You are currently browsing the tag archive for the ‘PLM costs’ tag.

Last week I shared my thoughts related to my observation that the ROI of PLM is not directly visible or measurable, and I explained why. Also, I explained that the alignment of an organization requires a myth to make it happen. A majority of readers agreed with these observations. Some others either misinterpreted the headlines or twisted the story in favor of their opinion.

Last week I shared my thoughts related to my observation that the ROI of PLM is not directly visible or measurable, and I explained why. Also, I explained that the alignment of an organization requires a myth to make it happen. A majority of readers agreed with these observations. Some others either misinterpreted the headlines or twisted the story in favor of their opinion.

A few came from Oleg Shilovitsky and as Oleg is quite open in his discussions, it allows me to follow-up on his statements. Other people might share similar thoughts but they haven’t had the time or opportunity to be vocal. Feel free to share your thoughts/experiences too.

Some misinterpretations from Oleg’s post: PLM circa 2020 – How to stop selling Myths

- The title “How to stop selling Myths” is the first misinterpretation.

We are not selling myths – more below. - “Jos Voskuil’s recommendation is to create a myth. In his PLM ROI Myths article, he suggests that you should not work on a business case, value, or even technology” is the second misinterpretation, you still need a business case, you need value and you need technology.

And I got some feedback from Lionel Grealou, who’s post was a catalyst for me to write the PLM ROI Myth post. I agree I took some shortcuts based on his blog post. You can read his comments here. The misinterpretation is:

- “Good luck getting your CFO approve the business change or PLM investment based on some “myth” propaganda :-)” as it is the opposite, make your plan, support your plan with a business case and then use the myth to align

I am glad about these statements as they allow me to be more precise, avoiding misperceptions/myth-perceptions.

A Myth is bad

Some people might think that a myth is bad, as the myth is most of the time abstract. I think these people do not realize that there a lot of myths that they are following; it is a typical social human behavior to respond to myths. Some myths:

Some people might think that a myth is bad, as the myth is most of the time abstract. I think these people do not realize that there a lot of myths that they are following; it is a typical social human behavior to respond to myths. Some myths:

- How can you be religious without believing in myths?

- In this country/world, you can become anything if you want?

- In the past, life was better

- I make this country great again

The reason human beings need myths is that without them, it is impossible to align people around abstract themes. Try for each of the myths above to create an end-to-end logical story based on factual and concrete information. Impossible!

Read Yuval Harari’s book Sapiens about the power of myths. Read Steven Pinker’s book Enlightenment Now to understand that statistics show a lot of current myths are false. However, this does not mean a myth is bad. Human beings are driven by social influences and myths – it is our brain.

Unless you have no social interaction, you might be immune to myths. With brings me to quoting Oleg once more time:

“A long time ago when I was too naive and too technical, I thought that the best product (or technology) always wins. Well… I was wrong. “

I went through the same experience, having studied physics and mathematics makes you think extremely logical. Something I enjoyed while developing software. Later, when I started my journey as the virtualdutchman mediating in PLM implementations, I discovered logical alone does not work in businesses. The majority of decisions are done based on “gut feelings” still presented as reasonable cases.

Unless you have an audience of Vulcans, like Mr. Spock, you need to deal with the human brain. Consider the myth as the envelope to pass the PLM-project to the management. C-level acts by myths as so far I haven’t seen C-level management spending serious time on understanding PLM. I will end with a quote from Paul Empringham:

I sometimes wish companies would spend 6 months+ to educate themselves on what it takes to deliver incremental PLM success BEFORE engaging with software providers

You don’t need a business case

Lionel is also skeptical about some “Myth-propaganda” and I agree with him. The Myth is the envelope, inside needs to be something valuable, the strategy, the plan, and the business case. Here I want to stress one more time that most business cases for PLM are focusing on tool and collaboration efficiency. And from there projecting benefits. However, how well can we predict the future?

Lionel is also skeptical about some “Myth-propaganda” and I agree with him. The Myth is the envelope, inside needs to be something valuable, the strategy, the plan, and the business case. Here I want to stress one more time that most business cases for PLM are focusing on tool and collaboration efficiency. And from there projecting benefits. However, how well can we predict the future?

