You are currently browsing the category archive for the ‘Blocking change’ category.

This blog post is especially written for our PLM Global Green Alliance LinkedIn members — a message from a “boomer” to the next generation of PLM enthusiasts.

This blog post is especially written for our PLM Global Green Alliance LinkedIn members — a message from a “boomer” to the next generation of PLM enthusiasts.

If you belong to that next generation, please read until the end and share your thoughts.

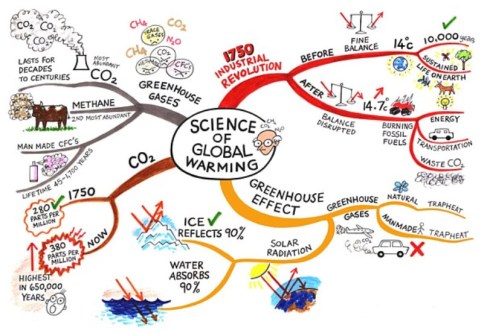

With last week’s announcement from the US government, no longer treating greenhouse gas emissions as a threat to the planet or climate.

We see a push to remove regulations that limit companies from continuing or expanding business without considering the broader consequences for other countries and future generations.

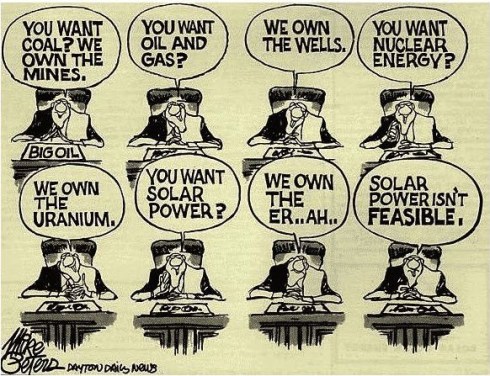

It feels like a short-term, greedy decision, largely influenced by those who benefit from fossil-carbon economies. Decisions like this make the energy transition harder, because the path of least resistance is always the easiest to follow.

Transitions are never simple. But when science is ignored, data is removed, and opinions replace facts, we are no longer supporting a transition — we are actively working against it.

My Story

When I started working in the PLM domain in 1999, climate change already existed in the background of society. The 1972 Limits to Growth report by the Club of Rome had created waves long before, encouraging some people to rethink business and lifestyle choices.

When I started working in the PLM domain in 1999, climate change already existed in the background of society. The 1972 Limits to Growth report by the Club of Rome had created waves long before, encouraging some people to rethink business and lifestyle choices.

For me, however, it stayed outside my daily focus. I was at the beginning of my career, excited about the new challenges.

And important to notice that connecting to the internet with a 28k modem was the standard, a world without social media constantly reminding us of global issues.

I enjoyed my role as the “Flying Dutchman,” travelling around the world to support PLM implementations and discussions. Flying was simply part of the job. Real communication meant being in the same room; early phone and video calls were expensive, awkward, and often ineffective. PLM was — and still is — a human business.

I enjoyed my role as the “Flying Dutchman,” travelling around the world to support PLM implementations and discussions. Flying was simply part of the job. Real communication meant being in the same room; early phone and video calls were expensive, awkward, and often ineffective. PLM was — and still is — a human business.

Back then, the effects of carbon emissions and global warming felt distant, almost abstract. Only around 2014 did the conversation become more mainstream for me, helped by social media, before algorithms and bots began driving polarization.

In 2015, while writing about PLM and global warming, I realized something that still resonates today: even when we understand change is needed, we often stick to familiar habits, because investments in the future rarely deliver immediate ROI for ourselves or our shareholders.

The PLM Green Global Alliance

When Rich McFall approached me in 2019 with the idea of creating an alliance where people and companies could share ideas and experiences around sustainability in the PLM domain, I was immediately interested — for two reasons.

- First, there was a certain sense of responsibility related to my past activities as the Flying Dutchman. Not guilt — life is about learning and gaining insight — but awareness that I needed to change, even if the past could not be changed.

- Second, and more importantly, the PLM Green Global Alliance offered a way to contribute. It gave me a reason to act — for personal peace of mind and for future generations. Not only for my children or grandchildren, but for all those who will share this planet with them.

In the first years of the PGGA, we saw strong engagement from younger professionals. Over time, however, we noticed that career priorities often came first — which is understandable.

Like me at the start of my career, many focus first on building their future. Career and sustainability can coexist, but investing extra time in long-term change is not easy when daily responsibilities already demand so much.

Your Chance to Work on the Future

The real challenge lies with those willing to go the extra mile — staying focused on today’s business while also investing energy in the long-term future.

The real challenge lies with those willing to go the extra mile — staying focused on today’s business while also investing energy in the long-term future.

At the same time, I understand that not everyone is in a position to speak out or dedicate time to sustainability initiatives. Circumstances differ. For many, current responsibilities leave little space for additional commitments.

Still, for those willing to join us, we have two requests to better understand your expectations.

Two weeks ago, I connected with our 40 newest members of the PLM Green Global Alliance. We are now close to 1,600 members — up from around 1,500 in September 2025, as mentioned in Working on the Long Term.

That post was a gentle call to action. Seeing our PGGA membership continue to grow is encouraging — and naturally raises a question:

1. What motivates people to join the PGGA LinkedIn group?

So far, only a small number of the recent new members have completed a survey that was especially sent to them to explore changing priorities. Due to the low response, we extended the invitation to all members. We are curious about your expectations — and quietly hopeful about your involvement.

If you haven’t filled in the survey yet, please click here and share your feedback. The survey is anonymous unless you choose to leave your details for follow-up. We will share the results in approximately 2 weeks from now.

If you haven’t filled in the survey yet, please click here and share your feedback. The survey is anonymous unless you choose to leave your details for follow-up. We will share the results in approximately 2 weeks from now.

2. Design for Sustainability – your contribution?

Last year, Erik Rieger and Matthew Sullivan launched a new workgroup within the PLM Green Global Alliance focused on Design for Sustainability. While the initial energy was strong, changes in personal priorities meant the team could not continue at the pace they hoped. Since many new members have joined since last May, we decided to relaunch the initiative.

If you are interested in contributing to the revival of Design for Sustainability, please take five minutes to complete the short survey. Your input will help shape the direction of the DfS working group and frame future discussions.

If you are interested in contributing to the revival of Design for Sustainability, please take five minutes to complete the short survey. Your input will help shape the direction of the DfS working group and frame future discussions.

Note: If you are worried about clicking on the links for the survey, you can always contact us directly (in private) to share your ambition

Conclusion

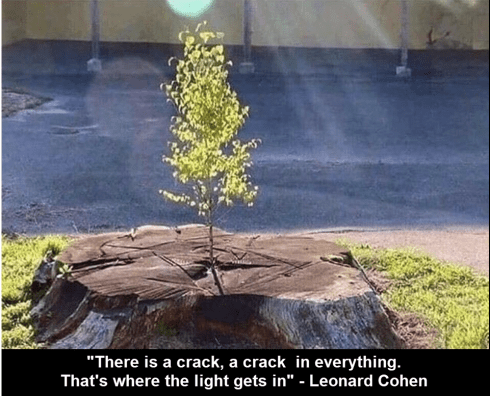

The outside world often pushes us to focus only on daily business. In some places, there is even active pressure to avoid long-term sustainability investments. Remember that pressure often comes from those invested in keeping the current system unchanged.

If you care about the future — your generation and those that follow — stay engaged. Small actions by millions of people can create meaningful change.

We look forward to your input and participation.

— says the boomer who still cares 😉

First, an important announcement. In the last two weeks, I have finalized preparations for the upcoming Share PLM Summit in Jerez on 27-28 May. With the Share PLM team, we have been working on a non-typical PLM agenda. Share PLM, like me, focuses on organizational change management and the HOW of PLM implementations; there will be more emphasis on the people side.

First, an important announcement. In the last two weeks, I have finalized preparations for the upcoming Share PLM Summit in Jerez on 27-28 May. With the Share PLM team, we have been working on a non-typical PLM agenda. Share PLM, like me, focuses on organizational change management and the HOW of PLM implementations; there will be more emphasis on the people side.

Often, PLM implementations are either IT-driven or business-driven to implement a need, and yes, there are people who need to work with it as the closing topic. Time and budget are spent on technology and process definitions, and people get trained. Often, only train the trainer, as there is no more budget or time to let the organization adapt, and rapid ROI is expected.

This approach neglects that PLM implementations are enablers for business transformation. Instead of doing things slightly more efficiently, significant gains can be made by doing things differently, starting with the people and their optimal new way of working, and then providing the best tools.

This approach neglects that PLM implementations are enablers for business transformation. Instead of doing things slightly more efficiently, significant gains can be made by doing things differently, starting with the people and their optimal new way of working, and then providing the best tools.

