You are currently browsing the category archive for the ‘Modularity’ category.

Within the PLM Green Global Alliance (PGGA), we had an internal kick-off meeting related to the topic of Design for Sustainability. As you might have seen on our website, Erik Rieger, PLM Evangelist and now working for PTC, took the initiative to start this focus group.

Within the PLM Green Global Alliance (PGGA), we had an internal kick-off meeting related to the topic of Design for Sustainability. As you might have seen on our website, Erik Rieger, PLM Evangelist and now working for PTC, took the initiative to start this focus group.

You might know Erik from a previous interview from the PGGA where we discussed TTPSC’s ecoPLM offering based on Windchill: PLM and Sustainability: talking about ecoPLM.

When Erik announced the Design for Sustainability initiative, it was Matthew Sullivan from CIMPA PLM Service who immediately contacted Erik to work together on this initiative.

When Erik announced the Design for Sustainability initiative, it was Matthew Sullivan from CIMPA PLM Service who immediately contacted Erik to work together on this initiative.

And again, you might know CIMPA PLM services from our recent interview with them related to regulations and best practices related to sustainability in the aerospace industry (CSRD, LCA, DPP, AI and more): PLM and Sustainability: talking with CIMPA.

Erik and Matthew decided to participate in an introductory interview, during which they shared their background, passion, and goals related to Design for Sustainability.

Watch the episode here:

Why Design for Sustainability?

Design for Sustainability (DfS) is an approach to designing products, services, systems, and experiences that prioritize environmental, social, and economic sustainability throughout their entire lifecycle. It means creating things in a way that reduces negative impacts on the planet and people while still being functional, profitable, and desirable.

In theory, this should be one of the key areas in which our PGGA members can have a common discussion.

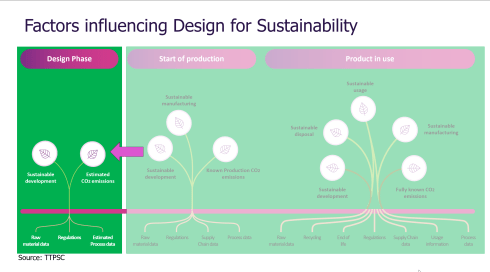

As Erik mentions, it is estimated that 80 % of the environmental impact is defined during the design phase. This is a number that has been coming back in several of our PGGA discussions with all the other software vendors.

More on Design for Sustainability

Just after the recording, Dave Duncan, head of Sustainability at PTC, published the eBook Product Sustainability for Dummies. An excellent book that brings all aspects of sustainability and products together in an easy-to-digest manner. There is also a chapter on Design for Sustainability in the eBook.

Just after the recording, Dave Duncan, head of Sustainability at PTC, published the eBook Product Sustainability for Dummies. An excellent book that brings all aspects of sustainability and products together in an easy-to-digest manner. There is also a chapter on Design for Sustainability in the eBook.

Note: Dave Duncan is a recognized PGGA leader in PLM and Sustainability, as we reported last year.

Read the post here: Leaders in PLM and Sustainability – December 2024

A call for action

We hope you watched and enjoyed the interview with Erik and Matthew as an inspiration to become active in this Design for Sustainability discussion group.

The intention is, as mentioned, to share experiences and discuss challenges within the group. It will be a private group where people can discuss openly to avoid any business conflicts. The plan is to start with an initial kick-off Zoom meeting in June the date still to be fixed.

The intention is, as mentioned, to share experiences and discuss challenges within the group. It will be a private group where people can discuss openly to avoid any business conflicts. The plan is to start with an initial kick-off Zoom meeting in June the date still to be fixed.

If you are interested in joining this exciting discussion group, please contact Erik Rieger, who will be the focal point for this group. We are looking forward to your contribution, and now is the time to prepare and act.

Join us in the discussion

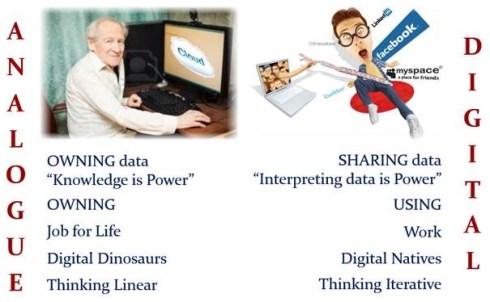

In my business ecosystem, I have seen a lot of discussions about technical and architectural topics since last year that are closely connected to the topic of artificial intelligence. We are discussing architectures and solutions that will make our business extremely effective. The discussion is mostly software vendor-driven as vendors usually do not have to deal with the legacy, and they can imagine focusing on the ultimate result.

Legacy (people, skills, processes and data) is the mean inhibitor for fast forward in such situations, as I wrote in my previous post: Data, Processes and AI.

However, there are also less visible discussions about business efficiency – methodology and business models – and future sustainability.

These discussions are more challenging to follow as you need a broader and long-term vision, as implementing solutions/changes takes much longer than buying tools.

These discussions are more challenging to follow as you need a broader and long-term vision, as implementing solutions/changes takes much longer than buying tools.

This time, I want to revisit the discussion on modularity and the need for business efficiency and sustainability.

Modularity – what is it?

Modularity is a design principle that breaks a system into smaller, independent, and interchangeable components, or modules, that function together as a whole. Each module performs a specific task and can be developed, tested, and maintained separately, improving flexibility and scalability.

Modularity is a design principle that breaks a system into smaller, independent, and interchangeable components, or modules, that function together as a whole. Each module performs a specific task and can be developed, tested, and maintained separately, improving flexibility and scalability.

Modularity is a best practice in software development. Although modular thinking takes a higher initial effort, the advantages are enormous for reuse, flexibility, optimization, or adding new functionality. And as software code has no material cost or scrap, modular software solutions excel in delivery and maintenance.

In the hardware world, this is different. Often, companies have a history of delivering a specific (hardware) solution, and the product has been improved by adding features and options where the top products remain the company’s flagships.

In the hardware world, this is different. Often, companies have a history of delivering a specific (hardware) solution, and the product has been improved by adding features and options where the top products remain the company’s flagships.

Modularity enables easy upgrades and replacements in hardware and engineering, reducing costs and complexity. As I work mainly with manufacturing companies in my network, I will focus on modularity in the hardware world.

Modularity – the business goal

How often have you heard that a business aims to transition from Engineering to Order (ETO) to Configure/Build to Order (BTO) or Assemble to Order (ATO)? Companies often believe that the starting point of implementing a PLM system is enough, as it will help identify commonalities in product variations, therefore leading to more modular products.

The primary targeted business benefits often include reduced R&D time and cost but also reduced risk due to component reuse and reuse of experience. However, the ultimate goal for CTO/ATO companies is to minimize R&D involvement in their sales and delivery process.

The primary targeted business benefits often include reduced R&D time and cost but also reduced risk due to component reuse and reuse of experience. However, the ultimate goal for CTO/ATO companies is to minimize R&D involvement in their sales and delivery process.

More options can be offered to potential customers without spending more time on engineering.

Four years ago, I discussed modularity with Björn Eriksson and Daniel Strandhammar, who wrote “The Modular Way” during the COVID-19 pandemic. I liked the book because it is excellent for understanding the broader scope of modularity along with marketing, sales, and long-term strategy. Each business type has its modularity benefits.

Four years ago, I discussed modularity with Björn Eriksson and Daniel Strandhammar, who wrote “The Modular Way” during the COVID-19 pandemic. I liked the book because it is excellent for understanding the broader scope of modularity along with marketing, sales, and long-term strategy. Each business type has its modularity benefits.

I had a follow-up discussion with panelists active in modularization and later with Daniel Strandhammar about the book’s content in this blog post: PLM and Modularity.

Next, I got involved with the North European Modularity Network (NEM) group, a group of Scandinavian companies that share modularization experiences and build common knowledge.

Historically, modularization has been a popular topic in North Europe, and meanwhile, the group is expanding beyond Scandinavia. Participants in the group focus on education-sharing strategies rather than tools.

Historically, modularization has been a popular topic in North Europe, and meanwhile, the group is expanding beyond Scandinavia. Participants in the group focus on education-sharing strategies rather than tools.

The 2023 biannual meeting I attended hosted by Vestas in Ringkobing was an eye-opener for me.