If you implement a process, let’s assume BOM-collaboration done with Excel by BOM-collaboration based on an Excel-on-the-cloud-like solution, you can measure the differences, assuming you can measure people’s efficiency. I guess this is what Oleg means when he explains OpenBOM has a real business case.

However, if you change the intent for people to work differently, for example, consult your supplier or manufacturing earlier in the design process, you touch human behavior. Why should I consult someone before I finish my job, I am measured on output not on collaboration or proactive response? Here is the real ROI challenge.

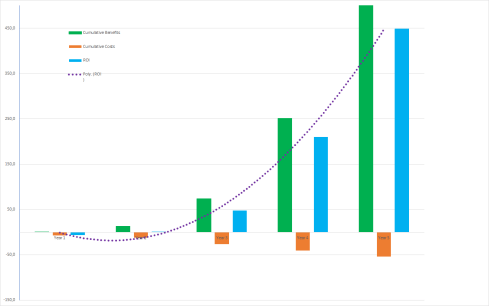

I have participated in dozens of business cases and at the end, they all look like the graph below:

The ROI is fantastic – after a little more than 2 years, we have a positive ROI, and the ROI only gets bigger. So if you trust the numbers, you would be a fool not to approve this project. Right?

And here comes the C-level gut-feeling. If I have a positive feeling (I follow the myth), then I will approve. If I do not like it, I will say I do not trust the numbers.

Needless to say that if there was a business case without ROI, we do not need to meet the C-level. Unless, and it happens incidental, at C-level, there was already a decision we need PLM from Vendor X because we played golf together, we are condemned together or we believe the same myths.

Needless to say that if there was a business case without ROI, we do not need to meet the C-level. Unless, and it happens incidental, at C-level, there was already a decision we need PLM from Vendor X because we played golf together, we are condemned together or we believe the same myths.

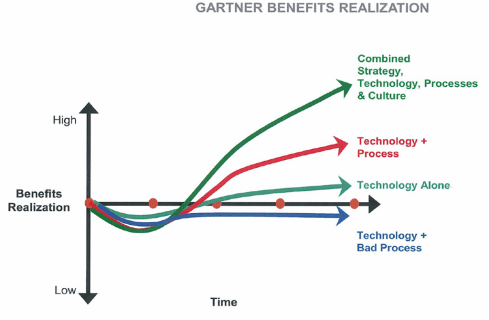

In reality, the old Gartner graph from realized benefits says it all. The impact of culture, processes, and people can make or break a plan.

You do not need an abstract story for PLM

Some people believe PLM on its own is a myth. You just need the right technology and people will start using it, spreading it out and see how we have improved business. Sometimes email is used as an example. Email is popular because you can with limited effort, collaborate with people, no matter where they are. Now twenty years later, companies are complaining about the lack of traceability, the lack of knowledge and understanding related to their products and processes.

PLM will always have the complexity of supporting traceability combined with real-time collaboration. If you focus only on traceability, people will complain that they are not a counter clerk. If you focus solely on collaboration, you miss the knowledge build-up and traceability.

That’s why PLM is a mix of governance, optimized processes to guarantee quality and collaboration, combined with a methodology to tune the existing processes implemented in tools that allow people to be confident and efficient. You cannot translate a business strategy into a function-feature list for a tool.

That’s why PLM is a mix of governance, optimized processes to guarantee quality and collaboration, combined with a methodology to tune the existing processes implemented in tools that allow people to be confident and efficient. You cannot translate a business strategy into a function-feature list for a tool.

Conclusion

Myths are part of the human social alignment of large groups of people. If a Myth is true or false, I will not judge. You can use the Myth as an envelope to package your business case. The business case should always be a combination of new ways of working (organizational change), optimized processes and finally, the best tools. A PLM tool-only business case is to my opinion far from realistic

Now preparing for PI PLMx London on 3-4 February – discussing Myths, Single BOMs and the PLM Green Alliance

I realized that time is flying when you are busy, and I promised to publish the conclusion from my previous post: More on who decides for plm in a mid market company. In my two previous posts, I described the difficulties companies have to select the right PLM system. So far I discussed the two extremes, the silent approach where a possible bottom up approach was discussed and as the opposite where an ‘academical’ approach was followed.

