You are currently browsing the category archive for the ‘Digital Twin’ category.

Our recent interviews this year with aPriori and SAP were with companies that had less of a focus on the traditional product design process and more of a focus on the (circular) manufacturing process. In these interviews the importance of working with connected data was discussed in a shared (digital) thread.

Our recent interviews this year with aPriori and SAP were with companies that had less of a focus on the traditional product design process and more of a focus on the (circular) manufacturing process. In these interviews the importance of working with connected data was discussed in a shared (digital) thread.

This time, we, Mark Reisig and Jos Voskuil, were excited to talk with Siemens, not only a well-known PLM vendor but also a manufacturer of products and, therefore, having a close understanding of what is needed and can be achieved with their software solutions.

Siemens

![]() As Siemens is such a broad enterprise; we were happy to speak with Ryan R. Rochelle, who focuses on Sustainable Production, Sustainable Manufacturing and Sustainable Industry within Siemens . In the interview we discussed the importance of digital twins and the feedback loops between design and manufacturing. Despite some flaws in the network connection, we are happy to share an informative interview.

As Siemens is such a broad enterprise; we were happy to speak with Ryan R. Rochelle, who focuses on Sustainable Production, Sustainable Manufacturing and Sustainable Industry within Siemens . In the interview we discussed the importance of digital twins and the feedback loops between design and manufacturing. Despite some flaws in the network connection, we are happy to share an informative interview.

Enjoy listening and watching the next 33 minutes, talking with Ryan Rochelle.

You can download the images shown during the interview HERE

What I have learned

- Like all PLM vendors in this domain, Siemens talks about the importance of a circular economy and the need for digital threads and digital twins, confirming the need for all of us to invest in the digitization of the product lifecycle.

- Siemens is in a unique position as both the industrial user and software provider of its PLM suite, therefore having a unique feedback loop on the usability and applicability of its software in its industry.

- In the area of sustainability, they learn from both customers and internal customers. They are customer zero. Here, they observe shifting in engineering activities to the left” to optimize processes, supply chain and manufacturing earlier . (<<PGGA>>: which aligns with our aPriori and Makersite interviews).

- Siemens, SiGreen’s solution is an example of this unique position, being be able to track the carbon footprint of products across the supply chain.

Want to learn more

- There is the Siemens Sustainable industries website

- How the Digital Enterprise helps attain sustainability

- The Journey to a Sustainability Lighthouse awarded by the World Economic Forum

Conclusion

We have been discussing the relationship between PLM and sustainability with relevant software vendors for over two years now. As we saw initially in 2022, a few companies were exploring the possibilities.

Now, with further regulations and advanced software capabilities, companies are starting to implement new capabilities to make their product development process and products more sustainable. Siemens, as a software provider and an industrial user of its tools, is leading this journey—is it time for your company to step up, too?

This post shares our second interview this year in the PLM Global Green Alliance series, where we talked with PLM-related software vendors and their activities related to Sustainability. Last year, we spoke mainly with the more traditional PLM vendors, but this year, we started with Makersite, a company specialized in Product Lifecycle Intelligence supporting sustainability analysis.

This post shares our second interview this year in the PLM Global Green Alliance series, where we talked with PLM-related software vendors and their activities related to Sustainability. Last year, we spoke mainly with the more traditional PLM vendors, but this year, we started with Makersite, a company specialized in Product Lifecycle Intelligence supporting sustainability analysis.

And now we are happy to talk this time with Mark Rushton, Senior Product Marketing Manager and Ryan Flavelle, Associate Product Owner, both at aPriori Technologies. For my PGGA partner Mark Reisig and me, it was an interesting discussion in a domain where the focus was not on product design at the time.

aPriori

aPriori, according to their website, focuses on Digital Manufacturing, digitizing the entire manufacturing process, from design to production, and therefore able to asses environmental impact in a reliable manner.

aPriori, according to their website, focuses on Digital Manufacturing, digitizing the entire manufacturing process, from design to production, and therefore able to asses environmental impact in a reliable manner.

It was an informative dialogue. Watch the 35-minute discussion here and learn how aPriori uniquely digitizes the manufacturing processes to support Sustainability.

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- aPriori’s customers have pushed the company to provide faster and digital sustainability insights in their manufacturing processes, illustrating that companies are really acting to understand their environmental impact. To measure is to know.

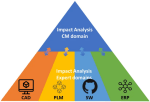

- In this interview, we saw the concepts of the digital twin of manufacturing processes and the digital twin of a plant.

- aPriori uniquely starts their impact analysis based on the 3d CAD geometry, being more accurate than what most LCA tools do, a BOM-based assessment,

Want to learn more?

Here are some links to the topics discussed in our meeting:

- How does aPriori software work – watch this demo

- aPriori’s Sustainability resources can be found here

- The blog Mark Reisig liked: the aPriori blog

- And the famous Manufacturing Insights Podcast

Conclusions

When it comes to sustainability in action, you need to be able measure and understand your environmental impact. Where traditional PLM activities focus on the design phase, there is also a lot to learn during the manufacturing phase. aPriori is doing this on a unique manner, not just based on BOM-analysis. In addition companies like aPriori have already a longer term experience with the virtual twin for manufacturing, originally used for cost and manufacturability analysis. Now extended to sustainability and their customers are working on it.

We are happy to start the year with the next round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability. This year, we will speak with some new companies, and we will also revisit some of our previous guests to learn about their progress.

We are happy to start the year with the next round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability. This year, we will speak with some new companies, and we will also revisit some of our previous guests to learn about their progress.

Where we talked with Aras, Autodesk, CIMdata, Dassault Systèmes, PTC, SAP, Sustaira and Transition Technologies PSC, there are still a lot of software companies with an exciting portfolio related to sustainability.

Therefore, we are happy to talk this time with Makersite, a company whose AI-powered Product Lifecycle Intelligence software, according to their home page, brings together your cost, environment, compliance, and risk data in one place to make smarter, greener decisions powered by the deepest understanding of your supply chain. Let’s explore

Makersite

![]() We were lucky to have a stimulating discussion with Neil D’Souza, Makersite’s CEO and founder, who was active in the field of sustainability for almost twenty years, even before it became a cool (or disputed) profession.

We were lucky to have a stimulating discussion with Neil D’Souza, Makersite’s CEO and founder, who was active in the field of sustainability for almost twenty years, even before it became a cool (or disputed) profession.

It was an exciting dialogue where we enjoyed realistic answers without all the buzzwords and marketing terms often used in the new domain of sustainability. Enjoy the 39 minutes of interaction below:

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- Makersite’s mission, to enable manufacturers to make better products, faster, initially applied to economic parameters, can be easily extended with sustainability parameters.The power of Makersite is that it connects to enterprise systems and sources using AI, Machine Learning and algorithms to support reporting views on compliance, sustainability, costs and risk.

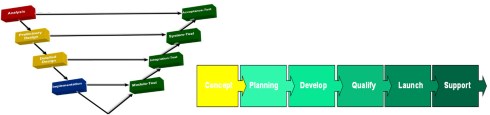

- Compliance and sustainability are the areas where I see a significant need for companies to invest. It is not a revolutionary business change but an extension of scope.We discussed this in the context of the stage-gate process, where sustainability parameters should be added at each gate.

- Neil has an exciting podcast, Five Lifes to Fifty, where he discusses the path to sustainable products with co-hosts Shelley Metcalfe and Jim Fava, and recently, they discussed sustainability in the context of the stage-gate process.

- Again, to move forward with sustainability, it is about creating the base and caring about the data internally to understand what’s happening, and from there, enable value engineering, including your supplier where possible (IP protection remains a topic) – confirming digital transformation (the connected way of working) is needed for business and sustainability.

Want to learn more?