The conference aims to start with the people, sharing human-related experiences and enabling networking between people – not only about the industry practices (there will be sessions and discussions on this topic too).

If you are curious about the details, listen to the podcast recording we published last week to understand the difference – click on the image on the left.

If you are curious about the details, listen to the podcast recording we published last week to understand the difference – click on the image on the left.

And if you are interested and have the opportunity, join us and meet some great thought leaders and others with this shared interest.

Why is modern PLM a dream?

If you are connected to the LinkedIn posts in my PLM feed, you might have the impression that everyone is gearing up for modern PLM. Articles often created with AI support spark vivid discussions. Before diving into them with my perspective, I want to set the scene by explaining what I mean by modern PLM and traditional PLM.

If you are connected to the LinkedIn posts in my PLM feed, you might have the impression that everyone is gearing up for modern PLM. Articles often created with AI support spark vivid discussions. Before diving into them with my perspective, I want to set the scene by explaining what I mean by modern PLM and traditional PLM.

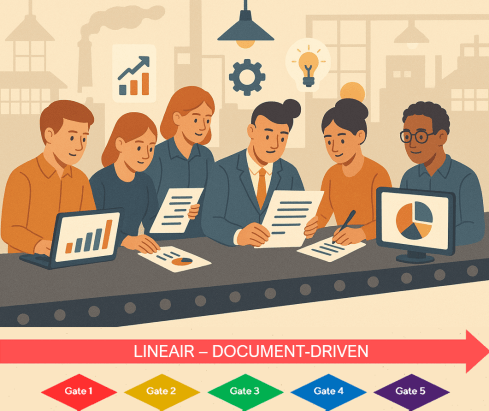

Traditional PLM

Traditional PLM is often associated with implementing a PLM system, mainly serving engineering. Downstream engineering data usage is usually pushed manually or through interfaces to other enterprise systems, like ERP, MES and service systems.

Traditional PLM is closely connected to the coordinated way of working: a linear process based on passing documents (drawings) and datasets (BOMs). Historically, CAD integrations have been the most significant characteristic of these systems.

The coordinated approach fits people working within their authoring tools and, through integrations, sharing data. The PLM system becomes a system of record, and working in a system of record is not designed to be user-friendly.

The coordinated approach fits people working within their authoring tools and, through integrations, sharing data. The PLM system becomes a system of record, and working in a system of record is not designed to be user-friendly.

Unfortunately, most PLM implementations in the field are based on this approach and are sometimes characterized as advanced PDM.

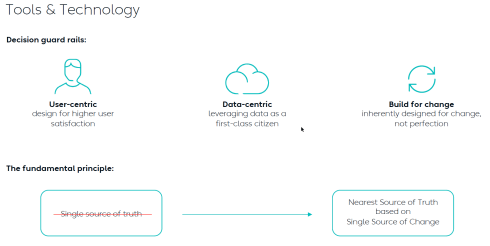

You recognize traditional PLM thinking when people talk about the single source of truth.

Modern PLM

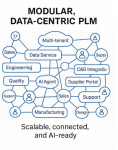

When I talk about modern PLM, it is no longer about a single system. Modern PLM starts from a business strategy implemented by a data-driven infrastructure. The strategy part remains a challenge at the board level: how do you translate PLM capabilities into business benefits – the WHY?

When I talk about modern PLM, it is no longer about a single system. Modern PLM starts from a business strategy implemented by a data-driven infrastructure. The strategy part remains a challenge at the board level: how do you translate PLM capabilities into business benefits – the WHY?

More on this challenge will be discussed later, as in our PLM community, most discussions are IT-driven: architectures, ontologies, and technologies – the WHAT.

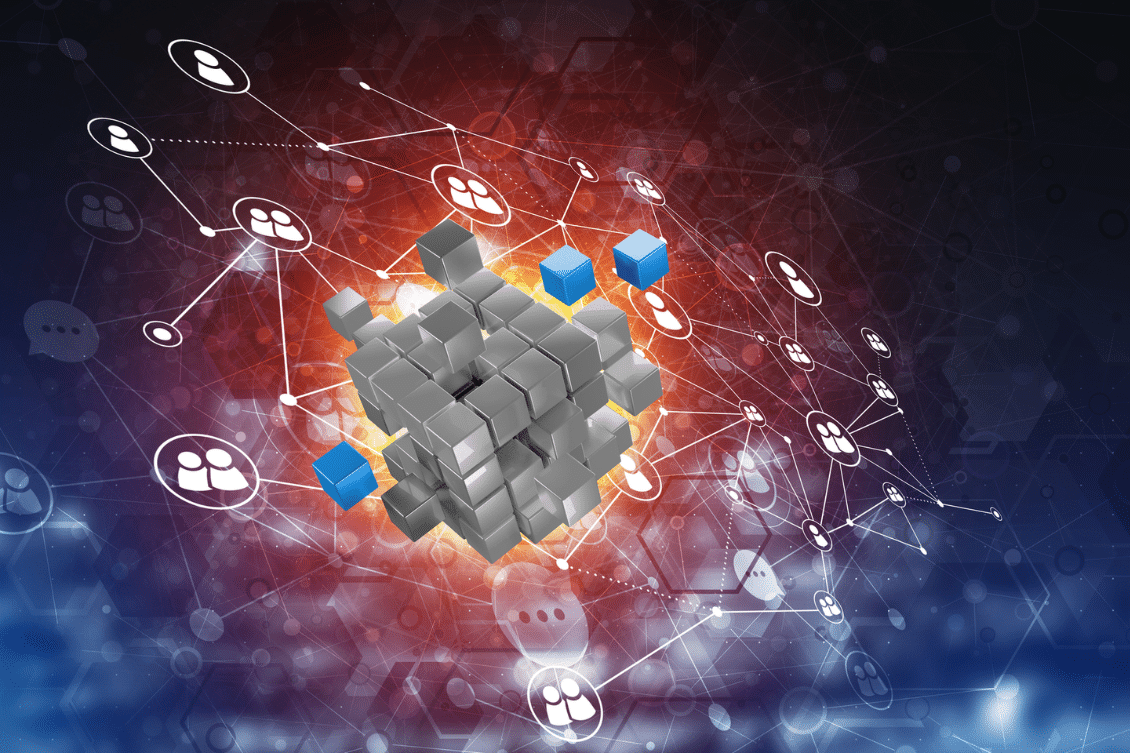

For the WHAT, there seems to be a consensus that modern PLM is based on a federated

For the WHAT, there seems to be a consensus that modern PLM is based on a federated

I think this article from Oleg Shilovitsky, “Rethinking PLM: Is It Time to Move Beyond the Monolith?“ AND the discussion thread in this post is a must-read. I will not quote the content here again.

After reading Oleg’s post and the comments, come back here

The reason for this approach: It is a perfect example of the connected approach. Instead of collecting all the information inside one post (book ?), the information can be accessed by following digital threads. It also illustrates that in a connected environment, you do not own the data; the data comes from accountable people.

Building such a modern infrastructure is challenging when your company depends mainly on its legacy—the people, processes and systems. Where to change, how to change and when to change are questions that should be answered at the top and require a vision and evolutionary implementation strategy.

A company should build a layer of connected data on top of the coordinated infrastructure to support users in their new business roles. Implementing a digital twin has significant business benefits if the twin is used to connect with real-time stakeholders from both the virtual and physical worlds.

But there is more than digital threads with real-time data. On top of this infrastructure, a company can run all kinds of modeling tools, automation and analytics. I noticed that in our PLM community, we might focus too much on the data and not enough on the importance of combining it with a model-based business approach. For more details, read my recent post: Model-based: the elephant in the room.

But there is more than digital threads with real-time data. On top of this infrastructure, a company can run all kinds of modeling tools, automation and analytics. I noticed that in our PLM community, we might focus too much on the data and not enough on the importance of combining it with a model-based business approach. For more details, read my recent post: Model-based: the elephant in the room.

Again, there are no quotes from the article; you know how to dive deeper into the connected topic.

Despite the considerable legacy pressure there are already companies implementing a coordinated and connected approach. An excellent description of a potential approach comes from Yousef Hooshmand‘s paper: From a Monolithic PLM Landscape to a Federated Domain and Data Mesh.

Despite the considerable legacy pressure there are already companies implementing a coordinated and connected approach. An excellent description of a potential approach comes from Yousef Hooshmand‘s paper: From a Monolithic PLM Landscape to a Federated Domain and Data Mesh.

You might recognize modern PLM thinking when people talk about the nearest source of truth and the single source of change.

Is Intelligent PLM the next step?

So far in this article, I have not mentioned AI as the solution to all our challenges. I see an analogy here with the introduction of the smartphone. 2008 was the moment that platforms were introduced, mainly for consumers. Airbnb, Uber, Amazon, Spotify, and Netflix have appeared and disrupted the traditional ways of selling products and services.