We should work more integrated, not only on the topic of Modularity and PLM but also on a third important topic: Sustainability in the context of the Circular Economy.

You can review my impression of the event and presentation in my post: “The week after North European Modularity (NEM)“

That post concludes that Modularity, like PLM, is a strategy rather than an R&D mission. Integrating modularity topics into PLM conferences or Circular Economy events would facilitate mutual learning and collaboration.

That post concludes that Modularity, like PLM, is a strategy rather than an R&D mission. Integrating modularity topics into PLM conferences or Circular Economy events would facilitate mutual learning and collaboration.

Modularity and Sustainability

The PLM Green Global Alliance started in 2020 initially had few members. However, after significant natural disasters and the announcement of regulations related to the European Green Deal, sustainability became a management priority. Greenwashing was no longer sufficient.

The PLM Green Global Alliance started in 2020 initially had few members. However, after significant natural disasters and the announcement of regulations related to the European Green Deal, sustainability became a management priority. Greenwashing was no longer sufficient.

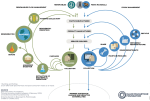

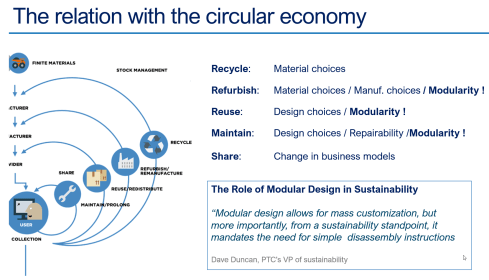

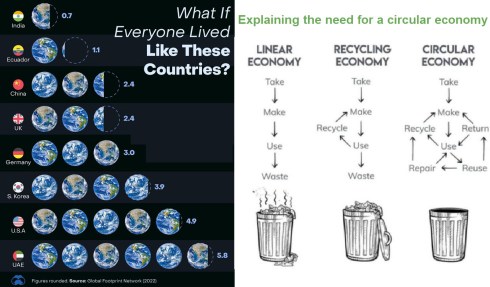

One key topic discussed in the PLM Green Global Alliance is the circular economy moderated by CIMPA PLM services. The circular economy is crucial as our current consumption of Earth’s resources is unsustainable.

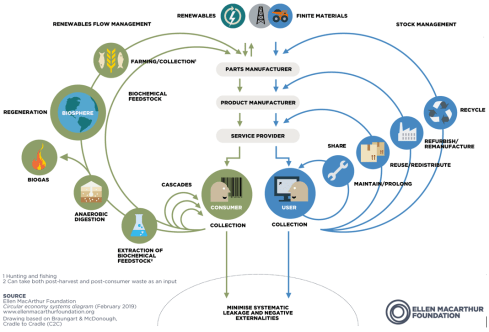

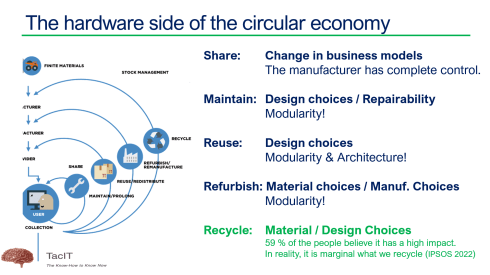

The well-known butterfly diagram from the Ellen MacArthur Foundation below, illustrates the higher complexity of a circular economy, both for the renewables (left) and the hardware (right)

In a circular economy, modularity is essential. The SHARE loop focuses on a Product Service Model, where companies provide services based on products used by different users. This approach requires a new business model, customer experience, and durable hardware. After Black Friday last year, I wrote about this transition: The Product Service System and a Circular Economy.

Modularity is vital in the MAINTAIN/PROLONG loop. Modular products can be upgraded without replacing the entire product, and modules are easier to repair. An example is Fairphone from the Netherlands, where users can repair and upgrade their smartphones, contributing to sustainability.

In the REUSE/REMANUFACTURE loop, modularity allows for reusing hardware parts when electronics or software components are upgraded. This approach reduces waste and supports sustainability.

The REFURBISH/REMANUFACTURE loop also benefits from modularity, though to a lesser extent. This loop helps preserve scarce materials, such as batteries, reducing the need for resource extraction from places like the moon, Mars, or Greenland.

A call for action

If you reached this point of the article, my question is now to reflect on your business or company. Modularity is, for many companies, a dream (or vision) and will become, for most companies, a must to provide a sustainable business.

If you reached this point of the article, my question is now to reflect on your business or company. Modularity is, for many companies, a dream (or vision) and will become, for most companies, a must to provide a sustainable business.

Modularity does not depend on PLM technology, as famous companies like Scania, Electrolux and Vestas have shown (in my reference network).

Where is your company and its business offerings?

IMPORTANT:

IMPORTANT:

If you aim to implement modularity to support the concepts of the Circular Economy, make sure you do it in a data-driven, model-based environment – here, technology counts.

Conclusion

Don’t miss the focus on the potential relevance of modularity for your company. Modularity improves business and sustainability, AND it touches all enterprise stakeholders. Technology alone will not save the business. Your thoughts?

Do you want to learn more about implementing PLM at an ETO space company?

Listen to our latest podcast: OHB’s Digital Evolution: Transforming Aerospace PLM with Lucía Núñez Núñez

It was a great pleasure to attend my favorite vendor-neutral PLM conference this year in Gothenburg—approximately 150 attendees, where most have expertise in the PLM domain.

It was a great pleasure to attend my favorite vendor-neutral PLM conference this year in Gothenburg—approximately 150 attendees, where most have expertise in the PLM domain.

We had the opportunity to learn new trends, discuss reality, and meet our peers.

The theme of the conference was:Value Drivers for Digitalization of the Product Lifecycle, a topic I have been discussing in my recent blog posts, as we need help and educate companies to understand the importance of digitalization for their business.

The two-day conference covered various lectures – view the agenda here – and of course the topic of AI was part of half of the lectures, giving the attendees a touch of reality.

The two-day conference covered various lectures – view the agenda here – and of course the topic of AI was part of half of the lectures, giving the attendees a touch of reality.

In this first post, I will cover the main highlight of Day 1.

Value Drivers for Digitalization of the Product Lifecycle

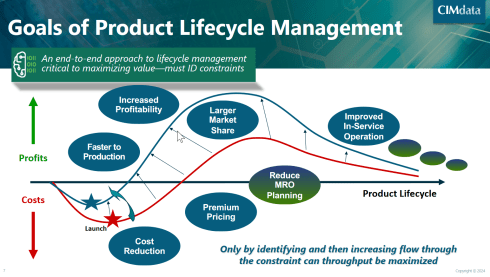

As usual, the conference started with Peter Bilello, president & CEO of CIMdata, stressing again that when implementing a PLM strategy, the maximum result comes from a holistic approach, meaning look at the big picture, don’t just focus on one topic.

As usual, the conference started with Peter Bilello, president & CEO of CIMdata, stressing again that when implementing a PLM strategy, the maximum result comes from a holistic approach, meaning look at the big picture, don’t just focus on one topic.

It was interesting to see again the classic graph (below) explaining the benefits of the end-to-end approach – I believe it is still valid for most companies; however, as I shared in my session the next day, implementing concepts of a Products Service System will require more a DevOp type of graph (more next week).

Next, Peter went through the CIMdata’s critical dozen with some updates. You can look at the updated 2024 image here.

Some of the changes: Digital Thread and Digital Twin are merged– as Digital Twins do not run on documents. And instead of focusing on Artificial Intelligence only, CIMdata introduced Augmented Intelligence as we should also consider solutions that augment human activities, not just replace them.

Some of the changes: Digital Thread and Digital Twin are merged– as Digital Twins do not run on documents. And instead of focusing on Artificial Intelligence only, CIMdata introduced Augmented Intelligence as we should also consider solutions that augment human activities, not just replace them.

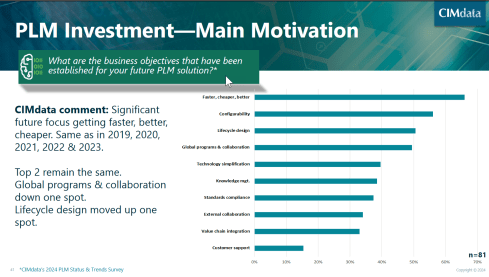

Peter also shared the results of a recent PLM survey where companies were asked about their main motivation for PLM investments. I found the result a little discouraging for several reasons:

The number one topic is still faster, cheaper and better – almost 65 % of the respondents see this as their priority. This number one topic illustrates that Sustainability has not reached the level of urgency, and perhaps the topic can be found in standards compliance.

