You are currently browsing the category archive for the ‘Material Compliance’ category.

Within the PLM Green Global Alliance (PGGA), we had an internal kick-off meeting related to the topic of Design for Sustainability. As you might have seen on our website, Erik Rieger, PLM Evangelist and now working for PTC, took the initiative to start this focus group.

Within the PLM Green Global Alliance (PGGA), we had an internal kick-off meeting related to the topic of Design for Sustainability. As you might have seen on our website, Erik Rieger, PLM Evangelist and now working for PTC, took the initiative to start this focus group.

You might know Erik from a previous interview from the PGGA where we discussed TTPSC’s ecoPLM offering based on Windchill: PLM and Sustainability: talking about ecoPLM.

When Erik announced the Design for Sustainability initiative, it was Matthew Sullivan from CIMPA PLM Service who immediately contacted Erik to work together on this initiative.

When Erik announced the Design for Sustainability initiative, it was Matthew Sullivan from CIMPA PLM Service who immediately contacted Erik to work together on this initiative.

And again, you might know CIMPA PLM services from our recent interview with them related to regulations and best practices related to sustainability in the aerospace industry (CSRD, LCA, DPP, AI and more): PLM and Sustainability: talking with CIMPA.

Erik and Matthew decided to participate in an introductory interview, during which they shared their background, passion, and goals related to Design for Sustainability.

Watch the episode here:

Why Design for Sustainability?

Design for Sustainability (DfS) is an approach to designing products, services, systems, and experiences that prioritize environmental, social, and economic sustainability throughout their entire lifecycle. It means creating things in a way that reduces negative impacts on the planet and people while still being functional, profitable, and desirable.

In theory, this should be one of the key areas in which our PGGA members can have a common discussion.

As Erik mentions, it is estimated that 80 % of the environmental impact is defined during the design phase. This is a number that has been coming back in several of our PGGA discussions with all the other software vendors.

More on Design for Sustainability

Just after the recording, Dave Duncan, head of Sustainability at PTC, published the eBook Product Sustainability for Dummies. An excellent book that brings all aspects of sustainability and products together in an easy-to-digest manner. There is also a chapter on Design for Sustainability in the eBook.

Just after the recording, Dave Duncan, head of Sustainability at PTC, published the eBook Product Sustainability for Dummies. An excellent book that brings all aspects of sustainability and products together in an easy-to-digest manner. There is also a chapter on Design for Sustainability in the eBook.

Note: Dave Duncan is a recognized PGGA leader in PLM and Sustainability, as we reported last year.

Read the post here: Leaders in PLM and Sustainability – December 2024

A call for action

We hope you watched and enjoyed the interview with Erik and Matthew as an inspiration to become active in this Design for Sustainability discussion group.

The intention is, as mentioned, to share experiences and discuss challenges within the group. It will be a private group where people can discuss openly to avoid any business conflicts. The plan is to start with an initial kick-off Zoom meeting in June the date still to be fixed.

The intention is, as mentioned, to share experiences and discuss challenges within the group. It will be a private group where people can discuss openly to avoid any business conflicts. The plan is to start with an initial kick-off Zoom meeting in June the date still to be fixed.

If you are interested in joining this exciting discussion group, please contact Erik Rieger, who will be the focal point for this group. We are looking forward to your contribution, and now is the time to prepare and act.

Join us in the discussion

This is a guest post from one of our active members of the PLM Green Global Alliance, Roger L. Franz.

This is a guest post from one of our active members of the PLM Green Global Alliance, Roger L. Franz.

Roger is supporting industry inquiries on regulated substances, sustainable product design and life cycle management, including carbon footprint.

He is a recognized authority on supply chain reporting for compliance with worldwide regulations. Roger brings decades of experience with engineering tools and enterprise IT systems.

Introduction.

More than just unsightly “plastic pollution,” the volume of consumer plastics and lack of closed-loop recovery have created a significant micro- and nano-plastics problem. These invisible plastic particles are found around the world, including in animal and human tissues.

For several reasons, including a much smaller volume of plastic used in electrotechnical products compared to consumer plastics and the generally longer life of hardware compared to the rapid turnover of consumer goods and packaging, the microplastics problem is not typically tagged as a major electronics problem- or at least not yet. Now is the time to be proactive.

The United Nations Environment Programme has posted summaries of recent discussions on using life cycle assessment (LCA) to address the global problem of plastic pollution. These Life Cycle Initiative areas relate to plastic products, chemicals of concern in plastic products, and plastic product design. The documents are about possible approaches to managing plastics with recommendations but are not detailed prescriptions, methods, or regulations.

The United Nations Environment Programme has posted summaries of recent discussions on using life cycle assessment (LCA) to address the global problem of plastic pollution. These Life Cycle Initiative areas relate to plastic products, chemicals of concern in plastic products, and plastic product design. The documents are about possible approaches to managing plastics with recommendations but are not detailed prescriptions, methods, or regulations.

While the studies did not specifically mention electrotechnical products, this industry will need to accelerate focus on engineering design tools and engineering plastics choices to avoid significantly adding on to the consumer plastic product problems.

Within the UNEP product design discussion, the section on “General considerations on possible approaches to product design, focusing on recyclability and reusability” included the following important point, which bears repeating: Product design approaches should include eco-design and circularity principles.

Product design approaches should include

eco-design and circularity principles.

But what does this mean? In the following discussion, we hope to break these approaches down into more tangible design choices. Even within the electrotechnical product category, there are many product variations, so no claim is made here to cover all of them.

Options for lower carbon footprint plastics already exist to some extent. Except for packaging, electronic components and products are typically made with engineering resins rather than the common consumer plastic “recycling arrow” types. Alternative types of lower carbon footprint engineering resins may be available to use rather than others with higher carbon footprints.

Many plastic manufacturers are currently conducting LCA to quantify the cradle-to-gate carbon footprint of their materials. Different polymer types have inherent differences in carbon footprint due to their different monomeric starting materials and manufacturing processes.

For many plastics, these flows are detailed by Plastics Europe. Polycarbonate, ABS, and several Polyamides, for example, are included. What is missing in these publicly available sources, as well as LCA inventory databases themselves, are many other engineering plastics; for example, while consumer PET is widely modeled, PBT (Polybutylene terephthalate) is not. These are just some of the data gaps that need to be resolved.

For many plastics, these flows are detailed by Plastics Europe. Polycarbonate, ABS, and several Polyamides, for example, are included. What is missing in these publicly available sources, as well as LCA inventory databases themselves, are many other engineering plastics; for example, while consumer PET is widely modeled, PBT (Polybutylene terephthalate) is not. These are just some of the data gaps that need to be resolved.

More sustainable feedstock is a good option since a given end polymer may be made from different monomeric chemicals, so the more sustainable plastic performs exactly like its classic version because it is the same. One of the growing alternatives includes feedstocks based on renewable, bio-based sources.

These need some evaluation, again using LCA, to ensure they are free of downsides like increased water use, eutrophication, and chemical pollution due to the use of herbicides, pesticides, fertilizers, and so on. Marketing claims of being a “green material” will need backup data! For guidelines on acceptable environmental benefits claims, refer to the US FTC Green Guides.