So far in this article, I have not mentioned AI as the solution to all our challenges. I see an analogy here with the introduction of the smartphone. 2008 was the moment that platforms were introduced, mainly for consumers. Airbnb, Uber, Amazon, Spotify, and Netflix have appeared and disrupted the traditional ways of selling products and services.

The advantage of these platforms is that they are all created data-driven, not suffering from legacy issues.

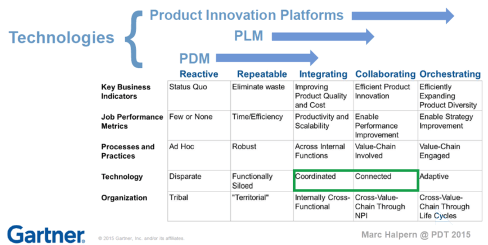

In our PLM domain, it took more than 10 years for platforms to become a topic of discussion for businesses. The 2015 PLM Roadmap/PDT conference was the first step in discussing the Product Innovation Platform – see my The Weekend after PDT 2015 post.

In our PLM domain, it took more than 10 years for platforms to become a topic of discussion for businesses. The 2015 PLM Roadmap/PDT conference was the first step in discussing the Product Innovation Platform – see my The Weekend after PDT 2015 post.

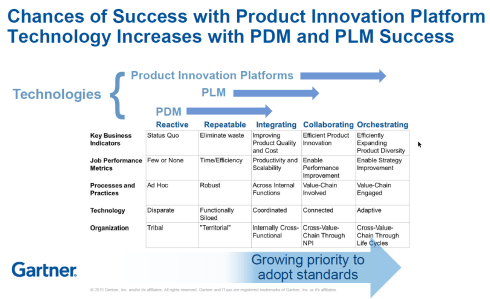

At that time, Peter Bilello shared the CIMdata perspective, Marc Halpern (Gartner) showed my favorite positioning slide (below), and Martin Eigner presented, according to my notes, this digital trend in PLM in his session:” What becomes different for PLM/SysLM?”

2015 Marc Halpern – the Product Innovation Platform (PIP)

While concepts started to become clearer, businesses mainly remained the same. The coordinated approach is the most convenient, as you do not need to reshape your organization. And then came the LLMs that changed everything.

Suddenly, it became possible for organizations to unlock knowledge hidden in their company and make it accessible to people.

Without drastically changing the organization, companies could now improve people’s performance and output (theoretically); therefore, it became a topic of interest for management. One big challenge for reaping the benefits is the quality of the data and information accessed.

I will not dive deeper into this topic today, as Benedict Smith, in his article Intelligent PLM – CFO’s 2025 Vision, did all the work, and I am very much aligned with his statements. It is a long read (7000 words) and a great starting point for discovering the aspects of Intelligent PLM and the connection to the CFO.

I will not dive deeper into this topic today, as Benedict Smith, in his article Intelligent PLM – CFO’s 2025 Vision, did all the work, and I am very much aligned with his statements. It is a long read (7000 words) and a great starting point for discovering the aspects of Intelligent PLM and the connection to the CFO.

You might recognize intelligent PLM thinking when people and AI agents talk about the most likely truth.

Conclusion

Are you interested in these topics and their meaning for your business and career? Join me at the Share PLM conference, where I will discuss “The dilemma: Humans cannot transform—help them!” Time to work on your dreams!

In the last two weeks, I have had mixed discussions related to PLM, where I realized the two different ways people can look at PLM. Are implementing PLM capabilities driven by a cost-benefit analysis and a business case? Or is implementing PLM capabilities driven by strategy providing business value for a company?

In the last two weeks, I have had mixed discussions related to PLM, where I realized the two different ways people can look at PLM. Are implementing PLM capabilities driven by a cost-benefit analysis and a business case? Or is implementing PLM capabilities driven by strategy providing business value for a company?

Most companies I am working with focus on the first option – there needs to be a business case.

This observation is a pleasant passageway into a broader discussion started by Rob Ferrone recently with his article Money for nothing and PLM for free. He explains the PDM cost of doing business, which goes beyond the software’s cost. Often, companies consider the other expenses inescapable.

This observation is a pleasant passageway into a broader discussion started by Rob Ferrone recently with his article Money for nothing and PLM for free. He explains the PDM cost of doing business, which goes beyond the software’s cost. Often, companies consider the other expenses inescapable.

At the same time, Benedict Smith wrote some visionary posts about the potential power of an AI-driven PLM strategy, the most recent article being PLM augmentation – Panning for Gold.

At the same time, Benedict Smith wrote some visionary posts about the potential power of an AI-driven PLM strategy, the most recent article being PLM augmentation – Panning for Gold.

It is a visionary article about what is possible in the PLM space (if there was no legacy ☹), based on Robust Reasoning and how you could even start with LLM Augmentation for PLM “Micro-Tasks.

Interestingly, the articles from both Rob and Benedict were supported by AI-generated images – I believe this is the future: Creating an AI image of the message you have in mind.

![]() When you have digested their articles, it is time to dive deeper into the different perspectives of value and costs for PLM.

When you have digested their articles, it is time to dive deeper into the different perspectives of value and costs for PLM.

From a system to a strategy

The biggest obstacle I have discovered is that people relate PLM to a system or, even worse, to an engineering tool. This 20-year-old misunderstanding probably comes from the fact that in the past, implementing PLM was more an IT activity – providing the best support for engineers and their data – than a business-driven set of capabilities needed to support the product lifecycle.

The biggest obstacle I have discovered is that people relate PLM to a system or, even worse, to an engineering tool. This 20-year-old misunderstanding probably comes from the fact that in the past, implementing PLM was more an IT activity – providing the best support for engineers and their data – than a business-driven set of capabilities needed to support the product lifecycle.

The System approach

Traditional organizations are siloed, and initially, PLM always had the challenge of supporting product information shared throughout the whole lifecycle, where there was no conventional focus per discipline to invest in sharing – every discipline has its P&L – and sharing comes with a cost.

At the management level, the financial data coming from the ERP system drives the business. ERP systems are transactional and can provide real-time data about the company’s performance. C-level management wants to be sure they can see what is happening, so there is a massive focus on implementing the best ERP system.

At the management level, the financial data coming from the ERP system drives the business. ERP systems are transactional and can provide real-time data about the company’s performance. C-level management wants to be sure they can see what is happening, so there is a massive focus on implementing the best ERP system.

In some cases, I noticed that the investment in ERP was twenty times more than the PLM investment.

Why would you invest in PLM? Although the ERP engine will slow down without proper PLM, the complexity of PLM compared to ERP is a reason for management to look at the costs, as the PLM benefits are hard to grasp and depend on so much more than just execution.

Why would you invest in PLM? Although the ERP engine will slow down without proper PLM, the complexity of PLM compared to ERP is a reason for management to look at the costs, as the PLM benefits are hard to grasp and depend on so much more than just execution.

See also my old 2015 article: How do you measure collaboration?

As I mentioned, the Cost of Non-Quality, too many iterations, time lost by searching, material scrap, manufacturing delays or customer complaints – often are considered inescapable parts of doing business (like everyone else) – it happens all the time..

The strategy approach

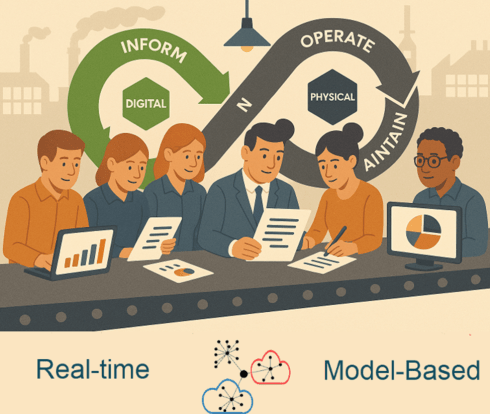

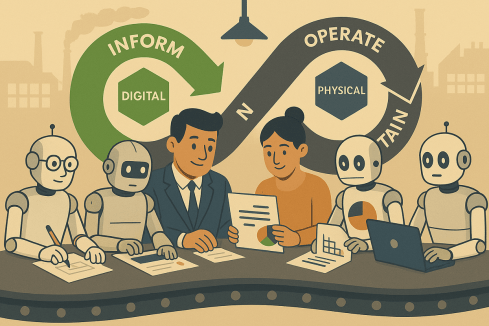

It is clear that when we accept the modern definition of PLM, we should be considering product lifecycle management as the management of the product lifecycle (as Patrick Hillberg says eloquently in our Share PLM podcast – see the image at the bottom of this post, too).

It is clear that when we accept the modern definition of PLM, we should be considering product lifecycle management as the management of the product lifecycle (as Patrick Hillberg says eloquently in our Share PLM podcast – see the image at the bottom of this post, too).