Here are some links to the topics discussed in our meeting:

- The Website – Makersite.io

- Makersite data foundation – makersite-data-foundation

- Makersite demo video – makersite-platform-demo

- Neil’s LinkedIn – neilsaviodsouza

Conclusions

With Makersite, we discovered an experienced company that used its experience in cost, compliance and risk analysis, including supply chains, to extend it to the domain of sustainability. As their technology partners page shows, they can be complementary in many industries and enterprises.

We will see another complementary solution soon in our following interview. Stay tuned.

Last week, I shared my first impressions from my favorite conference, in the post: The weekend after PLM Roadmap/PDT Europe 2023, where most impressions could be classified as traditional PLM and model-based.

Last week, I shared my first impressions from my favorite conference, in the post: The weekend after PLM Roadmap/PDT Europe 2023, where most impressions could be classified as traditional PLM and model-based.

There is nothing wrong with conventional PLM, as there is still much to do within this scope. A model-based approach for MBSE (Model-Based Systems Engineering) and MBD (Model-Based Definition) and efficient supplier collaboration are not topics you solve by implementing a new system.

Ultimately, to have a business-sustainable PLM infrastructure, you need to structure your company internally and connect to the outside world with a focus on standards to avoid a vendor lock-in or a dead end.

Ultimately, to have a business-sustainable PLM infrastructure, you need to structure your company internally and connect to the outside world with a focus on standards to avoid a vendor lock-in or a dead end.

In short, this is what I described so far in The weekend after ….part 1.

Now, let’s look at the relatively new topics for this audience.

Enabling the Marketing, Engineering & Manufacturing Digital Thread

Cyril Bouillard, the PLM & CAD Tools Referent at the Mersen Electrical Protection (EP) business unit, shared his experience implementing an end-to-end digital backbone from marketing through engineering and manufacturing.

Cyril Bouillard, the PLM & CAD Tools Referent at the Mersen Electrical Protection (EP) business unit, shared his experience implementing an end-to-end digital backbone from marketing through engineering and manufacturing.

Cyril showed the benefits of a modern PLM infrastructure that is not CAD-centric and focused on engineering only. The advantages of this approach are a seamless integrated flow of PLM and PIM (Product Information Management).

I wrote about this topic in 2019: PLM and PIM – the complementary value in a digital enterprise. Combining the concepts of PLM and PIM in an integrated, connected environment could also provide a serious benefit when collaborating with external parties.

Another benefit Cyril demonstrated was the integration of RoHS compliance to the BOM as an integrated environment. In my session, I also addressed integrated RoHS compliance as a stepping stone to efficiency in future compliance needs.

Another benefit Cyril demonstrated was the integration of RoHS compliance to the BOM as an integrated environment. In my session, I also addressed integrated RoHS compliance as a stepping stone to efficiency in future compliance needs.

Read more later or in this post: Material Compliance – as a stepping-stone towards Life Cycle Assessment (LCA)

Cyril concluded with some lessons learned.

Data quality is essential in such an environment, and there are significant time savings implementing the connected Digital Thread.

Meeting the Challenges of Sustainability in Critical Transport Infrastructures

Etienne Pansart, head of digital engineering for construction at SYSTRA, explained how they address digital continuity with PLM throughout the built assets’ lifecycle.

Etienne Pansart, head of digital engineering for construction at SYSTRA, explained how they address digital continuity with PLM throughout the built assets’ lifecycle.

Etienne’s story was related to the complexity of managing a railway infrastructure, which is a linear and vertical distribution at multiple scales; it needs to be predictable and under constant monitoring; it is a typical system of systems network, and on top of that, maintenance and operational conditions need to be continued up to date.

Regarding railway assets – a railway needs renewal every two years, bridges are designed to last a hundred years, and train stations should support everyday use.

When complaining about disturbances, you might have a little more respect now (depending on your country). However, on top of these challenges, Etienne also talked about the additional difficulties expected due to climate change: floods, fire, earth movements, and droughts, all of which will influence the availability of the rail infrastructure.

In that context, Etienne talked about the MINERVE project – see image below:

As you can see from the main challenges, there is an effort of digitalization for both the assets and a need to provide digital continuity over the entire asset lifecycle. This is not typically done in an environment with many different partners and suppliers delivering a part of the information.

Etienne explained in more detail how they aim to establish digital twins and MBSE practices to build and maintain a data-driven, model-based environment.

Having digital twins allows much more granular monitoring and making accurate design decisions, mainly related to sustainability, without the need to study the physical world.

His presentation was again a proof point that through digitalization and digital twins, the traditional worlds of Product Lifecycle Management and Asset Information Management become part of the same infrastructure.

And it may be clear that in such a collaboration environment, standards are crucial to connect the various stakeholder’s data sources – Etienne mentioned ISO 16739 (IFC), IFC Rail, and ISO 19650 (BIM) as obvious standards but also ISO 10303 (PLCS) to support the digital thread leveraged by OSLC.

And it may be clear that in such a collaboration environment, standards are crucial to connect the various stakeholder’s data sources – Etienne mentioned ISO 16739 (IFC), IFC Rail, and ISO 19650 (BIM) as obvious standards but also ISO 10303 (PLCS) to support the digital thread leveraged by OSLC.

I am curious to learn more about the progress of such a challenging project – having worked with the high-speed railway project in the Netherlands in 1995 – no standards at that time (BIM did not exist) – mainly a location reference structure with documents. Nothing digital.

The connected Digital Thread

The theme of the conference was The Digital Thread in a Heterogeneous, Extended Enterprise Reality, and in the next section, I will zoom in on some of the inspiring sessions for the future, where collaboration or information sharing is all based on a connected Digital Thread – a term I will explain in more depth in my next blog post.

Transforming the PLM Landscape:

The Gateway to Business Transformation

Yousef Hooshmand‘s presentation was the highlight of this conference for me.

Yousef Hooshmand‘s presentation was the highlight of this conference for me.

Yousef is the PLM Architect and Lead for the Modernization of the PLM Landscape at NIO, and he has been active before in the IT-landscape transformation at Daimler, on which he published the paper: From a monolithic PLM landscape to a federated domain and data mesh.

If you read my blog or follow Share PLM, you might seen the reference to Yousef’s work before, or recently, you can hear the full story at the Share PLM Podcast: Episode 6: Revolutionizing PLM: Insights.

If you read my blog or follow Share PLM, you might seen the reference to Yousef’s work before, or recently, you can hear the full story at the Share PLM Podcast: Episode 6: Revolutionizing PLM: Insights.

It was the first time I met Yousef in 3D after several virtual meetings, and his passion for the topic made it hard to fit in the assigned 30 minutes.

There is so much to share on this topic, and part of it we already did before the conference in a half-day workshop related to Federated PLM (more on this in the following review).

First, Yousef started with the five steps of the business transformation at NIO, where long-term executive commitment is a must.

His statement: “If you don’t report directly to the board, your project is not important”, caused some discomfort in the audience.

As the image shows, a business transformation should start with a systematic description and analysis of which business values and objectives should be targeted, where they fit in the business and IT landscape, what are the measures and how they can be tracked or assessed and ultimately, what we need as tools and technology.

In his paper From a Monolithic PLM Landscape to a Federated Domain and Data Mesh, Yousef described the targeted federated landscape in the image below.

And now some vendors might say, we have all these domains in our product portfolio (or we have slides for that) – so buy our software, and you are good.

And here Yousef added his essential message, illustrated by the image below.

Start by delivering the best user-centric solutions (in an MVP manner – days/weeks – not months/years). Next, be data-centric in all your choices and ultimately build an environment ready for change. As Yousef mentioned: “Make sure you own the data – people and tools can leave!”

And to conclude reporting about his passionate plea for Federated PLM:

“Stop talking about the Single Source of Truth, start Thinking of the Nearest Source of Truth based on the Single Source of Change”.

