You are currently browsing the category archive for the ‘Sustainability’ category.

Congratulations if you have shown you can resist the psychological and emotional pressure and did not purchase anything in the context of Black Friday. However, we must not forget that another big part of the world cannot afford this behavior, as they do not have the means to do so – ultimate Black Friday might be their dream and a fast track to more enormous challenges.

Congratulations if you have shown you can resist the psychological and emotional pressure and did not purchase anything in the context of Black Friday. However, we must not forget that another big part of the world cannot afford this behavior, as they do not have the means to do so – ultimate Black Friday might be their dream and a fast track to more enormous challenges.

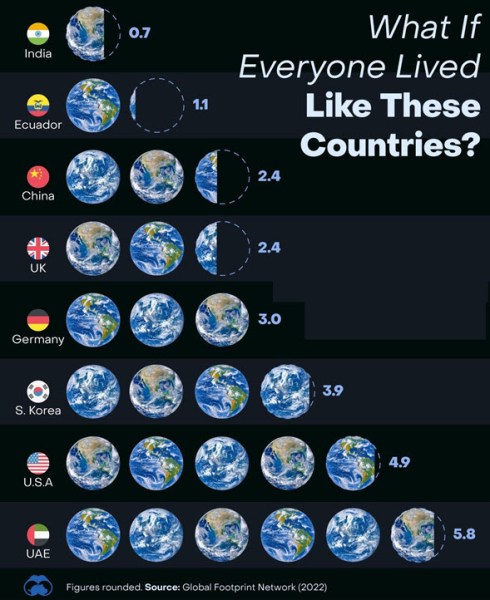

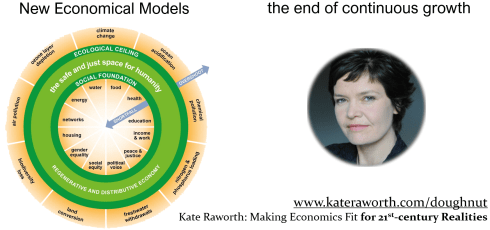

The difference between our societies, all living on the same planet, is illustrated in the image below, illustrating the unfairness of this situation

What the image also shows is a warning that we all have to act, as step by step, we will reach planet boundaries for resources.

Or we need more planets, and I understand a brilliant guy is already working on it. Let’s go to Mars and enjoy life there.

Or we need more planets, and I understand a brilliant guy is already working on it. Let’s go to Mars and enjoy life there.

For those generations staying on this planet, there is only one option: we need to change our economy of unlimited growth and reconsider how we use our natural resources.

The circular economy?

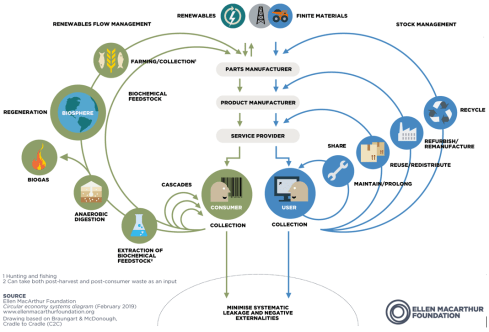

You are probably familiar with the butterfly diagram from the Ellen MacArthur Foundation, where we see the linear process: Take-Make-Use-Waste in the middle.

This approach should be replaced by more advanced regeneration loops on the left side and the five R’s on the right: Reduce, Repair, Reuse, Refurbish and Recycle as the ultimate goal is the minimum leakage of Earth resources.

Closely related to the Circular Economy concept is the complementary Cradle-To-Cradle design approach. In this case, while designing our products, we also consider the end of life of a product as the start for other products to be created based on the materials used.

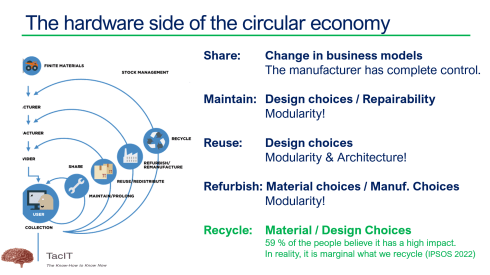

The CE butterfly diagram’s right side is where product design plays a significant role and where we, as a PLM community, should be active. Each loop has its own characteristics, and the SHARE loop is the one I focused on during the recent PLM Roadmap / PDT Europe conference in Gothenburg.

As you can see, the Maintain, Reuse, Refurbish and Recycle loops depend on product design strategies, in particular, modularity and, of course, depending on material choices.

It is important to note that the recycle loop is the most overestimated loop, where we might contribute to recycling (glass, paper, plastic) in our daily lives; however, other materials, like composites often with embedded electronics, have a much more significant impact.

It is important to note that the recycle loop is the most overestimated loop, where we might contribute to recycling (glass, paper, plastic) in our daily lives; however, other materials, like composites often with embedded electronics, have a much more significant impact.

Watch the funny meme in this post: “We did everything we could– we brought our own bags.”

![]() The title of my presentation was: Products as a Service – The Ultimate Sustainable Economy?

The title of my presentation was: Products as a Service – The Ultimate Sustainable Economy?

You can find my presentation on SlideShare here.

Let’s focus on the remainder of the presentation’s topic: Product As A Service.

The Product Service System

Where Product As A Service might be the ultimate dream for an almost wasteless society, Ida Auken, a Danish member of the parliament, gave a thought-provoking lecture in that context at the 2016 World Economic Forum. Her lecture was summarized afterward as

Where Product As A Service might be the ultimate dream for an almost wasteless society, Ida Auken, a Danish member of the parliament, gave a thought-provoking lecture in that context at the 2016 World Economic Forum. Her lecture was summarized afterward as

“In the future, you will own nothing and be happy.”

A theme also picked up by conspiracy thinkers during the COVID pandemic, claiming “they” are making us economic slaves and consumers. With Black Friday in mind, I do not think there is a conspiracy; it is the opposite.

Closer to implementing everywhere Product as a Service for our whole economy, we might be going into Product Service Systems.

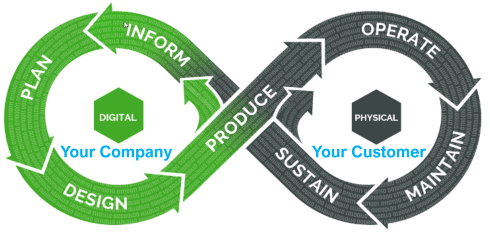

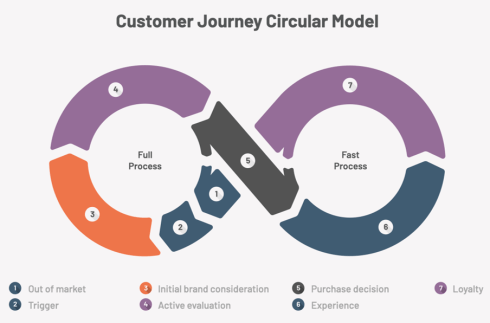

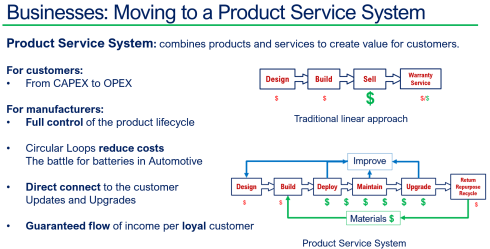

As the image shows, a product service system is a combination of providing a product with related services to create value for the customer.

In the ultimate format, the manufacturer owns the products and provides the services, keeping full control of the performance and materials during the product lifecycle. The benefits for the customer are that they pay only for the usage of the product and, therefore, do not need to invest upfront in the solution (CAPEX), but they only pay when using the solution (OPEX).

A great example of this concept is Spotify or other streaming services. You do not pay for the disc/box anymore; you pay for the usage, and the model is a win-win for consumers (many titles) and producers (massive reach).

A great example of this concept is Spotify or other streaming services. You do not pay for the disc/box anymore; you pay for the usage, and the model is a win-win for consumers (many titles) and producers (massive reach).

Although the Product Service System will probably reach consumers later, the most significant potential is currently in the B2B business model, e.g., transportation as a service and special equipment usage as a service. Examples are popping up in various industries.

My presentation focused on three steps that manufacturing companies need to consider now and in the future when moving to a Product Service System.