When you implement a strategy, it is evident that there should be a long(er) term vision behind it, which can be challenging for companies. Also, please read my previous article: The importance of a (PLM) vision.

I cannot believe that, although perhaps not fully understood, the importance of a data-driven approach will be discussed at many strategic board meetings. A data-driven approach is needed to implement a digital thread as the foundation for enhanced business models based on digital twins and to ensure data quality and governance supporting AI initiatives.

I cannot believe that, although perhaps not fully understood, the importance of a data-driven approach will be discussed at many strategic board meetings. A data-driven approach is needed to implement a digital thread as the foundation for enhanced business models based on digital twins and to ensure data quality and governance supporting AI initiatives.

It is a process I have been preaching: From Coordinated to Coordinated and Connected.

We can be sure that at the board level, strategy discussions should be about value creation, not about reducing costs or avoiding risks as the future strategy.

Understanding the (PLM) value

The biggest challenge for companies is to understand how to modernize their PLM infrastructure to bring value.

* Step 1 is obvious. Stop considering PLM as a system with capabilities, but investigate how you transform your infrastructure from a collection of systems and (document) interfaces towards a federated infrastructure of connected tools.

![]() Note: the paradigm shift from a Single Source of Truth (in my system) towards a Nearest Source of Truth and a Single Source of Change.

Note: the paradigm shift from a Single Source of Truth (in my system) towards a Nearest Source of Truth and a Single Source of Change.

* Step 2 is education. A data-driven approach creates new opportunities and impacts how companies should run their business. Different skills are needed, and other organizational structures are required, from disciplines working in siloes to hybrid organizations where people can work in domain-driven environments (the Systems of Record) and product-centric teams (the System of Engagement). AI tools and capabilities will likely create an effortless flow of information within the enterprise.

* Step 3 is building a compelling story to implement the vision. Implementing new ways of working based on new technical capabilities requires also organizational change. If your organization keeps working similarly, you might gain some percentage of efficiency improvements.

The real benefits come from doing things differently, and technology allows you to do it differently. However, this requires people to work differently, too, and this is the most common mistake in transformational projects.

The real benefits come from doing things differently, and technology allows you to do it differently. However, this requires people to work differently, too, and this is the most common mistake in transformational projects.

Companies understand the WHY and WHAT but leave the HOW to the middle management.

People are squeezed into an ideal performance without taking them on the journey. For that reason, it is essential to build a compelling story that motivates individuals to join the transformation. Assisting companies in building compelling story lines is one of the areas where I specialize.

People are squeezed into an ideal performance without taking them on the journey. For that reason, it is essential to build a compelling story that motivates individuals to join the transformation. Assisting companies in building compelling story lines is one of the areas where I specialize.

Feel free to contact me to explore the opportunity for your business.

It is not the technology!

With the upcoming availability of AI tools, implementing a PLM strategy will no longer depend on how IT understands the technology, the systems and the interfaces needed.

As Yousef Hooshmand‘s above image describes, a federated infrastructure of connected (SaaS) solutions will enable companies to focus on accurate data (priority #1) and people creating and using accurate data (priority #1). As you can see, people and data in modern PLM are the highest priority.

Therefore, I look forward to participating in the upcoming Share PLM Summit on 27-28 May in Jerez.

It will be a breakthrough – where traditional PLM conferences focus on technology and best practices. This conference will focus on how we can involve and motivate people. Regardless of which industry you are active in, it is a universal topic for any company that wants to transform.

Conclusion

Returning to this article’s introduction, modern PLM is an opportunity to transform the business and make it future-proof. It needs to be done for sure now or in the near future. Therefore PLM initiatives should be considered from the value point first instead of focusing on the costs. How well are you connected to your management’s vision to make PLM a value discussion?

Enjoy the podcast – several topics discuss relate to this post.

In the last two weeks, I had some interesting observations and discussions related to the need to have a (PLM) vision. I placed the word PLM between brackets, as PLM is no longer an isolated topic in an organization. A PLM strategy should align with the business strategy and vision.

In the last two weeks, I had some interesting observations and discussions related to the need to have a (PLM) vision. I placed the word PLM between brackets, as PLM is no longer an isolated topic in an organization. A PLM strategy should align with the business strategy and vision.

To be clear, if you or your company wants to survive in the future, you need a sustainable vision and a matching strategy as the times they are a changing, again!

I love the text: “Don’t criticize what you can’t understand” – a timeless quote.

First, there was Rob Ferrone’s article: Multi-view. Perspectives that shape PLM – a must-read to understand who to talk to about which dimension of PLM – and it is worth browsing through the comments too – there you will find the discussions, and it helps you to understand the PLM players.

First, there was Rob Ferrone’s article: Multi-view. Perspectives that shape PLM – a must-read to understand who to talk to about which dimension of PLM – and it is worth browsing through the comments too – there you will find the discussions, and it helps you to understand the PLM players.

Note: it is time that AI-generated images become more creative 😉

Next, there is still the discussion started by Gareth Webb, Digital Thread and the Knowledge Graph, further stirred by Oleg Shilovitsky.

Next, there is still the discussion started by Gareth Webb, Digital Thread and the Knowledge Graph, further stirred by Oleg Shilovitsky.

Based on the likes and comments, it is clearly a topic that creates interaction – people are thinking and talking about it – the Digital Thread as a Service.

One of the remaining points in this debate is still the HOW and WHEN companies decide to implement a Digital Thread, a Knowledge Graph and other modern data concepts.

So far my impression is that most companies implement their digital enhancements (treads/graphs) in a bottom-up approach, not driven by a management vision but more like band-aids or places where it fits well, without a strategy or vision.

So far my impression is that most companies implement their digital enhancements (treads/graphs) in a bottom-up approach, not driven by a management vision but more like band-aids or places where it fits well, without a strategy or vision.

The same week, we, Beatriz Gonzáles and I, recorded a Share PLM podcast session with Paul Kaiser from MHP Americas as a guest. Paul is the head of the Digital Core & Technology department, where he leads management and IT consulting services focused on end-to-end business transformation.

During our discussion, Paul mentioned the challenge in engagements when the company has no (PLM) vision. These companies expect external consultants to formulate and implement the vision – a recipe for failure due to wrong expectations.

During our discussion, Paul mentioned the challenge in engagements when the company has no (PLM) vision. These companies expect external consultants to formulate and implement the vision – a recipe for failure due to wrong expectations.

The podcast can be found HERE , and the session inspired me to write this post.

“We just want to be profitable“.

I believe it is a typical characteristic of small and medium enterprises that people are busy with their day-to-day activities. In addition, these companies rarely appoint new top management, which could shake up the company in a positive direction. These companies evolve …..

You often see a stable management team with members who grew up with the company and now monitor and guide it, watching its finances and competition. They know how the current business is running.

Based on these findings, there will be classical efficiency plans, i.e., cutting costs somewhere, dropping some non-performing products, or investing in new technology that they cannot resist. Still, minor process changes and fundamental organizational changes are not expected.

Based on these findings, there will be classical efficiency plans, i.e., cutting costs somewhere, dropping some non-performing products, or investing in new technology that they cannot resist. Still, minor process changes and fundamental organizational changes are not expected.

Most of the time, the efficiency plans provide single-digit benefits.

Everyone is happy when the company feels stable and profitable, even if the margins are under pressure. The challenge for this type of company without a vision is that they navigate in the dark when the outside world changes – like nowadays.

Everyone is happy when the company feels stable and profitable, even if the margins are under pressure. The challenge for this type of company without a vision is that they navigate in the dark when the outside world changes – like nowadays.

The world is changing drastically.

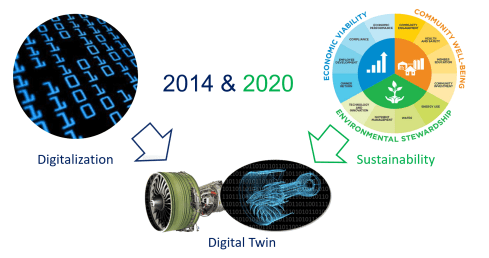

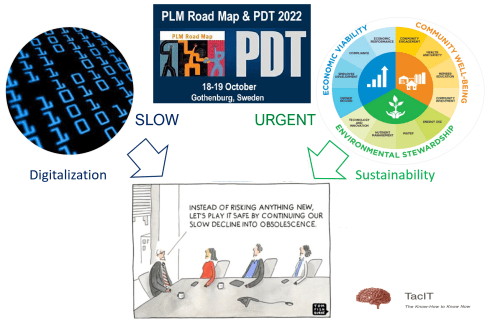

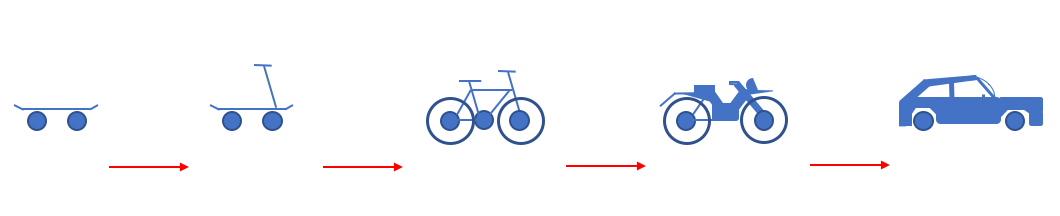

Since 2014, I have advocated for digital transformation in the PLM domain and explained it simply using the statement: From Coordinated to Connected, which already implies much complexity.

