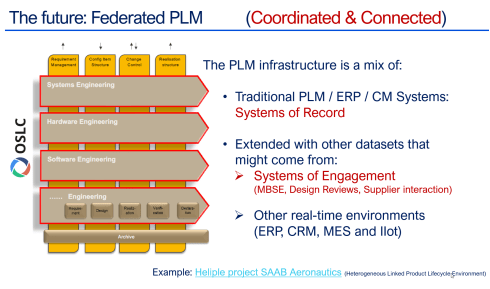

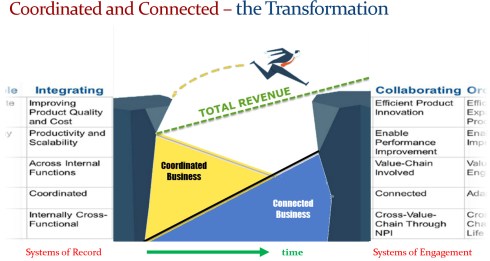

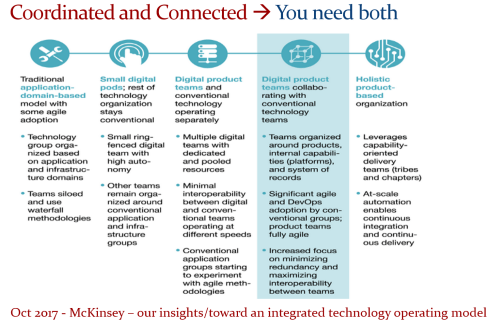

Those who have been following my blog posts over the past two years may have discovered that I consistently use the terms “System of Engagement” and “System of Record” in the context of a Coordinated and Connected PLM infrastructure.

Understanding the distinction between ‘System of Engagement‘ and ‘System of Record‘ is crucial for comprehending the type of collaboration and business purpose in a PLM infrastructure. When explored in depth, these terms will reveal the underlying technology.

The concept

A year ago, I had an initial discussion with three representatives of a typical system of engagement. I spoke with Andre Wegner from Authentise, MJ Smith from CoLab and Oleg Shilovitsky from OpenBOM. You can read and see the interview here: The new side of PLM? Systems of Engagement!

A year ago, I had an initial discussion with three representatives of a typical system of engagement. I spoke with Andre Wegner from Authentise, MJ Smith from CoLab and Oleg Shilovitsky from OpenBOM. You can read and see the interview here: The new side of PLM? Systems of Engagement!

As a follow-up, I had a more detailed interview with Taylor Young, the Chief Strategy Officer of CoLab, early this year.

CoLab introduced the term Design Engagement System (DES), a new TLA. Based on a survey among 250 global engineering leaders, we discussed the business impact and value of their DES System of Engagement.

CoLab introduced the term Design Engagement System (DES), a new TLA. Based on a survey among 250 global engineering leaders, we discussed the business impact and value of their DES System of Engagement.

You can read the discussion here: Where traditional PLM fails.

The business benefits

I like that CoLab’s external messaging focuses on the business capabilities and opportunities, which reminded me of the old Steve Jobs recording: Don’t talk about the product!

There are so many discussions on LinkedIn about the usage of various technologies and concepts without a connection to the business. I’ll let you explore and decide.

It’s worth noting that while the ‘System of Engagement’ offers significant business benefits, it’s not a standalone solution. The right technology is crucial for translating these benefits into tangible business results.

This was a key takeaway from my follow-up discussion with MJ Smith, CMO at CoLab, about the difference between Configuration and Customization.

Why configurability?

Hello MJ, it has been a while since we spoke, and this time, I am curious to learn how CoLab fits in an enterprise PLM infrastructure, zooming in on the aspects of configuration and customization.

Hello MJ, it has been a while since we spoke, and this time, I am curious to learn how CoLab fits in an enterprise PLM infrastructure, zooming in on the aspects of configuration and customization.

Using configurability, we can make a smaller number of features work for more use cases or business processes. Users do not want to learn and adopt many different features, and a system of engagement should make it easy to participate in a business process, even for infrequent or irregular users.

Using configurability, we can make a smaller number of features work for more use cases or business processes. Users do not want to learn and adopt many different features, and a system of engagement should make it easy to participate in a business process, even for infrequent or irregular users.