My presentation focused on three steps that manufacturing companies need to consider now and in the future when moving to a Product Service System.

Step 1: Get (digital) connected to your Product and customer

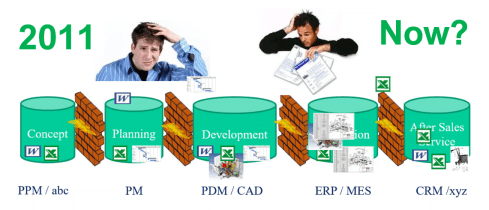

A foundational step companies must take is to create a digital infrastructure to support all stakeholders in the product service offering. Currently, many companies have a siloed approach where each discipline Marketing/Sales, R&D, Engineering, Manufacturing and Sales will have their own systems.

Digital Transformation in the PLM domain is needed here – where are you on this level?

But it is not only the technical silos that impede the end-to-end visibility of information. If there are no business targets to create and maintain the end-to-end information sharing, you can not expect it to happen.

Therefore, companies should invest in the digitalization of their ways of working, implementing an end-to-end digital thread AND changing their linear New Product Development process into a customer-driven DevOp approach. The PTC image below shows the way to imagine a end-to-end connected environment

In a Product Service System, the customer is the solution user, and the solution provider is responsible for the uptime and improvement of the solution over time.

As an upcoming bonus and a must, companies need to use AI to run their Product Service System as it will improve customer knowledge and trends. Don’t forget that AI (and Digital Twins) runs best on reliable data.

As an upcoming bonus and a must, companies need to use AI to run their Product Service System as it will improve customer knowledge and trends. Don’t forget that AI (and Digital Twins) runs best on reliable data.

Step 2 From Product to Experience

A Product Service System is not business as usual by providing products with some additional services. Besides concepts such as Digital Thread and Digital Twins of the solution, there is also the need to change the company’s business model.

In the old way, customers buy the product; in the Product Service System, the customer becomes a user. We should align the company and business to become user-centric and keep the user inspired by the experience of the Product Service System.

In the old way, customers buy the product; in the Product Service System, the customer becomes a user. We should align the company and business to become user-centric and keep the user inspired by the experience of the Product Service System.

In this context, there are two interesting articles to read:

- Jan Bosch: From Agile to Radical: Business Model

- Chris Seiler: How to escape the vicious circle in times of transformation?

The change in business model means that companies should think about a circular customer journey.

As the company will remain the product owner, it is crucial to understand what happens when the customers stop using the service or how to ensure maintenance and upgrades.

In addition, to keep the customer satisfied, it remains vital to discover the customer KPIs and how additional services could potentially improve the relationship. Again, AI can help find relationships that are not yet digitally established.

Step 2: From product to experience can already significantly impact organizations. The traditional salesperson’s role will disappear and be replaced by excellence in marketing, services and product management.

Step 2: From product to experience can already significantly impact organizations. The traditional salesperson’s role will disappear and be replaced by excellence in marketing, services and product management.

This will not happen quickly as, besides the vision, there needs to be an evolutionary path to the new business model.

Therefore, companies must analyze their portfolio and start experimenting with a small product, converting it into a product service system. Starting simple allows companies to learn and be prepared for scaling up.

A Product Service System also influences a company’s cash flow as revenue streams will change.

When scaling up slowly, the company might be able to finance this transition themselves. Another option, already happening, is for a third party to finance the Product Service System – think about car leasing, power by the hour, or some industrial equipment vendors.

When scaling up slowly, the company might be able to finance this transition themselves. Another option, already happening, is for a third party to finance the Product Service System – think about car leasing, power by the hour, or some industrial equipment vendors.

Step 3 Towards a doughnut economy?

The last step is probably a giant step or even a journey. An economic mindset shift is needed from the ever-growing linear economy towards an economy flourishing for everyone within economic, environmental and social boundaries.

Unlimited growth is the biggest misconception on a planet reaching its borders. Either we need more planets, or we need to adjust our society.

In that context, I read the book “The Doughnut Economy” by Kate Raworth, a recognized thought leader who explains how a future economic model can flourish, including a circular economy, and you will be happy.

But we must abandon the old business models and habits – there will be a lot of resistance to change before people are forced to change. This change can take generations as the outside world will not change without a reason, and the established ones will fight for their privileges.

But we must abandon the old business models and habits – there will be a lot of resistance to change before people are forced to change. This change can take generations as the outside world will not change without a reason, and the established ones will fight for their privileges.

It is a logical process where people and boundaries will learn to find a new balance. Will it be in a Doughnut Economy, or did we overlook some bright other concepts?

Conclusion

The week after Black Friday and hopefully the month after all the Christmas presents, it is time to formulate your good intentions for 2025. As humans, we should consume less; as companies, we should direct our future to a sustainable future by exploring the potential of the Product Service System and beyond.

I am sharing another follow-up interview about PLM and Sustainability with a software vendor or implementer. Last year, in November 2023, Klaus Brettschneider and Jos Voskuil from the PLM Green Global Alliance core team spoke with Transition Technologies PSC about their GreenPLM offering and their first experiences in the field.

I am sharing another follow-up interview about PLM and Sustainability with a software vendor or implementer. Last year, in November 2023, Klaus Brettschneider and Jos Voskuil from the PLM Green Global Alliance core team spoke with Transition Technologies PSC about their GreenPLM offering and their first experiences in the field.

As we noticed with most first interviews, sustainability was a topic of discussion in the PLM domain, but it was still in the early discovery phases for all of us.

![]() Last week, we spoke again with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services. The exciting part of this discussion is that system integrators are usually more directly connected to their customers in the field and, therefore, can be the source of understanding of what is happening.

Last week, we spoke again with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services. The exciting part of this discussion is that system integrators are usually more directly connected to their customers in the field and, therefore, can be the source of understanding of what is happening.

ecoPLM and more

Where Erik is a and he is a long term PLM expert and Rafal is the PLM Practice Lead for Industrial Sustainability. In the interview below they shared their experiences with a first implementation pilot in the field, the value of their _ecoPLM offering in the context of the broader PTC portfolio. And of course we discussed topics closely related to these points and put them into a broader context of sustainably.

Enjoy the 34 minutes discussion and you are always welcome to comment or start a discussion with us.

The slides shown in this presentation and some more can be downloaded HERE.

What I learned

- The GreenPLM offering has changed its name into ecoPLM as TT PSC customers are focusing on developing sustainable products, with currently supporting designer to understand the carbon footprint of their products.

- They are actually in a MVP approach with a Tier 1 automotive supplier to validate and improve their solution and more customers are adding Design for Sustainability to their objective, besides Time to Market, Quality and Cost.

- Erik will provide a keynote speech at the Green PLM conference on November 14th in Berlin – The conference is targeting a German speaking audience although the papers are in English. You can still register and find more info here

- TT PSC is one of the partners completing the PTC sustainability offering and working close with their product management.

- A customer quote: “Sustainability makes PLM sexy again”

Want to learn more?

Here are some links related to the topics discussed in our meeting:

- YouTube: ecoPLM: your roadmap for eco-friendly product development

- ecoPLM – a sustainable product development website

- YouTube: Win the Net-Zero Race with PLM (and PTC)

Conclusions

We are making great progress in the support to design and deliver more sustainable products – sustainability goes beyond marketing as Rafal Witkowski mentioned – the journey has started. What do you see in your company?

Recently, I attended several events related to the various aspects of product lifecycle management; most of them were tool-centric, explaining the benefits and values of their products.

In parallel, I am working with several companies, assisting their PLM teams to make their plans understood by the upper management, which has always been my mission in the past.

In parallel, I am working with several companies, assisting their PLM teams to make their plans understood by the upper management, which has always been my mission in the past.

However, nowadays, people working in the business are feeling more and more challenged and pained by not acting adequately to the upcoming business demands.