Heliple-2 PLM Federation:

A Call for Action & Contributions

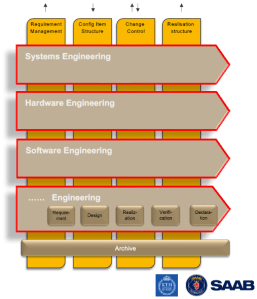

A great follow-up on Yousef’s session was Erik Herzog‘s presentation about the final findings of the Heliple 2 project, where SAAB Aeronautics, together with Volvo, Eurostep, KTH, IBM and Lynxwork, are investigating a new way of federated PLM, by using an OSLC-based, heterogeneous linked product lifecycle environment.

A great follow-up on Yousef’s session was Erik Herzog‘s presentation about the final findings of the Heliple 2 project, where SAAB Aeronautics, together with Volvo, Eurostep, KTH, IBM and Lynxwork, are investigating a new way of federated PLM, by using an OSLC-based, heterogeneous linked product lifecycle environment.

Heliple stands for HEterogeneous LInked Product Lifecycle Environment

The image below, which I shared several times before, illustrates the mindset of the project.

Last year, during the previous conference in Gothenburg, Erik introduced the concept of federated PLM – read more in my post: The week after PLM Roadmap / PDT Europe 2022, mentioning two open issues to be investigated: Operational feasibility (is it maintainable over time) and Realisation effectivity (is it affordable and maintainable at a reasonable cost)

As you can see from the slide below, the results were positive and encouraged SAAB to continue on this path.

One of the points to mention was that during this project, Lynxwork was used to speed up the development of the OSLC adapter, reducing costs, time and needed skills.

After this successful effort, Erik and several others who joined us at the pre-conference workshop agreed that this initiative is valid to be tested, discussed and exposed outside Sweden.

After this successful effort, Erik and several others who joined us at the pre-conference workshop agreed that this initiative is valid to be tested, discussed and exposed outside Sweden.

Therefore, the Federated PLM Interest Group was launched to join people worldwide who want to contribute to this concept with their experiences and tools.

A first webinar from the group is already scheduled for December 12th at 4 PM CET – you can join and register here.

More to come

Given the length of this blog post, I want to stop here.

Topics to share in the next post are related to my contribution at the conference The Need for a Governance Digital Thread, where I addressed the need for federated PLM capabilities with the upcoming regulations and practices related to sustainability, which require a connected Digital.

Topics to share in the next post are related to my contribution at the conference The Need for a Governance Digital Thread, where I addressed the need for federated PLM capabilities with the upcoming regulations and practices related to sustainability, which require a connected Digital.

I want to combine this post with the findings that Mattias Johansson, CEO of Eurostep, shared in his session: Why a Digital Thread makes a lot of sense, goes beyond manufacturing, and should be standards-based.

I want to combine this post with the findings that Mattias Johansson, CEO of Eurostep, shared in his session: Why a Digital Thread makes a lot of sense, goes beyond manufacturing, and should be standards-based.

There are some interesting findings in these two presentations.

And there was the introduction of AI at the conference, with some experts’ talks and thoughts. Perhaps at this stage, it is too high on Gartner’s hype cycle to go into details. It will surely be THE topic of discussion or interest you must have noticed.

And there was the introduction of AI at the conference, with some experts’ talks and thoughts. Perhaps at this stage, it is too high on Gartner’s hype cycle to go into details. It will surely be THE topic of discussion or interest you must have noticed.

The recent turmoil at OpenAI is an example of that. More to come for sure in the future.

Conclusion

The PLM Roadmap/PDT Europe conference was significant for me because I discovered that companies are working on concepts for a data-driven infrastructure for PLM and are (working on) implementing them. The end of monolithic PLM is visible, and companies need to learn to master data using ontologies, standards and connected digital threads.

Again, a “The weekend after …” post related to my favorite event to which I have contributed since 2014.

Expectations were high this time from my side, in particular because we would have a serious discussion related to connected digital threads and federated PLM.

More about these topics in my post next week as all content is not yet available for sharing.

The conference was sold out this time, and during the breaks, you had to navigate through the people to find your network opportunities. Also, the participation of the main PLM players as sponsors illustrated that everyone wanted to benefit from this opportunity to meet and learn from their industry peers.

The conference was sold out this time, and during the breaks, you had to navigate through the people to find your network opportunities. Also, the participation of the main PLM players as sponsors illustrated that everyone wanted to benefit from this opportunity to meet and learn from their industry peers.

Looking back to the conference, there were two noticeable streams.

- The stream where people share their current PLM experiences, traditionally the A&D action groups moderated by CIMdata, is part of this stream. This part I will cover in this post.

- There were forward-looking presentations related to standards, ontologies, and federated PLM—all with an AI flavor. This part I will cover in my next post(s).

The connection between all these sessions was the Digital Thread. The conference’s theme was: The Digital Thread in a Heterogeneous, Extended Enterprise Reality. Let’s start the review with the highlights from the first stream.

Digital Thread: Why Should We Care?

As usual, Peter Bilello from CIMdata kicked off the conference by setting the scene. Peter started by clarifying the two definitions of the Digital Thread.

- The first is a communication framework that allows a connected data flow and integrated view of an asset’s data (i.e., its Digital Twin) throughout its lifecycle across traditionally siloed functional perspectives.

In my terminology, the connected digital thread. - The second is a network of connected information sources around the product lifecycle supporting traceability and decision-making.

In my terminology, the coordinated digital thread is the most straightforward digital thread to achieve.

Peter recommends starting a digital thread by connecting at the beginning of product conceptualization, creating an environment where one can analyze the performance of the product portfolio and the product features and capabilities that need to be planned or how they perform in the field.

In addition, when defining the products, connect them with regulatory requirement databases as they have must-have requirements. A topic I addressed in my session too, besides the existing regulatory requirements, it is expected that in the upcoming years, due to environmental regulations, these requirements will increase, and it will be necessary to have them integrated with your digital thread.

Digital Threads require data governance and are the basis for the various digital twins. Peter discussed the multiple applications of the digital twin, primarily a relation between a virtual asset and a physical asset, except in the early concept phase.

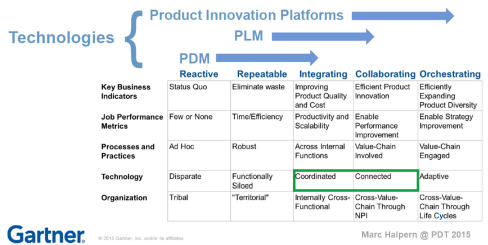

The digital thread is still in the early phase of implementation at companies. A CIMdata survey showed that companies still focus primarily on implementing traditional PDM capabilities, although as the image above shows, there is a growing interest in short-term digital twin/thread implementations.

People, Process & Technology:

The Pillars of Digital Transformation Success

The second keynote was from Christine McMonagle, Director of Digital Engineering Systems at Textron Systems a services and products supplier for the Aerospace and Defense industry. Christine leads the digital evolution in Textron Systems and presents nicely how a digital transformation should start from the people.Traditionally this industry has enough budget on the OEM level and therefore companies will not take a revolutionary approach when it comes to digital transformation.

The second keynote was from Christine McMonagle, Director of Digital Engineering Systems at Textron Systems a services and products supplier for the Aerospace and Defense industry. Christine leads the digital evolution in Textron Systems and presents nicely how a digital transformation should start from the people.Traditionally this industry has enough budget on the OEM level and therefore companies will not take a revolutionary approach when it comes to digital transformation.

Having your people at all levels involved and make them understand the need for change is crucial. A change does not happen top-down. You must educate people and understand what is possible and achievable to change – in the right direction. One of her concluding slides highlights the main points.

In the Q&A there to Christine’s sessions there was an interesting question related to the involvement of Human Resources (HR) in this project. There was a laugh that said it all – like in most companies HR is not focusing on organizational change, they focus more on operational issues – the Human is considered a Resource.