These need some evaluation, again using LCA, to ensure they are free of downsides like increased water use, eutrophication, and chemical pollution due to the use of herbicides, pesticides, fertilizers, and so on. Marketing claims of being a “green material” will need backup data! For guidelines on acceptable environmental benefits claims, refer to the US FTC Green Guides.

Reducing the amount of plastic by design is not only a good practice for sustainability, it also saves money. Some designs using parts with enough material to be modeled using generative design may be able to reduce the amount of material while reducing material usage and weight. Reducing factory scrap from injection molding processes leaving sprues in runners and use of captive regrind are other good options.

Choosing manufacturers using renewable fuels– and even benefits like reduction of water use during processing- is another area of choice for sustainability. Local sourcing is also a way to reduce the overall carbon footprint of a material by reducing the contribution of transportation.

Identify large plastic parts. Historical guidelines on eco-design have actually been around for years.

One good example is the ECMA 341 Standard, “Environmental Design Considerations for ICT & CE Products (4th Edition / December 2010), which says, “All plastic parts weighing 25 g or more and with a flat area of 200 mm2 or more are marked with the type of polymer, copolymer, polymer blends or alloys in conformance with ISO 11469.” This practice enables the identification of plastic types of large parts, while in practice, the ability to sort becomes less useful when a variety of goods are mixed in a production recycling facility. Success here depends either on manual sorting or more sophisticated methods like infrared spectroscopy to be effective. Some equipment recyclers have such capability.

One good example is the ECMA 341 Standard, “Environmental Design Considerations for ICT & CE Products (4th Edition / December 2010), which says, “All plastic parts weighing 25 g or more and with a flat area of 200 mm2 or more are marked with the type of polymer, copolymer, polymer blends or alloys in conformance with ISO 11469.” This practice enables the identification of plastic types of large parts, while in practice, the ability to sort becomes less useful when a variety of goods are mixed in a production recycling facility. Success here depends either on manual sorting or more sophisticated methods like infrared spectroscopy to be effective. Some equipment recyclers have such capability.

Keep it clean. More useful guidance from ECMA 341 is to avoid the following: non-recyclable composites; coatings and surface finishes on plastic parts; adhesive-backed stickers or foams on plastic parts; if stickers are required, they should be separable; and metal inserts in plastic parts unless easily removable with common tools. These are common sense from a clean recycling stream perspective and should not be difficult to implement.

Closing the end-of-life loop. Recycling is imperfect, and as far as this author has seen, is rarely in place for engineering plastics.

Processes under development to decompose plastics back to new monomer feedstocks, called chemical recycling or tertiary recycling. This approach is achieving some success with a limited number of materials, mostly for high-volume consumer plastics rather than engineering types.

Processes under development to decompose plastics back to new monomer feedstocks, called chemical recycling or tertiary recycling. This approach is achieving some success with a limited number of materials, mostly for high-volume consumer plastics rather than engineering types.

LCA is needed to validate that achieving plastic circularity this way with the necessary processing energy and chemicals will have a net environmental benefit. The obvious problem with all approaches is that plastics were never designed for the environment in the first place.

Selecting More Sustainable Additives is another area where product engineers have some choices. There are thousands of possible additives used in plastic, usually specified for a given grade and end application. These include flame retardants, processing aids, fillers, colorants, ultraviolet stabilizers, plasticizers for flexibility, and so on and on. While these choices are primarily the responsibility of the resin manufacturer, pressure from regulators and industry demand can influence the use of more sustainable additives.

Whenever possible, new products should avoid regulated substances by design, which may include Substances of Very High Concern (SVHC) as defined by the European Chemicals Agency (ECHA) and, more recently, polyfluorinated substances called PFAS. This is easier said than done but definitely belongs on the checklist of ecodesign considerations.

Besides plastics? While the present discussion is about plastics, choices of using altogether different materials may be possible in some cases.

High-volume hardware is probably unable to use alternative materials like wood, glass, bamboo, etc. Historically, though, until the rise of both solid-state and plastic technology in the 1950s, radios and televisions featured wooden cases and consoles. Miniaturization in the solid-state era brought in mostly plastic housings. One recent example that the author worked on was an audio teleconferencing system that featured either oak or walnut to blend with the executive conference room.

High-volume hardware is probably unable to use alternative materials like wood, glass, bamboo, etc. Historically, though, until the rise of both solid-state and plastic technology in the 1950s, radios and televisions featured wooden cases and consoles. Miniaturization in the solid-state era brought in mostly plastic housings. One recent example that the author worked on was an audio teleconferencing system that featured either oak or walnut to blend with the executive conference room.

While the intent was not specifically to avoid using plastic, it is an interesting example to think outside the plastic box. Wood avoids many of the issues with plastics, but of course, the plastics in the circuitry content remain to be addressed.

Other large household electrical/electronic goods are likely to use recyclable steel and/or stainless steel cabinets. And if you consider an automobile to be an electronic product, these metals come into play in high volume in automobile shredder residue. Using metal rather than plastic housings may be possible for some products; for example, aluminum may be used for personal communications and IT devices, bringing a tradeoff between initial cost and the potential advantage of aluminum being more highly recyclable for use in new equipment than any plastic.

Only LCA can quantify the tradeoffs. We should also mention toys, which increasingly incorporate some electronics and use colored plastics extensively.

New material technology. One of the many emerging material technologies is Engineered Wood. The cited research hardly suggests that a wood-based material could be a drop-in, for example, injection molded thermoplastics, but the possibility is most intriguing. However, just having a material of natural origins is not automatically a panacea for replacing plastics. Quite the contrary, significant cautions remain; for example,

“Chemical and thermal modifications are usually applied to adapt the wood structure and impart necessary functionalities. Most of these treatments use substantial amounts of chemicals, energy, and water. They also innocently incorporate unwanted chemically bonded structures into the wood and generate a large amount of waste products which are harmful to the environment. This brings a dilemma where an entirely sustainable and green material is converted to a non-environmentally friendly material”

(El Akban et. al, Green Chemistry, 2021).

For now, the point is that reconsidering classical synthetic polymers in the light of more natural and renewable materials may have an interesting future.

Modularity. The ease of disassembly into “modules” is often listed as an eco-design practice that improves circularity, but the present author is skeptical about providing practical details. More specific guidance requires each manufacturer to know how its products can be disassembled at their end of life and where such disassembly would lead in terms of reuse, remanufacturing, or material recovery. In the context of plastics, a large plastic housing that can be easily disassembled into a single clean material is more likely to be sent to a recycler rather than reused as a “module” in other products.

It is unfortunate that software tools to make early design choices for disassembly began to be developed 25 years ago but have gone by the wayside since. The author had personal experience with such a “Green Design Advisor” tool that modeled a product assembly from its raw materials and showed how disassembly into environmentally and economically viable recovery fractions could be optimized.

One example that is probably still true today is that an epoxy circuit board and its components would be a “module” to be submitted to size a reduction, separation, and metal recovery process. Such a tool could also model the choice of a plastic housing vs. a metal alloy and the impacts of circular recovery of the material choices. Disassembly modeling tools for product designers is an area that needs significant development now, while software using artificial intelligence (AI) claims to be the answer. We shall see.