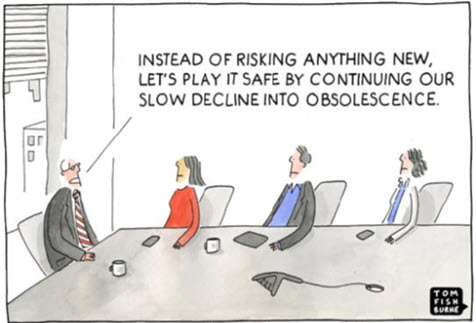

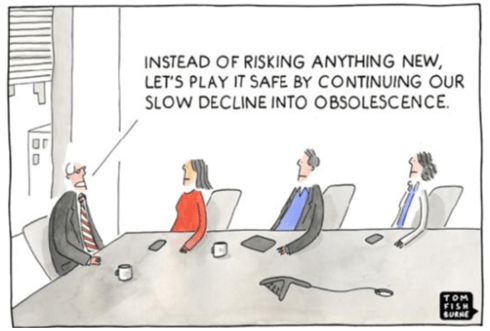

The image below has been shown so many times, and every time, the context becomes more relevant.

Too often, an evolutionary mindset with small steps is considered instead of looking toward the future and reasoning back for what needs to be done.

Let me share some experiences and potential solutions.

Don’t use the P** word!

The title of this post is one of the most essential points to consider. By using the term PLM, the discussion is most of the time framed in a debate related to the purchase or installation of a system, the PLM system, which is an engineering tool.

The title of this post is one of the most essential points to consider. By using the term PLM, the discussion is most of the time framed in a debate related to the purchase or installation of a system, the PLM system, which is an engineering tool.

PLM vendors, like Dassault Systèmes and Siemens, have recognized this, and the word PLM is no longer on their home pages.

They are now delivering experiences or digital industries software.

Other companies, such as PTC and Aras, broadened the discussion by naming other domains, such as manufacturing and services, all connected through a digital thread.

The challenge for all these software vendors is why a company would consider buying their products. A growing issue for them is also why would they like to change their existing PLM system to another one, as there is so much legacy.

The challenge for all these software vendors is why a company would consider buying their products. A growing issue for them is also why would they like to change their existing PLM system to another one, as there is so much legacy.

For all of these vendors, success can come if champions inside the targeted company understand the technology and can translate its needs into their daily work.

Here, we meet the internal PLM team, which is motivated by the technology and wants to spread the message to the organization. Often, with no or limited success, as the value and the context they are considering are not understood or felt as urgent.

Here, we meet the internal PLM team, which is motivated by the technology and wants to spread the message to the organization. Often, with no or limited success, as the value and the context they are considering are not understood or felt as urgent.

Lesson 1:

Don’t use the word PLM in your management messaging.

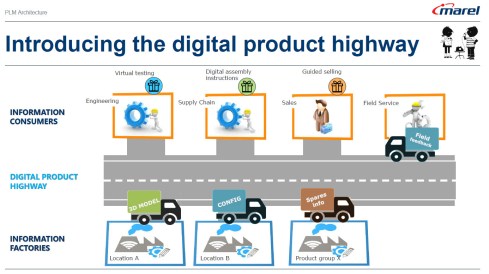

In some of the current projects I have seen, people talk about the digital highway or a digital infrastructure to take this hurdle. For example, listen to the SharePLM podcast with Roger Kabo from Marel, who talks about their vision and digital product highway.

In some of the current projects I have seen, people talk about the digital highway or a digital infrastructure to take this hurdle. For example, listen to the SharePLM podcast with Roger Kabo from Marel, who talks about their vision and digital product highway.

As soon as you use the word PLM, most people think about a (costly) system, as this is how PLM is framed. Engineering, like IT, is often considered a cost center, as money is made by manufacturing and selling products.

According to experts (CIMdata/Gartner), Product Lifecycle Management is considered a strategic approach. However, the majority of people talk about a PLM system. Of course, vendors and system integrators will speak about their PLM offerings.

According to experts (CIMdata/Gartner), Product Lifecycle Management is considered a strategic approach. However, the majority of people talk about a PLM system. Of course, vendors and system integrators will speak about their PLM offerings.

To avoid this framing, first of all, try to explain what you want to establish for the business. The terms Digital Product Highway or Digital Infrastructure, for example, avoid thinking in systems.

Lesson 2:

Don’t tell your management why they need to reward your project – they should tell you what they need.

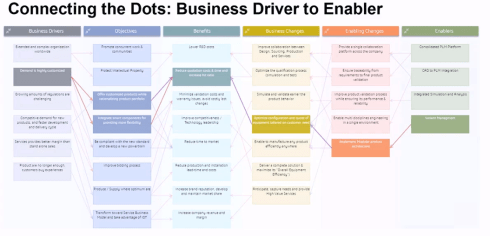

This might seem like a bit of strange advice; however, you have to realize that most of the time, people do not talk about the details at the management level. At the management level, there are strategies and business objectives, and you will only get attention when your proposal addresses the business needs. At the management level, there should be an understanding of the business need and its potential value for the organization. Next, analyzing the business changes and required tools will lead to an understanding of what value the PLM team can bring.

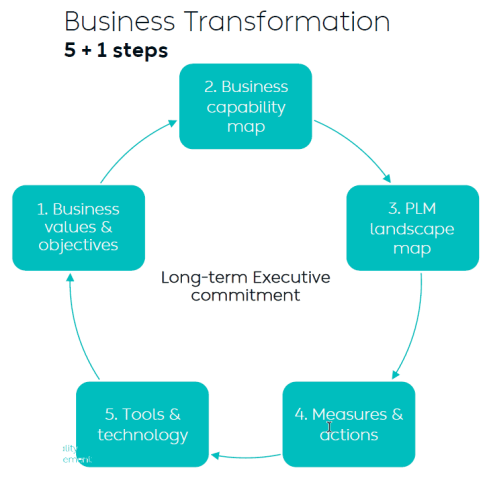

Yousef Hooshmand’s 5 + 1 approach illustrates this perfectly. It is crucial to note that long-term executive commitment is needed to have a serious project, and therefore, the connection to their business objective is vital.

Therefore, if you can connect your project to the business objectives of someone in management, you have the opportunity to get executive sponsorship. A crucial advice you hear all the time when discussing successful PLM projects.

Therefore, if you can connect your project to the business objectives of someone in management, you have the opportunity to get executive sponsorship. A crucial advice you hear all the time when discussing successful PLM projects.

Lesson 3:

Alignment must come from within the organization.

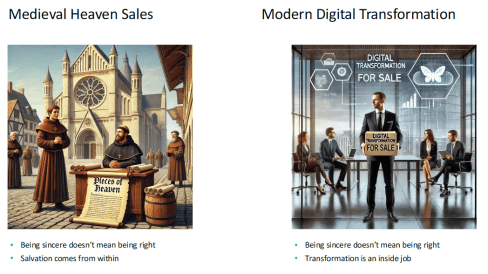

Last week, at the 20th anniversary of the Dutch PLM platform, Yousef Hooshmand gave the keynote speech starting with the images below:

On the left side, we see the medieval Catholic church sincerely selling salvation through indulgences, where the legend says Luther bought the hell, demonstrating salvation comes from inside, not from external activities – read the legend here.

On the right side, we see the Digital Transformation expert sincerely selling digital transformation to companies. According to LinkedIn, there are about 1.170.000 people with the term Digital Transformation in their profile.

On the right side, we see the Digital Transformation expert sincerely selling digital transformation to companies. According to LinkedIn, there are about 1.170.000 people with the term Digital Transformation in their profile.

As Yousef mentioned, the intentions of these people can be sincere, but also, here, the transformation must come from inside (the company).

When I work with companies, I use the Benefits Dependency Network methodology to create a storyboard for the company. The BDN network then serves as a base for creating storylines that help people in the organization have a connected view starting from their perspective.

Companies might hire strategic consultancy firms to help them formulate their long-term strategy. This can be very helpful where, in the best case, the consultancy firm educates the company, but the company should decide on the direction.

In an older blog post, I wrote about this methodology, presented by Johannes Storvik at the Technia Innovation forum, and how it defines a value-driven implementation.

Dassault Systèmes and its partners use this methodology in their Value Engagement process, which is tuned to their solution portfolio.

You can also watch the webinar Federated PLM Webinar 5 – The Business Case for the Federated PLM, in which I explained the methodology used.

Lesson 4:

PLM is a business need not an IT service

This lesson is essential for those who believe that PLM is still a system or an IT service. In some companies, I have seen that the (understaffed) PLM team is part of a larger IT organization. In this type of organization, the PLM team, as part of IT, is purely considered a cost center that is available to support the demand from the business.

This lesson is essential for those who believe that PLM is still a system or an IT service. In some companies, I have seen that the (understaffed) PLM team is part of a larger IT organization. In this type of organization, the PLM team, as part of IT, is purely considered a cost center that is available to support the demand from the business.