In the Q&A there to Christine’s sessions there was an interesting question related to the involvement of Human Resources (HR) in this project. There was a laugh that said it all – like in most companies HR is not focusing on organizational change, they focus more on operational issues – the Human is considered a Resource.

Between the regular sessions there were short sessions from sponsors: Altium, Contact Software, Dassault Systemes, ESI, inensia, Modular Management , PTC, SAP, Share PLM and Sinequa could pitch their value offering.

The Share PLM session, shortly after Christine’s presentation was a nice continuation of the focus on people. I loved the Share PLM image to the left explaining why people do not engage with our dreams.

Learn how LEONI is achieving Digital Continuity in the Automotive Industry.

Tobias Bauer, head of Product Data Standardization at LEONI talked about their FLOW project. FLOW is an acronym for Future Leoni Operating World. LEONI, well-known in the automotive industry produces cable and network solutions, including cable harnesses.

Tobias Bauer, head of Product Data Standardization at LEONI talked about their FLOW project. FLOW is an acronym for Future Leoni Operating World. LEONI, well-known in the automotive industry produces cable and network solutions, including cable harnesses.

Recently it has gone through a serious financial crisis and the need for restructuring. This makes it always challenging for a “visionary” PLM project. Tobias mentioned that after disappointing engagements with consultancy firms, they decided on a bottom-up approach to analyze existing processes using BPML. They agreed on a to-be state, fixing bottlenecks and streamlining the flow of information.

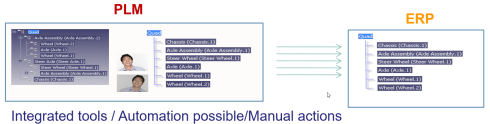

Tobias presented a smooth product data flow between their PLM system (PTC Windchill) and ERP (SAP S/4 HANA), clearly stating that the PLM system has become the controlled source of managing product changes.

Their key achievements reported so far were:

- related to BOM creation and routing (approx. 10x faster – from 2-3 days to ¼ day),

- better data consistency (fewer manual steps)

- complete traceability between the systems with PLM as the change management backbone.

The last point I would call the coordinated Digital Thread. The image below shows their current IT landscape in a simplified manner.

This solution might seem obvious for neutral PLM academics or experts, but it is an achievement to do this in an environment with SAP implemented. The eBOM-mBOM discussion is one of the most frequent held discussions – sometimes a battle.

Often, companies use their IT systems first and listen to the vendor’s experts to build integrations instead of starting from the natural business flow of information.

Aerospace & Defense Action groups outcomes

As usual, several Aerospace & Defense (A&D) action groups reported their progress during this conference. The A&D action groups are facilitated by CIMdata, and per topic, various OEMs and suppliers in the A&D industry study and analyze a particular topic, often inviting software vendors to demonstrate and discuss their capabilities with them.

Their activities and reports can be found on the A&D PLM Action page here; In the remainder of this post I will share briefly the ones presented. For a real deep dive in the topics I recommend to find the proceedings per topic on the A&D action page.

The Promise and Reality of the Digital Thread

James Roche CIMdata presented insights from industry research on The Promise and Reality of the Digital Thread. A total of 90 persons completed an in-depth survey about the status and implementation of digital thread concepts in their company. It is clear that the digital thread is still in its early days in this industry, and it is mainly about the coordinated digital thread. The image below reflects the highlights of the survey.

A&D Industry Digital Twin and Digital Thread Standards

Robert Rencher from Boeing explained the progress of their Digital Twin/Digital Thread project, where they had investigated the applicable standards to support a Digital Twin/Digital Thread (Phase 4 out of 7 currently planned). The image below shows that various standards may apply depending on business perspectives.

Their current findings are:

- Digital twin standards overlap, which is most likely a function of standards bodies representing their respective standards as an ongoing development from a historical perspective.

- The limited availability of mature digital twin/thread standards requires greater attention by standards organizations.

- The concept of the digital twin continues to evolve. This dynamic will be a challenge to standards bodies.

- The digital twin and the digital thread are distinct aspects of digital transformation. The corresponding digital twin and digital thread standards will be distinctly different.

- Coordinating the development of the respective standards between the digital twin/thread is needed.

- The digital twin’s organization, definition, and enablement depend on data and information provided by the digital thread.

Roadmap for Enabling Global Collaboration

Robert Gutwein (Pratt & Whitney Canada) and Agnes Gourillon-Jandot (Safran Aircraft Engines) reported their progress on the Global Collaboration project. Collaboration is challenged as exchange methods can vary, as well as dealing with the validation of exchanged information and governing the exchange of information in the context of IP protection.

One of the focal points was to introduce an approach to define standardized supplier agreements that anticipate modern model-based exchanges and collaboration methods.

Robert & Agnes presented the 8-step guideline for the aerospace industry in specific terms, explicitly mentioning the ISO44001 standard as being generic for all industries. An impression of the eight steps and sub-steps can be found below:

The 8-step approach will be supported by a 3rd-party Collaboration Management System (CMS app), which is not mandatory but recommended for use. When an interaction depends on a specific tool, it cannot become an ISO standard. The purpose of the methodology and app is to assist participants to ensure the collaboration aspect between stakeholders contains all the necessary steps & and people.

Model-based OEM/Supplier Collaboration Needs in Aviation Industry

Hartmut Hintze, working at Airbus Operations, presented the latest findings of the MBSE Data Interoperability working group and presented the model-based OEM/Supplier collaboration requirements and standards that need to be supported by the PLM/MBSE solution providers in the future. This collaboration goes beyond sharing CAD models, as you can see from the supplier engagement framework below:

As there are no standards-based tools, their first focus was looking into methodologies for model and behavior exchanges based on use cases. The use cases are then used to verify the state-of-the-art abilities of the various tools. At this moment, there is a focus on SysML V2 as a potential game-changer due to its new API support. As a relative novice on SysML, I cannot explain this topic in more simple words. I recommend that experts visit their presentations on the AD PAG publications page here.

Conclusions

The theme of the conference was related to the Digital Thread – and as you will discover it is valid for everyone. Learn to see the difference between the coordinated Digital Thread and the connected Digital Tread.This time, a lot of information about the Aerospace and Defense Action Groups (AD PAG), which are a fundamental part of this conference. The A&D industry has always been leading in advanced PLM concepts. However, more advanced concepts will come in my next post when touching the connected Digital Thread in the context of federated PLM and let’s not forget AI.

It might have been silent in the series of PLM and Sustainability … interviews where we as PLM Green Global Alliance core team members, talk with software vendors, implementers and consultants and their relation to PLM and sustainability. The interviews are still in a stage of exploring what is happening at this moment. More details per vendor or service provider next year.

It might have been silent in the series of PLM and Sustainability … interviews where we as PLM Green Global Alliance core team members, talk with software vendors, implementers and consultants and their relation to PLM and sustainability. The interviews are still in a stage of exploring what is happening at this moment. More details per vendor or service provider next year.

Our last interview was in April this year when we spoke with Mark Reisig, Green Energy Practice Director & Executive Consultant at CIMdata. You can find the interview here, and at that time, I mentioned the good news is that sustainability is no longer a software discussion.

As companies are planning or pushed by regulations to implement sustainable strategies, it becomes clear that education and guidance are needed beyond the tools.

This trend is also noticeable in our PLM Green Global Alliance community, which has grown significantly in the past half year. While writing this post, we have 862 members, not all as active as we hoped. Still, there is more good news related to dedicated contributors and more to come in the next PGGA update.

This time, we want to share the interview with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services.

This time, we want to share the interview with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services.