In conclusion, it must be recognized that most plastics were never designed for the environment in the first place. While there is currently no 100% perfect alternative, engineers do have options to improve the life cycle sustainability of tomorrow’s products.

- Select lower PCF plastics and avoid regulated additives.

- Reduce the amount of plastics if possible and keep larger parts free of different materials.

- Consider materials other than plastics.

- Be aware of new developments in both sources of plastic and end-of-life options.

Roger L. Franz / RogerLFranz@gmail.com – Sept. 2024

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

The initial interview in 2022 focused on companies getting pushed by legislation related to plastic packaging and how they could collect and analyze their product data.

Now, two years later, we discussed a much broader scope, including the Circular Economy and even Circular Manufacturing in the automotive industry. You can read and listen to this interview following this link: The PGGA talking again with SAP on Sustainability.

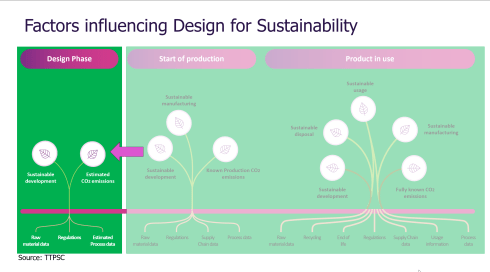

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

PTC

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

You could follow his movements through Europe on LinkedIn and his posting from the Munich workshop was fascinating. Besides meeting customers, there were also PTC partners like MakerSite, aPriori, and Transition Technologies PSC. All three companies have recently contributed to our PGGA series related to Sustainability.

Together with Dave, we spoke again with James Norman, who is responsible for driving PTC’s solutions and strategy for the digital and Sustainability transformation. He helped us make the connection between what’s happening in the field and what PTC is considering.

When listening to the interview, you will observe that in the PLM domain, so much has changed in the past two years.

Enjoy the 36 minutes of the interview and listen to what Dave has learned from the field, as reflected by James, on how PTC is addressing Sustainability.

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- The Corporate Sustainability Reporting Directive (CSRD) has forced companies to address Sustainability and the need for the digitalization of their processes (the digital thread)

- For Sustainability impact, do not focus just on the component properties; identify hot-spots when analyzing analyzing the impact of the product on the product level.

- As the OEM often only assembles the final product, the environmental impact is defined upstream in the supply chain.

- Modularity and Systems Thinking are crucial methodologies for implementing a Circular Economy.

- If you only consider the cradle-to-gate part of a product’s lifecycle, you might miss the big picture entirely. Even worse, you might implement design changes in the name of sustainability that result in outcomes far less sustainable than the original design. It’s crucial to look at the entire Product Service System/lifecycle to truly understand a product’s environmental impact

- We did not talk about Digital Twins and AI this time. Implementing a connected Digital Thread is, at this moment, the highest priority.

Want to learn more?

- There is the PTC Impact Report

- Dave Duncan’s article: Join PTC on Our Sustainability Journey

- A customer story: How Cummins Prioritizes Sustainability for New Product Designs

Conclusion

I enjoyed the dialogue with Dave and James and the progress we all have made towards understanding what is needed to ensure a sustainable future for our planet. So much has changed in two years.

PLM plays a crucial role in the discussion of a circular economy, the need for modularity, and sustainability reporting. All of these elements require a digital infrastructure related to the products we manufacture or use.

In addition, I was impressed by Dave’s pragmatic approach, who was in the hot spots of European manufacturing companies to understand their needs instead of telling them about their should-be dreams.

![]() I attended the PDSVISION forum for the first time, a two-day PLM event in Gothenburg organized by PTC’s largest implementer in the Nordics, also active in North America, the UK, and Germany.

I attended the PDSVISION forum for the first time, a two-day PLM event in Gothenburg organized by PTC’s largest implementer in the Nordics, also active in North America, the UK, and Germany.

The theme of the conference: Master your Digital Thread – a hot topic, as it has been discussed in various events, like the recent PLM Roadmap/PDT Europe conference in November 2023.

The event drew over 200 attendees, showing the commitment of participants, primarily from the Nordics, to knowledge sharing and learning.

The diverse representation included industry leaders like Vestas, pioneers in Sustainable Energy, and innovative startups like CorPower Ocean, who are dedicated to making wave energy reliable and competitive. Notably, the common thread among these diverse participants was their focus on sustainability, a growing theme in PLM conferences and an essential item on every board’s strategic agenda.

I enjoyed the structure and agenda of the conference. The first day was filled with lectures and inspiring keynotes. The second day was a day of interactive workshops divided into four tracks, which were of decent length so we could really dive into the topics. As you can imagine, I followed the sustainability track.

Here are some of my highlights of this conference.

Catching the Wind: A Digital Thread From Design to Service

Simon Saandvig Storbjerg, unfortunately remote, gave an overview of the PLM-related challenges that Vestas is addressing. Vestas, the undisputed market leader in wind energy, is indirectly responsible for 231 million tonnes of CO2 per year.

Simon Saandvig Storbjerg, unfortunately remote, gave an overview of the PLM-related challenges that Vestas is addressing. Vestas, the undisputed market leader in wind energy, is indirectly responsible for 231 million tonnes of CO2 per year.

One of the challenges of wind power energy is the growing complexity and need for variants. With continuous innovation and the size of the wind turbine, it is challenging to achieve economic benefits of scale.

As an example, Simon shared data related to the Lost Production Factor, which was around 5% in 2009 and reduced to 2% in 2017 and is now growing again. This trend is valid not only for Vestas but also for all wind turbine manufacturers, as variability is increasing.

Vestas is introducing modularity to address these challenges. I reported last year about their modularity journey related to the North European Modularity biannual meeting held at Vestas in Ringkøbing – you can read the post here.

Simon also addressed the importance of Model-Based Definition (MBD), which is crucial if you want to achieve digital continuity between engineering and manufacturing. In particular, in this industry, MBD is a challenge to involve the entire value chain, despite the fact that the benefits are proven and known. Change in people skills and processes remains a challenge.

The Future of Product Design and Development

The session led by PTC from Mark Lobo, General Manager for the PLM Segment, and Brian Thompson, General Manager of the CAD Segment, brought clarity to the audience on the joint roadmap of Windchill and Creo.

The session led by PTC from Mark Lobo, General Manager for the PLM Segment, and Brian Thompson, General Manager of the CAD Segment, brought clarity to the audience on the joint roadmap of Windchill and Creo.

Mark and Brian highlighted the benefits of a Model-Based Enterprise and Model-Based Definition, which are musts if you want to be more efficient in your company and value chain.

Mark and Brian highlighted the benefits of a Model-Based Enterprise and Model-Based Definition, which are musts if you want to be more efficient in your company and value chain.

The WHY is known, see the benefits described in the image, and requires new ways of working, something organizations need to implement anyway when aiming to realize a digital thread or digital twin.

In addition, Mark addressed PTC’s focus on Design for Sustainability and their partner network. In relation to materials science, the partnership with Ansys Granta MI is essential. It was presented later by Ansys and discussed on day two during one of the sustainability workshops.