The business usually focuses on incremental and economic profitability, less on transformational ways of working.

In this context, it is relevant to read Chris Seiler’s post: How to escape the vicious circle in times of transformation? Where he reflects on his 2002 MBA study, which is still valid for many big corporate organizations.

It is a long read, but it is gratifying if you are interested. It shows that PLM concepts should be discussed and executed at the business level. Of course, I read the article with my PLM-twisted brain.

The image above from Chris’s post could be a starting point for a Benefits-Dependent Network diagram, expanded with Objectives, Business Changes and Benefits to fight this vicious downturn.

As PLM is no longer a system but a business strategy, the PLM team should be integrated into the business potential overlooked by the CIO or CDO, as a CEO is usually not able to give this long-term executive commitment.

Lesson 5:

Educate yourselves and your management

![]() The last lesson is crucial, as due to improving technologies like AI and, earlier, the concepts of the digital twin, traditional ways of coordinated working will become inefficient and redundant.

The last lesson is crucial, as due to improving technologies like AI and, earlier, the concepts of the digital twin, traditional ways of coordinated working will become inefficient and redundant.

However, before jumping on these new technologies, everyone, at every level in the organization, should be aware of:

WHY will this be relevant for our business? Is it to cut costs – being more efficient as fewer humans are in the process? Is it to be able to comply with new upcoming (sustainability) regulations? Is it because the aging workforce leaves a knowledge gap?

WHAT will our business need in the next 5 to 10 years? Are there new ways of working that we want to introduce, but we lack the technology and the tools? Do we have skills in-house? Remember, digital transformation must come from the inside.

HOW are we going to adapt our business? Can we do it in a learning mode, as the end target is not clear yet—the MVP (Minimum Viable Product) approach? Are we moving from selling products to providing a Product Service System?

My lesson: Get inspired by the software vendors who will show you what might be possible. Get educated on the topic and understand what it would mean for your organization. Start from the people and the business needs before jumping on the tools.

My lesson: Get inspired by the software vendors who will show you what might be possible. Get educated on the topic and understand what it would mean for your organization. Start from the people and the business needs before jumping on the tools.

In the upcoming PLM Roadmap/PDT Europe conference on 23-24 October, we will be meeting again with a group of P** experts to discuss our experiences and progress in this domain. I will give a lecture here about what it takes to move to a sustainable economy based on a Product-as-a-service concept.

In the upcoming PLM Roadmap/PDT Europe conference on 23-24 October, we will be meeting again with a group of P** experts to discuss our experiences and progress in this domain. I will give a lecture here about what it takes to move to a sustainable economy based on a Product-as-a-service concept.

If you want to learn more – join us – here is the link to the agenda.

Conclusion

I hope you enjoyed reading a blog post not generated by ChatGPT, although I am using bullet points. With the overflow of information, it remains crucial to keep a holistic overview. I hope that with this post, I have helped the P** teams in their mission, and I look forward to learning from your experiences in this domain.

This is a guest post from one of our active members of the PLM Green Global Alliance, Roger L. Franz.

This is a guest post from one of our active members of the PLM Green Global Alliance, Roger L. Franz.

Roger is supporting industry inquiries on regulated substances, sustainable product design and life cycle management, including carbon footprint.

He is a recognized authority on supply chain reporting for compliance with worldwide regulations. Roger brings decades of experience with engineering tools and enterprise IT systems.

Introduction.

More than just unsightly “plastic pollution,” the volume of consumer plastics and lack of closed-loop recovery have created a significant micro- and nano-plastics problem. These invisible plastic particles are found around the world, including in animal and human tissues.

For several reasons, including a much smaller volume of plastic used in electrotechnical products compared to consumer plastics and the generally longer life of hardware compared to the rapid turnover of consumer goods and packaging, the microplastics problem is not typically tagged as a major electronics problem- or at least not yet. Now is the time to be proactive.

The United Nations Environment Programme has posted summaries of recent discussions on using life cycle assessment (LCA) to address the global problem of plastic pollution. These Life Cycle Initiative areas relate to plastic products, chemicals of concern in plastic products, and plastic product design. The documents are about possible approaches to managing plastics with recommendations but are not detailed prescriptions, methods, or regulations.

The United Nations Environment Programme has posted summaries of recent discussions on using life cycle assessment (LCA) to address the global problem of plastic pollution. These Life Cycle Initiative areas relate to plastic products, chemicals of concern in plastic products, and plastic product design. The documents are about possible approaches to managing plastics with recommendations but are not detailed prescriptions, methods, or regulations.

While the studies did not specifically mention electrotechnical products, this industry will need to accelerate focus on engineering design tools and engineering plastics choices to avoid significantly adding on to the consumer plastic product problems.

Within the UNEP product design discussion, the section on “General considerations on possible approaches to product design, focusing on recyclability and reusability” included the following important point, which bears repeating: Product design approaches should include eco-design and circularity principles.

Product design approaches should include

eco-design and circularity principles.

But what does this mean? In the following discussion, we hope to break these approaches down into more tangible design choices. Even within the electrotechnical product category, there are many product variations, so no claim is made here to cover all of them.

Options for lower carbon footprint plastics already exist to some extent. Except for packaging, electronic components and products are typically made with engineering resins rather than the common consumer plastic “recycling arrow” types. Alternative types of lower carbon footprint engineering resins may be available to use rather than others with higher carbon footprints.

Many plastic manufacturers are currently conducting LCA to quantify the cradle-to-gate carbon footprint of their materials. Different polymer types have inherent differences in carbon footprint due to their different monomeric starting materials and manufacturing processes.

For many plastics, these flows are detailed by Plastics Europe. Polycarbonate, ABS, and several Polyamides, for example, are included. What is missing in these publicly available sources, as well as LCA inventory databases themselves, are many other engineering plastics; for example, while consumer PET is widely modeled, PBT (Polybutylene terephthalate) is not. These are just some of the data gaps that need to be resolved.

For many plastics, these flows are detailed by Plastics Europe. Polycarbonate, ABS, and several Polyamides, for example, are included. What is missing in these publicly available sources, as well as LCA inventory databases themselves, are many other engineering plastics; for example, while consumer PET is widely modeled, PBT (Polybutylene terephthalate) is not. These are just some of the data gaps that need to be resolved.

More sustainable feedstock is a good option since a given end polymer may be made from different monomeric chemicals, so the more sustainable plastic performs exactly like its classic version because it is the same. One of the growing alternatives includes feedstocks based on renewable, bio-based sources.

These need some evaluation, again using LCA, to ensure they are free of downsides like increased water use, eutrophication, and chemical pollution due to the use of herbicides, pesticides, fertilizers, and so on. Marketing claims of being a “green material” will need backup data! For guidelines on acceptable environmental benefits claims, refer to the US FTC Green Guides.

These need some evaluation, again using LCA, to ensure they are free of downsides like increased water use, eutrophication, and chemical pollution due to the use of herbicides, pesticides, fertilizers, and so on. Marketing claims of being a “green material” will need backup data! For guidelines on acceptable environmental benefits claims, refer to the US FTC Green Guides.

Reducing the amount of plastic by design is not only a good practice for sustainability, it also saves money. Some designs using parts with enough material to be modeled using generative design may be able to reduce the amount of material while reducing material usage and weight. Reducing factory scrap from injection molding processes leaving sprues in runners and use of captive regrind are other good options.

Choosing manufacturers using renewable fuels– and even benefits like reduction of water use during processing- is another area of choice for sustainability. Local sourcing is also a way to reduce the overall carbon footprint of a material by reducing the contribution of transportation.

Identify large plastic parts. Historical guidelines on eco-design have actually been around for years.

One good example is the ECMA 341 Standard, “Environmental Design Considerations for ICT & CE Products (4th Edition / December 2010), which says, “All plastic parts weighing 25 g or more and with a flat area of 200 mm2 or more are marked with the type of polymer, copolymer, polymer blends or alloys in conformance with ISO 11469.” This practice enables the identification of plastic types of large parts, while in practice, the ability to sort becomes less useful when a variety of goods are mixed in a production recycling facility. Success here depends either on manual sorting or more sophisticated methods like infrared spectroscopy to be effective. Some equipment recyclers have such capability.