Moving from document/files to datasets and models, from a linear delivery model to a DevOps model, from waterfall to agile and many other From-To statements.

Moving From-To is a transformational journey, which means you will learn and adapt to new ways of working during the journey. Still, the journey should have a target, directed by a vision.

However, not many companies have started this journey because they just wanted to be profitable.

“Why should we go in an unknown direction?”

With the emergence of sustainability regulations, e.g., GHG and ESG reporting, carbon taxes, material reporting, and the Digital Product Passport, which goes beyond RoHS and REACH and applies to much more industries, there came the realization that there is a need to digitize the product lifecycle processes and data beyond documents. Manual analysis and validation are too expensive and unreliable.

At this stage, there is already a visible shift between companies that have proactively implemented a digitally connected infrastructure and companies that still see compliance with regulations as an additional burden. The first group brings products to the market faster and more sustainably than the second group because sustainability is embedded in their product lifecycle management.

![]() And just when companies felt they could manage the transition from Coordinated to Coordinated and Connected, there was the fundamental disruption of embedded AI in everything, including the PLM domain.

And just when companies felt they could manage the transition from Coordinated to Coordinated and Connected, there was the fundamental disruption of embedded AI in everything, including the PLM domain.

- Large Language Models LLMs can go through all the structured and unstructured data, providing real-time access to information, which would take experts years of learning. Suddenly, everyone can behave experienced.

- The rigidness of traditional databases can be complemented by graph databases, which visualize knowledge that can be added and discovered on the fly without IT experts. Suddenly, an enterprise is no longer a collection of interfaced systems but a digital infrastructure where data flows – some call it Digital Thread as a Service (DTaaS)

- Suddenly, people feel overwhelmed by complexity, leading to fear and doing nothing, a killing attitude.

I cannot predict what will happen in the next 5 to 10 years, but I am sure the current change is one we have never seen before. Be prepared and flexible to act—to be on top of the wave, you need the skills to get there.

Building the vision

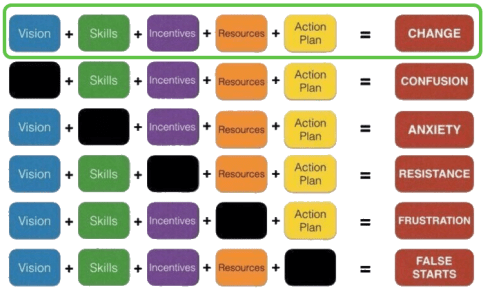

The image below might not be new to you, but it illustrates how companies could manage a complex change.

I will focus only on the first two elements, Vision and Skills, as they are the two elements we as individuals can influence. The other elements are partly related to financial and business constraints.

Vision and Skills are closely related because you can have a fantastic vision. Still, to realize the vision, you need a strategy driven by relevant skills to define and implement the vision. With the upcoming AI, traditional knowledge-based skills will suddenly no longer be a guarantee for future jobs.

AI brings a new dimension for everyone working in a company. To remain relevant, you must develop your unique human skills that make you different from robots or libraries. The importance of human skills might not be new, but now it has become apparent with the explosion of available AI tools.

AI brings a new dimension for everyone working in a company. To remain relevant, you must develop your unique human skills that make you different from robots or libraries. The importance of human skills might not be new, but now it has become apparent with the explosion of available AI tools.

Look at this 2013 table about predicted skills for the future – You can read the details in their paper, The Future of Employment, by Carl Benedikt Frey & Michael Osborne(2013) – click on the image to see the details.

In my 2015 PLM lectures, I joked when showing this image that my job as a PLM coach was secured, because you are a recreational therapist and firefighter combined.

It has become a reality, and many of my coaching engagements nowadays focus on explaining and helping companies formulate and understand their possible path forward. Helping them align and develop a vision of progressing in a volatile world – the technology is there, the skills and the vision are often not yet there.

![]() Combining business strategy with in-depth PLM concepts is a relatively unique approach in our domain. Many of my peers have other primary goals, such as Rob Ferrone’s article: Multi-view. Perspectives that shape PLM explains.

Combining business strategy with in-depth PLM concepts is a relatively unique approach in our domain. Many of my peers have other primary goals, such as Rob Ferrone’s article: Multi-view. Perspectives that shape PLM explains.

And then there is …..

The Share PLM Summit 2025

Modern times need new types of information building and sharing, and therefore, I am eager to participate in the upcoming Share PLM Summit at the end of May in Jerez (Spain).

See the link to the event here: The Share PLM Summit 2025 – with the theme: Where People Take Center Stage to Drive Human-Centric Transformations in PLM and Lead the Future of Digital Innovation.

In my lecture, I will focus on how humans can participate in/anticipate this digital AI-based transformation. But even more, I look forward to the lectures and discussions with other peers, as more people-centric thought leaders and technology leaders will join us:

Quoting Oleg Shilovitsky:

PLM was built to manage data, but too often, it makes people work for the data instead of working the other way around. At Share PLM Summit 2025, I’ll discuss how PLM must evolve from rigid, siloed systems to intelligent, connected, and people-centric data architectures.

We need both, and I hope to see you at the end of May at this unique PLM conference.

Conclusion

We are at a decisive point of the digital transformation as AI will challenge people skills, knowledge and existing ways of working. Combined with a turbulent world order, we need to prepare to be flexible and resilient. Therefore instead of focusing on current best practices we need to prepare for the future – a vision developed by skilled people. How will you or your company work on that? Join us if you have questions or ideas.

In my general 2025 outlook for PLM, My 2025 focus, I mentioned Sustainability at the end, as I believe it is a topic on its own, worth an entire blog post.

In my general 2025 outlook for PLM, My 2025 focus, I mentioned Sustainability at the end, as I believe it is a topic on its own, worth an entire blog post.

After our 2025 PLM Global Green Alliance core team kick-off last week, I felt the importance of sharing our thoughts, observations, and personal thoughts/focus.

The PGGA core team consists of Rich McFall – Climate Change, Klaus Brettschneider Life Cycle Assessment, Mark Reisig Sustainability and Green Energy, Evgeniya Burimskaya Circular Economy, Erik Reiger Design for Sustainability and me Talking about Sustainability.

The PGGA core team consists of Rich McFall – Climate Change, Klaus Brettschneider Life Cycle Assessment, Mark Reisig Sustainability and Green Energy, Evgeniya Burimskaya Circular Economy, Erik Reiger Design for Sustainability and me Talking about Sustainability.

Some interesting observations:

- Evgenia mentioned that in job interviews for CIMPA, it is motivating to see that new employees want to contribute to sustainability activities and the education of companies. Sustainability is part of their WHY (I will come back to that later)

- We have more and more PGGA members from Asia, while percentage of US members is declining. Where the US has the loudest voice against human-caused climate change and Sustainability, there are a lot of hidden and positive success stories from Asia, and we are looking for spokespeople from that region.

Regulations

In many lectures, I explained that digitization in PLM was going slow because this is a complex topic for many companies, and current business performance might be challenging but not too bad. So why would we go on an unknown and potentially risky transformation journey?

Due to sustainability regulations, digital transformation has gotten a push in the right direction. GHG (Greenhouse Gas) reporting, ESG (Environmental Social Governance) reporting, CSRD (Corporate Sustainability Reporting Directive), and the DPP (Digital Product Passport) have all created the need for companies to create digital threads for information that historically did not exist or was locked in documents.

Due to sustainability regulations, digital transformation has gotten a push in the right direction. GHG (Greenhouse Gas) reporting, ESG (Environmental Social Governance) reporting, CSRD (Corporate Sustainability Reporting Directive), and the DPP (Digital Product Passport) have all created the need for companies to create digital threads for information that historically did not exist or was locked in documents.

Therefore, it is interesting to read Oleg Shilovitsky’ s blog, Reimagining PLM for 2025: Key Strategic Trends, in which he also sees the importance of Sustainability and the Circular Economy.

Therefore, it is interesting to read Oleg Shilovitsky’ s blog, Reimagining PLM for 2025: Key Strategic Trends, in which he also sees the importance of Sustainability and the Circular Economy.