I realized that time is flying when you are busy, and I promised to publish the conclusion from my previous post: More on who decides for plm in a mid market company. In my two previous posts, I described the difficulties companies have to select the right PLM system. So far I discussed the two extremes, the silent approach where a possible bottom up approach was discussed and as the opposite where an ‘academical’ approach was followed.

Now it is time to get the answers on the academical approach.

These were the questions to be answered in the previous post:

- How much time has passed since the management decided PLM was good for their organization?

- How independent is the consultancy firm?

- Did they consider open source PLM as a solution?

- What was the ranking of the PLM vendors?

How much time has passed since the management decided PLM was good for their organization?

The whole process of selecting a PLM system often takes more than one or two years, starting from the first activities till the final conclusion to start. I believe this is unavoidable, as especially in mid-market companies the business values that PLM can bring are not always discussed and realized on the strategic level.

The whole process of selecting a PLM system often takes more than one or two years, starting from the first activities till the final conclusion to start. I believe this is unavoidable, as especially in mid-market companies the business values that PLM can bring are not always discussed and realized on the strategic level.

However, I believe the recent years PLM has been recognized by analysts, by software vendors and many young companies as a necessity for innovation and in the long term remaining competitive. And this is not only in the classical domains where PLM started – automotive / aero / industrial equipment. PLM value is everywhere in different industries, even apparel for example.

For companies that are now in the decision process, I believe 2009 and early 2010 are the years to decide, because a recovery of the economy might put back the focus on execution and not on strategy and they might miss the management focus for PLM. And as I wrote in a previous post, companies who made the best pit stop will benefit upmost.

For companies still in doubt: It is now or never

How independent is the consultancy firm?

It is clear that real independent consultancy firms do not exist – even if a consultant wants to be independent, there are three challenges to meet:

- How can a consultant evaluate or judge PLM systems they have not seen?

- How much experience does the consultant have in your business?

- How much work is there required in the project for the consultant?

As you can imagine, reviewing the above challenges, you will realize that consultants usually specialize in systems, where their expertise it required – as they also want to make a living. Consultants cannot afford to be an academic institute, as coming back to the previous point, all consultancy work at the end will be paid by the customer.

As you can imagine, reviewing the above challenges, you will realize that consultants usually specialize in systems, where their expertise it required – as they also want to make a living. Consultants cannot afford to be an academic institute, as coming back to the previous point, all consultancy work at the end will be paid by the customer.

So to conclude on this point, if you want to be cost-effective, a company should do already a pre-selection based on systems and possible implementation partners, that fit naturally to their type of business and then evaluate how consultancy can be achieved.

What you will find out is that the major ‘expensive’ packages have loads of consultants to offer en the more and more you go into a mid-market environment, consultants become rare. For software from PLM vendors you will usually find a reseller network with people close to your offices that can support you. For Open Source software you will need to find the consultancy services through their software delivery program.

Anyway remember: 50 % of the success of a PLM implementation is based on the right implementation approach and partner not on the PLM functions and features.

Did they consider open source PLM as a solution?

No, because the consultant was not familiar with it, and discouraged the company to look at it. In general Open Source PLM, like PLM On-Demand are interesting trends to follow and should not be neglected. However the focus and approach for this type of solutions is different. I will not generalize at this moment as also I have no clear picture where Open Source PLM or PLM on Demand would be a big differentiator. I will try to evaluate and report it in future posts.

No, because the consultant was not familiar with it, and discouraged the company to look at it. In general Open Source PLM, like PLM On-Demand are interesting trends to follow and should not be neglected. However the focus and approach for this type of solutions is different. I will not generalize at this moment as also I have no clear picture where Open Source PLM or PLM on Demand would be a big differentiator. I will try to evaluate and report it in future posts.

Comments from Open Source PLM Vendors or On Demand PLM Vendors are welcome to complete the PLM selection approach.

What was the ranking of the PLM vendors?

Ranking was done by the management, the selection team and the design department. These were the results plus their major comment:

Management

1. The slide show PLM provider – they liked the business pitch

2. The CAD supplier with PLM features and gadgets – good guys – we know them

3. The PLM provider who showed everything – too much handling of data – too complex

Selection Team

1. The PLM Provider who showed everything – they really did it

2. The CAD supplier with PLM features and gadgets– we understand where they are going

3. The slide show PLM provider – do they really have a solution?

The Designers

1. The CAD supplier with PLM features and gadgets– he knows what we want

2. The slide show PLM provider– could be a good solution too

3. The PLM Provider who showed everything – too complex, it will limit our productivity

As the management had the final vote, they decided for the slide show PLM Provider, as they felt most comfortable with them.