Many of the companies with Sustainability in their mission should understand that a digital PLM infrastructure is the foundation for most initiatives, like Lifecycle Analysis (LCA). Sustainability is more than part of standards compliance, if it was mentioned anyway.

Many of the companies with Sustainability in their mission should understand that a digital PLM infrastructure is the foundation for most initiatives, like Lifecycle Analysis (LCA). Sustainability is more than part of standards compliance, if it was mentioned anyway.

The second disappointing observation for the understanding of PLM is that customer support is mentioned only by 15 % of the companies. Again, connecting your products to your customers is the first step to a DevOp approach, and you need to be able to optimize your product offering to what the customer really wants.

Digital Transformation of the Value Chain in Pharma

The second keynote was from Anders Romare, Chief Digital and Information Officer at Novo Nordisk. Anders has been participating in the PDT conference in the past. See my 2016 PLM Roadmap/PDT Europe post, where Anders presented on behalf of Airbus: Digital Transformation through an e2e PLM backbone.

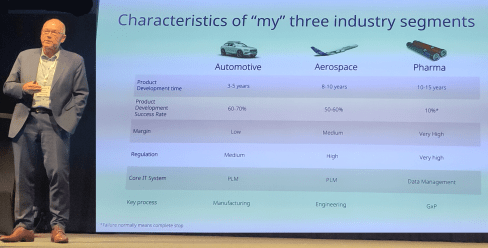

Anders started by sharing some of the main characteristics of the companies he has been working for. Volvo, Airbus and now Novo Nordisk. It is interesting to compare these characteristics as they say a lot about the industry’s focus. See below:

Anders is now responsible for digital transformation in Novo Nordisk, which is a challenge in a heavily regulated industry.

One of the focus areas for Novo Nordisk in 2024 is also Artificial Intelligence, as you can see from the image to the left (click on it for the details).

One of the focus areas for Novo Nordisk in 2024 is also Artificial Intelligence, as you can see from the image to the left (click on it for the details).

As many others in this conference, Anders mentioned AI can only be applicable when it runs on top of accurate data.

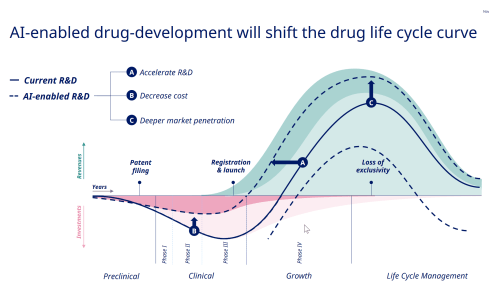

Understanding the potential of AI, they identified 59 areas where AI can create value for the business, and it is interesting to compare the traditional PLM curve Peter shared in his session with the potential AI-enabled drug-development curve as presented by Anders below:

Next, Anders shared some of the example cases of this exploration, and if you are interested in the details, visit their tech.life site.

When talking about the engineering framing of PLM, it was interesting to learn from Anders, who had a long history in PLM before Novo Nordisk, when he replied to a question from the audience that he would never talk about PLM at the management level. It’s very much aligned with my Don’t mention the P** word post.

A Strategy for the Management of Large Enterprise PLM Platforms

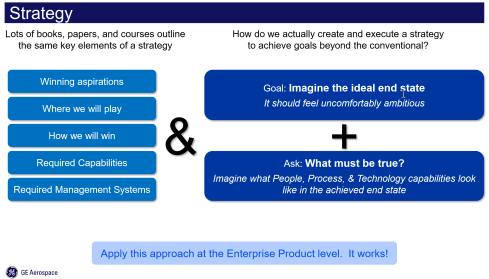

One of the highlights for me on Day 1 was Jorgen Dahl‘s presentation. Jorgen, a senior PLM director at GE Aerospace, shared their story towards a single PLM approach needed due to changes in businesses. And addressing the need for a digital thread also comes with an increased need for uptime.

I like his strategy to execution approach, as shown in the image below, as it contains the most important topics. The business vision and understanding, the imagination of the end status and What must be True?

In my experience, the three blocks are iteratively connected. When describing the strategy, you might not be able to identify the required capabilities and management systems yet.

But then, when you start to imagine the ideal end state, you will have to consider them. And for companies, it is essential to be ambitious – or, as Jorgen stated, uncomfortable ambitious. Go for the 75 % to almost 100 % to be true. Also, asking What must be True is an excellent way to allow people to be involved and creatively explore the next steps.

Note: This approach does not provide all the details, as it will be a multiyear journey of learning and adjusting towards the future. Therefore, the strategy must be aligned with the culture to avoid continuous top-down governance of the details. In that context, Jorgen stated:

“Culture is what happens when you leave the room.”

It is a more positive statement than the famous Peter Drucker’s quote: “Culture eats strategy for breakfast.”

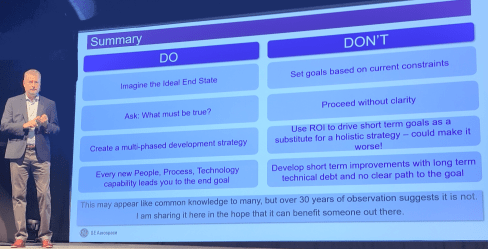

Jorgen’s concluding slide mentions potential common knowledge, although I believe the way Jorgen used the right easy-to-digest points will be helpful for all organizations to step back, look at their initiatives, and compare where they can improve.

How a Business Capability Model and Application Portfolio Management Support Through Changing Times

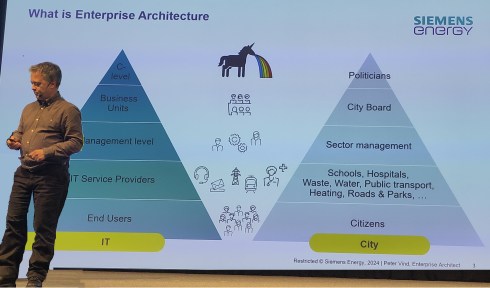

Peter Vind‘s presentation was nicely connected to the presentation from Jorgen Dahl. Peter, who is an enterprise architect at Siemens Energy, started by explaining where the enterprise architect fits in an organization and comparing it to a city.

In his entertaining session, he mentioned he has to deal with the unicorns at the C-level, who, like politicians in a city, sometimes have the most “innovative” ideas – can they be realized?

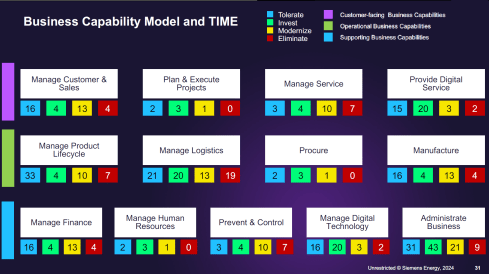

Peter explained how they used Business Capability Modeling when Siemens Energy went through various business stages. First, the carve-out from Siemens AG and later the merger with Siemens Gamesa. Their challenge is to understand which capabilities remain, which are new or overlapping, both during the carve-out and merging process.

The business capability modeling leads to a classification of the applications used at different levels of the organization, such as customer-facing, operational, or supporting business capabilities.

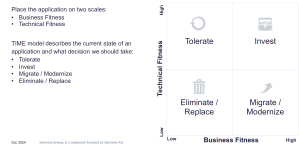

Next, for the lifecycle of the applications, the TIME approach was used, meaning that each application was mapped to business fitness and technical fitness. Click on the diagram to see the details.

The result could look like the mapping shown below – a comprehensive overview of where the action is

It is a rational approach; however, Peter mentioned that we also should be aware of the HIPPOs in an organization. If there is a HiPPO (Highest Paid Person’s Opinion) in play, you might face a political battle too.

It was a great educational session illustrating the need for an Enterprise Architect, the value of business capabilities modeling and the TIME concept.

And some more …

There were several other exciting presentations during day 1; however, as not all presentations are publicly available, I cannot discuss them in detail; I just looked at my notes.

