and tests). The target of simulation was to get the highest safety test results in the Europe NCAP rating – 5 stars.

The Renault modeling factory implemented a digital loop (below) to ensure that at the end of the design/simulation, a robust design would exist. Eric mentioned that for the Clio, they did not build a prototype anymore. The first physical tests were done on cars coming from the plant. Despite the investment in simulation software, a considerable saving in crash part over cost before TGA (Tooling Go Ahead).

Combined with the savings, the process has been much faster than before. From 10 weeks for a simulation loop towards 4 weeks. The next target is to reduce this time to 1 week. A real example of digitization and a connected model-based approach.

From virtual prototype to hybrid twin

ESI – their sponsor session Evolving from Virtual Prototype Testing to Hybrid Twin: Challenges & Benefits was an excellent complementary session to the presentation from Renault

PLM, MBSE and Supply chain – challenges and opportunities

Nigel Shaw’s presentation was one of my favorite presentations, as Nigel addressed the same topics that I have been discussing in the past years. His focus was on collaboration between the OEM and supplier with the various aspects of requirements management, configuration management, simulation and the different speeds of PLM (focus on mechanical) and ALM (focus on software)

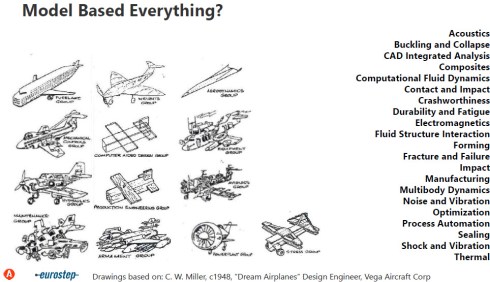

How can such activities work in a digitally-connected environment instead of a document-based approach? Nigel looked into the various aspects of existing standards in their domains and their future. There is a direction to MBE (Model-Based Everything) but still topics to consider. See below:

I agree with Nigel – the future is model-based – when will be the issue for the market leaders.

The ISO AP239 ed3 Project and the Through Life Cycle Interoperability Challenge

Yves Baudier from AFNET, a reference association in France regarding industry digitation, digital threads, and digital processes for Extended Enterprise/Supply chain. All about a digital future and Yves presentation was about the interoperability challenge, mentioning three of my favorite points to consider:

- Data becoming more and more a strategic asset – as digitalization of Industry and Services, new services enabled by data analytics

- All engineering domains (from concept design to system end of life) need to develop a data-centric approach (not only model-centric)– An opportunity for PLM to cover the full life-cycle

- Effectivity and efficiency of data interoperability through the life-cycle is now an essential industry requirement – e.g., “virtual product” and “digital twin” concepts

All the points are crucial for the domain of PLM.

In that context, Yves discussed the evolution of the ISO 10303-239 standard, also known as PLCS. The target with ISO AP239 ed3 is to become the standard for Aerospace and Defense for the full product lifecycle and through this convergence being able to push IT/PLM Vendors to comply – crucial for a digital enterprise

Time for the construction / civil industry

Christophe Castaing, director of digital engineering at Egis, shared with us their solution framework to manage large infrastructure projects by focusing on both the Asset Information (BIM-based) and the collaborative processes between the stakeholders, all based on standards. It was a broad and in-depth presentation – too much to share in a blog post. To conclude (see also Christophe’s slide below) in the construction industry more and more, there is the desire to have a digital twin of a given asset (building/construction), creating the need for standard information models.

Pierre Benning, IT director from Bouygues Public Works gave us an update on the MINnD project. MINnD standing for Modeling INteroperable INformation for sustainable INfrastructures in xD, a French research project dedicated to the deployment of BIM and digital engineering in the infrastructure sector. Where BIM has been starting from the construction industry, there is a need for a similar, digital modeling approach for civil infrastructure. In 2014 Christophe Castaing already reported the activities of the MINnD project – see The weekend after PDT 2014. Now Pierre was updating us on what are the activities for MINnD Season 2 – see below:

As you can see, again, the interest in digital twins for operations and maintenance. Perhaps here, the civil infrastructure industry will be faster than traditional industries because of its enormous value. BIM and GIS reconciliation is a precise topic as many civil infrastructures have a GIS aspect – Road/Train infrastructure for example. The third bullet is evident to me. With digitization and the integration of contractors and suppliers, BIM and PLM will be more-and-more conceptual alike. The big difference still at this moment: BIM has one standard framework where PLM-standards are still not in a consolidation stage.