I met them during the LiveWorx conference in Boston in May – you can read more about the conference in my post: The weekend after LiveWorx 2023. Here we decided to follow-up on GreenPLM/

GreenPLM

![]() The label “GreenPLM” is always challenging as it could be considered green-washing. However, in this case, GreenPLM is an additional software offering that can be implemented on top of a PLM system, enabling people to make scientifically informed decisions for a more sustainable, greener product.

The label “GreenPLM” is always challenging as it could be considered green-washing. However, in this case, GreenPLM is an additional software offering that can be implemented on top of a PLM system, enabling people to make scientifically informed decisions for a more sustainable, greener product.

For GreenPLM, Rafal’s and Erik’s experiences are based on implementing GreenPLM on top of the PTC Windchill suite. Listen for the next 34 minutes to an educative session and learn.

You can download the slides shown in the recording here.

What I learned

- It was more a general educative session related to the relation PLM and Sustainability, focusing on the importance of design decisions – the 80 % impact number.

- Erik considers sustainability not a disruption for designers; they already work within cost, quality and time parameters. Now, sustainability is the fourth dimension to consider.

- Erik’s opinion is also reflected in the pragmatic approach of GreenPLM as an additional extension of Windchill using PTC Navigate and OSLC standards.

- GreenPLM is more design-oriented than Mendix-based Sustaira, a sustainability platform we discussed in this series – you can find the recording here.

Want to learn more?

Here are some links related to the topics discussed in our meeting:

Conclusions

With GreenPLM, it is clear that the focus of design for sustainability is changing from a vision (led by software vendors and environmental regulations) towards implementations in the field. Pragmatic and an extension of the current PLM infrastructure. System integrators like Transition Technologies are the required bridge between vision and realization. We are looking for more examples from the field.

Two more weeks to go – don’t miss this opportunity when you are in Europe

Click on the image to see the full and interesting agenda/

We are happy to start the year with the next PLM Global Green Alliances (PGGA) series round: PLM and Sustainability.

Last year we spoke mainly with the prominent PLM software editors (Aras, Autodesk, Dassault Systèmes, PTC, SAP) and Sustaira (Sustainability platform – Siemens partner).

This time we talked with Mark Reisig, Sustainability and Green Energy Practice Director & Executive Consultant from CIMdata. The good news is that discussing a PLM strategy and Sustainability is no longer a software discussion.

This time we talked with Mark Reisig, Sustainability and Green Energy Practice Director & Executive Consultant from CIMdata. The good news is that discussing a PLM strategy and Sustainability is no longer a software discussion.

With CIMdata’s sustainability offering introduced last year, it becomes clear that the topic of sustainability reached a broader level than the tools.

CIMdata

CIMdata is well known in the PLM domain, focusing on Market Analysis, Education, Research & Strategic Management Consulting, all related to PLM.

CIMdata is well known in the PLM domain, focusing on Market Analysis, Education, Research & Strategic Management Consulting, all related to PLM.

Last year, Mark joined CIMdata as Green Energy Practice Director & Executive Consultant. Listening to Mark, you will discover he has an exciting background, starting with the “Keeling Curve”, his early interest in oceanography and wind turbines, working with GE later in his career and many years active in the PLM domain.

Learn more from the 40 minutes discussion with Mark below.

You can download the slides shown during the recording HERE

What we have learned

CIMdata has been discussing and promoting a circular economy already for a long time. A sustainable future and a circular economy have been a theme in many of the PLM Roadmap & PDT conferences. It is a logical relation as implementing a circular strategy depends significantly on the product design approach.

CIMdata has been discussing and promoting a circular economy already for a long time. A sustainable future and a circular economy have been a theme in many of the PLM Roadmap & PDT conferences. It is a logical relation as implementing a circular strategy depends significantly on the product design approach. CIMdata also combines Sustainability with the need to digitize the processes and data handled. A data-driven approach will allow companies to measure (and estimate) better their environmental impact.

CIMdata also combines Sustainability with the need to digitize the processes and data handled. A data-driven approach will allow companies to measure (and estimate) better their environmental impact.- CIMdata believes sustainability must be embedded in PLM for companies to reduce their product carbon footprint, and they must have greater visibility into their supply chain.

Mark mentions that focusing on a sustainable business model (product & business) is crucial for survival in the upcoming years, and this has increasingly landed at the board level of companies.

Mark mentions that focusing on a sustainable business model (product & business) is crucial for survival in the upcoming years, and this has increasingly landed at the board level of companies.- The major change has to be driven by the business. PLM vendors will not drive the change; they will align their portfolio offerings based on the market needs.

- It was clear Mark has a lot of experience in wind energy throughout his whole lifecycle 😊

Want to learn more

Mark already pointed to several valuable resources in our discussion to learn more. Here are the most important links related to CIMdata

- Sustainability and Green Energy Consulting Practice

Recent webinar: The Green Energy Transition and Sustainability from January 23, 2023

Recent webinar: The Green Energy Transition and Sustainability from January 23, 2023- Upcoming webinar: Meeting Sustainability and Green Energy Transition Objectives: The Industrial Perspective, April 27, 2023, 11:00 AM EDT

Conclusions

Last year we discussed sustainability with the software vendors and their product offerings. They all mentioned the importance of a data-driven approach and education. CIMdata has broadened the available sustainability offering for companies by providing additional education and strategy support.

Education at all levels is essential to make sustainable decisions. Sustainable for the company’s business and, above all, sustainable for the planet.

I will be @Livework in Boston, aiming to discuss PLM and Sustainability on behalf of the PGGA with PTC thought leaders. Will you be there too?

I was happy to present and participate at the 3DEXEPRIENCE User Conference held this year in Paris on 14-15 March. The conference was an evolution of the previous ENOVIA User conferences; this time, it was a joint event by both the ENOVIA and the NETVIBES brand.

I was happy to present and participate at the 3DEXEPRIENCE User Conference held this year in Paris on 14-15 March. The conference was an evolution of the previous ENOVIA User conferences; this time, it was a joint event by both the ENOVIA and the NETVIBES brand.

The conference was, for me, like a reunion. As I have worked for over 25 years in the SmarTeam, ENOVIA and 3DEXPERIENCE eco-system, now meeting people I have worked with and have not seen for over fifteen years.

My presentation: Sustainability Demands Virtualization – and it should happen fast was based on explaining the transformation from a coordinated (document-driven) to a connected (data-driven) enterprise.

There were 100+ attendees at the conference, mainly from Europe, and most of the presentations were coming from customers, where the breakout sessions gave the attendees a chance to dive deeper into the Dassault Systèmes portfolio.

Here are some of my impressions.

The power of ENOVIA and NETVIBES

I had a traditional view of the 3DEXPERIENCE platform based on my knowledge of ENOVIA, CATIA and SIMULIA, as many of my engagements were in the domain of MBSE or a model-based approach.

I had a traditional view of the 3DEXPERIENCE platform based on my knowledge of ENOVIA, CATIA and SIMULIA, as many of my engagements were in the domain of MBSE or a model-based approach.

However, at this conference, I discovered the data intelligence side that Dassault Systèmes is bringing with its NETVIBES brand.

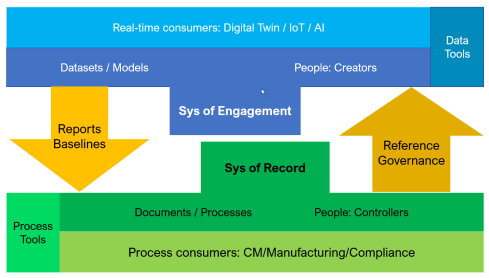

Where I would classify the ENOVIA part of the 3DEXPERIENCE platform as a traditional System of Record infrastructure (see Time to Split PLM?).

I discovered that by adding NETVIBES on top of the 3DEXPERIENCE platform and other data sources, the potential scope had changed significantly. See the image below:

As we can see, the ontologies and knowledge graph layer make it possible to make sense of all the indexed data below, including the data from the 3DEXPERIENCE Platform, which provides a modern data-driven layer for its consumers and apps.