Quoting Oleg:

Sustainability cannot be ignored and, therefore I expect more interest to environmental considerations in PLM strategies. Companies are incorporating sustainability metrics into product design and lifecycle assessment, aligning with Industry 5.0 and Engineering 5.0 principles. It is impossible without digital thread and data connectivity and, therefore will continue to support business strategies.

The challenge of regulations is that they limit someone’s freedom. Regulations are there to create an equal playing field for all and ensure society makes progress. Be it traffic regulations, business regulations or environmental regulations. The challenge is not to over-regulate and create a Kafkaesque society. Whereas if you are alone in the world or are the only important person in the world, you do not need regulations as you do not care.

The challenge of regulations is that they limit someone’s freedom. Regulations are there to create an equal playing field for all and ensure society makes progress. Be it traffic regulations, business regulations or environmental regulations. The challenge is not to over-regulate and create a Kafkaesque society. Whereas if you are alone in the world or are the only important person in the world, you do not need regulations as you do not care.

Now the challenge comes of how we deal with regulations.

The WHY!

I have learned to always look at the WHY. Why are companies doing business in a certain manner, why are people behaving in a certain manner even against common logic?

I have learned to always look at the WHY. Why are companies doing business in a certain manner, why are people behaving in a certain manner even against common logic?

There is the difference between the long-term WHY (strategy) and the short-term WHY(emotion). For most individuals the short-term WHY prevails, for companies and governments the long term WHY should lead their decisions.

Unfortunately short term decisions (money, food, comfort, legacy habits) get a higher priority by humans instead of long term goals (transformations and transitions).

Daniel Kahneman, Nobel prize winner writing about this in his book Thinking Fast and Slow. We see this dilemma, fast based on gut-feeling or slow based on a real analysis in companies, we see it in our society .

Daniel Kahneman, Nobel prize winner writing about this in his book Thinking Fast and Slow. We see this dilemma, fast based on gut-feeling or slow based on a real analysis in companies, we see it in our society .

- How many companies have a 10-years sustainable strategy and consistent roadmap?

- How many countries have a 10-years sustainable strategy and consistent roadmap?

Jan Bosch also mentioned the importance of the WHY in his Digital Reflection #15: Why do you get out of bed in the morning? Did you ask yourself this question?

Sustainability, like digitization in PLM, requires a behavioral change. From traditional linear coordinated ways of working we need to learn to work in a more complex and advanced environment with real-time data. Luckily if the data is accurate AI will help us to manage the complexity.

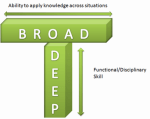

Still it is a transformational change in the way you work and this is a challenge for an existing workforce. They reached their status by being an expert in a certain discipline, by mastering specific skills. Now the needed expertise is changing (from Expert to T-shape) and new skills are needed. Are you able to acquire those new skills or do you give up and complain about the future?

Still it is a transformational change in the way you work and this is a challenge for an existing workforce. They reached their status by being an expert in a certain discipline, by mastering specific skills. Now the needed expertise is changing (from Expert to T-shape) and new skills are needed. Are you able to acquire those new skills or do you give up and complain about the future?

The same challenges happen related to sustainability. Our current (western) habits are draining the planet and only behavioral changes can stop or reduce the damage. Most of us are aware that the planet is limited in resources and we need an energy transition in the long term. But are you able to learn those new behaviors or do you give up and hold on to the good old past?

Note: It’s important to understand that individual actions are not the primary cause of the climate crisis, nor can they alone resolve it. This idea is often promoted by industries. The bigger question is whether our societies can change—consider where financial resources are being allocated.

Note: It’s important to understand that individual actions are not the primary cause of the climate crisis, nor can they alone resolve it. This idea is often promoted by industries. The bigger question is whether our societies can change—consider where financial resources are being allocated.

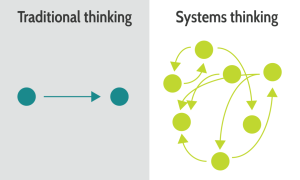

Sustainability and Systems Thinking

We cannot just produce product or consume like crazy if we care about future generations. It is not longer only about the money, it is about next generations and the environment – if you care. This complexity pushes us toward Systems Thinking – many topics are connected – addressing a single topic does not solve the rest.

We cannot just produce product or consume like crazy if we care about future generations. It is not longer only about the money, it is about next generations and the environment – if you care. This complexity pushes us toward Systems Thinking – many topics are connected – addressing a single topic does not solve the rest.

I wrote two posts in 2022 about Systems Thinking t: SYSTEMS THINKING – a must-have skill in the 21st century and as a follow-up based on interactions Systems Thinking: a second thought. The challenge with Systems Thinking is that the solution is not black or white and requires brain power.

Sustainability and Political Leadership

With what is happening currently in our societies you can see that sustainability is strongly connected to its country’s political system. The bad news for long term issues democracy is probably the worst. Let me share some observations.

Europe

Historically Europe has been a stable democracy since the second world war and the European Union has been able to establish quite a unified voice step by step. Of course the European Union was heavily influenced by the Automotive and Agricultural lobby. Still the European Green Deal was established with great consensus in the middle instead of focusing on the extremes. A multi-party parliament guarantees a balanced outcome. However type of democracy is still very sensitive for influences from lobbyist and external forces.

Historically Europe has been a stable democracy since the second world war and the European Union has been able to establish quite a unified voice step by step. Of course the European Union was heavily influenced by the Automotive and Agricultural lobby. Still the European Green Deal was established with great consensus in the middle instead of focusing on the extremes. A multi-party parliament guarantees a balanced outcome. However type of democracy is still very sensitive for influences from lobbyist and external forces.

There are so many Dunning-Kruger experts roaring down the common sense debates – mainly in democratic countries. It would be great if people started from the WHY. WHY is someone acting – is it a short-term gain/fear to loose or is there a long-term strategy.

As long as Europe can maintain its consensus culture there is hope for the long-term.

US

The US has been leading the world in polarization. With two major parties fighting always for the 51 % majority vote, there is no place for consensus. The winner takes it all. And although we call it a democracy, you need to have a lot of money to be elected and money is the driving power behind the elections. The WHY in most cases in the US is about short term money making, although I found an interesting point related to Elon Musk.

The US has been leading the world in polarization. With two major parties fighting always for the 51 % majority vote, there is no place for consensus. The winner takes it all. And although we call it a democracy, you need to have a lot of money to be elected and money is the driving power behind the elections. The WHY in most cases in the US is about short term money making, although I found an interesting point related to Elon Musk.

In his 2022 interview he shares his vision that the future is in solar energy and batteries with nuclear needed for the transition. Also he is no fan of longevity – quote from the video (5:30)

In his 2022 interview he shares his vision that the future is in solar energy and batteries with nuclear needed for the transition. Also he is no fan of longevity – quote from the video (5:30)

Most people don’t change their mind, they just die. And if they don’t die we will be stuck with old ideas and society won’t advance.

It is a great example of “If you cannot beat them – join them” and then use them to fund your missions. A narcistic president becomes your helper to achieve your long-term strategy.

Saudi Arabia

Here we are not talking about a democracy anymore and they might seem the biggest enemy for the climate. However they have a long-term strategy. While keeping the world addicted to fossil fuels, they invest heavily in solar and hydrogen and once the western world understands the energy transition is needed, they are far ahead in experience and remain a main energy supplier.

Here we are not talking about a democracy anymore and they might seem the biggest enemy for the climate. However they have a long-term strategy. While keeping the world addicted to fossil fuels, they invest heavily in solar and hydrogen and once the western world understands the energy transition is needed, they are far ahead in experience and remain a main energy supplier.

China

With 1.4 billion inhabitants and not a democracy either, China has a different mission. Initially as the manufacturing hub for the planet they needed huge amount of energy and therefore they are listed as the most polluting country in the world.

With 1.4 billion inhabitants and not a democracy either, China has a different mission. Initially as the manufacturing hub for the planet they needed huge amount of energy and therefore they are listed as the most polluting country in the world.

However their energy transition towards solar, water, wind and even nuclear goes so much faster than committed in the Paris agreements, as China has a long-term strategy to be energy independent and to be the major supplier in the energy transition. The long-term WHY is clear.

Russia

It is a pity to mention Russia as with their war-economy and reliance on fossil fuels, they are on a path towards oblivion. Even if they would win a few other wars, innovation is gone and fossil is ending. It will be a blessing for humanity. I hope they will find a new long-term strategy.

It is a pity to mention Russia as with their war-economy and reliance on fossil fuels, they are on a path towards oblivion. Even if they would win a few other wars, innovation is gone and fossil is ending. It will be a blessing for humanity. I hope they will find a new long-term strategy.

Conclusion

PLM and Sustainability are important for the long-term, despite the throw-back you might see on the short term due to politics and lobbies. In addition we need courage to keep on focusing on the long-term as our journey has just started.

Feel free to share your thoughts with compassion and respect for other opinions.