Digital Transformation for PLM is not an evolution

If you have been following my blog in the past two years, you may have noticed that I am exploring ways to solve the transition from traditional, coordinated PLM processes towards future, connected PLM. In this session, I shared with the audience that digital transformation is disruptive for PLM and requires thinking in two modes.

If you have been following my blog in the past two years, you may have noticed that I am exploring ways to solve the transition from traditional, coordinated PLM processes towards future, connected PLM. In this session, I shared with the audience that digital transformation is disruptive for PLM and requires thinking in two modes.

Thinking in two modes is not what people like, however, organizations can run in two modes. Also, I shared some examples from digital transformation stories that illustrate there was no transformation, either failure or smoke, and mirrors. You can download my presentation via SlideShare here.

Fireplace discussion: Bringing all the Trends Together, What’s next

We closed the day and the conference with a fireplace chat moderated by Dr. Ken Versprille from CIMdata, where we discussed, among other things, the increasing complexity of products and products as a service. We have seen during the sessions from BAE Systems Maritime and Bouygues Construction Group that we can do complex projects, however, when there are competition and time to deliver pressure, we do not manage the project so much, we try to contain the potential risk. It was an interactive fireplace giving us enough thoughts for next year.

Conclusion

Nothing to add to Håkan Kårdén’s closing tweet – I hope to see you next year.

The usage of standards has been a recurring topic the past 10 months, probably came back to the surface at PI PLMx Chicago during the PLM Leaders panel discussion. If you want to refresh the debate, Oleg Shilovitsky posted an overview: What vendors are thinking about PLM standards – Aras, Dassault Systemes, Onshape, Oracle PLM, Propel PLM, SAP, Siemens PLM.

It is clear for vendors when they would actively support standards they reduce their competitive advantage, after all, you are opening your systems to connect to other vendor solutions, reducing the chance to sell adjacent functionality. We call it vendor lock-in. If you think this approach only counts for PLM, I would suggest you open your Apple (iPhone) and think about vendor lock-in for a moment.

It is clear for vendors when they would actively support standards they reduce their competitive advantage, after all, you are opening your systems to connect to other vendor solutions, reducing the chance to sell adjacent functionality. We call it vendor lock-in. If you think this approach only counts for PLM, I would suggest you open your Apple (iPhone) and think about vendor lock-in for a moment.

Vendors will only adhere to standards when pushed by their customers, and that is why we have a wide variety of standards in the engineering domain.

Take the example of JT as a standard viewing format, heavily pushed by Siemens for the German automotive industry to be able to work downstream with CATIA and NX models. There was a JT-version (v9.5) that reached ISO 1306 alignment, but after that, Siemens changed JT (v10) again to optimize their own exchange scenarios, and the standard was lost.

Take the example of JT as a standard viewing format, heavily pushed by Siemens for the German automotive industry to be able to work downstream with CATIA and NX models. There was a JT-version (v9.5) that reached ISO 1306 alignment, but after that, Siemens changed JT (v10) again to optimize their own exchange scenarios, and the standard was lost.

And as customers did not complain (too much), the divergence continued. So it clear vendors will not maintain standards out of charity as your business does not work for charity either (or do you ?). So I do not blame them is there is no push from their customers to maintain them.

What about standards?

The discussion related to standards flared up around the IpX ConX19 conference and a debate between Oleg & Hakan Kardan (EuroSTEP) where Hakan suggested that PLCS could be a standard data model for the digital thread – you can read Oleg’s view here: Do we need a standard like PLCS to build a digital thread.

Oleg’s opening sentence made me immediately stop reading further as more and more I am tired of this type of framing if you want to do a serious discussion based on arguments. Such a statement is called framing and in particular in politics we see the bad examples of framing.

Standards are like toothbrushes, a good idea, but no one wants to use anyone else’s. The history of engineering and manufacturing software is full of stories about standards.

This opening sentence says all about the mindset related to standards – it is a one-liner – not a fact. It could have been a tweet in this society of experts.