The applications on top of this layer, standard or developed, can be considered Systems of Engagement.

My curiosity now: will Dassault Systèmes keep supporting the “old” system of record approach – often based on BOM structures (see also my post: The Rise and Fall of the BOM) combined with the new data-driven environment? In that case, you would have both approaches within one platform.

My curiosity now: will Dassault Systèmes keep supporting the “old” system of record approach – often based on BOM structures (see also my post: The Rise and Fall of the BOM) combined with the new data-driven environment? In that case, you would have both approaches within one platform.

The Virtual Twin versus the Digital Twin

It is interesting to notice that Dassault Systèmes consistently differentiates between the definition of the Virtual Twin and the Digital Twin.

According to the 3DS.com website:

Digital Twins are simply a digital form of an object, a virtual version.

Unlike a digital twin prototype that focuses on one specific object, Virtual Twin Experiences let you visualize, model and simulate the entire environment of a sophisticated experience. As a result, they facilitate sustainable business innovation across the whole product lifecycle.

Understandably, Dassault Systemes makes this differentiation. With the implementation of the Unified Product Structure, they can connect CAD geometry as datasets to other non-CAD datasets, like eBOM and mBOM data.

The Unified Product Structure was not the topic of this event but is worthwhile to notice.

REE Automotive

![]() The presentation from Steve Atherton from REE Automotive was interesting because here we saw an example of an automotive startup that decided to go pure for the cloud.

The presentation from Steve Atherton from REE Automotive was interesting because here we saw an example of an automotive startup that decided to go pure for the cloud.

REE Automotive is an Israeli technology company that designs, develops, and produces electric vehicle platforms. Their mission is to provide a modular and scalable electric vehicle platform that can be used by a wide range of industries, including delivery and logistics, passenger cars, and autonomous vehicles.

Steve Atherton is the PLM 3DExperience lead for REE at the Engineering Centre in Coventry in the UK, where they have most designers. REE also has an R&D center in Tel Aviv with offshore support from India and satellite offices in the US

Steve Atherton is the PLM 3DExperience lead for REE at the Engineering Centre in Coventry in the UK, where they have most designers. REE also has an R&D center in Tel Aviv with offshore support from India and satellite offices in the US

REE decided from the start to implement its PLM backbone in the cloud, a logical choice for such a global spread company.

The cloud was also one of the conference’s central themes, and it was interesting to see that a startup company like REE is pushing for an end-to-end solution based on a cloud solution. So often, you see startups choosing traditional systems as the senior members of the startup to take their (legacy) PLM knowledge to their next company.

The cloud was also one of the conference’s central themes, and it was interesting to see that a startup company like REE is pushing for an end-to-end solution based on a cloud solution. So often, you see startups choosing traditional systems as the senior members of the startup to take their (legacy) PLM knowledge to their next company.

The current challenge for REE is implementing the manufacturing processes (EBOM- MBOM) and complying as much as possible with the out-of-the-box best practices to make their cloud implementation future-proof.

Groupe Renault

Olivier Mougin, Head of PLM at Groupe RENAULT, talked about their Renaulution Virtual Twin (RVT) program. Renault has always been a strategic partner of Dassault Systèmes.

Olivier Mougin, Head of PLM at Groupe RENAULT, talked about their Renaulution Virtual Twin (RVT) program. Renault has always been a strategic partner of Dassault Systèmes.

I remember them as one of the first references for the ENOVIA V6 backbone.

The Renaulution Virtual Twin ambition: from engineering to enterprise platform, is enormous, as you can see below:

Each of the three pillars has transformational aspects beyond traditional ways of working. For each pillar, Olivier explained the business drivers, expected benefits, and why a new approach is needed. I will not go into the details in this post.

However, you can see the transformation from an engineering backbone to an enterprise collaboration platform – The Renaulution!.

Ahmed Lguaouzi, head of marketing at NETVIBES, enforced the extended power of data intelligence on top of an engineering landscape as the target architecture.

Renault’s ambition is enormous – the ultimate dream of digital transformation for a company with a great legacy. The mission will challenge Renault and Dassault Systèmes to implement this vision, which can become a lighthouse for others.

3DS PLM Journey at MIELE

An exciting session close to my heart was the digital transformation story from MIELE, explained by André Lietz, head of the IT Products PLM @ Miele. As an old MIELE dishwasher owner, I was curious to learn about their future.

An exciting session close to my heart was the digital transformation story from MIELE, explained by André Lietz, head of the IT Products PLM @ Miele. As an old MIELE dishwasher owner, I was curious to learn about their future.

Miele has been a family-owned business since 1899, making high-end domestic and commercial equipment. They are a typical example of the power of German mid-market companies. Moreover, family-owned gives them stability and the opportunity to develop a multi-year transformation roadmap without being distracted by investor demands every few years.

André, with his team, is responsible for developing the value chain inside the product development process (PDP), the operation of nearly 90 IT applications, and the strategic transformation of the overarching PLM Mission 2027+.

André, with his team, is responsible for developing the value chain inside the product development process (PDP), the operation of nearly 90 IT applications, and the strategic transformation of the overarching PLM Mission 2027+.

As the slide below illustrates, the team is working on four typical transformation drivers:

- Providing customers with connected, advanced products (increasing R&D complexity)

- Providing employees with a modern, digital environment (the war for digital talent)

- Providing sustainable solutions (addressing the whole product lifecycle)

- Improving internal end-to-end collaboration and information visibility (PLM digital transformation)

André talked about their DELMIA pilot plant/project and its benefits to connect the EBOM and MBOM in the 3DEXPERIENCE platform. From my experience, this is a challenging topic, particularly in German companies, where SAP dominated the BOM for over twenty years.

I am curious to learn more about the progress in the upcoming years. The vision is there; the transformation is significant, but they have the time to succeed! This can be another digital transformation example.

I am curious to learn more about the progress in the upcoming years. The vision is there; the transformation is significant, but they have the time to succeed! This can be another digital transformation example.

And more …

Besides some educational sessions by Dassault Systemes (Laurent Bertaud – NETVIBES data science), there were also other interesting customer testimonies from Fernando Petre (IAR80 – Fly Again project), Christian Barlach (ISC Sustainable Construction) and Thelma Bonello (Methode Electronics – end-to-end BOM infrastructure). All sessions helped to get a better understanding about what is possible and what is done in the domain of PLM.

Conclusion

I learned a lot during these days, particularly the virtual twin strategy and the related capabilities of data intelligence. As the event was also a reunion for me with many people from my network, I discovered that we all aim at a digital transformation. We have a mission and a vision. The upcoming years will be crucial to implement the mission and realizing the vision. It will be the early adopters like Renault pushing Dassault Systèmes to deliver. I hope to stay tuned. You too?

NOTE: Dassault Systèmes covered some of the expenses associated with my participation in this event but did not in any way influence the content of this post.

I am writing this post because one of my PLM peers recently asked me this question: “Is the BOM losing its position? He was in discussion with another colleague who told him:

I am writing this post because one of my PLM peers recently asked me this question: “Is the BOM losing its position? He was in discussion with another colleague who told him:

“If you own the BOM, you own the Product Lifecycle”.

This statement made me think of ä recent post from Jan Bosch recent post: Product Development fallacy #8: the bill of materials has the highest priority.

Software becomes increasingly an essential part of the final product, and combined with Jan’s expertise in software development, he wrote this article. I recommend reading the full post (4 min read) and next browse through the comments.

Software becomes increasingly an essential part of the final product, and combined with Jan’s expertise in software development, he wrote this article. I recommend reading the full post (4 min read) and next browse through the comments.