Driving Trade Compliance and Efficiency

Peter Sandeck, Director of Project Management at TE Connectivity shared what they did to motivate engineers to endorse their Jurisdiction and Classification Assessment (JCA) process. Peter showed how, through a Minimal Viable Product (MVP) approach and listening to the end-users, they reached a higher Customer Satisfaction (CSAT) score after several iterations of the solution developed for the JCA process.

Peter Sandeck, Director of Project Management at TE Connectivity shared what they did to motivate engineers to endorse their Jurisdiction and Classification Assessment (JCA) process. Peter showed how, through a Minimal Viable Product (MVP) approach and listening to the end-users, they reached a higher Customer Satisfaction (CSAT) score after several iterations of the solution developed for the JCA process.

This approach is an excellent example of an agile method in which engineers are involved. My remaining question is still – are the same engineers in the short term also pushed to make lifecycle assessments? More work; however, I believe if you make it personal, the same MVP approach could work again.

Value of Model-Based Product Architecture

Jussi Sippola, Chief Expert, Product Architecture Management & Modularity at Wärtsilä, presented an excellent story related to the advantages of a more modular product architecture. Where historically, products were delivered based on customer requirements through the order fulfillment process, now there is in parallel the portfolio management process, defining the platform of modules, features and options.

Jussi Sippola, Chief Expert, Product Architecture Management & Modularity at Wärtsilä, presented an excellent story related to the advantages of a more modular product architecture. Where historically, products were delivered based on customer requirements through the order fulfillment process, now there is in parallel the portfolio management process, defining the platform of modules, features and options.

Jussi mentioned that they were able to reduce the number of parts by 50 % while still maintaining the same level of customer capabilities. In addition, thanks to modularity, they were able to reduce the production lead time by 40 % – essential numbers if you want to remain competitive.

Conclusion

Day 1 was a day where we learned a lot as an audience, and in addition, the networking time and dinner in the evening were precious for me and, I assume, also for many of the participants. In my next post, we will see more about new ways of working, the AI dream and Sustainability.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago, in 2022, with the initial PLM vendors followed by additional software vendors and implementers who focus on Sustainability.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago, in 2022, with the initial PLM vendors followed by additional software vendors and implementers who focus on Sustainability.

The list is getting longer, and for some of them, we are now in the second round, learning what has happened in the field with their customers.

You can always read about these interviews on our PLM Green Global Alliance website or subscribe to the YouTube channel: @PLM_Global_Green_Alliance where we share the interview recordings.

This time, we spoke with Henrik Hulgaard from Configit. I spoke earlier with Henrik about Configuration Lifecycle Management – you can read our discussion here. Now, we talked about the relationship between Configit and Sustainability.

This time, we spoke with Henrik Hulgaard from Configit. I spoke earlier with Henrik about Configuration Lifecycle Management – you can read our discussion here. Now, we talked about the relationship between Configit and Sustainability.

Configit

![]() Configit is not a typical PLM or reporting software provider. They flourish on top of an existing (data-driven) infrastructure in order to provide consistency between all aspects of product design, manufacturing and usage.

Configit is not a typical PLM or reporting software provider. They flourish on top of an existing (data-driven) infrastructure in order to provide consistency between all aspects of product design, manufacturing and usage.

In their words:

“We build configuration solutions for manufacturing companies to master the challenges of getting configurable products and services to market faster and selling, manufacturing, and servicing them more effectively.”

We discussed how this is beneficial in the context of Sustainability with Henrik Hulgaard, their VP of Product Management.

Enjoy the 35-minute discussion below:

The slides shown during the interview, combined with additional company information, can be found HERE.

What we have learned

- Using Configit connected to your configurable products allows you to select the best performance for Sustainability if this is your motivation. It will enable companies to design and deliver configurable products where, in the end, in practice, the customer decides on the optimum configuration, fitting their purpose and ambition.

- Configurations and Modularity, which are building blocks of the circular economy, go hand in hand and cannot be considered standalone options.

- Even AI has entered the domain of configuration lifecycle management – we are in the early stages of learning more.

Want to learn more?

- The slide deck related to this interview

- The whitepaper: Sustainability transformation in manufacturing

- The Configit blog section

Conclusion

As a company, there are many ways to provide more sustainable products to your customers, such as by design and by customer choice. With Configit, companies can provide the most sustainable options for their manufacturing process or later support their customers to select the most sustainable options.

![]() I attended the PDSVISION forum for the first time, a two-day PLM event in Gothenburg organized by PTC’s largest implementer in the Nordics, also active in North America, the UK, and Germany.

I attended the PDSVISION forum for the first time, a two-day PLM event in Gothenburg organized by PTC’s largest implementer in the Nordics, also active in North America, the UK, and Germany.

The theme of the conference: Master your Digital Thread – a hot topic, as it has been discussed in various events, like the recent PLM Roadmap/PDT Europe conference in November 2023.

The event drew over 200 attendees, showing the commitment of participants, primarily from the Nordics, to knowledge sharing and learning.

The diverse representation included industry leaders like Vestas, pioneers in Sustainable Energy, and innovative startups like CorPower Ocean, who are dedicated to making wave energy reliable and competitive. Notably, the common thread among these diverse participants was their focus on sustainability, a growing theme in PLM conferences and an essential item on every board’s strategic agenda.

I enjoyed the structure and agenda of the conference. The first day was filled with lectures and inspiring keynotes. The second day was a day of interactive workshops divided into four tracks, which were of decent length so we could really dive into the topics. As you can imagine, I followed the sustainability track.

Here are some of my highlights of this conference.

Catching the Wind: A Digital Thread From Design to Service

Simon Saandvig Storbjerg, unfortunately remote, gave an overview of the PLM-related challenges that Vestas is addressing. Vestas, the undisputed market leader in wind energy, is indirectly responsible for 231 million tonnes of CO2 per year.

Simon Saandvig Storbjerg, unfortunately remote, gave an overview of the PLM-related challenges that Vestas is addressing. Vestas, the undisputed market leader in wind energy, is indirectly responsible for 231 million tonnes of CO2 per year.

One of the challenges of wind power energy is the growing complexity and need for variants. With continuous innovation and the size of the wind turbine, it is challenging to achieve economic benefits of scale.

As an example, Simon shared data related to the Lost Production Factor, which was around 5% in 2009 and reduced to 2% in 2017 and is now growing again. This trend is valid not only for Vestas but also for all wind turbine manufacturers, as variability is increasing.

Vestas is introducing modularity to address these challenges. I reported last year about their modularity journey related to the North European Modularity biannual meeting held at Vestas in Ringkøbing – you can read the post here.

Simon also addressed the importance of Model-Based Definition (MBD), which is crucial if you want to achieve digital continuity between engineering and manufacturing. In particular, in this industry, MBD is a challenge to involve the entire value chain, despite the fact that the benefits are proven and known. Change in people skills and processes remains a challenge.

The Future of Product Design and Development

The session led by PTC from Mark Lobo, General Manager for the PLM Segment, and Brian Thompson, General Manager of the CAD Segment, brought clarity to the audience on the joint roadmap of Windchill and Creo.

The session led by PTC from Mark Lobo, General Manager for the PLM Segment, and Brian Thompson, General Manager of the CAD Segment, brought clarity to the audience on the joint roadmap of Windchill and Creo.

Mark and Brian highlighted the benefits of a Model-Based Enterprise and Model-Based Definition, which are musts if you want to be more efficient in your company and value chain.

Mark and Brian highlighted the benefits of a Model-Based Enterprise and Model-Based Definition, which are musts if you want to be more efficient in your company and value chain.

The WHY is known, see the benefits described in the image, and requires new ways of working, something organizations need to implement anyway when aiming to realize a digital thread or digital twin.

In addition, Mark addressed PTC’s focus on Design for Sustainability and their partner network. In relation to materials science, the partnership with Ansys Granta MI is essential. It was presented later by Ansys and discussed on day two during one of the sustainability workshops.

Mark and Brian elaborated on the PTC SaaS journey – the future atlas platform and the current status of WindChill+ and Creo+, addressing a smooth transition from existing customers to a new future architecture.

And, of course, there was the topic of Artificial Intelligence.