One good example is the ECMA 341 Standard, “Environmental Design Considerations for ICT & CE Products (4th Edition / December 2010), which says, “All plastic parts weighing 25 g or more and with a flat area of 200 mm2 or more are marked with the type of polymer, copolymer, polymer blends or alloys in conformance with ISO 11469.” This practice enables the identification of plastic types of large parts, while in practice, the ability to sort becomes less useful when a variety of goods are mixed in a production recycling facility. Success here depends either on manual sorting or more sophisticated methods like infrared spectroscopy to be effective. Some equipment recyclers have such capability.

Keep it clean. More useful guidance from ECMA 341 is to avoid the following: non-recyclable composites; coatings and surface finishes on plastic parts; adhesive-backed stickers or foams on plastic parts; if stickers are required, they should be separable; and metal inserts in plastic parts unless easily removable with common tools. These are common sense from a clean recycling stream perspective and should not be difficult to implement.

Closing the end-of-life loop. Recycling is imperfect, and as far as this author has seen, is rarely in place for engineering plastics.

Processes under development to decompose plastics back to new monomer feedstocks, called chemical recycling or tertiary recycling. This approach is achieving some success with a limited number of materials, mostly for high-volume consumer plastics rather than engineering types.

Processes under development to decompose plastics back to new monomer feedstocks, called chemical recycling or tertiary recycling. This approach is achieving some success with a limited number of materials, mostly for high-volume consumer plastics rather than engineering types.

LCA is needed to validate that achieving plastic circularity this way with the necessary processing energy and chemicals will have a net environmental benefit. The obvious problem with all approaches is that plastics were never designed for the environment in the first place.

Selecting More Sustainable Additives is another area where product engineers have some choices. There are thousands of possible additives used in plastic, usually specified for a given grade and end application. These include flame retardants, processing aids, fillers, colorants, ultraviolet stabilizers, plasticizers for flexibility, and so on and on. While these choices are primarily the responsibility of the resin manufacturer, pressure from regulators and industry demand can influence the use of more sustainable additives.

Whenever possible, new products should avoid regulated substances by design, which may include Substances of Very High Concern (SVHC) as defined by the European Chemicals Agency (ECHA) and, more recently, polyfluorinated substances called PFAS. This is easier said than done but definitely belongs on the checklist of ecodesign considerations.

Besides plastics? While the present discussion is about plastics, choices of using altogether different materials may be possible in some cases.

High-volume hardware is probably unable to use alternative materials like wood, glass, bamboo, etc. Historically, though, until the rise of both solid-state and plastic technology in the 1950s, radios and televisions featured wooden cases and consoles. Miniaturization in the solid-state era brought in mostly plastic housings. One recent example that the author worked on was an audio teleconferencing system that featured either oak or walnut to blend with the executive conference room.

High-volume hardware is probably unable to use alternative materials like wood, glass, bamboo, etc. Historically, though, until the rise of both solid-state and plastic technology in the 1950s, radios and televisions featured wooden cases and consoles. Miniaturization in the solid-state era brought in mostly plastic housings. One recent example that the author worked on was an audio teleconferencing system that featured either oak or walnut to blend with the executive conference room.

While the intent was not specifically to avoid using plastic, it is an interesting example to think outside the plastic box. Wood avoids many of the issues with plastics, but of course, the plastics in the circuitry content remain to be addressed.

Other large household electrical/electronic goods are likely to use recyclable steel and/or stainless steel cabinets. And if you consider an automobile to be an electronic product, these metals come into play in high volume in automobile shredder residue. Using metal rather than plastic housings may be possible for some products; for example, aluminum may be used for personal communications and IT devices, bringing a tradeoff between initial cost and the potential advantage of aluminum being more highly recyclable for use in new equipment than any plastic.

Only LCA can quantify the tradeoffs. We should also mention toys, which increasingly incorporate some electronics and use colored plastics extensively.

New material technology. One of the many emerging material technologies is Engineered Wood. The cited research hardly suggests that a wood-based material could be a drop-in, for example, injection molded thermoplastics, but the possibility is most intriguing. However, just having a material of natural origins is not automatically a panacea for replacing plastics. Quite the contrary, significant cautions remain; for example,

“Chemical and thermal modifications are usually applied to adapt the wood structure and impart necessary functionalities. Most of these treatments use substantial amounts of chemicals, energy, and water. They also innocently incorporate unwanted chemically bonded structures into the wood and generate a large amount of waste products which are harmful to the environment. This brings a dilemma where an entirely sustainable and green material is converted to a non-environmentally friendly material”

(El Akban et. al, Green Chemistry, 2021).

For now, the point is that reconsidering classical synthetic polymers in the light of more natural and renewable materials may have an interesting future.

Modularity. The ease of disassembly into “modules” is often listed as an eco-design practice that improves circularity, but the present author is skeptical about providing practical details. More specific guidance requires each manufacturer to know how its products can be disassembled at their end of life and where such disassembly would lead in terms of reuse, remanufacturing, or material recovery. In the context of plastics, a large plastic housing that can be easily disassembled into a single clean material is more likely to be sent to a recycler rather than reused as a “module” in other products.

It is unfortunate that software tools to make early design choices for disassembly began to be developed 25 years ago but have gone by the wayside since. The author had personal experience with such a “Green Design Advisor” tool that modeled a product assembly from its raw materials and showed how disassembly into environmentally and economically viable recovery fractions could be optimized.

One example that is probably still true today is that an epoxy circuit board and its components would be a “module” to be submitted to size a reduction, separation, and metal recovery process. Such a tool could also model the choice of a plastic housing vs. a metal alloy and the impacts of circular recovery of the material choices. Disassembly modeling tools for product designers is an area that needs significant development now, while software using artificial intelligence (AI) claims to be the answer. We shall see.

In conclusion, it must be recognized that most plastics were never designed for the environment in the first place. While there is currently no 100% perfect alternative, engineers do have options to improve the life cycle sustainability of tomorrow’s products.

- Select lower PCF plastics and avoid regulated additives.

- Reduce the amount of plastics if possible and keep larger parts free of different materials.

- Consider materials other than plastics.

- Be aware of new developments in both sources of plastic and end-of-life options.

Roger L. Franz / RogerLFranz@gmail.com – Sept. 2024

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago, in 2022, with the initial PLM vendors followed by additional software vendors and implementers who focus on Sustainability.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago, in 2022, with the initial PLM vendors followed by additional software vendors and implementers who focus on Sustainability.

The list is getting longer, and for some of them, we are now in the second round, learning what has happened in the field with their customers.

You can always read about these interviews on our PLM Green Global Alliance website or subscribe to the YouTube channel: @PLM_Global_Green_Alliance where we share the interview recordings.

This time, we spoke with Henrik Hulgaard from Configit. I spoke earlier with Henrik about Configuration Lifecycle Management – you can read our discussion here. Now, we talked about the relationship between Configit and Sustainability.

This time, we spoke with Henrik Hulgaard from Configit. I spoke earlier with Henrik about Configuration Lifecycle Management – you can read our discussion here. Now, we talked about the relationship between Configit and Sustainability.

Configit

![]() Configit is not a typical PLM or reporting software provider. They flourish on top of an existing (data-driven) infrastructure in order to provide consistency between all aspects of product design, manufacturing and usage.

Configit is not a typical PLM or reporting software provider. They flourish on top of an existing (data-driven) infrastructure in order to provide consistency between all aspects of product design, manufacturing and usage.

In their words:

“We build configuration solutions for manufacturing companies to master the challenges of getting configurable products and services to market faster and selling, manufacturing, and servicing them more effectively.”

We discussed how this is beneficial in the context of Sustainability with Henrik Hulgaard, their VP of Product Management.

Enjoy the 35-minute discussion below:

The slides shown during the interview, combined with additional company information, can be found HERE.

What we have learned

- Using Configit connected to your configurable products allows you to select the best performance for Sustainability if this is your motivation. It will enable companies to design and deliver configurable products where, in the end, in practice, the customer decides on the optimum configuration, fitting their purpose and ambition.

- Configurations and Modularity, which are building blocks of the circular economy, go hand in hand and cannot be considered standalone options.

- Even AI has entered the domain of configuration lifecycle management – we are in the early stages of learning more.

Want to learn more?