Mark and Brian elaborated on the PTC SaaS journey – the future atlas platform and the current status of WindChill+ and Creo+, addressing a smooth transition from existing customers to a new future architecture.

And, of course, there was the topic of Artificial Intelligence.

Mark explained that PTC is exploring AI in various areas of the product lifecycle, like validating requirements, optimizing CAD models, streamlining change processes on the design side but also downstream activities like quality and maintenance predictions, improved operations and streamlined field services and service parts are part of the PTC Copilot strategy.

Mark explained that PTC is exploring AI in various areas of the product lifecycle, like validating requirements, optimizing CAD models, streamlining change processes on the design side but also downstream activities like quality and maintenance predictions, improved operations and streamlined field services and service parts are part of the PTC Copilot strategy.

PLM combined with AI is for sure a topic where the applicability and benefits can be high to improve decision-making.

PLM Data Merge in the PTC Cloud: The Why & The How

Mikael Gustafson from Xylem, a leading Global Water Solutions provider, described their recently completed project: merging their on-premise Windchill instance TAPIR and their cloud Windchill XGV into a single environment.

Mikael Gustafson from Xylem, a leading Global Water Solutions provider, described their recently completed project: merging their on-premise Windchill instance TAPIR and their cloud Windchill XGV into a single environment.

TAPIR stands for Technical Administration, Part Information Repository and is very much part-centric and used in one organization. XGV stands for Xylem Global Vault, and it is used in 28 organizations with more of a focus on CAD data (Creo and AutoCAD). Two different siloes are to be joined in one instance to build a modern, connected, data-driven future or, as Mikael phrased it: “A step towards a more manageable Virtual Product“.

It was a severe project involving a lot of resources and time, again showing the challenges of migrations. I am planning to publish a blog post, the draft title “Migration Migraine,” as this type of migration is prevalent in many places because companies want to implement a single PLM backbone beyond (mechanical) engineering.

It was a severe project involving a lot of resources and time, again showing the challenges of migrations. I am planning to publish a blog post, the draft title “Migration Migraine,” as this type of migration is prevalent in many places because companies want to implement a single PLM backbone beyond (mechanical) engineering.

What I liked about the approach was its focus on assessing the risks and prioritizing a mitigation strategy if necessary. As the list below shows, even the COVID-19 pandemic was challenging the project.

Often, big migration projects fail due to optimism or by assessing some of the risks at the start and then giving it a go.

When failures happen, there is often the blame game: Was it the software, the implementer, or the customer (past or present) that caused the troubles? Mediating in such environments has been a long time my mission as the “Flying Dutchman,” and from my experience, it is not about the blame game; it is, most of the time, too high expectations and not enough time or resources to fully control this journey.

When failures happen, there is often the blame game: Was it the software, the implementer, or the customer (past or present) that caused the troubles? Mediating in such environments has been a long time my mission as the “Flying Dutchman,” and from my experience, it is not about the blame game; it is, most of the time, too high expectations and not enough time or resources to fully control this journey.

As Michael said, Xylem was successful, and during the go-live, only a few non-critical issues popped up.

When asked what he would do differently with the project’s hindsight, Mikael mentioned he would do the migrations not as a big project but as smaller projects.

When asked what he would do differently with the project’s hindsight, Mikael mentioned he would do the migrations not as a big project but as smaller projects.

I can relate a lot to this answer as, by experience, the “one-time” migration projects have created a lot of stress for the company, and only a few of them were successful.

Starting being coordinated and then connected

Several sessions were held where companies shared their PLM journey, to be mapped along the maturity slide (slide 8) I shared in my session: The Why, What and How of Digital Transformation in the PLM domain. You can review the content here on SlideShare.

There was Evolabel, a company starting its PLM journey because they are suffering from ineffective work procedures, information islands and the increasing complexity of its products.

Evolabel realized it needed PLM to realize its market ambition: To be a market leader within five years. For Evolabel, PLM is a must that is repeatable and integrated internally.

Evolabel realized it needed PLM to realize its market ambition: To be a market leader within five years. For Evolabel, PLM is a must that is repeatable and integrated internally.

They shared how they first defined the required understanding and mindset for the needed capabilities before implementing them. In my terminology, they started to implement a coordinated PLM approach.

Teddy Svenson from JBT, a well-known manufacturer of food-tech solutions, described their next step in PLM. From an old AS/400 system with very little integration to PDM to a complete PLM system with parts, configurations, and change management.

Teddy Svenson from JBT, a well-known manufacturer of food-tech solutions, described their next step in PLM. From an old AS/400 system with very little integration to PDM to a complete PLM system with parts, configurations, and change management.

It is not an easy task but a vital stepping stone for future development and a complete digital thread, from sales to customer care. In my terminology, they were upgrading their technology to improve their coordinated approach to be ready for the next digital evolution.

![]() There were several other presentations on Day One – See the agenda here I cannot cover them all given the limited size of this blog post.

There were several other presentations on Day One – See the agenda here I cannot cover them all given the limited size of this blog post.

The Workshops

As I followed the Sustainability track, I cannot comment much on the other track; however, given the presenters and the topics, they all appeared to be very pragmatic and interactive – given the format.

Achieving sustainability goals by integrating material intelligence into the design process

![]() In the sustainability track, we started with Manuelle Clavel from Ansys Granta, who explained in detail how material data and its management are crucial for designing better-performing, more sustainable, and compliant products.

In the sustainability track, we started with Manuelle Clavel from Ansys Granta, who explained in detail how material data and its management are crucial for designing better-performing, more sustainable, and compliant products.

With the importance of compliance with (upcoming) regulations and the usage of material characteristics in the context of more sustainable products and being able to perform a Life Cycle Assessment, it is crucial to have material information digitally available, both in the CAD design environment as well in the PLM environment.

For me, a dataset of material properties is an excellent example of how it is used in a connected enterprise. You do not want to copy the information from system to system; it needs to be connected and available in real-time.

How can we design more sustainable products?

Together with Martin Lundqvist from QCM, I conducted an interactive session. We started with the need for digitalization, then looked at RoHS and REACH compliance and discussed the upcoming requirements of the Digital Product Passport.

We closed the session with a dialogue on the circular economy.

From the audience, we learned that many companies are still early in understanding the implementation of sustainability requirements and new processes. However, some were already quite advanced and acting. In particular, it is essential to know if your company is involved with batteries (DPP #1) or is close to consumers.

Conclusion

The PDSFORUM was for me an interesting experience for meeting companies at all different stages of their PLM journey. All sessions I attended were realistic, and the solutions were often pragmatic. In my day-to-day life, inspiring companies to understand a digital and sustainable future, you sometimes forget the journey everyone is going through.

Thanks, PDVISION, for inviting me to speak and learn at this conference.

and some sad news …..

I was sorry to learn that last week, Dr. Ken Versprille suddenly passed away. I know Ken, as shown in the picture – a passionate moderator and timekeeper of the PLM Roadmap / PDT conferences, well prepared for the details. May his spirit live through the future conferences – the next one already on May 8-9th in Washington, DC.

Our first PGGA interview with PLM-related software vendors was two years ago with SAP. At that time, Sustainability became more visible in corporate strategies, and regulations were imminent.