Mark explained that PTC is exploring AI in various areas of the product lifecycle, like validating requirements, optimizing CAD models, streamlining change processes on the design side but also downstream activities like quality and maintenance predictions, improved operations and streamlined field services and service parts are part of the PTC Copilot strategy.

Mark explained that PTC is exploring AI in various areas of the product lifecycle, like validating requirements, optimizing CAD models, streamlining change processes on the design side but also downstream activities like quality and maintenance predictions, improved operations and streamlined field services and service parts are part of the PTC Copilot strategy.

PLM combined with AI is for sure a topic where the applicability and benefits can be high to improve decision-making.

PLM Data Merge in the PTC Cloud: The Why & The How

Mikael Gustafson from Xylem, a leading Global Water Solutions provider, described their recently completed project: merging their on-premise Windchill instance TAPIR and their cloud Windchill XGV into a single environment.

Mikael Gustafson from Xylem, a leading Global Water Solutions provider, described their recently completed project: merging their on-premise Windchill instance TAPIR and their cloud Windchill XGV into a single environment.

TAPIR stands for Technical Administration, Part Information Repository and is very much part-centric and used in one organization. XGV stands for Xylem Global Vault, and it is used in 28 organizations with more of a focus on CAD data (Creo and AutoCAD). Two different siloes are to be joined in one instance to build a modern, connected, data-driven future or, as Mikael phrased it: “A step towards a more manageable Virtual Product“.

It was a severe project involving a lot of resources and time, again showing the challenges of migrations. I am planning to publish a blog post, the draft title “Migration Migraine,” as this type of migration is prevalent in many places because companies want to implement a single PLM backbone beyond (mechanical) engineering.

It was a severe project involving a lot of resources and time, again showing the challenges of migrations. I am planning to publish a blog post, the draft title “Migration Migraine,” as this type of migration is prevalent in many places because companies want to implement a single PLM backbone beyond (mechanical) engineering.

What I liked about the approach was its focus on assessing the risks and prioritizing a mitigation strategy if necessary. As the list below shows, even the COVID-19 pandemic was challenging the project.

Often, big migration projects fail due to optimism or by assessing some of the risks at the start and then giving it a go.

When failures happen, there is often the blame game: Was it the software, the implementer, or the customer (past or present) that caused the troubles? Mediating in such environments has been a long time my mission as the “Flying Dutchman,” and from my experience, it is not about the blame game; it is, most of the time, too high expectations and not enough time or resources to fully control this journey.

When failures happen, there is often the blame game: Was it the software, the implementer, or the customer (past or present) that caused the troubles? Mediating in such environments has been a long time my mission as the “Flying Dutchman,” and from my experience, it is not about the blame game; it is, most of the time, too high expectations and not enough time or resources to fully control this journey.

As Michael said, Xylem was successful, and during the go-live, only a few non-critical issues popped up.

When asked what he would do differently with the project’s hindsight, Mikael mentioned he would do the migrations not as a big project but as smaller projects.

When asked what he would do differently with the project’s hindsight, Mikael mentioned he would do the migrations not as a big project but as smaller projects.

I can relate a lot to this answer as, by experience, the “one-time” migration projects have created a lot of stress for the company, and only a few of them were successful.

Starting being coordinated and then connected

Several sessions were held where companies shared their PLM journey, to be mapped along the maturity slide (slide 8) I shared in my session: The Why, What and How of Digital Transformation in the PLM domain. You can review the content here on SlideShare.

There was Evolabel, a company starting its PLM journey because they are suffering from ineffective work procedures, information islands and the increasing complexity of its products.

Evolabel realized it needed PLM to realize its market ambition: To be a market leader within five years. For Evolabel, PLM is a must that is repeatable and integrated internally.

Evolabel realized it needed PLM to realize its market ambition: To be a market leader within five years. For Evolabel, PLM is a must that is repeatable and integrated internally.

They shared how they first defined the required understanding and mindset for the needed capabilities before implementing them. In my terminology, they started to implement a coordinated PLM approach.

Teddy Svenson from JBT, a well-known manufacturer of food-tech solutions, described their next step in PLM. From an old AS/400 system with very little integration to PDM to a complete PLM system with parts, configurations, and change management.

Teddy Svenson from JBT, a well-known manufacturer of food-tech solutions, described their next step in PLM. From an old AS/400 system with very little integration to PDM to a complete PLM system with parts, configurations, and change management.

It is not an easy task but a vital stepping stone for future development and a complete digital thread, from sales to customer care. In my terminology, they were upgrading their technology to improve their coordinated approach to be ready for the next digital evolution.

![]() There were several other presentations on Day One – See the agenda here I cannot cover them all given the limited size of this blog post.

There were several other presentations on Day One – See the agenda here I cannot cover them all given the limited size of this blog post.

The Workshops

As I followed the Sustainability track, I cannot comment much on the other track; however, given the presenters and the topics, they all appeared to be very pragmatic and interactive – given the format.

Achieving sustainability goals by integrating material intelligence into the design process

![]() In the sustainability track, we started with Manuelle Clavel from Ansys Granta, who explained in detail how material data and its management are crucial for designing better-performing, more sustainable, and compliant products.

In the sustainability track, we started with Manuelle Clavel from Ansys Granta, who explained in detail how material data and its management are crucial for designing better-performing, more sustainable, and compliant products.

With the importance of compliance with (upcoming) regulations and the usage of material characteristics in the context of more sustainable products and being able to perform a Life Cycle Assessment, it is crucial to have material information digitally available, both in the CAD design environment as well in the PLM environment.

For me, a dataset of material properties is an excellent example of how it is used in a connected enterprise. You do not want to copy the information from system to system; it needs to be connected and available in real-time.

How can we design more sustainable products?

Together with Martin Lundqvist from QCM, I conducted an interactive session. We started with the need for digitalization, then looked at RoHS and REACH compliance and discussed the upcoming requirements of the Digital Product Passport.

We closed the session with a dialogue on the circular economy.

From the audience, we learned that many companies are still early in understanding the implementation of sustainability requirements and new processes. However, some were already quite advanced and acting. In particular, it is essential to know if your company is involved with batteries (DPP #1) or is close to consumers.

Conclusion

The PDSFORUM was for me an interesting experience for meeting companies at all different stages of their PLM journey. All sessions I attended were realistic, and the solutions were often pragmatic. In my day-to-day life, inspiring companies to understand a digital and sustainable future, you sometimes forget the journey everyone is going through.

Thanks, PDVISION, for inviting me to speak and learn at this conference.

and some sad news …..

I was sorry to learn that last week, Dr. Ken Versprille suddenly passed away. I know Ken, as shown in the picture – a passionate moderator and timekeeper of the PLM Roadmap / PDT conferences, well prepared for the details. May his spirit live through the future conferences – the next one already on May 8-9th in Washington, DC.

We are happy to start the year with the next PLM Global Green Alliances (PGGA) series round: PLM and Sustainability.

Last year we spoke mainly with the prominent PLM software editors (Aras, Autodesk, Dassault Systèmes, PTC, SAP) and Sustaira (Sustainability platform – Siemens partner).

This time we talked with Mark Reisig, Sustainability and Green Energy Practice Director & Executive Consultant from CIMdata. The good news is that discussing a PLM strategy and Sustainability is no longer a software discussion.

This time we talked with Mark Reisig, Sustainability and Green Energy Practice Director & Executive Consultant from CIMdata. The good news is that discussing a PLM strategy and Sustainability is no longer a software discussion.

With CIMdata’s sustainability offering introduced last year, it becomes clear that the topic of sustainability reached a broader level than the tools.

CIMdata

CIMdata is well known in the PLM domain, focusing on Market Analysis, Education, Research & Strategic Management Consulting, all related to PLM.

CIMdata is well known in the PLM domain, focusing on Market Analysis, Education, Research & Strategic Management Consulting, all related to PLM.

Last year, Mark joined CIMdata as Green Energy Practice Director & Executive Consultant. Listening to Mark, you will discover he has an exciting background, starting with the “Keeling Curve”, his early interest in oceanography and wind turbines, working with GE later in his career and many years active in the PLM domain.

Learn more from the 40 minutes discussion with Mark below.