- The slide deck related to this interview

- The whitepaper: Sustainability transformation in manufacturing

- The Configit blog section

Conclusion

As a company, there are many ways to provide more sustainable products to your customers, such as by design and by customer choice. With Configit, companies can provide the most sustainable options for their manufacturing process or later support their customers to select the most sustainable options.

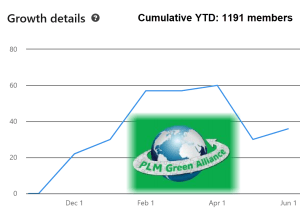

I am happy to see that the number of members of our PLM Green Global Alliance on LinkedIn has been growing fast recently.

I am happy to see that the number of members of our PLM Green Global Alliance on LinkedIn has been growing fast recently.

Early this year, we reached 1000 members; now, as of this post, we have almost 1200 members in our LinkedIn group—a growth of 20 % in less than half a year!

Each member of the #plmgreen alliance has a unique story and reason for joining.

I’m genuinely interested in learning more about your motivation. To kick off this conversation, I am sharing my journey, and I am eager to hear your thoughts, comments, and suggestions.

I’m genuinely interested in learning more about your motivation. To kick off this conversation, I am sharing my journey, and I am eager to hear your thoughts, comments, and suggestions.

Being aware this is again a long read, but I encourage you to read the article till the end.

Reading a 1500-word post was a 20th-century skill that helped people understand things with their nuances.

Let’s not lose this skill in the 21st century!

How it all started

Rich McFall reached out to me in late 2019, seeking individuals who shared our vision of establishing a platform for discussion and collaboration on green PLM. He was drawn to my 2015 blog post, ‘PLM and Global Warming,’ which I wrote six months before the famous Paris Agreement.

Rich McFall reached out to me in late 2019, seeking individuals who shared our vision of establishing a platform for discussion and collaboration on green PLM. He was drawn to my 2015 blog post, ‘PLM and Global Warming,’ which I wrote six months before the famous Paris Agreement.

In my 2015 blog post, I drew a parallel between the slow response to digital transformation in the PLM domain and our collective inaction against climate change.

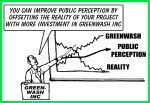

Despite the growing awareness of human-caused greenhouse gas emissions, there needed to be more urgency. This post was a call to action, not just for digital transformation in the PLM domain, but for our planet’s future. The cartoon below illustrates this mindset:

Both Rich and I felt that, when possible, we should use our energy and PLM-related skills to bring together a community of people who would take Climate Change and Sustainability seriously.

Rich’s focus was primarily on Climate Change and Greenhouse Gas emissions. – a hot topic in the US, where my passion and interest were related to Sustainability and the Circular Economy – two overlapping topics with a different impact, both parts of the UN Sustainable Development Goals (SDG) as formulated and adopted by all United Nations Member States in 2015.

Rich’s focus was primarily on Climate Change and Greenhouse Gas emissions. – a hot topic in the US, where my passion and interest were related to Sustainability and the Circular Economy – two overlapping topics with a different impact, both parts of the UN Sustainable Development Goals (SDG) as formulated and adopted by all United Nations Member States in 2015.

“Climate change creates fear and polarization, whereas the Circular Economy is more of a long-term concept, more complex to grasp, or implement, however crucial for the future of the planet.”

The start in 2020

When we started in early 2020, a few people were interested in contributing to the alliance—their names are at the bottom of this post. After several internal Zoom meetings, we decided to focus on different Green areas.

When we started in early 2020, a few people were interested in contributing to the alliance—their names are at the bottom of this post. After several internal Zoom meetings, we decided to focus on different Green areas.

The themes are available here: PLM Green Themes, i.e., Sustainability, the Circular Economy, Climate Change, Green Energy and Life Cycle Assessment.

In the beginning, the alliance was a small group of enthusiastic people supported by approximately 100 members in our LinkedIn group. As an organization of volunteers, we struggled with allocating time and resources to get the needed attention. In 2020, climate change and Sustainability were still niche topics in the PLM domain, and our audience was still small.

In the beginning, the alliance was a small group of enthusiastic people supported by approximately 100 members in our LinkedIn group. As an organization of volunteers, we struggled with allocating time and resources to get the needed attention. In 2020, climate change and Sustainability were still niche topics in the PLM domain, and our audience was still small.

Our interactive medium was the LinkedIn group, where comments and likes were easily shared. Our PLM Green Global Alliance website would be the place where we consolidate information—a challenging approach for us with limited skills and budget.

Starting the interviews in 2022

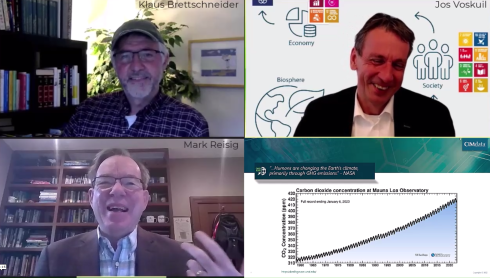

In 2022, we started interviewing PLM-related software vendors. Together with Klaus Brettschneider and, more recently, Mark Reisig, we were happy to discover what the major players in our PLM ecosystem were doing regarding Sustainability.

We spoke with SAP (Feb 2022 – Circular Economy), Autodesk (March 2020 – empowering engineers), Dassault Systemes (May 2022 – company targets & Virtual Twin), Sustaira (Sept 2022 – Connecting the dots – ESG reporting) and Aras (Oct 2022 – the need for a digital thread)

2023 – A year of transition

Besides the software vendors, consultancy firms started to address the need for more sustainable product development and understanding of what to do, and we spoke with CIMdata (April 2023 – the importance of sustainable business models) and Transition Technologies PSC (October 2023 – their GreenPLM offering on top of the PTC PLM suite)

However, as a PLM Green Global Alliance, we discovered that more and more companies were considering moving away from greenwashing and toward implementing actual measures, some of them driven by upcoming regulations and country initiatives.

However, as a PLM Green Global Alliance, we discovered that more and more companies were considering moving away from greenwashing and toward implementing actual measures, some of them driven by upcoming regulations and country initiatives.

It was also a significant year for the PLM Green Global Alliance, as besides receiving increasingly encouraging messages, both CIMdata and CIMPA joined the alliance as moderators.

![]() CIMdata, well known for its PLM consultancy and market analysis, started an additional consultancy practice related to PLM and Sustainability.

CIMdata, well known for its PLM consultancy and market analysis, started an additional consultancy practice related to PLM and Sustainability.

Mark Reisig, their lead consultant, joined us on the themes of Sustainability and Energy, also given his previous work career in that field.

CIMPA, a European PLM consultancy services company with roots in the aerospace industry, decided to support the alliance on the theme of the circular economy. Patrice Quencez and his team lead and moderate this activity.

CIMPA, a European PLM consultancy services company with roots in the aerospace industry, decided to support the alliance on the theme of the circular economy. Patrice Quencez and his team lead and moderate this activity.

Green in 2024 – what can we do?

Fear or Optimism? Fast and Slow!

One of the negative characteristics of the human mind is that we only want to act if it is indispensable. The brain’s evolutionary characteristic is to use the maximum amount of energy when there is a dangerous situation that forces us to act.

One of the negative characteristics of the human mind is that we only want to act if it is indispensable. The brain’s evolutionary characteristic is to use the maximum amount of energy when there is a dangerous situation that forces us to act.

There is enough proof for this theory, and it is the main reason why we continue bad habits. The best book to recommend is Thinking Fast and Slow by Daniel Kahneman.

Ask yourself:

- Should you study for the whole year or just before the exams?

- Would you start smoking knowing it is likely killing you in the long term?

- Would you save money for later, as then you might need it?

- Would you spend hours/days mastering a topic, or would you be an expert on social media with some easy facts and statistics?

- Would you act against climate change and overconsumption, knowing the reasons?

All the above questions illustrate that the majority of us (me too – there are no saints anymore) think fast, and media and marketing organizations know our weaknesses.

The result: we only get attention when there is a message of fear

The result: we only get attention when there is a message of fear

An explanation of why good news channels have no subscribers, whereas bad/fake news and polarising messages create an emotion to act.

In our PLM Green Alliance Group, Rich started with a monthly news digest related to Climate change. In the beginning, it felt like only bad news and the climate changes and disasters were showing us the urgency to handle. Read the last Climate Change Chronicles here.