Two weeks ago, this post from Ilan Madjar drew my attention. He pointed to a demo movie, explaining how to support Smart Part Numbering on the 3DEXPERIENCE platform. You can watch the recording here.

Two weeks ago, this post from Ilan Madjar drew my attention. He pointed to a demo movie, explaining how to support Smart Part Numbering on the 3DEXPERIENCE platform. You can watch the recording here.

I was surprised that Smart Part Numbering is still used, and if you read through the comments on the post, you see the various arguments that exist.

- “Many mid-market customers are still using it”

me: I think it is not only the mid-market – however, the argument is no reason to keep it alive. - “The problem remains in the customer’s desire (or need or capability) for change.”

me: This is part of the lowest resistance. - “User resistance to change. Training and management sponsorship has proven to be not enough.”

me: probably because discussions are feature-oriented, not starting from the business benefits. - “Cost and effort- rolling this change through downstream systems. The cost and effort of changing PN in PLM,ERP,MES, etc., are high. Trying to phase it out across systems is a recipe for a disaster.”

me: The hidden costs of maintaining Smart Numbers inside an organization are high and invisible, reducing the company’s competitiveness. - “Existing users often complain that it takes seconds to minutes more for unintelligent PN vs. using intelligent PN.”

me: If we talk about a disconnected user without access to information, it could be true if the number of Smart Numbers to comprehend is low.

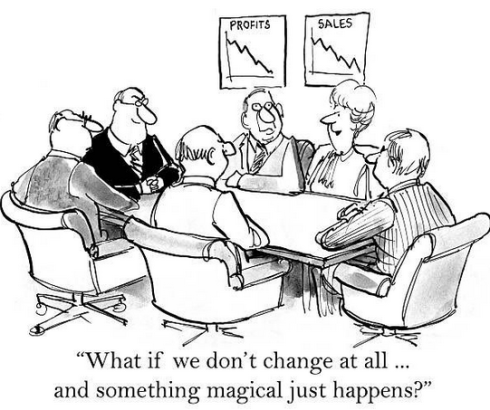

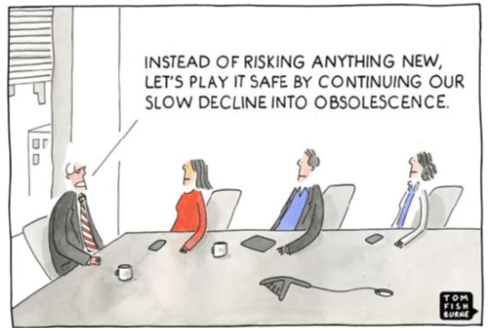

There were many other arguments for why you should not change. It reminded me of the image below:

Smart Numbers related to the Coordinated approach

Smart Part Numbers are a characteristic of best practices from the past. Where people were working in different systems, the information moving from one system to another was done manually.

For example, it is re-entering the Bill of Materials from the PDM system into the ERP system or attaching drawings to materials/parts in the ERP system. The filename often reflects the material or part number in the latter case.

The problems with the coordinated, smart numbering approach are:

New people in the organization need to learn the meaning of the numbering scheme. This learning process reduces the flexibility of an organization and increases the risk of making errors.

New people in the organization need to learn the meaning of the numbering scheme. This learning process reduces the flexibility of an organization and increases the risk of making errors.- Typos go unnoticed when transferring numbers from one system to another and only get noticed late when the cost of fixing the error might be 10 -100 fold.

- The argument that people will understand the meaning of a part is partly valid. A person can have a good guess of the part based on the smart part number; however, the details can be different unless you work every day with the same and small range of parts.

- Smart Numbers created a legacy. After Mergers and Acquisitions, there will be multiple part number schemes. Do you want to renumber old parts, meaning non-value-added, risky activities? Do you want to continue with various numbering schemes, meaning people need to learn more than one numbering schema – a higher entry barrier and risk of errors?

There were and still are many advanced smart numbering systems.

In one of my first PDM implementations in the Netherlands, I learned about the 12NC code system from Philips – introduced at Philips in 1963 and used to identify complete products, documentation, and bare components, up to the finest detail. At this moment, many companies in the Philips family (suppliers or offspring) still use this numbering system, illustrating that it is not only the small & medium enterprises that are reluctant to change their numbering system.

In one of my first PDM implementations in the Netherlands, I learned about the 12NC code system from Philips – introduced at Philips in 1963 and used to identify complete products, documentation, and bare components, up to the finest detail. At this moment, many companies in the Philips family (suppliers or offspring) still use this numbering system, illustrating that it is not only the small & medium enterprises that are reluctant to change their numbering system.

The costs of working with Smart Part Numbers are often unnoticed as they are considered a given.

From Coordinated to Connected

Digital transformation in the PLM domain means moving from coordinated practices toward practices that benefit from connected technology. In many of my blog posts, you can read why organizations need to learn to work in a connected manner. It is both for their business sustainability and also for being able to deal with regulations related to sustainability in the short term.

GHG reporting, ESG reporting, material compliance, and the DPP are all examples of the outside world pushing companies to work connected. Besides the regulations, if you are in a competitive business, you must be more efficient, innovative and faster than your competitors.

In a connected environment, relations between artifacts (datasets) are maintained in an IT infrastructure without requiring manual data transformations and people to process the data. In a connected enterprise, this non-value-added work will be reduced.

How to move away from Smart Numbering systems?

Several comments related to the Smart Numbering discussion mentioned that changing the numbering system is too costly and risky to implement and that no business case exists to support it. This statement only makes sense if you want your business to become obsolete slowly. Modern best practices based on digitization should be introduced as fast as possible, allowing companies to learn and adapt. There is no need for a big bang.

Several comments related to the Smart Numbering discussion mentioned that changing the numbering system is too costly and risky to implement and that no business case exists to support it. This statement only makes sense if you want your business to become obsolete slowly. Modern best practices based on digitization should be introduced as fast as possible, allowing companies to learn and adapt. There is no need for a big bang.

Start with mapping, prioritizing, and mapping value streams in your company. Where do we see the most significant business benefits related to cost of handling, speed, and quality?

Start with mapping, prioritizing, and mapping value streams in your company. Where do we see the most significant business benefits related to cost of handling, speed, and quality?

Note: It is not necessary to start with engineering as they might be creators of data – start, for example, with the xBOM flow, where the xBOM can be a concept BOM, the engineering BOM, the Manufacturing BOM, and more. Building this connected data flow is an investment for every department; do not start from the systems.

Note: It is not necessary to start with engineering as they might be creators of data – start, for example, with the xBOM flow, where the xBOM can be a concept BOM, the engineering BOM, the Manufacturing BOM, and more. Building this connected data flow is an investment for every department; do not start from the systems.

- Next point: Do not rename or rework legacy data. These activities do not add value; they can only create problems. Instead, build new process definitions that do not depend on the smartness of the number.

Make sure these objects have, besides the part number, the right properties, the right status, and the right connections. In other words, create a connected digital thread – first internally in your company and next with your ecosystem (OEMs, suppliers, vendors)

Make sure these objects have, besides the part number, the right properties, the right status, and the right connections. In other words, create a connected digital thread – first internally in your company and next with your ecosystem (OEMs, suppliers, vendors)

- Next point: Give newly created artifacts a guaranteed unique ID independent of others. Each artifact has its status, properties and context. In this step, it is time to break any 1 : 1 relation between a physical part and a CAD-part or drawing. If a document gets revised, it gets a new version, but the version change should not always lead to a part number change. You can find many discussions on why to decouple parts and documents and the flexibility it provides.

- Next point: New generated IDs are not necessarily generated in a single system. The idea of a single source of truth is outdated. Build your infrastructure upon existing standards if possible. For example, the UID of the Digital Product Passport will be based on the ISO/IEC 15459 standard, similar to the UID for retail products managed by the GS1 standard. Or, probably closer to home, look into your computer’s registry, and you will discover a lot of software components with a unique ID that specific programs or applications can use in a shared manner.

When will it happen?

In January 2016, I wrote about “the impact of non-intelligent part numbers” and surprisingly almost 8 years later and we are still in the same situation.

I just read Oleg Shilovitsky’s post The Data Dilemma: Why Engineers and Manufacturing Companies Struggle to Find Time for Data Management where he mentions Legacy Systems and Processes, Overwhelming Workloads, Lack of (Data) Expertise, Short-Term Focus and Resource Constraints as inhibitors.

I just read Oleg Shilovitsky’s post The Data Dilemma: Why Engineers and Manufacturing Companies Struggle to Find Time for Data Management where he mentions Legacy Systems and Processes, Overwhelming Workloads, Lack of (Data) Expertise, Short-Term Focus and Resource Constraints as inhibitors.

You probably all know the above cartoon. How can companies get out of this armor or habits? Will they be forced by the competition or by regulations. What do you think ?