You can download the slides shown during the recording HERE

What we have learned

CIMdata has been discussing and promoting a circular economy already for a long time. A sustainable future and a circular economy have been a theme in many of the PLM Roadmap & PDT conferences. It is a logical relation as implementing a circular strategy depends significantly on the product design approach.

CIMdata has been discussing and promoting a circular economy already for a long time. A sustainable future and a circular economy have been a theme in many of the PLM Roadmap & PDT conferences. It is a logical relation as implementing a circular strategy depends significantly on the product design approach. CIMdata also combines Sustainability with the need to digitize the processes and data handled. A data-driven approach will allow companies to measure (and estimate) better their environmental impact.

CIMdata also combines Sustainability with the need to digitize the processes and data handled. A data-driven approach will allow companies to measure (and estimate) better their environmental impact.- CIMdata believes sustainability must be embedded in PLM for companies to reduce their product carbon footprint, and they must have greater visibility into their supply chain.

Mark mentions that focusing on a sustainable business model (product & business) is crucial for survival in the upcoming years, and this has increasingly landed at the board level of companies.

Mark mentions that focusing on a sustainable business model (product & business) is crucial for survival in the upcoming years, and this has increasingly landed at the board level of companies.- The major change has to be driven by the business. PLM vendors will not drive the change; they will align their portfolio offerings based on the market needs.

- It was clear Mark has a lot of experience in wind energy throughout his whole lifecycle 😊

Want to learn more

Mark already pointed to several valuable resources in our discussion to learn more. Here are the most important links related to CIMdata

- Sustainability and Green Energy Consulting Practice

Recent webinar: The Green Energy Transition and Sustainability from January 23, 2023

Recent webinar: The Green Energy Transition and Sustainability from January 23, 2023- Upcoming webinar: Meeting Sustainability and Green Energy Transition Objectives: The Industrial Perspective, April 27, 2023, 11:00 AM EDT

Conclusions

Last year we discussed sustainability with the software vendors and their product offerings. They all mentioned the importance of a data-driven approach and education. CIMdata has broadened the available sustainability offering for companies by providing additional education and strategy support.

Education at all levels is essential to make sustainable decisions. Sustainable for the company’s business and, above all, sustainable for the planet.

I will be @Livework in Boston, aiming to discuss PLM and Sustainability on behalf of the PGGA with PTC thought leaders. Will you be there too?

We are happy to close the year with the first round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability.

We are happy to close the year with the first round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability.

We interviewed PLM-related software vendors in this series, discussing their sustainability mission and offering.

We talked with SAP, Autodesk, Dassault Systèmes, Sustaira and Aras and now with PTC. It was an exciting discussion, looking back at their Lifecycle Analysis (LCA) history and ending with a cliffhanger about what’s coming next year.

PTC

The discussion was with Dave Duncan, VP Sustainability at PTC, focusing on industrial Sustainability as well as PTC’s internal footprint reduction programs, joined by James Norman, who globally leads PTC’s Community of Practice for PLM and Design-for-Sustainability.

The discussion was with Dave Duncan, VP Sustainability at PTC, focusing on industrial Sustainability as well as PTC’s internal footprint reduction programs, joined by James Norman, who globally leads PTC’s Community of Practice for PLM and Design-for-Sustainability.

Interesting to notice from this discussion, listen to the introduction of Dave and James and their history with Sustainability long before it became a buzzword and then notice how long it takes till digital thread and digital twin are mentioned – enjoy the 38 minutes of interaction below

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- It was interesting to learn that just before the financial crisis in 2008, PTC invested (together with James Norman) in lifecycle analysis. But, unfortunately, a focus on restoring the economy silenced this activity until (as Dave Duncan says) a little more than six months ago, when Sustainability is almost in the top 3 of every company’s agenda.

- Regulation and financial reporting are the current drivers for companies to act related to Sustainability.

- The digital thread combined with the notion of relying on data quality are transformational aspects.

- Another transformational aspect is connecting sustainability as an integrated part of product development instead of a separate marketing discipline.

- Early next year, we will learn more about the realization of the PTC Digital Twin.

Want to learn more

Here are some links to the topics discussed in our meeting:

- The Innovators Program

- The Cummins Case Study

- The PTC Digital Twin description

- The PTC ServiceMax announcement

Conclusions

It was great to conclude with PTC this year. I hope readers following this series: “The PLM Global Green Alliance meets …” has given a good first impression of where PLM-related vendors are heading regarding their support for a sustainable future.

We touched base with them, the leaders, and the experts in their organizations. We discussed the need for data-driven infrastructures, the relation with the circular economy and compliance.

Next year we plan to follow up with them, now looking more into the customer experiences, tools, and methodology used.

After two quiet weeks of spending time with my family in slow motion, it is time to start the year.

After two quiet weeks of spending time with my family in slow motion, it is time to start the year.

First of all, I wish you all a happy, healthy, and positive outcome for 2022, as we need energy and positivism together. Then, of course, a good start is always cleaning up your desk and only leaving the relevant things for work on the desk.

Still, I have some books at arm’s length, either physical or on my e-reader, that I want to share with you – first, the non-obvious ones:

The Innovators Dilemma

A must-read book was written by Clayton Christensen explaining how new technologies can overthrow established big companies within a very short period. The term Disruptive Innovation comes up here. Companies need to remain aware of what is happening outside and ready to adapt to your business. There are many examples even recently where big established brands are gone or diminished in a short period.

A must-read book was written by Clayton Christensen explaining how new technologies can overthrow established big companies within a very short period. The term Disruptive Innovation comes up here. Companies need to remain aware of what is happening outside and ready to adapt to your business. There are many examples even recently where big established brands are gone or diminished in a short period.

In his book, he wrote about DEC (Digital Equipment Company) market leader in minicomputers, not having seen the threat of the PC. Or later Blockbuster (from video rental to streaming), Kodak (from analog photography to digital imaging) or as a double example NOKIA (from paper to market leader in mobile phones killed by the smartphone).

The book always inspired me to be alert for new technologies, how simple they might look like, as simplicity is the answer at the end. I wrote about in 2012: The Innovator’s Dilemma and PLM, where I believed cloud, search-based applications and Facebook-like environments could disrupt the PLM world. None of this happened as a disruption; these technologies are now, most of the time, integrated by the major vendors whose businesses are not really disrupted. Newcomers still have a hard time to concur marketspace.

In 2015 I wrote again about this book, The Innovator’s dilemma and Generation change. – image above. At that time, understanding disruption will not happen in the PLM domain. Instead, I predict there will be a more evolutionary process, which I would later call: From Coordinated to Connected.

The future ways of working address the new skills needed for the future. You need to become a digital native, as COVID-19 pushed many organizations to do so. But digital native alone does not bring success. We need new ways of working which are more difficult to implement.

Sapiens

The book Sapiens by Yuval Harari made me realize the importance of storytelling in the domain of PLM and business transformation. In short, Yuval Harari explains why the human race became so dominant because we were able to align large groups around an abstract theme. The abstract theme can be related to religion, the power of a race or nation, the value of money, or even a brand’s image.

The book Sapiens by Yuval Harari made me realize the importance of storytelling in the domain of PLM and business transformation. In short, Yuval Harari explains why the human race became so dominant because we were able to align large groups around an abstract theme. The abstract theme can be related to religion, the power of a race or nation, the value of money, or even a brand’s image.

The myth (read: simplified and abstract story) hides complexity and inconsistencies. It allows everyone to get motivated to work towards one common goal. A Yuval says: “Fiction is far more powerful because reality is too complex”.

Too often, I have seen well-analyzed PLM projects that were “killed” by management because it was considered too complex. I wrote about this in 2019 PLM – measurable or a myth? claiming that the real benefits of PLM are hard to predict, and we should not look isolated only to PLM.

My 2020 follow-up post The PLM ROI Myth, eludes to that topic. However, even if you have a soundproof business case at the management level, still the myth might be decisive to justify the investment.

That’s why PLM vendors are always working on their myths: the most cost-effective solution, the most visionary solution, the solution most used by your peers and many other messages to influence your emotions, not your factual thinking. So just read the myths on their websites.

If you have no time to read the book, look at the above 2015 Ted to grasp the concept and use it with a PLM -twisted mind.

Re-use your CAD

In 2015, I read this book during a summer holiday (meanwhile, there is a second edition). Although it was not a PLM book, it was helping me to understand the transition effort from a classical document-driven enterprise towards a model-based enterprise.