Our first PGGA interview with PLM-related software vendors was two years ago with SAP. At that time, Sustainability became more visible in corporate strategies, and regulations were imminent.

This time, Klaus Brettschneider and I want to learn what has happened related to Sustainability. Is there visible progress in their organizations and customer base? And what is hot now?

And we were positively surprised by a conversation going in many directions.

SAP

The interview was again with Darren West. Darren is the product expert for SAP’s Circular Economy solutions and this time, Stephan Fester supported him. Stephan is co-leading the SAP Global Circular Manufacturing Practice and, therefore, is well-connected to the field. Last year, in particular, working in discrete manufacturing and discussing circular manufacturing.

The interview was again with Darren West. Darren is the product expert for SAP’s Circular Economy solutions and this time, Stephan Fester supported him. Stephan is co-leading the SAP Global Circular Manufacturing Practice and, therefore, is well-connected to the field. Last year, in particular, working in discrete manufacturing and discussing circular manufacturing.

Thanks to the expertise of our guests, the discussion went in various directions, with circularity as the central theme.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

But also, we discussed the Digital Product Passport. Catena-X, what is it, and what is it targeting?

We also discussed how to deal with the scarcity of materials and materials harvesting. The interview could not be complete without mentioning AI.

Enjoy the 35-minute interview with Darren and Stephan on our YouTube channel.

The slides shown in this recording can be found here: PGGA talking again with SAP.

What we have learned

- Regulations heavily push SAP customers and require adequate reporting tools, not only for finance and material use but also for sustainability KPIs

- The Responsible Design & Production module launched two years ago is already in use with 60+ customers, showing the importance of having data-driven decision support for plastic packaging – to be extended to the product. Of course, as a PLM community, we are interested in understanding the next steps toward the product.

- The insights from Stephan Fester on circular manufacturing can be a logical evolution of the linear product process, as Stephan’s image shows.

- Great insights on Catena-X as an independent network for data sharing in the global network

Want to learn more?

Events and Shows:

- SAP at Hannover Messe – April 22-26, 2024 – event information

- SAP Sapphire, Orlando, USA – June 3-5, 2024 – event information

- SAP Sapphire, Barcelona, Spain – June 11-13, 2024 – event information

Websites:

- Circular Manufacturing at Scale – Microsite

- SAP Responsible Design and Production – product page

- SAP Circular Economy page

- SAP Sustainability home page

Conclusion

It was a great discussion with a company that is quite active in supporting its customers on a sustainable journey. The journey is complex and has many aspects, as Darren and Stephan shared in this dialogue. The good news is that SAP’s customers are actively implementing measures and processes – going circular is happening!

Join the PDSFORUM next month and join me to get inspired an participate in a Think Thank session on day 2 related to designing more sustainable products. Will we meet there?

We are happy to start the year with the next round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability. This year, we will speak with some new companies, and we will also revisit some of our previous guests to learn about their progress.

We are happy to start the year with the next round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability. This year, we will speak with some new companies, and we will also revisit some of our previous guests to learn about their progress.

Where we talked with Aras, Autodesk, CIMdata, Dassault Systèmes, PTC, SAP, Sustaira and Transition Technologies PSC, there are still a lot of software companies with an exciting portfolio related to sustainability.

Therefore, we are happy to talk this time with Makersite, a company whose AI-powered Product Lifecycle Intelligence software, according to their home page, brings together your cost, environment, compliance, and risk data in one place to make smarter, greener decisions powered by the deepest understanding of your supply chain. Let’s explore

Makersite

![]() We were lucky to have a stimulating discussion with Neil D’Souza, Makersite’s CEO and founder, who was active in the field of sustainability for almost twenty years, even before it became a cool (or disputed) profession.

We were lucky to have a stimulating discussion with Neil D’Souza, Makersite’s CEO and founder, who was active in the field of sustainability for almost twenty years, even before it became a cool (or disputed) profession.

It was an exciting dialogue where we enjoyed realistic answers without all the buzzwords and marketing terms often used in the new domain of sustainability. Enjoy the 39 minutes of interaction below:

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- Makersite’s mission, to enable manufacturers to make better products, faster, initially applied to economic parameters, can be easily extended with sustainability parameters.The power of Makersite is that it connects to enterprise systems and sources using AI, Machine Learning and algorithms to support reporting views on compliance, sustainability, costs and risk.

- Compliance and sustainability are the areas where I see a significant need for companies to invest. It is not a revolutionary business change but an extension of scope.We discussed this in the context of the stage-gate process, where sustainability parameters should be added at each gate.

- Neil has an exciting podcast, Five Lifes to Fifty, where he discusses the path to sustainable products with co-hosts Shelley Metcalfe and Jim Fava, and recently, they discussed sustainability in the context of the stage-gate process.

- Again, to move forward with sustainability, it is about creating the base and caring about the data internally to understand what’s happening, and from there, enable value engineering, including your supplier where possible (IP protection remains a topic) – confirming digital transformation (the connected way of working) is needed for business and sustainability.

Want to learn more?

Here are some links to the topics discussed in our meeting:

- The Website – Makersite.io

- Makersite data foundation – makersite-data-foundation

- Makersite demo video – makersite-platform-demo

- Neil’s LinkedIn – neilsaviodsouza

Conclusions

With Makersite, we discovered an experienced company that used its experience in cost, compliance and risk analysis, including supply chains, to extend it to the domain of sustainability. As their technology partners page shows, they can be complementary in many industries and enterprises.

We will see another complementary solution soon in our following interview. Stay tuned.

During May and June, I wrote a guest chapter for the next edition of John Stark’s book Product Lifecycle Management (Volume 2): The Devil is in the Details.

During May and June, I wrote a guest chapter for the next edition of John Stark’s book Product Lifecycle Management (Volume 2): The Devil is in the Details.

The book is considered a standard in the academic world when studying aspects of PLM.

Looking into the table of contents through the above link, it shows that understanding PLM in its full scope is broad. I wrote about it recently: PLM is Complex (and we have to accept it?), and Roger Tempest and others are still fighting to get the job as PLM Professional recognized Associate Yourself With Professional PLM.

To make the scope broader, John invited me to write a chapter about PLM and Sustainability, which is an actual topic in many organizations. As sustainability is my dedicated topic in the PLM Global Green Alliance (PGGA) core team, I was happy to accept this challenge.

To make the scope broader, John invited me to write a chapter about PLM and Sustainability, which is an actual topic in many organizations. As sustainability is my dedicated topic in the PLM Global Green Alliance (PGGA) core team, I was happy to accept this challenge.

This activity is challenging because writing a chapter on a current topic might make it outdated soon. For the same reason, I never wanted to write a PLM book as I wrote in my 2014 post: Did you notice PLM is changing?

The book, with the additional chapter, will be available later this year. I want to share with you in this post the topics I addressed in this chapter. Perhaps relevant for your organization or personal interests. Also, I am looking forward to learning if I missed any topics.

The book, with the additional chapter, will be available later this year. I want to share with you in this post the topics I addressed in this chapter. Perhaps relevant for your organization or personal interests. Also, I am looking forward to learning if I missed any topics.