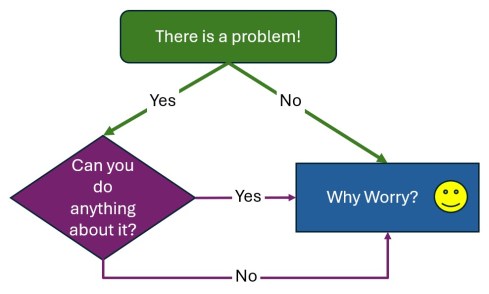

Bad news and fear might paralyze people. You might think the topic is too big for me to handle; therefore, let’s do nothing. Do you remember the diagram below?

Fortunately, many people believe that something needs to be done.

A recent UNDP survey shows that 80 percent of people globally want more decisive government climate action. Read the news here, and if you are interested in how your country compares to the rest of the world, check it here.

A recent UNDP survey shows that 80 percent of people globally want more decisive government climate action. Read the news here, and if you are interested in how your country compares to the rest of the world, check it here.

The good news is that the majority supports measures; the bad news is that the minority is the most vocal and influential by having the means and motives not to change the current status quo. And they have been organizing themselves for years.

Therefore, there is some optimism – we need to organize!

Looking back, particularly over the last 1½ years, there are reasons for optimism. Progress might not go as fast as desired, but if you are open to action and your newsfeed algorithm is also switched to positive, you will find encouraging messages.

For example, follow Assaad Razouk; his posts are often encouraging – not creating rage.

Read the monthly ESG Newsletters published by Vincent de la Mar from Sustaira and discover the positive trend. You can find his latest May newsletter here as an example: Sustainability & ESG Insights May ’24: Biden’s carbon market plans & how to get back on track to Paris Targets.

Following the progress within Europe – after the European Green Deal with all its aspects, recently, the Nature Restoration Law was signed, pushing companies to use more generative resources. The Nature Restoration Law and the European Green Deal are regulations pushing for a more circular economy as both the left side (regenerative) and right side (hardware) of the famous butterfly are addressed.

Conclusion

We are making progress, and I hope this post makes you realize that you need to worry about climate change and the Sustainability of our planet. My passion, and the passion of all the people listed below, is to support a movement and not to be silent.

Now, I am asking you to share your story. Which topics do we need to address first? Can you share examples or facts that illustrate—that with 1200 members, we should not be part of the silent majority but become a respected voice?

We’d like to express our exceptional gratitude to all those who supported us or are still supporting us at any stage of our PLM Green Global Alliance. Feel motivated to join this group of the non-silent majority.

In an alfabetical order: Xavier Adam, Zoe Bezpalko, Tom Boudeville, Klaus Brettschneider, Nina Dar, Stephane Declee, Dave Duncan, Stephan Fester, Bjorn Fidjeland, Ryan Flavelle, Matthias Fohrer, Roger L. Franz, Lionel Grealou, Jon den Hartog, Patrick Hilberg, Yousef Hooshmand, Hannes Lindfred, Ilan Madjar, Vincent de la Mar, James Norman, Rich McFall, Frank Popielas, Patrice Quencez, Mark Reisig, Audrey Reyniers, Erik Rieger, Ryan Rochelle, Mark Rushton, Neil D’Souza, Jonathan Thery, Oleg Shilovitsky, Florence Verzelen, Darren West ,Patrick Willemsen, Rafał Witkowski, Morgan Zimmermann.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

The initial interview in 2022 focused on companies getting pushed by legislation related to plastic packaging and how they could collect and analyze their product data.

Now, two years later, we discussed a much broader scope, including the Circular Economy and even Circular Manufacturing in the automotive industry. You can read and listen to this interview following this link: The PGGA talking again with SAP on Sustainability.

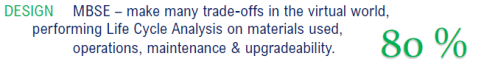

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

PTC

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

You could follow his movements through Europe on LinkedIn and his posting from the Munich workshop was fascinating. Besides meeting customers, there were also PTC partners like MakerSite, aPriori, and Transition Technologies PSC. All three companies have recently contributed to our PGGA series related to Sustainability.

Together with Dave, we spoke again with James Norman, who is responsible for driving PTC’s solutions and strategy for the digital and Sustainability transformation. He helped us make the connection between what’s happening in the field and what PTC is considering.

When listening to the interview, you will observe that in the PLM domain, so much has changed in the past two years.

Enjoy the 36 minutes of the interview and listen to what Dave has learned from the field, as reflected by James, on how PTC is addressing Sustainability.

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- The Corporate Sustainability Reporting Directive (CSRD) has forced companies to address Sustainability and the need for the digitalization of their processes (the digital thread)

- For Sustainability impact, do not focus just on the component properties; identify hot-spots when analyzing analyzing the impact of the product on the product level.

- As the OEM often only assembles the final product, the environmental impact is defined upstream in the supply chain.

- Modularity and Systems Thinking are crucial methodologies for implementing a Circular Economy.

- If you only consider the cradle-to-gate part of a product’s lifecycle, you might miss the big picture entirely. Even worse, you might implement design changes in the name of sustainability that result in outcomes far less sustainable than the original design. It’s crucial to look at the entire Product Service System/lifecycle to truly understand a product’s environmental impact

- We did not talk about Digital Twins and AI this time. Implementing a connected Digital Thread is, at this moment, the highest priority.

Want to learn more?

- There is the PTC Impact Report

- Dave Duncan’s article: Join PTC on Our Sustainability Journey

- A customer story: How Cummins Prioritizes Sustainability for New Product Designs

Conclusion

I enjoyed the dialogue with Dave and James and the progress we all have made towards understanding what is needed to ensure a sustainable future for our planet. So much has changed in two years.

PLM plays a crucial role in the discussion of a circular economy, the need for modularity, and sustainability reporting. All of these elements require a digital infrastructure related to the products we manufacture or use.

In addition, I was impressed by Dave’s pragmatic approach, who was in the hot spots of European manufacturing companies to understand their needs instead of telling them about their should-be dreams.

Two weeks ago, I shared my first post about PDM/PLM migration challenges on LinkedIn: How to avoid Migration Migraine – part 1. Most of the content discussed was about data migrations.

Two weeks ago, I shared my first post about PDM/PLM migration challenges on LinkedIn: How to avoid Migration Migraine – part 1. Most of the content discussed was about data migrations.

Starting from moving data stored in relational databases to modern object-oriented environments – the technology upgrade. But also the challenges a company can have when merging different data siloes (CAD & BOM related) into a single PLM backbone to extend the support of product data beyond engineering.

Luckily, the post generated a lot of reactions and feedback through LinkedIn and personal interactions last week.

Luckily, the post generated a lot of reactions and feedback through LinkedIn and personal interactions last week.

The amount of interaction illustrated the relevance of the topic for people; they recognized the elephant in the room, too.

Working with a partner

Data migrations and consolidation are typically not part of a company’s core business, so it is crucial to find the right partner for a migration project. The challenge with migrations is that there is potentially a lot to do technically, but only your staff can assess the quality and value of migrations.

Data migrations and consolidation are typically not part of a company’s core business, so it is crucial to find the right partner for a migration project. The challenge with migrations is that there is potentially a lot to do technically, but only your staff can assess the quality and value of migrations.

Therefore, when planning a migration, make sure you work on it iteratively with an experienced partner who can provide a set of tools and best practices. Often, vendors or service partners have migration tools that still need to be tuned to your As-Is and To-Be environment.

To get an impression of what a PLM service partner can do and which topics or tools are relevant in the context of mid-market PLM, you can watch this xLM webinar on YouTube. So make sure you select a partner who is familiar with your PDM/PLM infrastructure and who has the experience to assess complexity.

To get an impression of what a PLM service partner can do and which topics or tools are relevant in the context of mid-market PLM, you can watch this xLM webinar on YouTube. So make sure you select a partner who is familiar with your PDM/PLM infrastructure and who has the experience to assess complexity.

Migration lessons learned

In my PLM coaching career I have seen many migrations. In the early days they were more related to technology upgrades, consolidation of data and system replacements. Nowadays the challenges are more related to become more data-driven. Here are 5 lessons that I learned in the past twenty years:

In my PLM coaching career I have seen many migrations. In the early days they were more related to technology upgrades, consolidation of data and system replacements. Nowadays the challenges are more related to become more data-driven. Here are 5 lessons that I learned in the past twenty years:

- A fixed price for the migration can be a significant risk as the quality of the data and the result are hard to comprehend upfront. In case of a fixed price, either you would pay for the moon (taking all the risk), or your service partner would lose a lot of money. In a sustainable business model, there should be no losers.