In 2015, I read this book during a summer holiday (meanwhile, there is a second edition). Although it was not a PLM book, it was helping me to understand the transition effort from a classical document-driven enterprise towards a model-based enterprise.

Jennifer Herron‘s book helps companies to understand how to break down the (information) wall between engineering and manufacturing.

At that time, I contacted Jennifer to see if others like her and Action Engineering could explain Model-Based Definition comprehensively, for example, in Europe- with no success.

As the Model-Based Enterprise becomes more and more the apparent future for companies that want to be competitive or benefit from the various Digital Twin concepts. For that reason, I contacted Jennifer again last year in my post: PLM and Model-Based Definition.

As you can read, the world has improved, there is a new version of the book, and there is more and more information to share about the benefits of a model-based approach.

I am still referencing Action Engineering and their OSCAR learning environment for my customers. Unfortunately, many small and medium enterprises do not have the resources and skills to implement a model-based environment.

I am still referencing Action Engineering and their OSCAR learning environment for my customers. Unfortunately, many small and medium enterprises do not have the resources and skills to implement a model-based environment.

Instead, these companies stay on their customers’ lowest denominator: the 2D Drawing. For me, a model-based definition is one of the first steps to master if your company wants to provide digital continuity of design and engineering information towards manufacturing and operations. Digital twins do not run on documents; they require model-based environments.

The book is still on my desk, and all the time, I am working on finding the best PLM practices related to a Model-Based enterprise.

It is a learning journey to deal with a data-driven, model-based environment, not only for PLM but also for CM experts, as you might have seen from my recent dialogue with CM experts: The future of Configuration Management.

It is a learning journey to deal with a data-driven, model-based environment, not only for PLM but also for CM experts, as you might have seen from my recent dialogue with CM experts: The future of Configuration Management.

Products2019

This book was an interesting novelty published by John Stark in 2020. John is known for his academic and educational books related to PLM. However, during the early days of the COVID-pandemic, John decided to write a novel. The novel describes the learning journey of Jane from Somerset, who, as part of her MBA studies, is performing a research project for the Josef Mayer Maschinenfabrik. Her mission is to report to the newly appointed CEO what happens with the company’s products all along the lifecycle.

This book was an interesting novelty published by John Stark in 2020. John is known for his academic and educational books related to PLM. However, during the early days of the COVID-pandemic, John decided to write a novel. The novel describes the learning journey of Jane from Somerset, who, as part of her MBA studies, is performing a research project for the Josef Mayer Maschinenfabrik. Her mission is to report to the newly appointed CEO what happens with the company’s products all along the lifecycle.

Although it is not directly a PLM book, the book illustrates the complexity of PLM. It Is about people and culture; many different processes, often disconnected. Everyone has their focus on their particular discipline in the center of importance. If you believe PLM is all about the best technology only, read this book and learn how many other aspects are also relevant.

I wrote about the book in 2020: Products2019 – a must-read if you are new to PLM if you want to read more details. An important point to pick up from this book is that it is not about PLM but about doing business.

PLM is not a magical product. Instead, it is a strategy to support and improve your business.

System Lifecycle Management

Another book, published a little later and motivated by the extra time we all got during the COVID-19 pandemic, was Martin Eigner‘s book System Lifecycle Management.

Another book, published a little later and motivated by the extra time we all got during the COVID-19 pandemic, was Martin Eigner‘s book System Lifecycle Management.

A 281-page journey from the early days of data management towards what Martin calls System Lifecycle Management (SysLM). He was one of the first to talk about System Lifecycle Management instead of PLM.

I always enjoyed Martin’s presentations at various PLM conferences where we met. In many ways, we share similar ideas. However, during his time as a professor at the University of Kaiserslautern (2003-2017), he explored new concepts with his students.

I briefly mentioned the book in my series The road to model-based and connected PLM (Part 5) when discussing SLM or SysLM. His academic research and analysis make this book very valuable. It takes you in a very structured way through the times that mechatronics becomes important, next the time that systems (hardware and software) become important.

I briefly mentioned the book in my series The road to model-based and connected PLM (Part 5) when discussing SLM or SysLM. His academic research and analysis make this book very valuable. It takes you in a very structured way through the times that mechatronics becomes important, next the time that systems (hardware and software) become important.

We discussed in 2015 the applicability of the bimodal approach for PLM. However, as many enterprises are locked in their highly customized PDM/PLM environments, their legacy blocks the introduction of modern model-based and connected approaches.

Where John Stark’s book might miss the PLM details, Martin’s book brings you everything in detail and with all its references.

Where John Stark’s book might miss the PLM details, Martin’s book brings you everything in detail and with all its references.

It is an interesting book if you want to catch up with what has happened in the past 20 years.

More Books …..

More books on my desk have helped me understand the past or that helped me shape the future. As this is a blog post, I will not discuss more books this time reaching my 1500 words.

Still books worthwhile to read – click on their images to learn more:

I discussed this book two times last year. An introduction in PLM and Modularity and a discussion with the authors and some readers of the book: The Modular Way – a follow-up discussion

I discussed this book two times last year. An introduction in PLM and Modularity and a discussion with the authors and some readers of the book: The Modular Way – a follow-up discussion

x

x

A book I read this summer contributed to a better understanding of sustainability. I mentioned this book in my presentation for the Swedish CATIA Forum in October last year – slide 29 of

A book I read this summer contributed to a better understanding of sustainability. I mentioned this book in my presentation for the Swedish CATIA Forum in October last year – slide 29 of

System Thinking becomes crucial for a sustainable future, as I addressed in my post PLM and Sustainability.

System Thinking becomes crucial for a sustainable future, as I addressed in my post PLM and Sustainability.

Sustainability is my area of interest at the PLM Green Global Alliance, an international community of professionals working with Product Lifecycle Management (PLM) enabling technologies and collaborating for a more sustainable decarbonized circular economy.

Conclusion

There is a lot to learn. Tell us something about your PLM bookshelf – which books would you recommend. In the upcoming posts, I will further focus on PLM education. So stay tuned and keep on learning.

In April this year, I published the post PLM and Modularity in which I had a dialogue with Daniel Strandhammar from Brick Strategy. Daniel and his colleague Bjorn Eriksson published the book “the Modular Way” written during the COVID-19 lockdowns.

In April this year, I published the post PLM and Modularity in which I had a dialogue with Daniel Strandhammar from Brick Strategy. Daniel and his colleague Bjorn Eriksson published the book “the Modular Way” written during the COVID-19 lockdowns.

We promised a recorded follow-up discussion with readers from the book. The follow-up initially planned for somewhere in May happened last week in June, with a significant contribution from the participants.

Theodor Ernstson, Henk Jan Pels, Jan Johansson and François Sychowicz shared their impression of the book with Daniel and Bjorn. Next, the following questions were posed and discussed:

- Modular design as a concept is already more than 50 years old, using different definitions, approaches and methodologies. In the book, an interesting list of steps is proposed. Is this list shared across modularity experts, or are they specific to this book?

- Do you see different ways of approaching modularity depending on the industry, or is it the same?

- When implementing modularization, which departments need to change their way of working most?

- How big a factor is the use of common technology in modularization?

- How do you position modularization vs. system engineering?

- As a measure of module quality, the concept of “independent” modules is often used to avoid that adding or changing a module might cause another module to fail. Have you seen this happening in your projects, and do you consider the concept of an “independent” module realizable?

- How do we make modularization stand out on the C-level agenda?

Watch the discussion here:

We felt that with this discussion, we only touched the tip of the iceberg. Each of the questions could be a theme for a deep conversation for some of us. Perhaps also for you – feel free to comment on this post or express your opinion. Based on the feedback, I am happy to moderate more detailed discussions related to modularity.

Conclusion

Reading books makes sense. Having a discussion afterward with some readers and the authors makes even more sense. Normally we would do this during a physical conference, meanwhile enjoying a drink or a snack. However, having a global and sustainable model of discussing and learning these virtual events might be the future. An entry point for enriching your network and knowledge.

This time in the series of complementary practices to PLM, I am happy to discuss product modularity. In my previous post related to Virtual Events, I mentioned I had finished reading the book “The Modular Way”, written by Björn Eriksson & Daniel Strandhammar, founders of the consulting company Brick Strategy.