Introduction

The chapter starts with defining the context. PLM is considered a strategy supported by a connected IT infrastructure, and for the definition of sustainability, I refer to the relevant SDGs as described on our PGGA theme page: PLM and Sustainability

Next, I discuss two major concepts indissoluble connected with sustainability.

The Circular Economy

On a planet with limited resources and still a growing consumption of raw materials, we need to follow the concepts of the circular economy in our businesses and lives. The circular economy section addresses mainly the hardware side of the butterfly as, here, PLM practices have the most significant impact.

The circular economy requires collaboration among various stakeholders, including businesses, governments and consumers. It involves rethinking production processes and establishing new consumption patterns. Policies and regulations will push for circular economy patterns, as seen in the following paragraphs.

Systems Thinking

A significant change in bringing products to the market will be the need to change how we look at our development processes. Historically, many of these processes were linear and only focused on time to market, cost and quality. Now, we have to look into other dimensions, like environmental impact, usage and impact on the planet. As I wrote in the past Systems Thinking – a must-have skill in the 21st century?

Systems Thinking is a cognitive approach that emphasizes understanding complex problems by considering interconnections, feedback loops, and emergent properties. It provides a holistic perspective and explores multiple viewpoints.

Systems Thinking guides problem-solving and decision-making and requires you to treat a solution with a mindset of a system interacting with other systems.

Regulations

More sustainable products and services will be driven primarily by existing and upcoming regulations. In this section, I refer to the success of the CFC (ChloroFluorCarbon) emission reduction, leading to slowly fixing the hole in the Ozon layer. Current regulations like WEEE, RoHS and REACH are already relevant for many companies, and compliance with these regulations is a good exercise for more stringent regulations related to Carbon emissions and upcoming related to the Digital Product Passport.

Making regulatory compliance a part of the concept phase ensures no late changes are needed to become compliant, saving time and costs. In addition, making regulatory compliance as much as possible with a data-driven approach reduces the overhead required to prove regulatory compliance. Both topics are part of a PLM strategy.

![]() In this context, see Lionel Grealou’s article 5 Brand Value Benefits at the Intersection of Sustainability and Product Compliance. The article has also been shared in our PGGA LinkedIn group.

In this context, see Lionel Grealou’s article 5 Brand Value Benefits at the Intersection of Sustainability and Product Compliance. The article has also been shared in our PGGA LinkedIn group.

Business

On the business side, the Greenhouse Gas Protocol is explained. How companies will have to report their Scope 1 and Scope 2 emissions and, ultimately, Scope 3 – see the image below for the details.

GHG reporting will support companies, investors and consumers to decide where to prioritize and put their money.

Ultimately, companies have to be profitable to survive in their business. The ESG framework is relevant in this context as it will allow investors to put their money not only based on short-term gains (as expected) but also on Environmental or Social parameters. There are a lot of discussions related to the ESG framework, as you might have read in Vincent de la Mar’s monthly newsletter, Sustainability & ESG Insights, which is also published in our PGGA group – a link below..

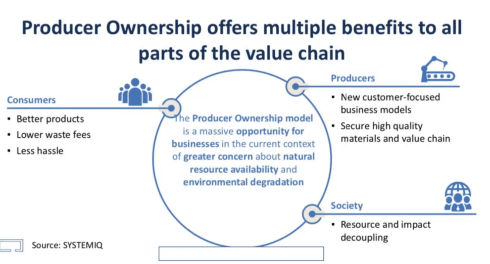

Besides ESG guidelines, there is also the drive by governments and consumers to push for a Product as a Service economy. Instead of owning products, consumers would pay for the usage of these products.

The concept is not new when considering lease cars, EV scooters, or streaming services like Spotify and Netflix. In the CIMdata PLM Roadmap/PDT Fall 2021 conference, we heard Kenn Webster explaining: In the future, you will own nothing & you will be happy.

Changing the business to a Product as a Service is not something done overnight. It requires repairable, upgradeable products. And business related, it requires a connected ecosystem of all stakeholders – the manufacturer, the finance company, and the operating entities.

Digital Transformation

All the subjects discussed before require real-time reporting and analysis combined with data access to compliance-related databases. More in the section related to Life Cycle Assessment. As I discussed last year in several conferences, a sustainability initiative starts with data-driven and model-based approaches during the concept phase, but when manufacturing and operating (connected) products in the field. You can read the entire story here: Sustainability and Data-Driven PLM – the Perfect Storm.

Life Cycle Analysis

Special attention is given in this chapter to Life Cycle Analysis, which seems to be a popular topic among PLM vendors. Here, they can provide tools to make a lifecycle assessment, and you can read an impression of these tools in a guest blog from Roger L. Franz titled PLM Tools to Design for Sustainability – PLM Green Global Alliance.

However, Lifecycle Analysis is not as simple. Looking at the ISO 14040 framework, which describes – having the right goals and scope in mind, allows you to do an LCA where the Product Category Rules (PCS) will enable companies to compare their products with others.

PCRs include the description of the product category, the goal of the LCA, functional units, system boundaries, cut-off criteria, allocation rules, impact categories, information on the use phase, units, calculation procedures, requirements for data quality, and other information on the lifecycle Inventory Phase.

So be aware there is more to do than installing a tool.

Digital Twin

This section describes the importance of implementing a digital twin for the design phase, allowing companies to develop, test and analyze their products and services first virtually. Trade-off studies on virtual products are much cheaper, and when they are done in a data-driven, model-based environment, it will be the most efficient environment. In my terminology, setting up such a collaboration environment might be considered a System of Engagement.

This section describes the importance of implementing a digital twin for the design phase, allowing companies to develop, test and analyze their products and services first virtually. Trade-off studies on virtual products are much cheaper, and when they are done in a data-driven, model-based environment, it will be the most efficient environment. In my terminology, setting up such a collaboration environment might be considered a System of Engagement.

The second crucial digital twin mentioned is the digital twin from a product in operation where performance can be monitored and usage can be optimized for a minimal environmental impact. Suppose a company is able to create a feedback loop between its products in the field and its product innovation platform. In that case, it can benchmark its design models and update the product behavior for better performance.

The manufacturing digital twin is also discussed in the context of environmental impact, as choosing the right processes and resources can significantly affect scope 3 emissions.

The chapter finishes with the story of a fictive company, WePack, where we can follow the impact and implementations of the topics described in this chapter.

Conclusion

As I described in the introduction, the topic of PLM and Sustainability is relatively new and constantly evolving. What do you think? Did I miss any dimensions?

Feel free to contribute to our PLM Global Green Alliance LinkedIn group.

It has been busy recently in the context of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability, where we interview PLM-related software vendors, discussing their sustainability mission and offering.

It has been busy recently in the context of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability, where we interview PLM-related software vendors, discussing their sustainability mission and offering.

We talked with SAP, Autodesk, and Dassault Systèmes and last week with Sustaira. Now the discussion was with the team from Aras. Aras is known as a non-traditional PLM player, having the following slogan on their website:

It is a great opening statement for our discussion. Let’s discover more.

Aras

The discussion was with Patrick Willemsen, Director of Technical Community EMEA and Matthias Fohrer, Director of Global Alliances EMEA at Aras. It was an interesting interview; as we discussed, Aras focuses on the digital thread, connecting data from all sources with an infrastructure designed to support a company in its PLM domain.