If you cannot afford these 10 minutes, here is my favorite quote from the article:

An excessive focus on the bill of materials leads to significant challenges for companies that are undergoing a digital transformation and adopting continuous value delivery. The lack of headroom, high coupling and versioning hell may easily cause an explosion of R&D expenditure over time.

Where did the BOM focus come from? A historical overview related to the rise (and fall) of the BOM.

In the beginning, there was the drawing.

Before the era of computers, there was “THE drawing”, describing assemblies, subassemblies or parts. And on the drawing, you can find the parts list if relevant. This parts list was the first Bill of Material, describing the parts/materials shown on the drawing.

Before the era of computers, there was “THE drawing”, describing assemblies, subassemblies or parts. And on the drawing, you can find the parts list if relevant. This parts list was the first Bill of Material, describing the parts/materials shown on the drawing.

Next came MRP/ERP

With the introduction of the MRP system (Material Requirement Planning), it was the first step that by using computers, people could collect the material requirements for one system as data and process.

With the introduction of the MRP system (Material Requirement Planning), it was the first step that by using computers, people could collect the material requirements for one system as data and process.

Entering new materials/parts described on drawings was still a manual process, as well as referring to existing parts on the drawing. Reuse of parts was a manual process based on individual knowledge.

In the nineties, MRP evolved into ERP (Enterprise Resource Planning), which included the MRP part and added resource and manufacturing planning and financial reporting.

The ERP system became the most significant IT system, the execution system of the company. As it was the first enterprise system implemented, it was the first moment we learned about implementation challenges – people change and budget overruns. However, as the ERP system brought visibility to the company’s execution, it became a “must-have” system for management.

The ERP system became the most significant IT system, the execution system of the company. As it was the first enterprise system implemented, it was the first moment we learned about implementation challenges – people change and budget overruns. However, as the ERP system brought visibility to the company’s execution, it became a “must-have” system for management.

The introduction of mainstream 2D CAD did not affect the company’s culture so much. Drawings became electronic drawings, and the methodology of the parts list on the drawing remained.

Sometimes the interaction with the MRP/ERP system was enhanced by an interface – sending the drawing BOM to ERP. The advantage of the interface: no manual transfer of data reducing typos and BOM errors. The disadvantages at that time: relatively expensive (connectivity between systems was a challenge) and mostly one direction.

Sometimes the interaction with the MRP/ERP system was enhanced by an interface – sending the drawing BOM to ERP. The advantage of the interface: no manual transfer of data reducing typos and BOM errors. The disadvantages at that time: relatively expensive (connectivity between systems was a challenge) and mostly one direction.

And then there was PDM.

In parallel with the introduction of ERP systems, mainstream 3D CAD systems became affordable, particularly SolidWorks, Solid Edge and Inventor. These 3D CAD systems allow sharing of parts and assemblies in different products, and the PDM database was the first aid to support part reuse, versioning and standardization.

In parallel with the introduction of ERP systems, mainstream 3D CAD systems became affordable, particularly SolidWorks, Solid Edge and Inventor. These 3D CAD systems allow sharing of parts and assemblies in different products, and the PDM database was the first aid to support part reuse, versioning and standardization.

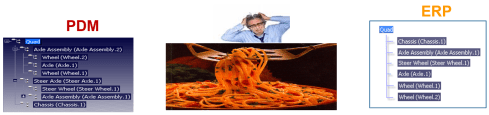

By extracting the parts from the assemblies and subassemblies, it was possible to generate a BOM structure in the PDM system to be transferred or typed into the ERP system. We did not talk about EBOM or MBOM then, as there was only one BOM in the ERP system, and the PDM system was a tool to feed the ERP system.

Many companies still have based their processes on this approach. ERP (read SAP nowadays) is the central execution system, and PDM is an external system. You might remember the story and image from my previous post about people, processes and tools. The bad practice example: Asking the ERP system to provide a part number when starting to design a part.

Many companies still have based their processes on this approach. ERP (read SAP nowadays) is the central execution system, and PDM is an external system. You might remember the story and image from my previous post about people, processes and tools. The bad practice example: Asking the ERP system to provide a part number when starting to design a part.

And then products started to change.

In the early 2000s, I worked with SmarTeam to define the E&E (Electronics and Electrical) template. One of the new concepts was to synchronize all design data coming from different disciplines to a single BOM structure.

In the early 2000s, I worked with SmarTeam to define the E&E (Electronics and Electrical) template. One of the new concepts was to synchronize all design data coming from different disciplines to a single BOM structure.

It was the time we started to talk about the EBOM. A type of BOM, as the structure to consolidate all the design data, was based on parts.

The EBOM, most of the time, reflects the design intent in logical groups and sending the relevant parts in the correct order to the ERP system was a favorite expensive customization for service providers. How to transfer an engineering BOM view to an ERP system that only understands the manufacturing view?

Note: not all ERP systems have the data model to differentiate between engineering parts and manufacturing parts

The image below illustrates the challenge and the customer’s perception.

The automated link between the design side (EBOM) and manufacturing side (MBOM) was a mission impossible – too many exceptions for the (spaghetti) code.

And then came the MBOM.

The identified issues connecting PDM and ERP led to the concept of implementing the MBOM in the PLM system. The MBOM in PLM is one of the characteristics of a PLM implementation compared to a PDM implementation. In a traditional PLM system, there is an interaction and connection between the EBOM and MBOM. EBOM parts should end up as MBOM parts. This interaction can be supported by automation, however, as it is in the same system, still leaving manual changes possible.

The MBOM structure in PLM could then be the information structure to transfer to the ERP system; however, there is more, as Jörg W. Fischer wrote in his provoking post-Die MBOM muss weg (The MBOM must go). He rightly points out (in German) that the MBOM is not a structure on its own but a combination of different views based on Assembly Drawings, Process Planning and Material Requirements.

The MBOM structure in PLM could then be the information structure to transfer to the ERP system; however, there is more, as Jörg W. Fischer wrote in his provoking post-Die MBOM muss weg (The MBOM must go). He rightly points out (in German) that the MBOM is not a structure on its own but a combination of different views based on Assembly Drawings, Process Planning and Material Requirements.

His conclusion:

Calling these structures, MBOM is trying to squeeze all three structures into one. That usually doesn’t work and then leads to much more emotional discussions in the project. It also costs a lot of money. It is, therefore, better not to use the term MBOM at all.

And indeed, just having an MBOM in your PLM system might help you to prepare some of the manufacturing steps, the needed resources and parts. The MBOM result still has to be localized at the local plant where the manufacturing takes place. And here, the systems used are the ERP system and the MES system.

The main advantage of having the MBOM in the PLM system is the direct relation between specification and manufacturing intent, allowing manufacturing engineering to work collaboratively with engineering in the same environment.

- The first benefit is fewer iterations and a shorter time to production, thanks to early interaction and manufacturing involvement in the engineering process.

- The second benefit is: product knowledge is centralized in a single system. Consolidating your Product Knowledge in ERP does not make sense due to global localization and the missing capabilities to manage the iterative engineering processes on non-existing parts.

And then came the SBOM, the xBOM

Traditional PLM vendors and implementations kept using xBOM structures as placeholders for related specification data (mechanical designs, electrical, software deliverables, serialized products). Most of the time, related files.

Traditional PLM vendors and implementations kept using xBOM structures as placeholders for related specification data (mechanical designs, electrical, software deliverables, serialized products). Most of the time, related files.

And with this approach, talking about digital thread, PLM systems also touch on the concepts of Configuration Management.

And with this approach, talking about digital thread, PLM systems also touch on the concepts of Configuration Management.

I will not go into the details here but look at the two images by clicking on them and see a similar mindset.

It is about the traceability of information in structures and systems. These structures work well in a relatively static and linear product development and delivery environment, as illustrated below:

Engineering change and release processes are based on managing the changes in different structures from the left to the right.

And then came software!