Conclusion

Despite proven business benefits and insights, it remains challenging for companies to move toward modern, data-driven practices where Smart Number generators are no longer needed. When talking one-on-one to individuals, they are convinced a change is necessary, and they are pointing to the “others”.

I wish you all a prosperous 2024 and the power to involve the “others”.

Today I read Rhiannon Gallagherer’s LinkedIn post: If Murray Isn’t Happy, No One Is Happy: Value Your Social Nodes. The story reminded me of a complementary blog post I wrote in 2014, although with a small different perspective.

Today I read Rhiannon Gallagherer’s LinkedIn post: If Murray Isn’t Happy, No One Is Happy: Value Your Social Nodes. The story reminded me of a complementary blog post I wrote in 2014, although with a small different perspective.

After reviewing my post, I discovered that nine years later, we are still having the same challenges of how to involve people in a business transformation.

People are the most important assets companies claim, but where do they focus their spending and efforts?

Probably more on building the ideal processes and having the best IT solution.

Organisational Change Management is not in their comfort zone. People like Rhiannon Gallagher, but also in my direct network, the team from Share PLM, are focusing on this blind spot. Don’t forget this part of your digital transformation efforts.

Organisational Change Management is not in their comfort zone. People like Rhiannon Gallagher, but also in my direct network, the team from Share PLM, are focusing on this blind spot. Don’t forget this part of your digital transformation efforts.

And just for fun, there rest of the post below is the article from 2014. At that time, I was not yet focusing on digital transformation in the PLM domain. That started end of 2014 – the beginning of 2015.

PLM and Blockers

(read it with 2014 in mind – where were you?)

In the past month (April 2014), I had several discussions related to the complexity of PLM.

- Why is PLM conceived as complex?

- Why is it hard to sell PLM internally into an organization?

- Or, to phrase it differently: “What makes PLM so difficult for normal human beings. As conceptually it is not so complex”

(2023 addition: PLM is complex (and we have to accept it?) )

So what makes it complex? What is behind PLM?

The main concept behind PLM is that people need to share data. It can be around a project, a product, or a plant through the whole lifecycle. In particular, during the early lifecycle phases, there is a lot of information that is not yet 100 percent mature.

The main concept behind PLM is that people need to share data. It can be around a project, a product, or a plant through the whole lifecycle. In particular, during the early lifecycle phases, there is a lot of information that is not yet 100 percent mature.

You could decide to wait till everything is mature before sharing it with others (the classical sequential manner). However, the chances of doing it right the first time are low. Several iterations between disciplines will be required before the data is approved.

The more and more a company works sequentially, the higher the costs of changes and the longer the time to market. Due to the rigidness of this sequential approach, it becomes difficult to respond rapidly to changing customer or market demands.

Therefore, in theory (and it is not only a PLM theory), concurrent engineering should reduce the number of iterations and the total time to market by working in parallel on not yet approved data.

PLM goes further. It is about the sharing of data, and as it originally started in the early phases of the product lifecycle, the concept of PLM was considered something related to engineering. And to be fair, most of the PLM (CAD-related) vendors have a high focus on the early stages of the lifecycle and have strengthened this idea.

PLM goes further. It is about the sharing of data, and as it originally started in the early phases of the product lifecycle, the concept of PLM was considered something related to engineering. And to be fair, most of the PLM (CAD-related) vendors have a high focus on the early stages of the lifecycle and have strengthened this idea.

However, sharing can go much further, e.g., early involvement of suppliers (still engineering) or downstream support for after-sales/services (the new acronym SLM – Service Lifecycle Management).

In my recent (2014) blog posts, I discussed the concepts of SLM and the required data model for that.

Anticipated sharing

The complexity lies in the word “sharing”. What does sharing mean for an organization, where historically, every person was awarded for their knowledge instead of being awarded for sharing and spreading knowledge. Guarding your knowledge was job protection.

Many so-called PLM implementations have failed to reach the sharing target as the implementation focus was on storing data per discipline and not necessarily storing data to become shareable and used by others. This is a huge difference.

(2023 addition: At that time, all PLM systems were Systems of Record)

Some famous (ERP) vendors claim if you store everything in their system, you have a “single version of the truth”.

Some famous (ERP) vendors claim if you store everything in their system, you have a “single version of the truth”.

Sounds attractive. However, my garbage bin at home is also a place where everything ends up in a single place, but a garbage bin has not been designed for sharing. Another person has no clue or time to analyze what is inside.

Even data stored in the same system can be hidden from others as the way to find data is not anticipated.

Data sharing instead of document deliverables

The complexity of PLM is that data should be created and shared in a matter not necessarily in the most efficient manner for a single purpose. With some extra effort, you can make the information usable and searchable for others. Typical examples are drawings and document management, where the whole process for a person is focused on delivering a specific document on time. Ok, for that purpose, but this document becomes a legacy for the long term as you need to know (or remember) what is inside the document.

A logical implication of data sharing is that, instead of managing documents, organizations start to collect and share data elements (a 3D model, functional properties, requirements, physical properties, logistical properties, etc.). Data can be connected and restructured easily through reports and dashboards, therefore, providing specific views for different roles in the organization. Sharing has become possible, and it can be done online. Nobody needed to consolidate and extract data from documents (Excels ?)

A logical implication of data sharing is that, instead of managing documents, organizations start to collect and share data elements (a 3D model, functional properties, requirements, physical properties, logistical properties, etc.). Data can be connected and restructured easily through reports and dashboards, therefore, providing specific views for different roles in the organization. Sharing has become possible, and it can be done online. Nobody needed to consolidate and extract data from documents (Excels ?)

(2023 addition: The data-driven PLM infrastructure talking about datasets)

This does not fit older generations and departmental-managed business units that are rewarded only for their individual efficiency.

Here is an extract of a LinkedIn discussion from 2014, where the two extremes are visible. Unfortunately (or perhaps good), LinkedIn does not keep everything online. There is already so much “dark data” on the internet.

Here is an extract of a LinkedIn discussion from 2014, where the two extremes are visible. Unfortunately (or perhaps good), LinkedIn does not keep everything online. There is already so much “dark data” on the internet.

Joe stating:

“The sad thing about PLM is that only PLM experts can understand it! It seems to be a very tight knit club with very little influence from any outside sources.

I think PLM should be dumped. It seems to me that computerizing engineering documentation is relatively easy process. I really think it has been over complicated. Of course we need to get the CAD vendors out of the way. Yes it was an obvious solution, but if anyone took the time to look down the road they would see that they were destroying a well established standard that were so cost effective and simple. But it seems that there is no money in simple”

And at the other side, Kais stated:

“If we want to be able to use state-of-the art technology to support the whole enterprise, and not just engineering, and through-life; then product information, in its totality, must be readily accessible and usable at all times and not locked in any perishable CAD, ERP or other systems. The Data Centric Approach that we introduced in the Datamation PLM Model is built on these concepts”

Readers from my blog will understand I am very much aligned with Kais, and PLM guys have a hard time convincing Joe of the benefits of PLM (I did not try).

Making the change happen

Besides this LinkedIn discussion, I had discussions with several companies where my audience understood the data-centric approach. It was nice to be in the room together, sharing ideas of what would be possible. However, the outside world is hard to convince, and here the challenge is organizational change management. Who will support you and who will work against you?.

Besides this LinkedIn discussion, I had discussions with several companies where my audience understood the data-centric approach. It was nice to be in the room together, sharing ideas of what would be possible. However, the outside world is hard to convince, and here the challenge is organizational change management. Who will support you and who will work against you?.

BLOCKERS: I read an interesting article in IndustryWeek from John Dyer with the title: What Motivates Blockers to Resist Change?

John describes the various types of blockers, and when reading the article combined with my PLM twisted brain, I understood again that this is one of the reasons why PLM is perceived as complex – you need to change, and there are blockers:

Blocker (noun) – Someone who purposefully opposes any change (improvement) to a process for personal reasons

“Blockers” can occupy any position in a company. They can be any age, gender, education level or pay rate. We tend to think of blockers as older, more experienced workers who have been with the company for a long time, and they don’t want to consider any other way to do things. While that may be true in some cases, don’t be surprised to find blockers who are young, well-educated and fairly new to the company.”

The problem with blockers

The combination of business change and the existence of blockers is one of the biggest risks for companies to go through a business transformation. By the way, this is not only related to PLM; it is related to any required change in business.

Some examples:

A company I worked with was eager to study its path to the future, which required more global collaboration, a competitive business model and a more customer-centric approach. After a long evaluation phase, they decided they needed PLM, which was new for most of the people in the company. Although the project team was enthusiastic, they were not able to pass the blockers for a change – so no PLM. Ironically enough, they lost a significant part of their business to companies that have implemented PLM. Defending the past is not a guarantee for the future.