The discussion was with Patrick Willemsen, Director of Technical Community EMEA and Matthias Fohrer, Director of Global Alliances EMEA at Aras. It was an interesting interview; as we discussed, Aras focuses on the digital thread, connecting data from all sources with an infrastructure designed to support a company in its PLM domain.

As I mentioned in a previous blog post, PLM and Sustainability – if we want to work efficiently on Sustainability, we need to have a data-driven and connected infrastructure.

And this made this discussion interesting to follow– please look/listen to the 30 minutes conversation below.

Slides shown during the interview and additional company information can be found HERE.

What we have learned

There were several interesting points in our discussion where we were aligned; first of all, the sustainable value of bringing your solutions to the cloud.

There were several interesting points in our discussion where we were aligned; first of all, the sustainable value of bringing your solutions to the cloud.

So we discussed the topic of Sustainability and the cloud, and it was interesting to read this week McKinsey’s post The green IT revolution: A blueprint for CIOs to combat climate change containing this quote:

“Moving to the cloud has more impact than optimizing data centers”– the article is quite applicable for Aras.

Next, I liked the message that it is all about collaboration between different parties.

As Matthias mentioned, nobody can do it on their own. According to Aras’ studies, 70% see Sustainability as an important area to improve themselves; nobody can do it on his own. Partnerships are crucial, as well as digital connections between the stakeholders. It is a plea for systems thinking in a connected manner, connecting to existing material libraries.

As Matthias mentioned, nobody can do it on their own. According to Aras’ studies, 70% see Sustainability as an important area to improve themselves; nobody can do it on his own. Partnerships are crucial, as well as digital connections between the stakeholders. It is a plea for systems thinking in a connected manner, connecting to existing material libraries.

The third point we were aligned with is that PLM and Sustainability are a learning journey. As Patrick explained, it is about embracing the circular economy and learning step by step.

The third point we were aligned with is that PLM and Sustainability are a learning journey. As Patrick explained, it is about embracing the circular economy and learning step by step.

<– Click on the image to enlarge.

Want to learn more?

Aras has published several white papers and surveys and hosted webinars related to Sustainability. Here are a few of them:

Aras Survey Challenges 2022: From Sustainability to Digitalization

White Paper: The Circular Economy as a Model for the Future

Webinar: Greener Business, PLM, Traceability, and Beyond

Webinar: How PLM Paves the Way for Sustainability

Blog: The Circular Economy as a Model for the Future

Conclusions

It is clear that Aras provides an infrastructure for a connected enterprise. They combine digital PLM capabilities with the option to extend their reach by supporting sustainability-related processes, like systems thinking and lifecycle assessments. And as they mention, no one can do it alone; we depend on collaboration and learning for all stakeholders.

On more week to go – join us if you can – click here

The summer holidays are over, and with the PLM Global Green Alliance, we are glad to continue with our series: PLM and Sustainability, where we interview PLM-related software vendors, talking about their sustainability mission and offering.

The summer holidays are over, and with the PLM Global Green Alliance, we are glad to continue with our series: PLM and Sustainability, where we interview PLM-related software vendors, talking about their sustainability mission and offering.

We talked with SAP, Autodesk, and Dassault Systèmes. This week we spoke with Sustaira, and soon we will talk with Aras. Sustaira, an independent Siemens partner, is the provider of a sustainability platform based on Mendix.

SUSTAIRA

The interview with Vincent de la Mar, founder and CEO of Sustaira, was quite different from the previous interviews. In the earlier interviews, we talked with people driving sustainability in their company and software portfolio. Now with Sustaira, we were talking with a relatively new company with a single focus on sustainability.

The interview with Vincent de la Mar, founder and CEO of Sustaira, was quite different from the previous interviews. In the earlier interviews, we talked with people driving sustainability in their company and software portfolio. Now with Sustaira, we were talking with a relatively new company with a single focus on sustainability.

Sustaira provides an open platform targeting purely sustainability by offering relevant apps and infrastructure based on Mendix.

Listen to the interview and discover the differences and the potential for you.

Slides shown during the interview and additional company information: Sustaira Overview 2022.

What we have learned

Using the proven technology of the Mendix platform allows you to build a data-driven platform focused on sustainability for your company.

Using the proven technology of the Mendix platform allows you to build a data-driven platform focused on sustainability for your company.

As I wrote in my post: PLM and Sustainability, there is the need to be data-driven and connected with federated data sources for accurate data.

This is a technology challenge. Sustaira, as a young company, has taken up this challenge and provides various apps related to sustainability topics on its platform. Still, they remain adaptable to your organization.

Secondly, I like the concept that although Mendix is part of the Siemens portfolio, you do not need to have Siemens PLM installed. The openness of the Sustaira platform allows you to implement it in your organization independent of your PLM infrastructure.

Secondly, I like the concept that although Mendix is part of the Siemens portfolio, you do not need to have Siemens PLM installed. The openness of the Sustaira platform allows you to implement it in your organization independent of your PLM infrastructure.

The final observation – the rule of people, process, and technology – is still valid. To implement Sustaira in an efficient and valuable manner, you need to be clear in your objectives and sustainability targets within the organization. And these targets should be more detailed than the corporate statement in the annual report.

Want to Learn more

To learn more about Sustaira and the wide variety of offerings, you can explore any of these helpful links:

- First, here is a short video introducing Sustaira

- With this link, anyone can sign up for the free version of the Sustaira platform and begin exploring today!

- Lastly, for additional information, demos, downloadable content, and more, head over to the Sustiara Content Hub.

Conclusion

It was interesting to learn about Sustaira and how they started with a proven technology platform (Mendix) to build their sustainability platform. Being sustainable involves using trusted data and calculations to understand the environmental impact at every lifecycle stage.

Again we can state that the technology is there. Now it is up to companies to act and connect the relevant data sources to underpin and improve their sustainability efforts.

In the last weeks, I had several discussions related to sustainability. What can companies do to become sustainable and prove it? But, unfortunately, there is so much greenwashing at this moment.

In the last weeks, I had several discussions related to sustainability. What can companies do to become sustainable and prove it? But, unfortunately, there is so much greenwashing at this moment.

Look at this post: 10 Companies and Corporations Called Out For Greenwashing.

Therefore I thought about which practical steps a company should take to prepare for a sustainable future, as the change will not happen overnight. It reminds me of the path towards a digital, model-based enterprise (my other passion). In my post Why Model-Based definition is important for all, I mentioned that MBD (Model-Based Definition) could be considered the first stepping-stone toward a Model-Based enterprise.

Therefore I thought about which practical steps a company should take to prepare for a sustainable future, as the change will not happen overnight. It reminds me of the path towards a digital, model-based enterprise (my other passion). In my post Why Model-Based definition is important for all, I mentioned that MBD (Model-Based Definition) could be considered the first stepping-stone toward a Model-Based enterprise.

The analogy for Material Compliance came after an Aras seminar I watched a month ago. The webinar How PLM Paves the Way for Sustainability with Insensia (an Aras implementer) demonstrates how material compliance is the first step toward sustainable product development.