In design review, this means cross-functional teams and suppliers who are not the core users of CAD or PLM.

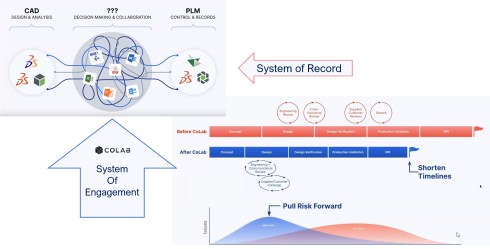

I agree, and for that reason, we see the discussion of Systems of Record (not user-friendly and working in a coordinated mode) and Systems of Engagement (focus on the end-user and working in a connected mode). How do you differentiate with CoLab?

I agree, and for that reason, we see the discussion of Systems of Record (not user-friendly and working in a coordinated mode) and Systems of Engagement (focus on the end-user and working in a connected mode). How do you differentiate with CoLab?

From a technology perspective, as a System of Engagement, CoLab wants to eliminate complex, multi-step workflows that require users to navigate between 5-10+ different point solutions to complete a review.

From a technology perspective, as a System of Engagement, CoLab wants to eliminate complex, multi-step workflows that require users to navigate between 5-10+ different point solutions to complete a review.

For example:

- SharePoint for sending data

- CAD viewers for interrogating models

- PowerPoint for documenting markups – using screenshots

- Email or Teams meetings for discussing issues

- Spreadsheets for issue tracking

- Traditional PLM systems for consolidation

As mentioned before, the participants can be infrequent or irregular users from different companies. This gap exists today, with only 20% of suppliers and 49% of cross-functional teams providing valuable design feedback (see the 2023 report here). To prevent errors and increase design quality, NPD teams must capture helpful feedback from these SMEs, many of whom only participate in 2 to 3 design reviews each year.

As mentioned before, the participants can be infrequent or irregular users from different companies. This gap exists today, with only 20% of suppliers and 49% of cross-functional teams providing valuable design feedback (see the 2023 report here). To prevent errors and increase design quality, NPD teams must capture helpful feedback from these SMEs, many of whom only participate in 2 to 3 design reviews each year.

Configuration and Customization

Back to the interaction between the System of Engagement (CoLab) and Systems or Records, in this case, probably the traditional PLM system. I think it is important to define the differences between Configuration and Customization first.

Back to the interaction between the System of Engagement (CoLab) and Systems or Records, in this case, probably the traditional PLM system. I think it is important to define the differences between Configuration and Customization first.

These would be my definitions:

- Configuration involves setting up standard options and features in software to meet specific needs without altering the code, such as adjusting settings or using built-in tools.

- Customization involves modifying the software’s code or adding new features to tailor it more precisely to unique requirements, which can include creating custom scripts, plugins, or changes to the user interface.

Both configuration and customization activities can be complex depending on the system we are discussing.

It’s also interesting to consider how configurability and customization can go hand in hand. What starts as a customization for one customer could become a configurable feature later.

It’s also interesting to consider how configurability and customization can go hand in hand. What starts as a customization for one customer could become a configurable feature later.

For software providers like CoLab, the key is to stay close to your customers so that you can understand the difference between a niche use case – where customization may be the best solution – vs. something that could be broadly applicable.

In my definition of customization, I first thought of connecting to the various PLM and CAD systems. Are these interfaces standardized, or are they open to configuration and customization?

In my definition of customization, I first thought of connecting to the various PLM and CAD systems. Are these interfaces standardized, or are they open to configuration and customization?

CoLab offers out-of-the-box integrations with PLM systems, including Windchill, Teamcenter, and 3DX Enovia. By integrating PLM with CoLab, companies can share files straight from PLM to CoLab without having to export or convert to a neutral format like STP.

CoLab offers out-of-the-box integrations with PLM systems, including Windchill, Teamcenter, and 3DX Enovia. By integrating PLM with CoLab, companies can share files straight from PLM to CoLab without having to export or convert to a neutral format like STP.

By sharing CAD from PLM to CoLab, companies make it possible for non-PLM users – inside the company and outside (e.g., suppliers, customers) to participate in design reviews. This use case is an excellent example of how a system of engagement can be used as the connection point between two companies, each with its own system of record.

CoLab can also send data back to PLM. For example, you can see whether there is an open review on a part from within Windchill PLM and how many unresolved comments exist on a file shared with CoLab from PLM. Right now, there are some configurable aspects to our integrations – such as file-sharing controls for Windchill users.

We plan to invest more in the configurability of the PLM to DES interface. We will also invest in our REST API, which customers can use to build custom integrations if they like, instead of using our OOTB integrations.

To get an impression, look at this 90-second demo of CoLab’s Windchill integration for reference.

Talking about IP security is a topic that is always mentioned when companies interact with each other, and in particular in a connected mode. Can you tell us more about how Colab deals with IP protection?

Talking about IP security is a topic that is always mentioned when companies interact with each other, and in particular in a connected mode. Can you tell us more about how Colab deals with IP protection?

CoLab has enterprise customers, like Schaeffler, implementing attribute-based access controls so that users can only access files in CoLab that they would otherwise have access to in Windchill.

CoLab has enterprise customers, like Schaeffler, implementing attribute-based access controls so that users can only access files in CoLab that they would otherwise have access to in Windchill.

We also have customers who integrate CoLab with their ERP system to auto-provision guest accounts for suppliers so they can participate in design reviews.

This means that the OEM is responsible for identifying which data is shared within CoLab. I am curious: Are these kinds of IP-sharing activities standardized because you have a configurable interface to the PLM/ERP, or is this still a customization?

This means that the OEM is responsible for identifying which data is shared within CoLab. I am curious: Are these kinds of IP-sharing activities standardized because you have a configurable interface to the PLM/ERP, or is this still a customization?

I am referring to this point in the Federated PLM Interest Group. We discuss using OSLC as one of the connecting interfaces between the System of Record and the System of Engagement (Modules)—it’s still in the early days, as you can read in this article—but we see encouraging similar results. Is this a topic of attention for CoLab, too?

The interface between CoLab and PLM is the same for every customer (not custom) but can be configured with attributes-based access controls. End users who have access must explicitly share files. Further access controls can also be put in place on the CoLab side to protect IP.

The interface between CoLab and PLM is the same for every customer (not custom) but can be configured with attributes-based access controls. End users who have access must explicitly share files. Further access controls can also be put in place on the CoLab side to protect IP.

We are taking a similar approach to integrating as outlined by OSLC. The OSLC concept is interesting to us, as it appears to provide a framework for better-supporting concepts such as versions and variants. The interface delegation concepts are also of interest.

Conclusion

It was great to dive deeper into the complementary value of CoLab as a typical System of Engagement. Their customers are end-users who want to collaborate efficiently during design reviews. By letting their customers work in a dedicated but connected environment, they are released from working in a traditional, more administrative PLM system.

Interfacing between these two environments will be an interesting topic to follow in the future. Will it be, for example, OSLC-based, or do you see other candidates to standardize?

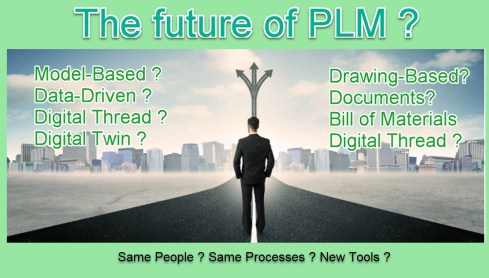

The past two weeks have been a fascinating journey, delving into the intersection of Curiosity, Innovation, and modern PLM. Where many PLM-related posts are about the best products and the best architectures, there is also the “soft” angle – people and culture – which I believe is the most important to start from. Without the right people and the right mindset, every PLM implementation is ready to fail.

The past two weeks have been a fascinating journey, delving into the intersection of Curiosity, Innovation, and modern PLM. Where many PLM-related posts are about the best products and the best architectures, there is also the “soft” angle – people and culture – which I believe is the most important to start from. Without the right people and the right mindset, every PLM implementation is ready to fail.

This time, on Earth Day (April 22nd), Stefaan organized an interactive webinar titled “Curiosity and the Planet,” which addressed the need for new technologies and approaches to living in a sustainable future. With my Green PLM-twisted mind, I immediately saw the overlap and intersection between our missions.