As the management had the final vote, they decided for the slide show PLM Provider, as they felt most comfortable with them.

The reason to drop the CAD supplier was that they were too afraid this provider does not know all about PLM. Both management and users felt the PLM provider that showed everything was too complex, this opposite to the project team where the members were very familiar with PLM capabilities after two years investigation and many demos and trade shows.

Conclusion: Selecting PLM, even in an academical manner is a subjective process. As in general the customer does not exactly knows what he needs and often the PLM provider shows too much in detail, the real journey starts at implementation time. And in this stage you need an experienced implementation partner who can match and communicate the expectations

The last month I have been working with Aerosud Aviation in South Africa to finalize and conclude on ROI and the lessons learned around their PLM implementation, which started in May 2007. I was lucky to be involved in the initial scoping of the project in 2007 and assisted the local Value Added Reseller together with the team from Dassault Systèmes UK team in a step by step project towards PLM.

The last month I have been working with Aerosud Aviation in South Africa to finalize and conclude on ROI and the lessons learned around their PLM implementation, which started in May 2007. I was lucky to be involved in the initial scoping of the project in 2007 and assisted the local Value Added Reseller together with the team from Dassault Systèmes UK team in a step by step project towards PLM.

When I met the people in Aerosud the first time in 2007, I noticed it was a young company, with open-minded people, everyone trying to improve their daily activities per department. There was the need for PLM as some of their major customers required Aerosud to have a PLM system in place. Also Configuration Management was mentioned many times in the interviews and what I learned that time: Excel was the tool for configuration management.

When I met the people in Aerosud the first time in 2007, I noticed it was a young company, with open-minded people, everyone trying to improve their daily activities per department. There was the need for PLM as some of their major customers required Aerosud to have a PLM system in place. Also Configuration Management was mentioned many times in the interviews and what I learned that time: Excel was the tool for configuration management.

Based on the initial interviews a plan needed to be developed in which steps to implement PLM. The following three major points were the guidance for the implementation:

- The company was thinking documents and understanding documents especially Excel

- The company had no clear understanding of what PLM would mean for them as real awareness was not inside the company. Customers like Boeing and Airbus talked about the importance of PLM, but how this could impact Aerosud as a company was no commonly clear

- People in the company had a major focus on their department and there was no availability of a overarching group of people leading the implementation

You could say you will see the above points in many smaller and medium-sized companies. I wrote about it also in one of my previous posts: Where does PLM start beyond document management ?

The project phases

The good news for Aerosud was that their PLM Champion was an expert in CATIA and was familiar with writing macros in Visual Basic plus the fact that everyone in the company was open for using the system as standard as possible – no demands for special behavior of the system: “because we do this already for 100 years”

The good news for Aerosud was that their PLM Champion was an expert in CATIA and was familiar with writing macros in Visual Basic plus the fact that everyone in the company was open for using the system as standard as possible – no demands for special behavior of the system: “because we do this already for 100 years”

The last phrase you hear a lot in ancient Europe

The choice was to start with implementing ENOVIA SmarTeam Design Express and to focus in two phases around design data management (phase 1) and the usage of design data by other users (phase 2)

The plan was that each phase would take maximum 2-3 months and we would give the users the time to digest and change their habits towards the standards in the system. In reality it took almost a year, not due to technical or conceptual issues, but this was the maximum pace we could have with the amount of time and available resources. The good news after these two phases was that the first bullet was much clearer understood – the difference between having a system with a single version of the truth or Excel management.

In the summer of 2008 (our summer – as it was winter in South Africa) there was a management workshop in Aerosud and here after three days of discussion the position of PLM became clear. One year ago this would not have been possible, now people had seen ENOVIA SmarTeam and they could imagine what benefits the system could further bring. This addressed the second bullet I mentioned before. Although this workshop was not scheduled upfront, looking back now I see this was a crucial point to get understanding for the next PLM steps.