- Start (even now) with checking and fixing your data quality. For example, when you are aware of a mismatch between CAD assemblies and BOM data, analyze and fix discrepancies even before the migration.

- One immediate action to take when moving from CAD assemblies to BOM structures is to check or fill the properties in the CAD system to support a smooth transition. Filling properties might be a temporary action, as later, when becoming more data-driven, some of these properties, e.g., material properties or manufacturer part numbers, should not be maintained in the CAD system anymore. However, they might help migration tools to extract a richer dataset.

- Focus on implementing an environment ready for the future. Don’t let your past data quality compromise complexity. In such a case, learn to live with legacy issues that will be fixed only when needed. A 100 % matching migration is not likely to happen because the source data might also be incorrect, even after further analysis.

- The product should probably not be configured in the CAD environment, even because the CAD tool allows it. I had this experience with SolidWorks in the past. PDM became the enemy because the users managed all configuration options in the assembly files, making it hard to use it on the BOM or Product level (the connected digital thread).

The future is data-driven

In addition, these migration discussions made me aware again that so many companies are still in the early phases of creating a unified PLM infrastructure in their company and implementing the coordinated approach – an observation I shared in my report on the PDSFORUM 2024 conference.

In addition, these migration discussions made me aware again that so many companies are still in the early phases of creating a unified PLM infrastructure in their company and implementing the coordinated approach – an observation I shared in my report on the PDSFORUM 2024 conference.

Due to sustainability-related regulations and the need to understand product behavior in the field (Digital Twin / Product As A Service), becoming data-driven is an unavoidable target in the near future. Implementing a connected digital thread is crucial to remaining competitive and sustainable in business.

However, the first step is to gain insights about the available data (formats and systems) and its quality. Therefore, implementing a coordinated PLM backbone should immediately contain activities to improve data quality and implement a data governance policy to avoid upcoming migration issues.

However, the first step is to gain insights about the available data (formats and systems) and its quality. Therefore, implementing a coordinated PLM backbone should immediately contain activities to improve data quality and implement a data governance policy to avoid upcoming migration issues.

Data-driven environments, the Systems of Engagement, bring the most value when connected through a digital thread with the Systems of Record (PLM. ERP and others), therefore, design your processes, even current ones, user-centric, data-centric and build for change (see Yousef Hooshmand‘s story in this post – also image below).

The data-driven Future is not a migration.

The last part of this article will focus on what I believe is a future PLM architecture for companies. To be more precise, it is not only a PLM architecture anymore. It should become a business architecture based on connected platforms (the systems of record) and inter-platform connected value streams (the systems of engagement).

The discussion is ongoing, and from the technical and business side, I recommend reading Prof Dr. Jorg Fischer’s recent articles, for example. The Crisis of Digitalization – Why We All Must Change Our Mindset! or The MBOM is the Steering Wheel of the Digital Supply Chain! A lot of academic work has been done in the context of TeamCenter and SAP.

The discussion is ongoing, and from the technical and business side, I recommend reading Prof Dr. Jorg Fischer’s recent articles, for example. The Crisis of Digitalization – Why We All Must Change Our Mindset! or The MBOM is the Steering Wheel of the Digital Supply Chain! A lot of academic work has been done in the context of TeamCenter and SAP.

Also, Martin Eigner recently described in The Constant Conflict Between PLM and ERP a potential digital future of enterprise within the constraints of existing legacy systems.

Also, Martin Eigner recently described in The Constant Conflict Between PLM and ERP a potential digital future of enterprise within the constraints of existing legacy systems.

In my terminology, they are describing a hybrid enterprise dominated by major Systems of Record complemented by Systems of Engagement to support optimized digital value streams.

Whereas Oleg Shilovitsky, coming from the System of Engagement side with OpenBOM, describes the potential technologies to build a digital enterprise as you can read from one of his recent posts: How to Unlock the Future of Manufacturing by Opening PLM/ERP to Connect Processes and Optimize Decision Support.

Whereas Oleg Shilovitsky, coming from the System of Engagement side with OpenBOM, describes the potential technologies to build a digital enterprise as you can read from one of his recent posts: How to Unlock the Future of Manufacturing by Opening PLM/ERP to Connect Processes and Optimize Decision Support.

All three thought leaders talk about the potential of connected aspects in a future enterprise. For those interested in the details there is a lot to learn and understand.

For the sake of the migration story I stay out of the details. However interesting to mention, they also do not mention data migration—is it the elephant in the room?

I believe moving from a coordinated enterprise to a integrated (coordinated and connected) enterprise is not a migration, as we are no longer talking about a single system that serves the whole enterprise.

I believe moving from a coordinated enterprise to a integrated (coordinated and connected) enterprise is not a migration, as we are no longer talking about a single system that serves the whole enterprise.

The future of a digital enterprise is a federated environment where existing systems need to become more data-driven, and additional collaboration environments will have their internally connected capabilities to support value streams.

With this in mind you can understand the 2017 McKinsey article– Our insights/toward an integrated technology operating model – the leading image below:

And when it comes to realization of such a concept, I have described the Heliple-2 project a few times before as an example of such an environment, where the target is to have a connection between the two layers through standardized interfaces, starting from OSLC. Or visit the Heliple Federated PLM LinkedIn group.

Data architecture and governance are crucial.

The image above generalizes the federated PLM concept and illustrates the two different systems connected through data bridges. As data must flow between the two sides without human intervention, the chosen architecture must be well-defined.

Here, I want to use a famous quote from Youssef Housmand’s paper From a Monolithic PLM Landscape to a Federated Domain and Data Mesh. Click on the image to listen to the Share PLM podcast with Yousef.

Here, I want to use a famous quote from Youssef Housmand’s paper From a Monolithic PLM Landscape to a Federated Domain and Data Mesh. Click on the image to listen to the Share PLM podcast with Yousef.

From a Single Source of Truth towards a principle of the Nearest Source of Truth based on a Single Source of Change

- If you agree with this quote, you have a future mindset of federated PLM.

- If you still advocate the Single Source of Truth, you are still in the Monolithic PLM phase.

It’s not a problem if you are aware that the next step should be federated and you are not ready yet.

However, in particular, environmental regulations and sustainability initiatives can only be performed in data-driven, federated environments. Think about the European Green Deal with its upcoming Ecodesign for Sustainable Products Directive (ESPR), which demands digital traceability of products, their environmental impact, and reuse /recycle options, expressed in the Digital Product Passport.

Reporting, Greenhouse Gas Reporting and ESG reporting are becoming more and more mandatory for companies, either by regulations or by the customers. Only a data-driven connected infrastructure can deal with this efficiently. Sustaira, a company we interviewed with the PLM Green Global Alliance last year, delivers such a connected infrastructure.

Reporting, Greenhouse Gas Reporting and ESG reporting are becoming more and more mandatory for companies, either by regulations or by the customers. Only a data-driven connected infrastructure can deal with this efficiently. Sustaira, a company we interviewed with the PLM Green Global Alliance last year, delivers such a connected infrastructure.

Read the challenges they meet in their blog post: Is inaccurate sustainability data holding you back?

Finally, to perform Life Cycle Assessments for design options or Life Cycle Analyses for operational products, you need connections to data sources in real-time. The virtual design twin or the digital twin in operation does not run on documents.

Conclusion

Data migration and consolidation to modern systems is probably a painful and challenging process. However, the good news is that with the right mindset to continue and with a focus on data quality and governance, the next step to a integrated coordinated and connected enterprise will not be that painful. It can be an evolutionary process, as the McKinsey article describes it.

![]() I attended the PDSVISION forum for the first time, a two-day PLM event in Gothenburg organized by PTC’s largest implementer in the Nordics, also active in North America, the UK, and Germany.

I attended the PDSVISION forum for the first time, a two-day PLM event in Gothenburg organized by PTC’s largest implementer in the Nordics, also active in North America, the UK, and Germany.

The theme of the conference: Master your Digital Thread – a hot topic, as it has been discussed in various events, like the recent PLM Roadmap/PDT Europe conference in November 2023.