This time, on Earth Day (April 22nd), Stefaan organized an interactive webinar titled “Curiosity and the Planet,” which addressed the need for new technologies and approaches to living in a sustainable future. With my Green PLM-twisted mind, I immediately saw the overlap and intersection between our missions. As companies need to find their path to the digitization of their PLM infrastructure due to regulations, ESG reporting, and potentially the introduction of digital product passports and the circular economy, they need to act fast in an area not familiar to them.

As companies need to find their path to the digitization of their PLM infrastructure due to regulations, ESG reporting, and potentially the introduction of digital product passports and the circular economy, they need to act fast in an area not familiar to them.

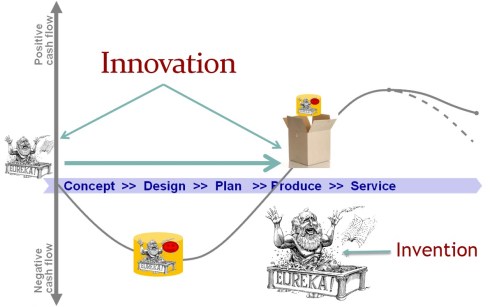

I presented this topic at the 2013 Product Innovation Conference in Berlin. The title of the presentation was PLM Loves Innovation, and you can find it

I presented this topic at the 2013 Product Innovation Conference in Berlin. The title of the presentation was PLM Loves Innovation, and you can find it

It is like in soccer. Having eleven highly skilled young players does not make a team successful. Success depends on the combination of the trainer and the coach, and it is a continuous interaction throughout the season.

It is like in soccer. Having eleven highly skilled young players does not make a team successful. Success depends on the combination of the trainer and the coach, and it is a continuous interaction throughout the season.

Two weeks ago, I shared my first post about PDM/PLM migration challenges on LinkedIn:

Two weeks ago, I shared my first post about PDM/PLM migration challenges on LinkedIn:

Data migrations and consolidation are typically not part of a company’s core business, so it is crucial to find the right partner for a migration project. The challenge with migrations is that there is potentially a lot to do technically, but only your staff can assess the quality and value of migrations.

Data migrations and consolidation are typically not part of a company’s core business, so it is crucial to find the right partner for a migration project. The challenge with migrations is that there is potentially a lot to do technically, but only your staff can assess the quality and value of migrations. To get an impression of what a PLM service partner can do and which topics or tools are relevant in the context of mid-market PLM, you can watch

To get an impression of what a PLM service partner can do and which topics or tools are relevant in the context of mid-market PLM, you can watch  In my PLM coaching career I have seen many migrations. In the early days they were more related to technology upgrades, consolidation of data and system replacements. Nowadays the challenges are more related to become more data-driven. Here are 5 lessons that I learned in the past twenty years:

In my PLM coaching career I have seen many migrations. In the early days they were more related to technology upgrades, consolidation of data and system replacements. Nowadays the challenges are more related to become more data-driven. Here are 5 lessons that I learned in the past twenty years:

I believe moving from a coordinated enterprise to a integrated (coordinated and connected) enterprise is not a migration, as we are no longer talking about a single system that serves the whole enterprise.

I believe moving from a coordinated enterprise to a integrated (coordinated and connected) enterprise is not a migration, as we are no longer talking about a single system that serves the whole enterprise.

In the past months, I have had several discussions related to migrating PLM data, either from one system to another or from consolidating a collection of applications into a single environment. Does this sound familiar?

In the past months, I have had several discussions related to migrating PLM data, either from one system to another or from consolidating a collection of applications into a single environment. Does this sound familiar? Halfway I realized I was too ambitious; therefore, another post will follow this introduction. Here, I will focus on the business side and the digital transformation journey.

Halfway I realized I was too ambitious; therefore, another post will follow this introduction. Here, I will focus on the business side and the digital transformation journey. The Garbage Out-In statement is somehow the paradigm we are used to in our day-to-day lives. When you buy a new computer, you use backup and restore. Even easier, nowadays, the majority of the data is already in the cloud.

The Garbage Out-In statement is somehow the paradigm we are used to in our day-to-day lives. When you buy a new computer, you use backup and restore. Even easier, nowadays, the majority of the data is already in the cloud. TIP 1: Every migration is a moment to clean up your data. By dragging everything with you, the burden of migrating becomes bigger. In easy migrations, do a clean-up—it prevents future, more extensive issues.