In the summer of 2008 (our summer – as it was winter in South Africa) there was a management workshop in Aerosud and here after three days of discussion the position of PLM became clear. One year ago this would not have been possible, now people had seen ENOVIA SmarTeam and they could imagine what benefits the system could further bring. This addressed the second bullet I mentioned before. Although this workshop was not scheduled upfront, looking back now I see this was a crucial point to get understanding for the next PLM steps.

The next PLM steps were extending to a real Item-centric data model, because if you want to do PLM you need to work around Bill of Materials and all related information to the items in the Bill of Material. At the end this gives you configuration management without chasing Excels.

Again the next steps were divided in two phases with again a scope of 2 – 3 months. The implementation would be based on the ENOVIA SmarTeam Engineering Express methodology which came as a logic extension of the current implementation, without having to change the database or existing data model.

In the first phase we had awareness sessions for BOM (discussing EBOM / MBOM / Effectivity, etc) plus in parallel we introduced the item as place holder for the information. Not longer folders or projects as the base.

Introduction of the item was conceptual not a big issue and the major activities in this phase were focused on connection legacy data or current data from projects to the items. Data coming from various sources (directories, legacy databases) plus NC data became connected and visible in the single version of truth.

In the second phase of moving to PLM the focus was on EBOM and MBOM. Initially assuring that from the designer point of view the CATIA design and EBOM were connected as smoothly as possible, trying to avoid a lot of administrative overhead on the designer (sometimes unavoidable – see my previous post: Where is my ROI, Mr. Voskuil)

After having implemented a streamlined CATIA – EBOM connection, the focus moved to the MBOM. For me this is the differentiator for companies if they implement PLM or just Product Data Management). Implementing the MBOM requires a culture change and this is the place where the ERP people need to see the benefits instead of the threats . Luckily in Aerosud the manufacturing engineers were working in their Excels initially and not in the ERP system – which happens a lot in older companies.

For that reason the concept of MBOM in PLM was much better understood. Now Aerosud is experiencing these capabilities and once they become obvious for everyone the third bullet will be addressed: people start to work in processes cross-departmental instead of optimizing their department with a specific tool.

As this activity will continue, I also conducted with the Aerosud management and PLM implementation team an ROI assessment. Estimates about the experienced and projected benefits were kept low and on the realistic side. The result was that the outcome for the ROI period was approx 27 months, almost the same time as the whole project had as throughput time. This proved again the statement about a phased PLM approach. payback of project comes in parallel with the implementation and will ultimately fund the next steps.

As this activity will continue, I also conducted with the Aerosud management and PLM implementation team an ROI assessment. Estimates about the experienced and projected benefits were kept low and on the realistic side. The result was that the outcome for the ROI period was approx 27 months, almost the same time as the whole project had as throughput time. This proved again the statement about a phased PLM approach. payback of project comes in parallel with the implementation and will ultimately fund the next steps.

End of July I will be holding a webinar with more details about this implementation for the Dassault VAR Community. I will be happy to expand this information for a wider audience afterwards, as I believe the project is representative for many mid-market companies that struggle to find the place where PLM fits ….. and brings ROI

End of July I will be holding a webinar with more details about this implementation for the Dassault VAR Community. I will be happy to expand this information for a wider audience afterwards, as I believe the project is representative for many mid-market companies that struggle to find the place where PLM fits ….. and brings ROI

Let me know if you are interested in this follow up and I will collect the inputs for a follow up.

Finally I have time to continue on my sequence: “How to come to measurable PLM benefits ?” I think it is a topic where everyone talks about, but little is known in concrete figures. One of the main challenges is also “What to measure ? “. As I added to Martin’s comment on my previous post, we can measure comparable activities, like how much time and people are involved in average for an engineering change. And when a company makes the statement: “We reduced the time for an engineering change in average from 23 days to 8 days” – what does it mean ?

Finally I have time to continue on my sequence: “How to come to measurable PLM benefits ?” I think it is a topic where everyone talks about, but little is known in concrete figures. One of the main challenges is also “What to measure ? “. As I added to Martin’s comment on my previous post, we can measure comparable activities, like how much time and people are involved in average for an engineering change. And when a company makes the statement: “We reduced the time for an engineering change in average from 23 days to 8 days” – what does it mean ?

Does is mean people have spent less time to understand and implement correctly the change ? Probably – so there might me xxx amount of money related to this saving in time. Of course, there might be also a saving in distribution costs, assuming in the traditional approach a paper-based distribution process was used – people spending time in distribution, printing, copying etc.

Everyone experienced with Excel and formulas can make these kind of calculations (and I did it too) and often I was surprised about the huge benefits showing up in the spreadsheet. So please continue filling spreadsheets as in general the benefits will be high

In parallel a second approach should be considered. Benchmarking against similar companies and Aberdeen has published some papers in this area, (see for example: The Best Kept Secret of Top SMB Product Developers -Finding the Shortest Path to PLM Value) . Maybe less specific per activity but they offer a good secondary view of the PLM benefits, in this case viewed from the business point of view.

Back to ROI measuring – and now in the planning phase

The planning phase, by my definition is the phase where we have a concept and we start to analyze which activities and which resources are required to develop the concept. In a Built To Order process, the planning phase might overlap the concept phase, as the inputs from the prospect require besides to provide a solution also the need to have it done within a certain budget and timeframe.

The planning phase, by my definition is the phase where we have a concept and we start to analyze which activities and which resources are required to develop the concept. In a Built To Order process, the planning phase might overlap the concept phase, as the inputs from the prospect require besides to provide a solution also the need to have it done within a certain budget and timeframe.

So the most important questions related to the planning phase are:

- How many projects we are doing are similar in approach?

Measure: time spent in finding similar solutions / percentage reuse /classify projects

Analyze: Can we improve by standardization - How often do we have to do a major change /disruption in our planning ?

Measure: the amount of projects that have small compared to major changes (define a rule to differentiate)

Analyze: What is the reason for the major changes - During execution of a project – do we know if we are on track ?

Measure: Select an arbitrary project and make a status

Analyze: Was this status correct looking back later ? ( a month – some months) - How much time and effort do we spent to understand the status of a project ?

Measure: Select an arbitrary project and make a status

Analyze: How much time and people were involved to get the status - How much time does it take to plan an engineering change ?

Measure: Once an ECO (Engineering Change Order) has been approved, what does it take to plan the change

(perhaps you already planned too as part of the ECR process- excellent) – resources and time

Analyze: Can we improve by doing things different

Again all the above points can be addressed by PLM, either through a sales and product configurator (a configurator btw already requires a certain level of standardization or modularization of products. I will write more on configurators and how to get there perhaps in the future. Meanwhile read this excellent white paper from the Valent Group: 7 Myths of Configurators).

Project and program management combined with template best practices, how to do execute an customer order or a new product introduction are also providing huge benefits. Every time you have the chance to do something similar, you have reduced the risk dramatically. So investing in standardization and templates is an investment in risk reduction and increased reliability

At then the measurable results will come from two sides: customer satisfaction and market share (hard to measure) and internal increased efficiency (easy to measure)which contributes to your margin or to your market share as you can follow a different price point.

Conclusion

Conclusion

The keywords for the planning phase are: standardization, reuse (in the broadest context) and activities that can be monitored with low effort . This allows companies to control their margin and their risks and their health status.

And planning is import – see video below (and I hope all are still alive)

I am writing this week’s post on my way to a customer to finalize an implementation and in parallel describing the Return On Investment of this project. But before that, I would like to have a short note about my previous post ‘Free PLM software does not help companies“.

I am writing this week’s post on my way to a customer to finalize an implementation and in parallel describing the Return On Investment of this project. But before that, I would like to have a short note about my previous post ‘Free PLM software does not help companies“.

The reason I wrote this post was because I wanted to assure that companies do not believe that ROI for implementing PLM is based on the software costs. PLM implementations are a combination of software, business skills and the company culture. Specially in the current economical situation, I wanted to make clear that these factors are not overlooked. Also I did not want to say Open Source PLM is bad, I made my points on the messaging, however in functionality and usage I do not see a big difference between other types of PLM systems. I got some interesting comments on this post and I advise all of you, who have read the post to go through the comments to get a broader perspective. Once I have had some more opportunity to investigate this area deeper, I will come with a more in-depth post on this topic.

To PLM or Not To PLM

But now back to: To PLM or Not To PLM, where I wrote in a first post on this topic that before judging the costs and ROI of PLM, we should start analyzing our current processes and situation and use this as a baseline to guesstimate the PLM benefits.

The first PLM phase to analyze is the concept phase, where new ideas are picked up (or not). Actually this is the phase where we define the future of the company. The economical recession in a way forces companies to rethink their strategy and fortunately all of the competition is in a similar position. downturn means less activities, the company might be in the position to allocate time to address these analysis for PLM ROI. Instead of making people redundant, use these people to work on a new and optimized product strategy.

Existential questions to ask yourself as a company

Existential questions to ask yourself as a company

The basic questions to ask about the concept phase:

- Do we know where our products are currently in their lifecycle ?

Measure: quantity, sales trends, margin

Analyze: is our portfolio healthy ? - How do customer rate our products ?

Measure: market share, market awareness, customer satisfaction, quality, field issues

Analyze: will customers keep on buying from us ? - Where are we different from the competition ?

Measure: where do we win/ where do we loose and compare per quarter ?

Analyze: how can we improve the success ratio ? - In case of bidding

Measure: how many bids do we handle per quarter and with which effort

Analyze: What is the win percentage and how to influence this ? - Who are our customers ?

Measure: does the 80-20 rule apply – does 80 % of the revenue come from 20 % of the customers ?

Analyze: What is the trend specially in relation to the current market situation - Where does innovation come from ?

Measure: the amount of new ideas, the source (people, customers) and the ones that reach it to the portfolio

Analyze: Do we have a guarantee for innovation ?

Additional questions to be asked due to current financial and global situation:

- How do we strive for climate neutral products – sustainable development ?

Measure: the amount of energy used to build the products but also to recycle and what remains

Analyze: How can we change our products and production process ? - How do we capture our company’s IP due to the aging workforce in most of the countries

Measure: How many people with the specific knowledge will retire in 5 – 10 years ?

Analyze: Where and how can I assure this knowledge remains in the company ?

For many of the above questions you might say that you know how to conduct your business as you are doing most of these activities and even more. However the question you should ask yourself also is: How long does it take to answer these questions and to react on these trends ?

Because all the above topics are positively influenced by PLM – here it the PLM ROI !

Project and Portfolio Management, company wide workflow process allow the company to measure, to run analysis and to have information within hours (or worse case in days), where in a company where every department and discipline has their own environment, the effort to collect this information becomes huge and not natural. And as it will take a lot of time to collect the information, people tend to react on their guts or intuition, which might be wrong if you are among the wrong people or if the world changes in a way never seen before.

Project and Portfolio Management, company wide workflow process allow the company to measure, to run analysis and to have information within hours (or worse case in days), where in a company where every department and discipline has their own environment, the effort to collect this information becomes huge and not natural. And as it will take a lot of time to collect the information, people tend to react on their guts or intuition, which might be wrong if you are among the wrong people or if the world changes in a way never seen before.

Additional capturing product and process knowledge allows companies to contain their IP. And just to make this point clear: Product knowledge is not only CAD and Bills of Materials. It is all collected information: issues during design, during production, coming from field services, best practices used and more. The challenge anyway for every PLM system is to provide an environment, user-friendly enough for all users, to start managing their total product IP in a single environment.

Conclusion

PLM as a total approach brings a lot of value and control in the concept phase, the phase where the company’s future is merely defined. And it is obvious that the future should be green and sustainable. Use the current downturn to shape the future – the questions in this post and your analysis should be the base.

Last week I conducted another ENOVIA SmarTeam Express training, this time in the Coventry office from Dassault Systems. The conclusion from the audience was that the SmarTeam Engineering Express concept is a perfect entry PLM system for the mid-market. It show the general best practices of PLM for a mid-market from concept to manufacturing. Additionally is provides the company a flexible PLM platform to further grow and expand to directions that bring more benefits.

Last week I conducted another ENOVIA SmarTeam Express training, this time in the Coventry office from Dassault Systems. The conclusion from the audience was that the SmarTeam Engineering Express concept is a perfect entry PLM system for the mid-market. It show the general best practices of PLM for a mid-market from concept to manufacturing. Additionally is provides the company a flexible PLM platform to further grow and expand to directions that bring more benefits.

But here I want to stop, as you will start to believe it is a marketing speech. In a certain way it is marketing. Marketing is needed to influence people and companies to change their way of thinking. Without marketing we would never buy Personal Computers, mobile phones, MP3 players, certain drinks and more. We tend to forget why we need certain products and what the real benefits are. PLM is not at that level of market understanding yet.