Modern connected products are no longer mechanical products. The product’s functionality no longer depends on the mechanical properties but mainly on embedded electronics and software used. For example, look at the mechanical design of a telecom transmission tower – its behavior merely comes from non-mechanical components, and they can change over time. Still, the Bill of Material contains a lot of concrete and steel parts.

Modern connected products are no longer mechanical products. The product’s functionality no longer depends on the mechanical properties but mainly on embedded electronics and software used. For example, look at the mechanical design of a telecom transmission tower – its behavior merely comes from non-mechanical components, and they can change over time. Still, the Bill of Material contains a lot of concrete and steel parts.

The ultimate example is comparing a Tesla (software on wheels) with a traditional car. For modern connected products, electronics and software need to be part of the solution. Software and electronics allow the product to be upgraded over time. Managing these products in the same manner as mechanical products is impossible, inefficient and therefore threatening your company’s future business.

I requote Jan Bosch:

An excessive focus on the bill of materials leads to significant challenges for companies that are undergoing a digital transformation and adopting continuous value delivery. The lack of headroom, high coupling and versioning hell may easily cause an explosion of R&D expenditure over time.

The model-based, connected enterprise

I will not solve the puzzle of the future in this post. You can read my observations in my series: The road to model-based and connected PLM. We need a new infrastructure with at least two modes. One that still serves as a System of Record, storing information in a traditional manner, like a Bill of Materials for the static parts, as not everyone and everything can be connected.

In addition, we need various Systems of Engagement that enable close to real-time interaction between products (systems) and relevant stakeholders for the engagement scope(multidisciplinary / consumers).

In addition, we need various Systems of Engagement that enable close to real-time interaction between products (systems) and relevant stakeholders for the engagement scope(multidisciplinary / consumers).

Digital twins are examples of such environments. Currently, these Systems of Engagement often work disconnected from the System of Record due to the lack of understanding of how to connect. (standard connectors? / OSLC?)

Our mission is to explore, as I wrote in my post Time to split PLM and drop our mechanical mindset.

And while I was finalizing this post, I read a motivating post from Jan Bosch again for all of you working on understanding and pushing the digital transformation in your eco-system.

And while I was finalizing this post, I read a motivating post from Jan Bosch again for all of you working on understanding and pushing the digital transformation in your eco-system.

The title: Be the protagonist of your life: 15 rules A starting point for more to come.

Conclusion

The BOM is no longer the master of the product lifecycle when it comes to managing connected products, where functionality mainly depends on software. BOM structures with related documents are just one of the extracted baselines from a data-driven, connected enterprise. This traditional PLM infrastructure requires other, non-BOM-driven structures to represent the actual status of a virtual or physical product.

The BOM is not dead, but there is more ………

Your thoughts?

Those who have read my blog posts over the years will have seen the image to the left.

Those who have read my blog posts over the years will have seen the image to the left.

The people, processes and tools slogan points to the best practice of implementing (PLM and CM) systems.

Theoretically, a PLM implementation will move smoothly if the company first agrees on the desired processes and people involved before a system implementation using the right tools.

Too often, companies start from their historical landscape (the tools – starting with a vendor selection) and then try to figure out the optimal usage of their systems. The best example of this approach is the interaction between PDM(PLM) and ERP.

PDM and ERP

Historically ERP was the first enterprise system that most companies implemented. For product development, there was the PDM system, an engineering tool, and for execution, there was the ERP system. Since ERP focuses on the company’s execution, the system became the management’s favorite.

Historically ERP was the first enterprise system that most companies implemented. For product development, there was the PDM system, an engineering tool, and for execution, there was the ERP system. Since ERP focuses on the company’s execution, the system became the management’s favorite.

The ERP system and its information were needed to run and control the company. Unfortunately, this approach has introduced the idea that the ERP system should also be the source of the part information, as it was often the first enterprise system for a company. The PDM system was often considered an engineering tool only. And when we talk about a PLM system, who really implements PLM as an enterprise system or was it still an engineering tool?

This is an example of Tools, Processes, and People – A BAD PRACTICE.

Imagine an engineer who wants to introduce a new part needed for a product to deliver. In many companies at the beginning of this century, even before starting the exercise, the engineer had to request a part number from the ERP system. This is implementation complexity #1.

Imagine an engineer who wants to introduce a new part needed for a product to deliver. In many companies at the beginning of this century, even before starting the exercise, the engineer had to request a part number from the ERP system. This is implementation complexity #1.

Next, the engineer starts developing versions of the part based on the requirements. Ultimately the engineer might come to the conclusion this part will never be implemented. The reserved part number in ERP has been wasted – what to do?

It sounds weird, but this was a reality in discussions on this topic until ten years ago.

Next, as the ERP system could only deal with 7 digits, what about part number reuse? In conclusion, it is a considerable risk that reused part numbers can lead to errors. With the introduction of the PLM systems, there was the opportunity to bridge the gap between engineering and manufacturing. Now it is clear for most companies that the engineer should create the initial part number.

Next, as the ERP system could only deal with 7 digits, what about part number reuse? In conclusion, it is a considerable risk that reused part numbers can lead to errors. With the introduction of the PLM systems, there was the opportunity to bridge the gap between engineering and manufacturing. Now it is clear for most companies that the engineer should create the initial part number.

Only when the conceptual part becomes approved to be used for the realization of the product, an exchange with the ERP system will be needed. Using the same part number or not, we do not care if we can map both identifiers between these environments and have traceability.

It took almost 10 years from PDM to PLM until companies agreed on this approach, and I am curious about your company’s status.

Meanwhile, in the PLM world, we have evolved on this topic. The part and the BOM are no longer simple entities. Instead, we often differentiate between EBOM and MBOM, and the parts in those BOMs are not necessarily the same.

Meanwhile, in the PLM world, we have evolved on this topic. The part and the BOM are no longer simple entities. Instead, we often differentiate between EBOM and MBOM, and the parts in those BOMs are not necessarily the same.

In this context, I like Prof. Dr. Jörg W. Fischer‘s framing:

EBOM is the specification, and MBOM is the realization.

(Leider schreibt Er viel auf Deutsch).

An interesting discussion initiated by Jörg last week was again about the interaction between PLM and ERP. The article is an excellent example of how potentially mainstream enterprises are thinking. PLM = Siemens, ERP = SAP – an illustration of the “tools first” mindset before the ideal process is defined.

An interesting discussion initiated by Jörg last week was again about the interaction between PLM and ERP. The article is an excellent example of how potentially mainstream enterprises are thinking. PLM = Siemens, ERP = SAP – an illustration of the “tools first” mindset before the ideal process is defined.

There was nothing wrong with that in the early days, as connectivity between different systems was difficult and expensive. Therefore people with a 20 year of experience might still rely on their systems infrastructure instead of data flow.

But enough about the bad practice – let’s go to people, processes, (data), and Tools

People, Processes, Data and Tools?

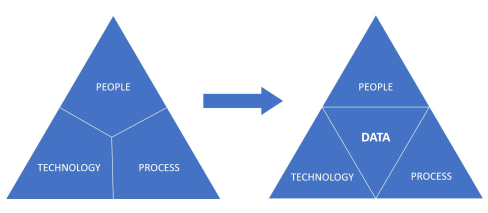

I got inspired by this topic, seeing this post two weeks ago from Juha Korpela, claiming:

Okay, so maybe a hot take, maybe not, but: the old “People, Process, Technology” trinity is one of the most harmful thinking patterns you can have. It leaves out a key element: Data.

His full post was quite focused on data, and I liked the ” wrapping post” from Dr. Nicolas Figay here, putting things more in perspective from his point of view. The reply made me think about how this discussion fits into the PLM digital transformation discussion. How would it work in the two major themes I use to explain the digital transformation in the PLM landscape?

For incidental readers of my blog, these are the two major themes I am using: