You are currently browsing the tag archive for the ‘ROI’ tag.

Last week I shared my thoughts related to my observation that the ROI of PLM is not directly visible or measurable, and I explained why. Also, I explained that the alignment of an organization requires a myth to make it happen. A majority of readers agreed with these observations. Some others either misinterpreted the headlines or twisted the story in favor of their opinion.

Last week I shared my thoughts related to my observation that the ROI of PLM is not directly visible or measurable, and I explained why. Also, I explained that the alignment of an organization requires a myth to make it happen. A majority of readers agreed with these observations. Some others either misinterpreted the headlines or twisted the story in favor of their opinion.

A few came from Oleg Shilovitsky and as Oleg is quite open in his discussions, it allows me to follow-up on his statements. Other people might share similar thoughts but they haven’t had the time or opportunity to be vocal. Feel free to share your thoughts/experiences too.

Some misinterpretations from Oleg’s post: PLM circa 2020 – How to stop selling Myths

- The title “How to stop selling Myths” is the first misinterpretation.

We are not selling myths – more below. - “Jos Voskuil’s recommendation is to create a myth. In his PLM ROI Myths article, he suggests that you should not work on a business case, value, or even technology” is the second misinterpretation, you still need a business case, you need value and you need technology.

And I got some feedback from Lionel Grealou, who’s post was a catalyst for me to write the PLM ROI Myth post. I agree I took some shortcuts based on his blog post. You can read his comments here. The misinterpretation is:

- “Good luck getting your CFO approve the business change or PLM investment based on some “myth” propaganda :-)” as it is the opposite, make your plan, support your plan with a business case and then use the myth to align

I am glad about these statements as they allow me to be more precise, avoiding misperceptions/myth-perceptions.

A Myth is bad

Some people might think that a myth is bad, as the myth is most of the time abstract. I think these people do not realize that there a lot of myths that they are following; it is a typical social human behavior to respond to myths. Some myths:

Some people might think that a myth is bad, as the myth is most of the time abstract. I think these people do not realize that there a lot of myths that they are following; it is a typical social human behavior to respond to myths. Some myths:

- How can you be religious without believing in myths?

- In this country/world, you can become anything if you want?

- In the past, life was better

- I make this country great again

The reason human beings need myths is that without them, it is impossible to align people around abstract themes. Try for each of the myths above to create an end-to-end logical story based on factual and concrete information. Impossible!

Read Yuval Harari’s book Sapiens about the power of myths. Read Steven Pinker’s book Enlightenment Now to understand that statistics show a lot of current myths are false. However, this does not mean a myth is bad. Human beings are driven by social influences and myths – it is our brain.

Unless you have no social interaction, you might be immune to myths. With brings me to quoting Oleg once more time:

“A long time ago when I was too naive and too technical, I thought that the best product (or technology) always wins. Well… I was wrong. “

I went through the same experience, having studied physics and mathematics makes you think extremely logical. Something I enjoyed while developing software. Later, when I started my journey as the virtualdutchman mediating in PLM implementations, I discovered logical alone does not work in businesses. The majority of decisions are done based on “gut feelings” still presented as reasonable cases.

Unless you have an audience of Vulcans, like Mr. Spock, you need to deal with the human brain. Consider the myth as the envelope to pass the PLM-project to the management. C-level acts by myths as so far I haven’t seen C-level management spending serious time on understanding PLM. I will end with a quote from Paul Empringham:

I sometimes wish companies would spend 6 months+ to educate themselves on what it takes to deliver incremental PLM success BEFORE engaging with software providers

You don’t need a business case

Lionel is also skeptical about some “Myth-propaganda” and I agree with him. The Myth is the envelope, inside needs to be something valuable, the strategy, the plan, and the business case. Here I want to stress one more time that most business cases for PLM are focusing on tool and collaboration efficiency. And from there projecting benefits. However, how well can we predict the future?

Lionel is also skeptical about some “Myth-propaganda” and I agree with him. The Myth is the envelope, inside needs to be something valuable, the strategy, the plan, and the business case. Here I want to stress one more time that most business cases for PLM are focusing on tool and collaboration efficiency. And from there projecting benefits. However, how well can we predict the future?

If you implement a process, let’s assume BOM-collaboration done with Excel by BOM-collaboration based on an Excel-on-the-cloud-like solution, you can measure the differences, assuming you can measure people’s efficiency. I guess this is what Oleg means when he explains OpenBOM has a real business case.

However, if you change the intent for people to work differently, for example, consult your supplier or manufacturing earlier in the design process, you touch human behavior. Why should I consult someone before I finish my job, I am measured on output not on collaboration or proactive response? Here is the real ROI challenge.

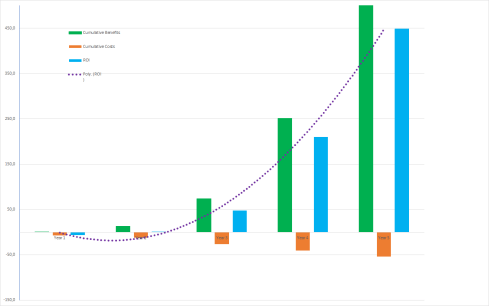

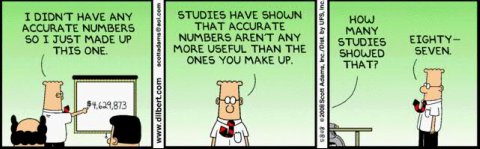

I have participated in dozens of business cases and at the end, they all look like the graph below:

The ROI is fantastic – after a little more than 2 years, we have a positive ROI, and the ROI only gets bigger. So if you trust the numbers, you would be a fool not to approve this project. Right?

And here comes the C-level gut-feeling. If I have a positive feeling (I follow the myth), then I will approve. If I do not like it, I will say I do not trust the numbers.

Needless to say that if there was a business case without ROI, we do not need to meet the C-level. Unless, and it happens incidental, at C-level, there was already a decision we need PLM from Vendor X because we played golf together, we are condemned together or we believe the same myths.

Needless to say that if there was a business case without ROI, we do not need to meet the C-level. Unless, and it happens incidental, at C-level, there was already a decision we need PLM from Vendor X because we played golf together, we are condemned together or we believe the same myths.

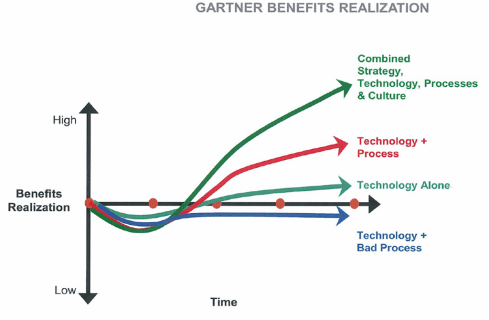

In reality, the old Gartner graph from realized benefits says it all. The impact of culture, processes, and people can make or break a plan.

You do not need an abstract story for PLM

Some people believe PLM on its own is a myth. You just need the right technology and people will start using it, spreading it out and see how we have improved business. Sometimes email is used as an example. Email is popular because you can with limited effort, collaborate with people, no matter where they are. Now twenty years later, companies are complaining about the lack of traceability, the lack of knowledge and understanding related to their products and processes.

PLM will always have the complexity of supporting traceability combined with real-time collaboration. If you focus only on traceability, people will complain that they are not a counter clerk. If you focus solely on collaboration, you miss the knowledge build-up and traceability.

That’s why PLM is a mix of governance, optimized processes to guarantee quality and collaboration, combined with a methodology to tune the existing processes implemented in tools that allow people to be confident and efficient. You cannot translate a business strategy into a function-feature list for a tool.

That’s why PLM is a mix of governance, optimized processes to guarantee quality and collaboration, combined with a methodology to tune the existing processes implemented in tools that allow people to be confident and efficient. You cannot translate a business strategy into a function-feature list for a tool.

Conclusion

Myths are part of the human social alignment of large groups of people. If a Myth is true or false, I will not judge. You can use the Myth as an envelope to package your business case. The business case should always be a combination of new ways of working (organizational change), optimized processes and finally, the best tools. A PLM tool-only business case is to my opinion far from realistic

Now preparing for PI PLMx London on 3-4 February – discussing Myths, Single BOMs and the PLM Green Alliance

It’s the beginning of the year. Companies are starting new initiatives, and one of them is potentially the next PLM-project. There is a common understanding that implementing PLM requires a business case with ROI and measurable results. Let me explain why this understanding is a myth and requires a myth.

It’s the beginning of the year. Companies are starting new initiatives, and one of them is potentially the next PLM-project. There is a common understanding that implementing PLM requires a business case with ROI and measurable results. Let me explain why this understanding is a myth and requires a myth.

I was triggered by a re-post from Lionel Grealou, titled: Defining the PLM Business Case. Knowing Lionel is quite active in PLM and digital transformation, I was a little surprised by the content of the post. Then I noticed the post was from January 2015, already 5 years old. Clearly, the world has changed (perhaps the leadership has not changed).

So I took this post as a starting point to make my case.

In 2015, we were in the early days of digital transformation. Many PLM-projects were considered as traditional linear projects. There is the AS-IS situation, there is the TO-BE situation. Next, we know the (linear) path to the solution and we can describe the project and its expected benefits.

In 2015, we were in the early days of digital transformation. Many PLM-projects were considered as traditional linear projects. There is the AS-IS situation, there is the TO-BE situation. Next, we know the (linear) path to the solution and we can describe the project and its expected benefits.

It works if you understand and measure exactly the AS-IS situation and know almost entirely the TO-BE situation (misperception #1).

However, implementing PLM is not about installing a new transactional system. PLM implementations deal with changing ways-of-working and therefore implementing PLM takes time as it is not just a switch of systems. Lionel was addressing this point:

“The inherent risks associated with any long term business benefit driven projects include the capability of the organization to maintain a valid business case with a benefit realization forecast that remains above the initial baseline. The more rework is required or if the program delivery slips, the more the business case gets eroded and the longer the payback period.”

Interestingly here is the mentioning “..the business case gets eroded” – this is most of the time the case. Lionel proposes to track business benefits. Also, he mentions the justification of the PLM-project could be done by considering PLM as a business transformation tool (misperception #2) or a way to mitigate risk,s due to unsupported IT-solutions (misperception #3).

Let’s dive into these misperceptions

#1 Compare the TO-BE and the AS-IS situation

Two points here.

- Does your company measure the AS-IS situation? Do you know how your company performs when it comes to PLM related processes? The percentage of time spent by engineers for searching for data has been investigated – however, PLM goes beyond engineering. What about product management, marketing, manufacturing, and service? Typical performance indicators mentioned are:

- Do you know the exact TO-BE situation? In particular, when you implement PLM, it is likely to be in the scope of a digital transformation. If you implement to automate and consolidate existing processes, you might be able to calculate the expected benefits. However, you do not want to freeze your organization’s processes. You need to implement a reliable product data infrastructure that allows you to enhance, change, or add new processes when required. In particular, for PLM, digital transformation does not have a clear target picture and scope yet. We are all learning.

#2 PLM is a business transformation tool

Imagine you install the best product innovation platform relevant for your business and selected by your favorite consultancy firm. It might be a serious investment; however, we are talking about the future of the company, and the future is in digital platforms. So nothing can go wrong now.

Imagine you install the best product innovation platform relevant for your business and selected by your favorite consultancy firm. It might be a serious investment; however, we are talking about the future of the company, and the future is in digital platforms. So nothing can go wrong now.

Does this read like a joke? Yes, it is, however, this is how many companies have justified their PLM investment. First, they select the best tool (according to their criteria, according to their perception), and then business transformation can start. Later in time, the implementation might not be so successful; the vendor and/or implementer will be blamed. Read: The PLM blame game

When you go to PLM conferences, you will often hear the same mantras: Have a vision, Have C-level sponsoring/involved, No Big Bang, it is a business project, not an IT-project, and more. And vendor-sponsored sessions always talk about amazing fast implementations (or did they mean installing the POC ?)

When you go to PLM conferences, you will often hear the same mantras: Have a vision, Have C-level sponsoring/involved, No Big Bang, it is a business project, not an IT-project, and more. And vendor-sponsored sessions always talk about amazing fast implementations (or did they mean installing the POC ?)

However, most of the time, C-level approves the budget without understanding the full implications (expecting the tool will do the work); business is too busy or does not get enough allocated time to supporting implementation (expecting the tool will do the work). So often the PLM-project becomes an IT-project executed mainly by the cheapest implementation partner (expecting the tool will do the work). Again this is not a joke!

A business transformation can only be successful if you agree on a vision and a learning path. The learning path will expose the fact that future value streams require horizontal thinking and reallocation of responsibilities – breaking the silos, creating streams.

Small teams can demonstrate these benefits without disrupting the current organization. However, over time the new ways of working should become the standard, therefore requiring different types of skills (people), different ways of working (different KPIs and P&L for departments), and ultimate different tools.

Small teams can demonstrate these benefits without disrupting the current organization. However, over time the new ways of working should become the standard, therefore requiring different types of skills (people), different ways of working (different KPIs and P&L for departments), and ultimate different tools.

As mentioned before, many PLM-projects start from the tools – a guarantee for discomfort and/or failure.

#3 – mitigate risks due to unsupported IT-solutions

Often PLM projects are started because the legacy environment becomes outdated. Either because the hardware infrastructure is no longer supported/affordable or the software code dependencies on the latest operating systems are no longer guaranteed.

A typical approach to solve this is a big-bang project – the new PLM system needs to contain all the old data and meanwhile, to justify the project, the new PLM system needs to bring additional business value. The latter part is most of the time not difficult to identify as traditional PLM implementations most of the time were in reality, cPDM environments with a focus on engineering only.

A typical approach to solve this is a big-bang project – the new PLM system needs to contain all the old data and meanwhile, to justify the project, the new PLM system needs to bring additional business value. The latter part is most of the time not difficult to identify as traditional PLM implementations most of the time were in reality, cPDM environments with a focus on engineering only.

However, the legacy migration can have such a significant impact on the new PLM-system that it destroys the potential for the future. I wrote about this issue in The PLM Migration Dilemma

How to approach PLM ROI?

A PLM-project never will get a budget or approval from the board when there is no financial business case. Building the right financial business case for PLM is a skill that is often overlooked. During the upcoming PI PLMx London conference (3 – 4 February), I will moderate a Focus Group where we will discuss how to get PLM on the Exec’s agenda.

A PLM-project never will get a budget or approval from the board when there is no financial business case. Building the right financial business case for PLM is a skill that is often overlooked. During the upcoming PI PLMx London conference (3 – 4 February), I will moderate a Focus Group where we will discuss how to get PLM on the Exec’s agenda.

Two of my main experiences:

- Connect your PLM-project to the business strategy. As mentioned before, isolated PLM fails most of the time because business transformation, organizational change and the targeted outcome are not included. If PLM is not linked to an actual business strategy, it will be considered as a costly IT-project with all its bad connotations. Have a look at my older post: PLM, ROI and disappearing jobs

- Create a Myth. Perhaps the word Myth is exaggerated – it is about an understandable vision. Myth connects nicely to the observations from behavioral experts that our brain does not decide on numbers but by emotion. Big decisions and big themes in the world or in a company need a myth: “Make our company great again” could be the tagline. In such a case people get aligned without a deep understanding of what is the impact or business case; the myth will do the work – no need for a detailed business case. A typical human behavior, see also my post: PLM as a myth.

Conclusion

There should never be a business case uniquely for PLM – it should always be in the context of a business strategy requiring new ways of working and new tools. In business, we believe that having a solid business case is the foundation for success. Sometimes an overwhelming set of details and numbers can give the impression that the business case is solid. Consultancy firms are experts in this area to build a business case based on emotion. They know how to combine numbers with a myth. Therefore look at their approach – don’t be too technical / too financial. If the myth will hold, at the end depends on the people and organization, not on the investments in tools and services.

Three weeks ago, I closed my PLM-twisted mind for a short holiday. Meanwhile, some interesting posts appeared about the PLM journey.

- Is it a journey?

- Should the journey be measurable?

- And what kind of journey could you imagine?

Together these posts formed a base for a decent discussion amongst the readers. I like these discussions. For me, the purpose of blogging is not the same as tweeting. It is not about just making noise so others will chime in or react (tweeting), it is about sharing an opinion, and if more people are interested, the discussion can start. And a discussion is not about right or false, as many conversations happen to be nowadays, it is about learning.

Let’s start with the relevant posts.

How to measure PLM?

The initial discussion started with Oleg Shilovitsky’s post about the need to measure the value of PLM. As Oleg mentions in his comments:

“During the last decades, I learned that every company that measured what they do was winning the business and succeeded (let’s count Google, Amazon, etc ..)”

This is an interesting statement, just measure! The motto people are using for digital businesses. In particular for the fast-moving software business. Sounds great, so let’s measure PLM. What can we measure with PLM? Oleg suggests as an example:

This is an interesting statement, just measure! The motto people are using for digital businesses. In particular for the fast-moving software business. Sounds great, so let’s measure PLM. What can we measure with PLM? Oleg suggests as an example:

“Let’s say before PLM implemented a specific process, sales needed 2 days to get a quote. After PLM process implementation, it is 15 min.”

So what does this result tell us? Your sales can do 64 times more sales quotes. Do we need fewer salespeople now? We do not know from this KPI what is the real value for the company. This because there are so many other dependencies related to this process, and that makes PLM different from, for example, ERP. We do not talk about optimizing a process as Oleg might suggest below:

“Some of my PLM friends like to say – PLM is a journey and not some kind of software. Well, I’m not sure to agree about “journey,” but I can take PLM as a process. A process, which includes all stages of product development, manufacturing, support, and maintenance.”

Note: I do not want to be picky on Oleg, as he is provoking us all many times with just his thoughts. Moreover, several of them are a good points for discussion. So please dive into his LinkedIn posts and follow the conversation.

Note: I do not want to be picky on Oleg, as he is provoking us all many times with just his thoughts. Moreover, several of them are a good points for discussion. So please dive into his LinkedIn posts and follow the conversation.

In Oleg’s follow-up post on measuring the value, he continued with Can we measure the PLM-journey which summarizes the comments from the previous post with a kind of awkward conclusion:

What is my conclusion? It is a time for PLM get out of old fashion guessing and strategizing and move into digital form of thinking – calculating everything. Modern digital businesses are strongly focused on the calculation and measurement of everything. Performance of websites, metrics of application usage, user experience, efficiency, AB testing of everything. Measurement of PLM related activity sounds like no brainier decision to me. Just my thoughts…

I think all of us agree that there needs to be a kind of indicative measurement in place to justify investments in place. There must be expected benefits that solve current business problems or bottlenecks.

My points that I want to share with you are:

- It is hard to measure non-comparable ways of working – how do you measure collaboration?

- Do you know what to measure? – engineering/innovation is not an ERP process

- People and culture have so much impact on the results – how do you measure your company’s capability to adapt to new ways of working?

Meanwhile, we continue our journey…

Is PLM a never-ending journey?

In the context of the discussion related to the PLM journey, I assume Chad Jackson from Lifecycle Insights added his 3 minutes of thoughts. You can watch the video here:

Vlogging seems to become more prevalent in the US. The issue for me is that vlogs only touch the surface, and they are hard to scan for interesting reusable content. Something you miss when you are an experienced speed-reader. I like written content as it is easier to pick and share relevant pieces, like what I am doing now in this post.

Chad states that as long as PLM delivers quantified value, PLM could be expanding. This sounds like a journey, and I could align here. The only additional thought I would like to add to this point is that it is not necessary expanding all the time, it is also about a continuous change in the world and therefore your organization. So instead of expanding, there might be a need to do things differently: Have you noticed PLM is changing.

Chad states that as long as PLM delivers quantified value, PLM could be expanding. This sounds like a journey, and I could align here. The only additional thought I would like to add to this point is that it is not necessary expanding all the time, it is also about a continuous change in the world and therefore your organization. So instead of expanding, there might be a need to do things differently: Have you noticed PLM is changing.

Next Chad mentions organizational fatigue. I understand the point – our society and business are currently changing extremely fast, which causes people to long for the past. A typical behavior I observe everywhere: in the past, everything was better. However, if companies would go back and operate like in the past, they would be out of business. We moved from the paper drawing board to 3D CAD, managing it through PDM and PLM to remain significant. So there is always a journey.

Fatigue comes from choosing the wrong directions, having a reactive culture – instead of being inspired and motivated to reach the next stage, the current stage is causing already so much stress. Due to the reactive culture, people cannot imagine a better future – they are too busy. I believe it is about culture and inspiration that makes companies successful – not by just measuring. For avoiding change, think about the boiling frog metaphor, and you see what I mean

Fatigue comes from choosing the wrong directions, having a reactive culture – instead of being inspired and motivated to reach the next stage, the current stage is causing already so much stress. Due to the reactive culture, people cannot imagine a better future – they are too busy. I believe it is about culture and inspiration that makes companies successful – not by just measuring. For avoiding change, think about the boiling frog metaphor, and you see what I mean

Upgrading to PLM when PDM falls short

At the same time, Jim Brown from Tech-Clarity published a PTC-sponsored eBook: Upgrading to PLM when PDM fall short, in which as he states:

This eBook explains how to recognize that you’ve outgrown PDM and offers several options to find the data and process management capabilities your company needs, whether it’s time to find a more capable PDM or upgrade to PLM. It also provides practical advice on what to look for in a PLM solution, to ensure a successful implementation, and in a software partner.

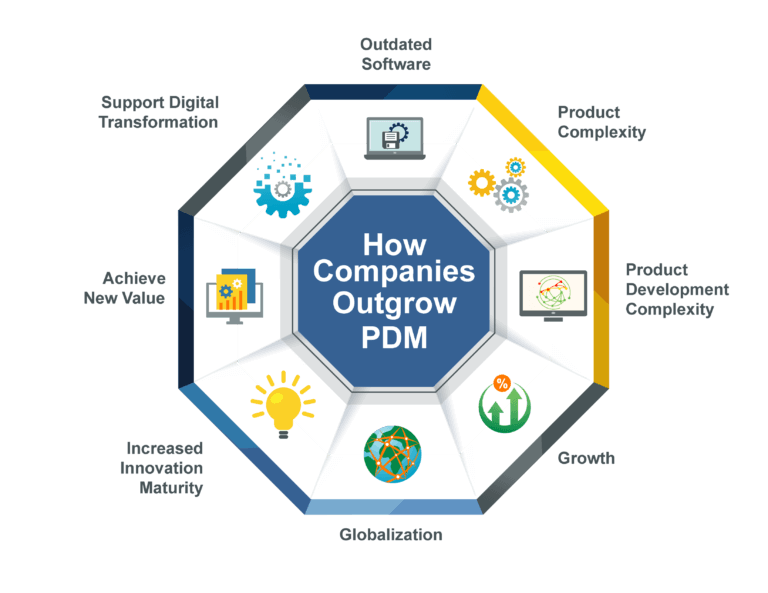

Jim is mentioning various business drivers that can drive this upgrade path. Enlarge the image to the left. I challenge all the believers in measurable digital results to imagine which KPIs they would use and how they can be related to pure PLM.

Jim is mentioning various business drivers that can drive this upgrade path. Enlarge the image to the left. I challenge all the believers in measurable digital results to imagine which KPIs they would use and how they can be related to pure PLM.

Here the upgrade process is aiming at replacing PDM by PLM something PLM vendors like. Immediate a significant numbers of licenses for the same basic PDM functionality – for your company hard to justify there is no additional value.

In many situations, I have seen that this type of PDM upgrade projects became advanced PDM projects – not PLM. The new PLM system was introduced in the engineering department and became an even bigger silo than before as other disciplines/departments were not willing to work with this new “monster” and preferred their own system. They believe that PLM is a system to be purchased and implemented, which is killing for a real PLM strategy.

Still, if you are interested and have time for a puzzle, follow this discussion and add your thoughts

Conclusion

During my holidays, there was a vivid discussion related to the PLM value and journey. Looking back, it is clear we are part of a PLM journey. Some do not take part in the journey and keep on hanging to the past, those who understand the journey are all seeing different Points Of Interests – the characteristics of a journey

During my holidays, there was a vivid discussion related to the PLM value and journey. Looking back, it is clear we are part of a PLM journey. Some do not take part in the journey and keep on hanging to the past, those who understand the journey are all seeing different Points Of Interests – the characteristics of a journey

Image and article related to the article “The Onrushing Wave” in the Economist Jan 18th, 2014

When PLM is discussed at management level, often the goal is to increase efficiency, which translates into doing the same with fewer people. And it is the translation that is creating worries inside the company. The PLM system is going to cut down the amount of jobs in our company.

The result: People, who fear their job is at risk, will make sure PLM will fail and become blockers. These people will be the ones defending the “good old way of working” and create a mood of complexity for the new PLM system.

I wrote some time ago a post about PLM and Blockers

At the end there is frustration at all levels in the company and PLM systems are to blame.

How to address the fear for disappearing jobs block a PLM implementation?

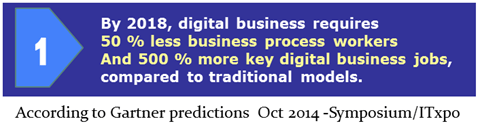

First of all if you implement PLM now, do not target efficiency only. There is a digital revolution ongoing, radically changing standard businesses and markets. The picture at the top says it all. If you are still not convinced, read the “old” article from the Economist or more related to PLM, I just read this article from Accenture consulting talking about Digital PLM. I liked the opening sentence from that article:

“It’s time to adopt a digital model for product lifecycle management – or get left behind.”

The digital revolution forces companies to become extremely flexible and agile. Business models can rapidly change. Where perhaps your company was the market leader, a few years you can be in trouble, due to the decoupling of products and services in a different business model. There are a few places where you do not have to worry (yet). If you are in a governmental type of business (no competition – you are the only preferred supplier) the less worried you might be for the upcoming digital revolution. Other types of companies need to make a strategic plan.

The digital revolution forces companies to become extremely flexible and agile. Business models can rapidly change. Where perhaps your company was the market leader, a few years you can be in trouble, due to the decoupling of products and services in a different business model. There are a few places where you do not have to worry (yet). If you are in a governmental type of business (no competition – you are the only preferred supplier) the less worried you might be for the upcoming digital revolution. Other types of companies need to make a strategic plan.

Making a strategic plan

The strategic plan starts at the board level and has, of course, elements of efficiency. However, the major strategic discussion should be: “How will we differentiate our company in the future and stay in business and profitable”. This cannot be by competing on price only. It requires you can excite your future customers and who these customers are might not be clear yet either.

The strategic plan starts at the board level and has, of course, elements of efficiency. However, the major strategic discussion should be: “How will we differentiate our company in the future and stay in business and profitable”. This cannot be by competing on price only. It requires you can excite your future customers and who these customers are might not be clear yet either.

Different business models can give the company a better position in the market. The current trend in competitive markets is that the value does not come from selling products. Selling services or operation capacity (OPEX instead of CAPEX) are currently upcoming new business models and they need constant anticipation to what happens in the market or at your potential customer base.

Digitalization of information and being able to work with real-time information, instead of information hidden in documents, handled by document controllers, creates the opportunity to change. For example the potential of “The Internet of Everything” is huge.

At the board level, you need the vision where the company should be in the next 5 to 10 years. It will not bubble up automatically in an organization. And when talking about PLM, it should be digital PLM.

Next communication

It is not easy to communicate the above if you have not lived through the whole process in your mind. Management needs to be able to explain the vision and its impact on the organization in such a way that it empowers people instead of making them afraid of change. We all know the examples of charismatic CEOs, like Steve Jobs, who could energize a company and its customers. However, it is clear that not every CEO is like Steve Jobs.

Once you are able to communicate the vision, it will be logical that the organization needs new processes and in modern digital processes create different responsibilities and need different management styles.

Disappearing jobs

When you start implementing PLM in a modern approach (digital PLM according to Accenture) there will be jobs disappearing. There is no need to be secretive about that; it is a result of the vision that should be known to everyone in the company.

Disappearing jobs are:

- jobs where people are processing data (from one format to the other) and checking follow-up processes (from on Excel to the other). If your daily job is collecting data and filling spreadsheets with data your job is at risk. In a digital environment, the data will be real-time available and can be filtered and presented in automatic reports or dashboards.

- Jobs where team managers have the major task to decide on priorities for the team and fight with other discipline team managers on priorities. In a digital environment, empowered employees will understand conflicting activities and they will be able to discuss and decide immediately with the relevant people. No need for an intermediate layer of people handling escalations only. It is true that this modern approach requires a different management style and people who can deal with being empowered. In general, empowered people feel more motivated that employees who are just doing what their managers tell them to do. The business change from hierarchical and siloed organizations towards networked organizations is critical and challenging – all depending on trust and the right change management.

- The classical fire-fighters. At first glance they are considered as crucial as they solve all the issues with great energy, do not run away when work needs to be done and make it happen. From the management perspective, these people are blocking change as they flourish from the chaos and do not fix or prevent new issues coming up.

For all other people in the company, digital PLM should bring relief – see the Gartner quote below.

Digital business jobs imply spending less time in searching for information. Less work in a reactive mode as information in the right context in real-time will be available. End to end visibility of information combined with transparency will lead to higher performance and motivation. It requires changing behaviors, motivation must come from the inspiration of the management and the understanding that your company is becoming more flexible and more competitive than before. And for that reasons keeping you in business and providing you an interesting place to work.

Conclusion: Do not use PLM to improve efficiency only and ROI discussions. There is a strategic need to be ready and stay in business for the future. Modern PLM is an enabler, however, requires a vision, inspiring communication and a path for employees to be empowered.

I am curious about your opinion – will this happen to your company / industry?

Two weeks ago I got this message from WordPress, reminding me that I started blogging about PLM on May 22nd in 2008. During some of my spare time during weekends, I began to read my old posts again and started to fix links that have been disappearing.

Initially when I started blogging, I wanted to educate mid-market companies about PLM. A sentence with a lot of ambiguities. How do you define the mid-market and how do you define PLM are already a good start for a boring discussion. And as I do not want to go into a discussion, here are my “definitions”

Warning: This is a long post, full of generalizations and a conclusion.

PLM and Mid-market

The mid-market companies can be characterized as having a low-level of staff for IT and strategic thinking. Mid-market companies are do-ers and most of the time they are good in their domain based on their IP and flexibility to deliver this to their customer base. I did not meet mid-market companies with a 5-year and beyond business vision. Mid-market companies buy systems. They bought an ERP system 25-30 years ago (the biggest trauma at that time). They renewed their ERP system for the Y2K problem/fear and they switched from drawing board towards a 2D CAD system. Later they bought a 3D CAD system, introducing the need for a PDM system to manage all data.

PLM is for me a vision, a business approach supported by an IT-infrastructure that allows companies to share and discover and connect product related information through the whole lifecycle. PLM enables companies to react earlier and better in the go-to-market process. Better by involving customer inputs and experience from the start in the concept and design phases. Earlier thanks to sharing and involving other disciplines/suppliers before crucial decisions are made, reducing the amount of iterations and the higher costs of late changes.

Seven years ago I believed that a packaged solution, combined with a pre-configured environment and standard processes would be the answer for mid-market companies. The same thought currently PLM vendors have with a cloud-based solution. Take it, us it as it is and enjoy.

Seven years ago I believed that a packaged solution, combined with a pre-configured environment and standard processes would be the answer for mid-market companies. The same thought currently PLM vendors have with a cloud-based solution. Take it, us it as it is and enjoy.

Here I have changed my opinion in the past seven years. Mid-market companies consider PLM as a more complex extension of PDM and still consider ERP (and what comes with that system) as the primary system in the enterprise. PLM in mid-market companies is often seen as an engineering tool.

LESSON 1 for me:

The benefits of PLM are not well-understood by the mid-market

To read more:

PLM for the mid-market – mission impossible?

PLM for the SMB – a process or culture change ?

Culture change in a mid-sized company – a management responsibility

Mid-market PLM – what did I learn in 2009 ?

Implementing PLM is a change not a tool

Who decides for PLM in a mid-market company ?

More on: Who decides for PLM in a mid-market company ?

Globalization and Education

In the past seven years, globalization became an important factor for all type of companies. Companies started offshoring labor intensive work to low-labor-cost countries introducing the need for sharing product data outside their local and controlled premises. Also, acquisitions by larger enterprises and by some of the dominant mid-market companies, these acquisitions introduced a new area of rethinking. Acquisitions introduced discussions about: what are real best practices for our organization? How can we remain flexible, meanwhile adapt and converge our business processes to be future ready?

In the past seven years, globalization became an important factor for all type of companies. Companies started offshoring labor intensive work to low-labor-cost countries introducing the need for sharing product data outside their local and controlled premises. Also, acquisitions by larger enterprises and by some of the dominant mid-market companies, these acquisitions introduced a new area of rethinking. Acquisitions introduced discussions about: what are real best practices for our organization? How can we remain flexible, meanwhile adapt and converge our business processes to be future ready?

Here I saw two major trends in the mid-market:

Lack of (PLM) Education

To understand and implement the value of PLM, you need to have skills and understanding of more than just a vendor-specific PLM system. You need to understand the basics of change processes (Engineering Change Request, Engineering Change Order, Manufacturing Change Order and more). And you need to understand the characteristics of a CAD document structure, a (multidisciplinary) EBOM, the MBOM (generic and/or plant specific) and the related Bill of Processes. This education does not exist in many countries and people are (mis-)guided by their PLM/ERP vendor, explaining why their system is the only system that can do the job.

To understand and implement the value of PLM, you need to have skills and understanding of more than just a vendor-specific PLM system. You need to understand the basics of change processes (Engineering Change Request, Engineering Change Order, Manufacturing Change Order and more). And you need to understand the characteristics of a CAD document structure, a (multidisciplinary) EBOM, the MBOM (generic and/or plant specific) and the related Bill of Processes. This education does not exist in many countries and people are (mis-)guided by their PLM/ERP vendor, explaining why their system is the only system that can do the job.

Interesting enough the most read posts on my blog are about the MBOM, the ETO, BTO and CTO processes. This illustrates there is a need for a proper, vendor-independent and global accepted terminology for PLM

Some educational posts:

Bill of Materials for Dummies – ETO ranked #1

ECR/ECO for Dummies ranked #2

BOM for Dummies – CTO ranked #4

BOM for Dummies: BOM and CAD ranked #7

BOM for Dummies – BTO

Where does PLM start beyond document management ?

The dominance of ERP

As ERP systems were introduced long before PLM (and PDM), these systems are often considered by the management of a mid-market company as the core. All the other tools should be (preferably) seen as an extension of ERP and if possible, let´s implement ERP vendor´s functionality to support PLM – the Swiss knife approach – one tool for everything. This approach is understandable as at the board level there are no PLM discussions. Companies want to keep their “Let´s do it”-spirit and not reshuffle or reorganize their company, according to modern insights of sharing. Strangely enough, you see in many businesses the initiative to standardize on a single ERP system first, instead of standardizing on a single PLM approach first. PLM can bring the global benefits of product portfolio management and IP-sharing, where ERP is much more about local execution.

As ERP systems were introduced long before PLM (and PDM), these systems are often considered by the management of a mid-market company as the core. All the other tools should be (preferably) seen as an extension of ERP and if possible, let´s implement ERP vendor´s functionality to support PLM – the Swiss knife approach – one tool for everything. This approach is understandable as at the board level there are no PLM discussions. Companies want to keep their “Let´s do it”-spirit and not reshuffle or reorganize their company, according to modern insights of sharing. Strangely enough, you see in many businesses the initiative to standardize on a single ERP system first, instead of standardizing on a single PLM approach first. PLM can bring the global benefits of product portfolio management and IP-sharing, where ERP is much more about local execution.

LESSON 2:

PLM is not understood at the board level, still considered as a tool

Some post related to PLM and ERP

Where is the MBOM ? ranked #3

Connecting PLM and ERP (post 1) – (post 2) – (post 3) ranked #8

PLM and ERP – the culture change

5 reasons not to implement PLM – Reason #3 We already have an ERP system

The human factor

A lot of the reasons why PLM has the challenge to become successful have to do with its broad scope. PLM has an unclear definition and most important, PLM forces people to share data and work outside their comfort zones. Nobody likes to share by default. Sharing makes day-to-day life more complicated, sharing might create visibility on what you actually contribute or fix. In many of my posts, I described these issues from various viewpoints: the human brain, the innovators dilemma, the way the older generation (my generation) is raised and used to work. Combined with the fact that many initial PLM/PDM implementations have created so many legacies, the need to change has become a risk. In the discussion and selection of PLM I have seen many times that in the end a company decides to keep the old status quo (with new tools) instead of really having the guts to move toward the future. Often this was a result of investors not understanding (and willing to see) the long term benefits of PLM.

A lot of the reasons why PLM has the challenge to become successful have to do with its broad scope. PLM has an unclear definition and most important, PLM forces people to share data and work outside their comfort zones. Nobody likes to share by default. Sharing makes day-to-day life more complicated, sharing might create visibility on what you actually contribute or fix. In many of my posts, I described these issues from various viewpoints: the human brain, the innovators dilemma, the way the older generation (my generation) is raised and used to work. Combined with the fact that many initial PLM/PDM implementations have created so many legacies, the need to change has become a risk. In the discussion and selection of PLM I have seen many times that in the end a company decides to keep the old status quo (with new tools) instead of really having the guts to move toward the future. Often this was a result of investors not understanding (and willing to see) the long term benefits of PLM.

LESSON 3:

PLM requires a long-term vision and understanding, which most of the time does not fit current executive understanding (lack of education/time to educate) and priority (shareholders)

Many recent posts are about the human factor:

The Innovator´s dilemma and PLM

Our brain blocks PLM acceptance

How to get users excited or more committed to a new PLM system?

The digital transformation

The final and most significant upcoming change is the fact that we are entering a complete new era: From linear and predictable towards fast and iterative, meaning that classical ways we push products to the market will become obsolete. The traditional approach was based on lessons learned from mechanical products after the second world-war. Now through globalization and the importance of embedded software in our products, companies need to deliver and adapt products faster than the classical delivery process as their customers have higher expectations and a much larger range to choose from. The result from this global competitiveness is that companies will change from delivering products towards a more-and-more customer related business model (continuous upgrades/services). This requires companies to revisit their business and organization, which will be extremely difficult. Business wise and human change require new IT concepts – platform? / cloud services? / Big data?

The final and most significant upcoming change is the fact that we are entering a complete new era: From linear and predictable towards fast and iterative, meaning that classical ways we push products to the market will become obsolete. The traditional approach was based on lessons learned from mechanical products after the second world-war. Now through globalization and the importance of embedded software in our products, companies need to deliver and adapt products faster than the classical delivery process as their customers have higher expectations and a much larger range to choose from. The result from this global competitiveness is that companies will change from delivering products towards a more-and-more customer related business model (continuous upgrades/services). This requires companies to revisit their business and organization, which will be extremely difficult. Business wise and human change require new IT concepts – platform? / cloud services? / Big data?

Older enterprises, mid-market and large enterprises will be extremely challenged to make this change in the upcoming 10 years. It will be a matter of survival and I believe the Innovator´s Dilemma applies here the most.

LESSON 4:

The digital transformation is apparent as a trend for young companies and strategic consultants. This message is not yet understood at the board level of many businesses.

Some recent post related to this fast upcoming trend:

From a linear world to fast and circular ?

Did you notice PLM is changing?

Documents or Intelligent Data ?

The difference between files and data-oriented – a tutorial (part 1) – (part 2) – (part 3)

PLM and/or SLM? – (part 1) – (part 2)

Breaking down the silos with data

ROI (Return On Investment)

I also wrote about ROI – a difficult topic to address as in most discussions related to ROI, companies are talking about the costs of the implementation, not about the tremendous larger impact a new business approach or model can have, once enabled through PLM. Most PLM ROI discussions are related to efficiency and quality gains, which are significant and relevant. However these benefits are relative small and not comparable with the ability to change your business (model) to become more customer centric and stay in business.

I also wrote about ROI – a difficult topic to address as in most discussions related to ROI, companies are talking about the costs of the implementation, not about the tremendous larger impact a new business approach or model can have, once enabled through PLM. Most PLM ROI discussions are related to efficiency and quality gains, which are significant and relevant. However these benefits are relative small and not comparable with the ability to change your business (model) to become more customer centric and stay in business.

Some of the ROI posts:

To PLM or Not to PLM – measuring the planning phase ranked #5

Free PLM Software does not help companies ranked #6

PLM selection–additional thoughts

PLM Selection: Proof Of Concept observations

Where is my PLM Return On Investment (ROI) ?

Conclusion

A (too) long post this time however perhaps a good post to mark 7 years of blogging and use it as a reference for the topics I briefly touched here. PLM has many aspects. You can do the further reading through the links.

From the statistics it is clear that the education part scores the best – see rankings. For future post, let me know by creating a comment what you are looking for in this blog: PLM Mid-Market, Education, PLM and ERP, Business Change, ROI, Digitalization, or …??

Also I have to remain customer centric – thanks for reading and providing your feedback

Above Image courtesy of the marketoonist.com – Tom Fishburne

Image related to digital transformation: The Economist – the onrushing wave

Recently I have been reading various interesting articles, it started with Why Amazon can’t Make a Kindle in the USA from Steve Denning and from here I followed several interesting links.

Recently I have been reading various interesting articles, it started with Why Amazon can’t Make a Kindle in the USA from Steve Denning and from here I followed several interesting links.

Most of the articles were business driven and not with a focus on technology. However what caught my attention was the similarity of issues that were raised in these articles as-if it was about PLM.

At the end it is a plea/cry for change to be more competitive in the future. With the current economical stand still, I believe there is a need and an opportunity for this change also in PLM. I am not pointing to regime changes all around the world, but somehow they are all connected to this new wave of globalization and openness to information.

And as my domain is PLM, I took PLM 2.0 as the vehicle to describe the change currently in the PLM world. Although PLM 2.0 is a term invented by Dassault Systems, I will use it as the placeholder to describe the changes in PLM.

In four posts I will guide you in the upcoming weeks through the thought process:

| This week | : What is PLM 2.0 ? |

| Next | : Challenges in current PLM |

| Next | : Change in business |

| Final post | : Why PLM 2.0 – conclusions |

I hope you will stay with me when going through these four steps and look forward to your immediate feedback.

What is PLM 2.0 ?

In 2006 Dassault Systems announced PLM 2.0 as the new generation of PLM implemented on their V6 platform. If you go to the 3DS website you see the following definition of PLM 2.0

Look for the header PLM 2.0: PLM Online for All

In the DS definition you will find several keywords that will help us further to understand the PLM 2.0 capabilities:

a typical Dassault Systems viewpoint, as they are coming from the world or 3D CAD and virtualization and the company’s vision is around lifelike – and life is mostly in 3D.

3D as interface towards all product related information is a paradigm shift for companies that were used to display only metadata on boring tabular screens where you navigate on numbers and text. The other major CAD-related PLM vendors of course could follow this paradigm too, as 3D visualization of information is known to them. However when coming from an ERP-based PLM system you will see 3D is something far out of reach for these vendors (at this moment).

This is what I believe is a crucial keyword for all PLM future implementations it builds upon the Business Information concepts that became in fashion 8 years ago. Online means direct access to the actual data. No information conversion, no need for import or export, but sharing and filtering. What you are allowed to see is actual data and an actual status. Imagine what kind of impact working on-line would have on your organization. Evaluation of trends, Key Performance Indicators directly available – still of course the interpretation to be done by experts.

Intellectual Property – a topic that should be on every company’s agenda. The reason a company currently exists and will exist in the future is based on how they manage their unique knowledge. This knowledge can be based on how certain processes are done, which components are chosen, which quality steps are critical and more. Working in a global collaboration environment challenges the company to keep their IP hidden for others, for sure when you talk about online data. Losing your IP means for a company to be vulnerable for the future – read in the referenced blog post from Steve Jennings about DELL.

This is currently the platform for change as technologies are now enabling people and companies to implement applications in a different manner. Not only on premises, but it could be online, Software As A Service, Cloud based solutions and through standardized programming interfaces, companies could implement end-to-end business process without a huge, monolithic impact. Also Web 2.0 provides the platform for communities.

The concept of communities opens new perspectives for collaboration. In general people in a community, have a common interest or task, and they share thoughts, deliverables back to the community across all company borders. This is the power of the community and the collective intelligence built inside such a community. Without company borders it should give the people a better perspective on their market on their business due to the global participation

The vision is there – now ….

All the above keywords are capabilities for the future and in the world of PLM you see that every PLM vendor / implementer is struggling with them. How to implement them consistently across their offering is the major challenge for the upcoming years, assuming PLM 2.0 is considered as the next step.

If you look at the PLM vendors beside Dassault Systems, you see that Siemens and PTC are closest to following the PLM 2.0 approach, without mentioning the term PLM 2.0. Other vendors even refuse to talk about PLM, but they share already similar components, for example Autodesk.

Interesting to see that the ERP-based PLM vendors do not follow this trend in their communication, they are still working on consolidating and completing their ‘classical’ PLM components

But the classical PLM vendors struggle with the change in paradigm too.

- What to do with current, huge and structured implementations ?

- Is PLM 2.0 having the same demands or can it be different ?

Here you see opportunities for new comers in this market as you can implement online collaboration, intellectual property creation/handling and communities in different manners with different types of implementation demands.

So far my introduction in PLM 2.0. Browsing on the web, I did not find too much other viewpoints on this specific terminology, so I am curious about your thoughts or and complementary comments on this topic.

In my next post I will zoom in into the challenges of PLM and relate them to the PLM 2.0 vision

My take on PLM (classical) and PLM 2.0

Referenced in this context – not directly mentioned:

- IBM visionary presentation from 2006 – Michael Neukirchen

- The future of PLM – Martin Ohly (global PLM blog)

- PLM 2.0 technology or facelift – Oleg Shilovitsky

- Social Media and PLM explained for Dummies – Jos Voskuil

- Going Social With Product Development – Jim Brown

This time it is hard to write my blog post. First of all, because tomorrow there will be the soccer final between Holland and Spain and as a Virtual Dutchman I still dream of a real cup for the Dutch team.

This time it is hard to write my blog post. First of all, because tomorrow there will be the soccer final between Holland and Spain and as a Virtual Dutchman I still dream of a real cup for the Dutch team.

Beside that I had several discussions around PLM (Product Lifecycle Management), CM (Configuration Management) and ALM (Asset Lifecycle Management), where all insiders agreed that it is hard to explain and sell the value and best practices, because it is boring, because it is not sexy, etc, etc.

So why am I still doing this job…..

Product Lifecycle Management (PLM)

If you look at trade shows and major events of PLM vendors, the eye-catching  stuff is 3D (CAD).

stuff is 3D (CAD).

Dassault Systemes introduced in 2006 3DLive as the 3D collaboration layer for all users with the capability to provide in a 3D manner (see what you mean) on-line role specific information, coming from different information sources. Recently Siemens introduced their HD PLM, which as far as I understood, brings decision making capabilities (and fun) to the user.

Both user interfaces are focusing on providing information in a user-friendly and natural way – this is sexy to demonstrate, but a question never asked: “Where does the information come from ? “

And this is the boring but required part of PLM. Without data stored or connected to the PLM system, there is no way these sexy dashboards can provide the right information. The challenge for PLM systems will be to extract this information from various applications and from users to have the discipline to enter the needed data.

Those software vendors, who find an invisible way to capture the required information hold the key to success. Will it be through a more social collaboration with a lot of fun, I am afraid not. The main issue is that the people who need to enter the data are not rewarded for doing it. It is downstream the organization, in the product lifecycle, that other people benefit from the complete information. And I even suspect in some organizations that there are people who do not want share data to assure being required in the organization – see also Some users do not like the single version of the truth.

So who can reward these users and make them feel important. I believe this is a management job and no sexy (3D) environment will help here

Configuration Management (CM)

Although it is considered a part of PLM, I added configuration management to my post as a separate bullet. Two weeks ago, I attended the second day of the CMII Europe conference in Amsterdam. What I learned from this event was that the members of the CMII community are a group of enthusiastic people with somehow the same vision as PLM missionaries.

Although it is considered a part of PLM, I added configuration management to my post as a separate bullet. Two weeks ago, I attended the second day of the CMII Europe conference in Amsterdam. What I learned from this event was that the members of the CMII community are a group of enthusiastic people with somehow the same vision as PLM missionaries.

Quoting the organization: “CMII is about changing faster and documenting better. It is about accommodating change and keeping requirements clear, concise and valid.”

And it was interesting to listen to speeches of the members. Like with PLM, everyone is convinced configuration management brings a lot of value to a company, they are also fighting for acknowledgement. Not sexy is what I learned here and also here those people who are responsible for data accuracy are not necessary the ones that benefit (the most).

Like PLM, but even more in Configuration Management, the cultural change should not be neglected. Companies are used to have a certain level of “configuration management”, often based on manual processes, not always as efficient, clear and understood and satisfactory for the management, till something happens due to incorrect information.

Of course the impact of an error differentiates per industry, a problem occurring due to wrong information for an airplane is something different compared to a problem with a sound system.

So the investment in configuration management pays of for complex products with critical behaviors and in countries where labor costs are high. It was interesting to learn that a CM maturity assessment showed that most companies score below average when it comes to management support and that they score above average when talking about the tools they have in place.

This demonstrates for me that also for configuration management, companies believe tools will implement the change without a continuous management push. I remember that in several PLM selection processes, prospects were asking for all kind of complex configuration management capabilities, like complex filtering of a product structure. Perhaps pushed by a competitor, as at the end it was never implemented 😦

Asset Lifecycle Management (ALM)

In some previous posts, I wrote about the benefits a PLM system can bring, when used as the core system for all asset related information. For nuclear plants, the IAEA (International Atomic Energy Agency) recommends to use configuration management best practices and I have met an owner/operator of a nuclear plant who recognized that a PLM system brings the right infrastructure, instead of SAP for example, which has more focus on operational data.

In some previous posts, I wrote about the benefits a PLM system can bring, when used as the core system for all asset related information. For nuclear plants, the IAEA (International Atomic Energy Agency) recommends to use configuration management best practices and I have met an owner/operator of a nuclear plant who recognized that a PLM system brings the right infrastructure, instead of SAP for example, which has more focus on operational data.

Also I had a meeting with another owner/operator, who was used to manage their asset data in a classical manner – documents in an as-built environment and changes of documents in various projects environments.

When discussing the ALM best practices based on a PLM system, it was clear all the benefits it could bring, but also we realized that implementing these concepts would require a conceptual revolution. People would need to start thinking asset centric (with lifecycle behavior) instead of document centric with only revisions.

When discussing the ALM best practices based on a PLM system, it was clear all the benefits it could bring, but also we realized that implementing these concepts would require a conceptual revolution. People would need to start thinking asset centric (with lifecycle behavior) instead of document centric with only revisions.

This kind of change requires a management vision, clear explanation of the benefits and a lot of attention for the user. Only then when these changes have been implemented, and data is available in a single repository, only then the fun and sexy environments become available for use.

Conclusion

PLM, CM and ALM are not sexy especially for the users who need to provide the data. But they provide the base for sexy applications where users have instant access to complete information to make the right decisions. To get there a cultural change is required. The management needs to realize that the company changes into becoming proactive (avoiding errors) instead of being reactive (trying to contain errors); investing upfront and never be able to know what the losses would be in case an error occurred.

Not sexy, however the benefits this approach can bring allow employees and companies to continue to do their work for a secure future

And now … time to close as the final is near

Two weeks ago I received through the PLM group on LinkedIn, the following question from Nathalie: “Do you know any specific examples of what some companies have done to get their users ready, excited or more committed to the new PLM system?”

Two weeks ago I received through the PLM group on LinkedIn, the following question from Nathalie: “Do you know any specific examples of what some companies have done to get their users ready, excited or more committed to the new PLM system?”

When digging in my mind and planning to give a quick answer, I realized it was an interesting question with a contradiction embedded: users and excitement for a new PLM system.

This week I was attending the SmarTeam User Group meeting in the Netherlands, where an excellent presentation was given by Simon and Hessel from a Dutch company called Meyn (Poultry processing) about their PLM implementation. They shared their excitement !

Combined with an interesting discussion on Oleg’s blog with Frank, I believe I have the ingredients to answer the above question more complete.

PLM is not exiting for users

I think this is fact number one. When you go to tradeshows or PLM exhibitions, you see usually only 3D CAD demos, nobody tries to demonstrate PLM functions and features in detail. As a side step, I believe the best PLM system should be almost invisible for the user. Users want to work in their own environment with applications like CAD, Excel (BOM handling apps), Office, FEA tools, Simulation tools and more.

I think this is fact number one. When you go to tradeshows or PLM exhibitions, you see usually only 3D CAD demos, nobody tries to demonstrate PLM functions and features in detail. As a side step, I believe the best PLM system should be almost invisible for the user. Users want to work in their own environment with applications like CAD, Excel (BOM handling apps), Office, FEA tools, Simulation tools and more.

ERP has a more clear value proposal, if you want to define and schedule your manufacturing and manage the financial transactions, everyone has accepted that you need ERP. User acceptance is not relevant, users have to work with the provided interface as otherwise production or accounting will fail, there is no alternative.

In contrary, the clear value and definition of PLM are not clear to user. For that reason these users do not get excited when confronted with PLM. They have been surviving without implementing PLM, so they believe there is an alternative.

But we know there are PLM benefits?

My previous post – PLM in the mid-market a mission impossible? – lead to a discussion with Oleg and Frank coming with anew and interesting view point. Frank mentioned that in the German area, many mid-market companies do PLM without purchasing an enterprise PLM system from the known vendors.

The discussion focused on granularity, as all of us believed that a set-by-step approach towards PLM best practices, driven by people who understand the company very well, is the key to success. For this approach you need people inside the customer’s organization who can formulate the vision assisted by consultants working very dedicated in that industry. It requires a different type of consultant as those active in the big enterprise projects.

The discussion focused on granularity, as all of us believed that a set-by-step approach towards PLM best practices, driven by people who understand the company very well, is the key to success. For this approach you need people inside the customer’s organization who can formulate the vision assisted by consultants working very dedicated in that industry. It requires a different type of consultant as those active in the big enterprise projects.

Instead of implementing PLM as a standard process, in this approach the customer drives and leads the activities where they see benefits in their overall business process. To achieve this, the company must have has a clear vision, where they want to be in the next 5 – 10 years.

Next implementations steps should fit in this strategy and prioritized based on different parameters and these steps are not always with a focus on PLM.

And here lies the key for successful PLM implementations.

The implementation might be based on an academic approach around a core PLM data model and best practices. Mid-market offerings are around an OOTB (Out-Of-The-Box) quick implementation – the PLM system/implementer leads.

The implementation might be based on an academic approach around a core PLM data model and best practices. Mid-market offerings are around an OOTB (Out-Of-The-Box) quick implementation – the PLM system/implementer leads.

Something the management of likes to hear; quick and with little customization, which would translate in lower costs of implementation and disruption of the organization. But then, the end-users start to complain. There is too much change their standard way of working and they do not see the advantages – keying in more data in a system does not help them.

The introduction of PLM brings more complexity and as the new system has to prove itself, there is not big enthusiasm from the average user. The management can push, like in the ERP situation, but in general also the management is anxious to learn if this OOTB-approach brings the benefits and when it fails they ask the vendor where the estimated ROI can be found.

The introduction of PLM brings more complexity and as the new system has to prove itself, there is not big enthusiasm from the average user. The management can push, like in the ERP situation, but in general also the management is anxious to learn if this OOTB-approach brings the benefits and when it fails they ask the vendor where the estimated ROI can be found.

Concluding you will be lucky if users get excited form the OOTB approach.

In the second and granular approach, the company defines their strategy and vision, not necessary a 100 % PLM vision. This strategy need to be clear and shared with the employees in the company, especially for those who are affected by changes.

In the second and granular approach, the company defines their strategy and vision, not necessary a 100 % PLM vision. This strategy need to be clear and shared with the employees in the company, especially for those who are affected by changes.

Next together with implementation partners, who bring in the know-how and possible software tools, a part of the company’s process is addressed and improved. It can be in any area, changing the CAD engine, automate BOM handling, connect sales to engineering or connect after sales/service to engineering.

Many of these areas of interest have different solutions, some are extensions of the CAD environment, some of them are extensions of the ERP environment and some of them are extensions of the IT-platform used in the company.

This approach is not sold by the PLM vendors, as they want to introduce their system as the IT-platform, wrap around the CAD and even capture the definition of the MBOM and initiation of the Item master.

A step-by-step approach based on different granular components, every time in the direction of the company’s strategy, plus all the time feed-back to the end-users on the positive impact of the change, is for me the key to success. In my previous post I was looking for a global provider for these required components.

With the step by step approach with granular solutions, we get users involved and excited.

And this brings me the to the presentation from Meyn

The first time I got involved with Meyn was in October 2004. At that time they had chosen to move from their BaaN-2D CAD infrastructure to a new environment with BaaN – 3D CAD (CATIA). Simon presented their target strategy and vision: moving away from being an Engineering To Order company to become primarily a Configure To Order company.

The first time I got involved with Meyn was in October 2004. At that time they had chosen to move from their BaaN-2D CAD infrastructure to a new environment with BaaN – 3D CAD (CATIA). Simon presented their target strategy and vision: moving away from being an Engineering To Order company to become primarily a Configure To Order company.

ENOVIA SmarTeam was chosen to manage the 3D CAD and to connect the information to BaaN. Initially Meyn started in the classical PLM approach, but already after a few months, the understanding was there, they need have step-by-step approach, focused on results for the new CATIA users, without communicating around a complete PLM focused project.

So they followed a stepped approach, they called them waves.

Moving from Engineering to Order to Configure to Order is not software implementation. It requires rationalization of your products; convert them into modular, configurable parts. For this you need to be an engineering expert, not a software expert.

But when it comes to implementation of this concept in the software, you need both experts. And through this collaboration, a methodology for skeleton design was established which was driven by Meyn. And the reason the users were excited was, that they were doing real engineering, the benefits were significant visible.

Customer project related engineering time (typical ETO), which was in the beginning their core activity, became around 30 % of the time. More time could be spent on developing new machines in a modular way. With almost the same amount of engineers the turn-over of the company had more than doubled. A win-win environment which makes also the end-users excited.

Customer project related engineering time (typical ETO), which was in the beginning their core activity, became around 30 % of the time. More time could be spent on developing new machines in a modular way. With almost the same amount of engineers the turn-over of the company had more than doubled. A win-win environment which makes also the end-users excited.

Still the backend with ERP at Meyn remained almost the same similar to the time they were working in the 2D environment. And the most interesting conclusion at the end of the presentation was, they are still using the same slide with the vision and they can explain why each step was taken and justify it by measurable benefits.

And this brings me to the answer of the question

“Do you know any specific examples of what some companies have done to get their users ready, excited or more committed to the new PLM system”?

- The management needs to have a clear vision where they want to be as a company in the future. This is not an IT-vision, but a business vision which explain why changes are needed. This vision should be clear to the employees. Communicate!

- Where possible provide metrics!

- Do not talk about a PLM system; it can be also in other tools. Talk about improvement steps in the business processes contributing to the vision. The PLM system is the information backbone, not the front-end. Management and implementers should talk business functionality not IT functions and features. Do not talk in applications!

- Build step by step user scenarios with focus on methodology and user understanding. Implementations with a function-feature focus are hard to accept by the users. Talk business!

- The management should present their vision again and again, supported by metrics what has been accomplished and what has been learned for the future – repeat!

Conclusion

There are thousands of mid-market companies that have a vision to improve their business. The PLM system should never be the topic of discussion with the end users; it is the change in working methods that is important, supported by various systems -CAD/ERP/CRM – and almost invisible …….. PLM