For that reason I will give the 5 objections why not to implement PLM that I heard the most and comment on them.

The 5 reasons not to implement PLM I heard the most were:

- The costs for a PLM implementation are too high

- A PLM implementation takes too long

- We already have an ERP system

- Isn’t PLM the same as managing CAD files ?

- We are so busy, there is no time to have a PLM implementation in our company

In this post I will address the first reason. Others in upcoming posts.

Note: I use generalizations in this post as specific cases my vary – specially when talking about comparisons with ERP system.

1. The cost for a PLM implementation are too high.

This is the argument I heard the most. And indeed, if you accumulate the total costs of a PLM implementation after 2-3 years, you might get that impression. The main reason for this perception is the fact that often companies have suffered from an ERP implementation in the past. I do not want to blame the ERP companies for the high costs of implementation, as they were the first major business system implemented in manufacturing companies. There were many horror stories in the past, but now you can say ERP has become mature and processes to implement are clear too. For that reason ERP companies now can provide an estimated cost and ROI (Return On Investment) for manufacturing companies. I guess that manufacturing companies that have not invested in ERP the past 20 years, probably stopped to exists, so benefits for ERP are clear.

But at what costs ? PLM is not as mature as ERP. This means a PLM vendor cannot come to a manufacturing company, identify its main business process and apply a PLM template. The major reason for that is the fact that the PLM vision encompasses many different processes in a company, many of them currently not even identified in mid-market companies. This leads to the situation where PLM implementers together with their customers spend time to learn and pay the price for learning. Most of the learning has been done already by the big enterprises, now the mid-market companies need to understand what is relevant for them.

We know learning has it costs, and specially when external (paid) resources are involved, the costs might add up too high. In parallel the biggest mistake made to implement PLM is to consider it the same way ERP is implemented. A project team builds in a isolated environment a new ‘to be’ PLM environment, once and a while involving key users for their feedback. Then after 8 months – 1 year they role out the PLM implementation to the users as a ‘big boom’. As a logical reaction the users object to this radical change, which leads to compromises, and rework of some of the project deliverables. At the end after 2 years the company might have an acceptable PLM implementation, meanwhile having a bad taste of a failed and costly project. And the ROI still to come……

See the diagram below:

So how can we avoid these high costs ?

First of all the investment of a PLM is done because we believe there is a Return On Investment. Companies invest in order to improve their competitiveness and PLM is a main driver for manufacturing companies. So how can we assure ROI and lower the total costs ?

A first best practice is the phase a PLM implementation into small, digestible steps with a durations of 3 to 6 months. Each step will have its investment and its limited scope. The result will be that even after the first step, people can start working with the new system, experience the impact of the new PLM system and start bringing ROI as the benefits will start paying of.

These benefits plus the fact that the company and their users start to understand what a PLM system can bring for them and this leads to a clearer and lower cost of implementation for the next phases. The figure below gives an impression of how costs and ROI will work out in this situation.

The Express offerings from ENOVIA, SDE (SmarTeam Design Express) and SNE (SmarTeam Engineering Express) are exactly targeting this approach. Instead of imagining what PDM and PLM could do for a company. They allow the company to quickly start and experience and later grow to the optimized environment.

The management of the company should always keep their ultimate PLM vision in mind, still anticipating changes as business evolves. Each implementation phase should fit in the ultimate PLM vision and its implementation should be judged on bring ROI.

This is a main difference between PLM and ERP. An ERP implementation focuses on a specific logistical process to implement. This implementation cannot be done for 50 % and than later another 30 % and again another 10 % till the ultimate ERP vision has been reached. It must be done in one implementation as it targets the whole production process.

A PLM implementation however is an implementation of Best Practices all around Product IP and innovation. The world in which products are defined has changed drastically due to globalization, customer focus and changed technologies. This means that the way companies define and develop their products have to be flexible and changeable. PLM implementations require a step by step approach, every time improving those areas that bring the best ROI. Still the company needs to remain flexible in to anticipate for future changes, merges, acquisitions or even different business processes.

Conclusion: PLM systems are not costly in case of a phased implementation targeting immediate ROI per phase and flexibility in the future.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…