TIP 1: Every migration is a moment to clean up your data. By dragging everything with you, the burden of migrating becomes bigger. In easy migrations, do a clean-up—it prevents future, more extensive issues. Before discussing the various scenarios, let’s examine what companies are doing. For early PLM adopters in the Automotive, Aerospace, and Defense Industries, migrations from mainframes to modern infrastructures have become impossible. The real problem is not only the changing hardware but also the changing data and data models.

Before discussing the various scenarios, let’s examine what companies are doing. For early PLM adopters in the Automotive, Aerospace, and Defense Industries, migrations from mainframes to modern infrastructures have become impossible. The real problem is not only the changing hardware but also the changing data and data models. From a business perspective, migrations are considered a negative distractor. Talking about them raises awareness of their complexity, which might jeopardize enthusiasm.

From a business perspective, migrations are considered a negative distractor. Talking about them raises awareness of their complexity, which might jeopardize enthusiasm.

One of my earlier projects, starting in 2010 with SmarTeam, was migrating a mainframe-based application for airplane certification to a modern Microsoft infrastructure.

One of my earlier projects, starting in 2010 with SmarTeam, was migrating a mainframe-based application for airplane certification to a modern Microsoft infrastructure.

The disadvantage was that SmarTeam ended up being so highly customized that automatic upgrades would not work for this version anymore—a new legacy was created with modern technology.

The disadvantage was that SmarTeam ended up being so highly customized that automatic upgrades would not work for this version anymore—a new legacy was created with modern technology.

I have experienced a situation where a company has poorly defined 3D parts and no properties, as all the focus was on using the 3D to generate the 2D drawing.

I have experienced a situation where a company has poorly defined 3D parts and no properties, as all the focus was on using the 3D to generate the 2D drawing.

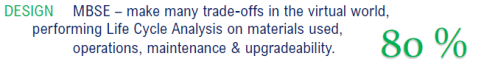

The session led by PTC from

The session led by PTC from

Mark explained that PTC is exploring AI in various areas of the product lifecycle, like validating requirements, optimizing CAD models, streamlining change processes on the design side but also downstream activities like quality and maintenance predictions, improved operations and streamlined field services and service parts are part of the PTC Copilot strategy.

Mark explained that PTC is exploring AI in various areas of the product lifecycle, like validating requirements, optimizing CAD models, streamlining change processes on the design side but also downstream activities like quality and maintenance predictions, improved operations and streamlined field services and service parts are part of the PTC Copilot strategy.

It was a severe project involving a lot of resources and time, again showing the challenges of migrations. I am planning to publish a blog post, the draft title “Migration Migraine,” as this type of migration is prevalent in many places because companies want to implement a single PLM backbone beyond (mechanical) engineering.

It was a severe project involving a lot of resources and time, again showing the challenges of migrations. I am planning to publish a blog post, the draft title “Migration Migraine,” as this type of migration is prevalent in many places because companies want to implement a single PLM backbone beyond (mechanical) engineering.

When failures happen, there is often the blame game: Was it the software, the implementer, or the customer (past or present) that caused the troubles? Mediating in such environments has been a long time my mission as the “Flying Dutchman,” and from my experience,

When failures happen, there is often the blame game: Was it the software, the implementer, or the customer (past or present) that caused the troubles? Mediating in such environments has been a long time my mission as the “Flying Dutchman,” and from my experience, When asked what he would do differently with the project’s hindsight, Mikael mentioned he would do the migrations not as a big project but as smaller projects.

When asked what he would do differently with the project’s hindsight, Mikael mentioned he would do the migrations not as a big project but as smaller projects.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

My conclusion is that this example shows the unique situation of an inspired leader with 20 years of experience in this business who does not choose ways of working from the past but starts a new company in the same industry, but now based on a modern platform approach instead of individual traditional tools.

My conclusion is that this example shows the unique situation of an inspired leader with 20 years of experience in this business who does not choose ways of working from the past but starts a new company in the same industry, but now based on a modern platform approach instead of individual traditional tools.

The presentation of Renault was also an exciting surprise. Last year, they shared the scope of the Renaulution project at the conference (see also my post:

The presentation of Renault was also an exciting surprise. Last year, they shared the scope of the Renaulution project at the conference (see also my post:

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…