This time in the series of complementary practices to PLM, I am happy to discuss product modularity. In my previous post related to Virtual Events, I mentioned I had finished reading the book “The Modular Way”, written by Björn Eriksson & Daniel Strandhammar, founders of the consulting company Brick Strategy.

The first time I got aware of Brick Strategy was precisely a year ago during the Technia Innovation Forum, the first virtual event I attended since COVID-19. Daniel’s presentation at that event was one of the four highlights that I shared about the conference. See My four picks from PLMIF.

The first time I got aware of Brick Strategy was precisely a year ago during the Technia Innovation Forum, the first virtual event I attended since COVID-19. Daniel’s presentation at that event was one of the four highlights that I shared about the conference. See My four picks from PLMIF.

As I wrote in my last post:

Modularity is a popular topic in many board meetings. How often have you heard: “We want to move from Engineering To Order (ETO) to more Configure To Order (CTO)”? Or another related incentive: “We need to be cleverer with our product offering and reduced the number of different parts”.

Next, the company buys a product that supports modularity, and management believes the work has been done. Of course, not. Modularity requires a thoughtful strategy.

I am now happy to have a dialogue with Daniel to learn and understand Brick Strategy’s view on PLM and Modularization. Are these topics connected? Can one live without the other? Stay tuned till the end if you still have questions for a pleasant surprise.

The Modular Way

Daniel, first of all, can you give us some background and intentions of the book “The Modular Way”?

Let me start by putting the book in perspective. In today’s globalized business, competition among industrial companies has become increasingly challenging with rapidly evolving technology, quickly changing customer behavior, and accelerated product lifecycles. Many companies struggle with low profitability.

Let me start by putting the book in perspective. In today’s globalized business, competition among industrial companies has become increasingly challenging with rapidly evolving technology, quickly changing customer behavior, and accelerated product lifecycles. Many companies struggle with low profitability.

To survive, companies need to master product customizations, launch great products quickly, and be cost-efficient – all at the same time. Modularization is a good solution for industrial companies with ambitions to improve their competitiveness significantly.

The aim of modularization is to create a module system. It is a collection of pre-defined modules with standardized interfaces. From this, you can build products to cater to individual customer needs while keeping costs low. The main difference from traditional product development is that you develop a set of building blocks or modules rather than specific products.

The aim of modularization is to create a module system. It is a collection of pre-defined modules with standardized interfaces. From this, you can build products to cater to individual customer needs while keeping costs low. The main difference from traditional product development is that you develop a set of building blocks or modules rather than specific products.

The Modular Way explains the concept of modularization and the ”how-to.” It is a comprehensive and practical guidebook, providing you with inspiration, a framework, and essential details to succeed with your journey. The book is based on our experience and insights from some of the world’s leading companies.

Björn and I have long thought about writing a book to share our combined modularization experience and learnings. Until recently, we have been fully busy supporting our client companies, but the halted activities during the peak of the COVID-19 pandemic gave us the perfect opportunity.

Björn and I have long thought about writing a book to share our combined modularization experience and learnings. Until recently, we have been fully busy supporting our client companies, but the halted activities during the peak of the COVID-19 pandemic gave us the perfect opportunity.

PLM and Modularity

Did you have PLM in mind when writing the book?

Yes, definitely. We believe that modularization and a modular way of working make product lifecycle management more efficient. Then we talk foremost about the processes, roles, product structure, decision making etc. Companies often need minor adjustments to their IT systems to support and sustain the new way of working.

Yes, definitely. We believe that modularization and a modular way of working make product lifecycle management more efficient. Then we talk foremost about the processes, roles, product structure, decision making etc. Companies often need minor adjustments to their IT systems to support and sustain the new way of working.

Companies benefit the most from modularization when the contents, or foremost the products, are well structured for configuration in streamlined processes.

![]() Many times, this means “thinking ahead” and preparing your products for more configuration and less engineering in the sales process, i.e., go from ETO to CTO.

Many times, this means “thinking ahead” and preparing your products for more configuration and less engineering in the sales process, i.e., go from ETO to CTO.

Modularity for Everybody?

It seems like the modularity concept is prevalent in the Scandinavian countries, with famous examples of Scania, LEGO, IKEA, and Electrolux mentioned in your book. These examples come from different industries. Does it mean that all companies could pursue modularity, or are there some constraints?

It seems like the modularity concept is prevalent in the Scandinavian countries, with famous examples of Scania, LEGO, IKEA, and Electrolux mentioned in your book. These examples come from different industries. Does it mean that all companies could pursue modularity, or are there some constraints?

We believe that companies designing and manufacturing products fulfilling different customer needs within a defined scope could benefit from modularization. Off-the-shelf content, commonality and reuse increase efficiency. However, the focus, approach and benefits are different among different types of companies.

We believe that companies designing and manufacturing products fulfilling different customer needs within a defined scope could benefit from modularization. Off-the-shelf content, commonality and reuse increase efficiency. However, the focus, approach and benefits are different among different types of companies.

We have, for example, seen low-volume companies expecting the same benefits as high-volume consumer companies. This is unfortunately not the case.

Companies can improve their ability and reduce the efforts to configure products to individual needs, i.e., customization. And when it comes to cost and efficiency improvements, high-volume companies can reduce product and operational costs.

Companies can improve their ability and reduce the efforts to configure products to individual needs, i.e., customization. And when it comes to cost and efficiency improvements, high-volume companies can reduce product and operational costs.

Image:

Low-volume companies can shorten lead time and increase efficiency in R&D and product maintenance. Project solution companies can shorten the delivery time through reduced engineering efforts.

As an example, Electrolux managed to reduce part costs by 20 percent. Half of the reduction came from volume effects and the rest from design for manufacturing and assembly.

All in all, Electrolux has estimated its operating cost savings at approximately SEK 4bn per year with full effect, or around 3.5 percentage points of total costs, compared to doing nothing from 2010–2017. Note: SEK 4 bn is approximate Euro 400 Mio

All in all, Electrolux has estimated its operating cost savings at approximately SEK 4bn per year with full effect, or around 3.5 percentage points of total costs, compared to doing nothing from 2010–2017. Note: SEK 4 bn is approximate Euro 400 Mio

Where to start?

Thanks to your answer, I understand my company will benefit from modularity. To whom should I talk in my company to get started? And if you would recommend an executive sponsor in my company, who would recommend leading this initiative.

Thanks to your answer, I understand my company will benefit from modularity. To whom should I talk in my company to get started? And if you would recommend an executive sponsor in my company, who would recommend leading this initiative.

Defining a modular system, and implementing a modular way of working, is a business-strategic undertaking. It is complex and has enterprise-wide implications that will affect most parts of the organization. Therefore, your management team needs to be aligned, engaged, and prioritize the initiative.

Defining a modular system, and implementing a modular way of working, is a business-strategic undertaking. It is complex and has enterprise-wide implications that will affect most parts of the organization. Therefore, your management team needs to be aligned, engaged, and prioritize the initiative.

The implementation requires a cross-functional team to ensure that you do it from a market and value chain perspective. Modularization is not something that your engineering or IT organization can solve on its own.

![]() We recommend that the CTO or CEO owns the initiative as it requires horizontal coordination and agreement.

We recommend that the CTO or CEO owns the initiative as it requires horizontal coordination and agreement.

Modularity and Digital Transformation

The experiences you are sharing started before digital transformation became a buzzword and practice in many companies. In particular, in the PLM domain, companies are still implementing past practices. Is modularization applicable for the current (coordinated) and for the (connected) future? And if yes, is there a difference?

The experiences you are sharing started before digital transformation became a buzzword and practice in many companies. In particular, in the PLM domain, companies are still implementing past practices. Is modularization applicable for the current (coordinated) and for the (connected) future? And if yes, is there a difference?

Modularization means that your products have a uniform design based on common concepts and standardized interfaces. To the market, the end products are unique, and your processes are consistent. Thus, modularization plays a role independently of where you are on the digital transformation journey.

Modularization means that your products have a uniform design based on common concepts and standardized interfaces. To the market, the end products are unique, and your processes are consistent. Thus, modularization plays a role independently of where you are on the digital transformation journey.