The analogy for Material Compliance came after an Aras seminar I watched a month ago. The webinar How PLM Paves the Way for Sustainability with Insensia (an Aras implementer) demonstrates how material compliance is the first step toward sustainable product development.

Let’s understand why

The first steps

Companies that currently deliver solutions mostly only focus on economic gains. The projects or products they sell need to be profitable and competitive, which makes sense if you want a future.

Companies that currently deliver solutions mostly only focus on economic gains. The projects or products they sell need to be profitable and competitive, which makes sense if you want a future.

And this would not have changed if the awareness of climate impact has not become apparent.

First, CFKs and hazardous materials lead to new regulations. Next global agreements to fight climate change – the Paris agreement and more to come – have led and will lead to regulations that will change how products will be developed. All companies will have to change their product development and delivery models when it becomes a global mandate.

A required change is likely going to happen. In Europe, the Green Deal is making stable progress. However, what will happen in the US will be a mystery as even their supreme court becomes a political entity against sustainability (money first).

A required change is likely going to happen. In Europe, the Green Deal is making stable progress. However, what will happen in the US will be a mystery as even their supreme court becomes a political entity against sustainability (money first).

Still, compliance with regulations will be required if a company wants to operate in a global market.

What is Material Compliance?

In 2002, the European Union published a directive to restrict hazardous substances in materials. The directive, known as RoHS (Restriction of Hazardous Substances), was mainly related to electronic components. In the first directive, six hazardous materials were restricted.

In 2002, the European Union published a directive to restrict hazardous substances in materials. The directive, known as RoHS (Restriction of Hazardous Substances), was mainly related to electronic components. In the first directive, six hazardous materials were restricted.

The most infamous are Cadmium(Cd), Lead(Pb), and Mercury (Hg). In 2006 all products on the EU market must pass RoHS compliance, and in 2011 was now connected the CE marking of products sold in the European market was.

In 2015 four additional chemical substances were added, most softening PVC but also affecting the immune system. Meanwhile, other countries have introduced similar RoHS regulations; therefore, we can see it as a global restricting. Read more here: The RoHS guide.

In 2015 four additional chemical substances were added, most softening PVC but also affecting the immune system. Meanwhile, other countries have introduced similar RoHS regulations; therefore, we can see it as a global restricting. Read more here: The RoHS guide.

Consumers buying RoHS-compliant products now can be assured that none of the threshold values of the substances is reached in the product. The challenge for the manufacturer is to go through each of the components of the MBOM. To understand if it contains one of the ten restricted substances and, if yes, in which quantity.

Therefore, they need to get that information from each relevant supplier a RoHS declaration.

Besides RoHS, additional regulations protect the environment and the consumer. For example, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance deals with the regulations created to improve the environment and protect human health. In addition, REACH addresses the risks associated with chemicals and promotes alternative methods for the hazard assessment of substances.

Besides RoHS, additional regulations protect the environment and the consumer. For example, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance deals with the regulations created to improve the environment and protect human health. In addition, REACH addresses the risks associated with chemicals and promotes alternative methods for the hazard assessment of substances.

The compliance process in four steps

Material compliance is most of all the job of engineers. Therefore around 2005, some of my customers started to add RoHS support to their PLM environment.

Step 1

The image below shows the simple implementation – the PDF-from from the supplier was linked to the (M)BOM part.

An employee had to manually add the substances into a table and ensure the threshold values were not reached. But, of course, there was already a selection of preferred manufacturer parts during the engineering phase. Therefore RoHS compliance was almost guaranteed when releasing the EBOM.

An employee had to manually add the substances into a table and ensure the threshold values were not reached. But, of course, there was already a selection of preferred manufacturer parts during the engineering phase. Therefore RoHS compliance was almost guaranteed when releasing the EBOM.

But this process could be done more cleverly.

Step 2

So the next step was that manufacturers started to extend their PLM data model with the additional attributes for RoHS compliance. Again, this could be done cleverly or extremely generic, adding the attributes to all parts.

So now, when receiving the material declaration, a person just has to add the substance values to the part attributes. Then, through either standard functionality or customization, a compliance report could be generated for the (M)BOM. So this already saves some work.

So now, when receiving the material declaration, a person just has to add the substance values to the part attributes. Then, through either standard functionality or customization, a compliance report could be generated for the (M)BOM. So this already saves some work.

Step 3

The next step was to provide direct access to these attributes to the supplier and push the supplier to do the work.

Now the overhead for the manufacturer has been reduced again. This is because only the supplier needs to do the job for his customer.

Now the overhead for the manufacturer has been reduced again. This is because only the supplier needs to do the job for his customer.

Step 4

In step 4, we see a real connected environment, where information is stored only once, referenced by manufacturers, and kept actual by the part suppliers.

Who will host the RoHS databank? From some of my customer projects, I recall IHS as a data provider – it seems they are into this business when you look at their website HERE.

Who will host the RoHS databank? From some of my customer projects, I recall IHS as a data provider – it seems they are into this business when you look at their website HERE.

Where is your company at this moment?

Having seen the four stepping-stones leading towards efficient RoHS compliance, you see the challenge of moving from a document-driven approach to a data-driven approach.

Now let’s look into the future. Concepts like Life Cycle Assessment (LCA) or a Digital Product Passport (DPP) will require a fully connected approach.

Now let’s look into the future. Concepts like Life Cycle Assessment (LCA) or a Digital Product Passport (DPP) will require a fully connected approach.

Where is your company at this moment – have you reached RoHS compliance step 3 or 4? A first step to learn and work connected and data-driven.

Life Cycle Assessment – the ultimate target

A lifecycle assessment, or lifecycle analysis (two times LCA again), is a methodology to assess the environmental impact of a product (or solution) through its whole lifecycle. From materials sourcing, manufacturing, transportation, usage, service, and decommissioning. And by assessing, we mean a clear, verifiable, and shareable manner, not just guessing.

A lifecycle assessment, or lifecycle analysis (two times LCA again), is a methodology to assess the environmental impact of a product (or solution) through its whole lifecycle. From materials sourcing, manufacturing, transportation, usage, service, and decommissioning. And by assessing, we mean a clear, verifiable, and shareable manner, not just guessing.

Traditional engineering education is not bringing these skills, although LCA is not new, as this 10-years old YouTube movie from Autodesk illustrates:

What is new is that due to global understanding, we are reaching the limits of what our planet can endure; we must act now. Upcoming international regulations will enforce life cycle analysis reporting for manufacturers or service providers. This will happen gradually.

Meanwhile, we all should work on a circular economy, the major framework for a sustainable planet- click on the image on the left.

Meanwhile, we all should work on a circular economy, the major framework for a sustainable planet- click on the image on the left.

In my post, I wrote about these combined topics: SYSTEMS THINKING – a must-have skill in the 21st century.

Life Cycle Analysis – Digital Twin – Digitization

The big elephant in the room is that when we talk about introducing LCA in your company, it has a lot to do with the digitization of your company. Assessment data in a document can require too much human effort to maintain the data at the right quality. The costs are not affordable if your competitor is more efficient.

When coming to the Analysis part, here, a model-based, data-driven infrastructure is the most efficient way to run virtual analysis, using digital twin concepts at each stage of the product lifecycle.

When coming to the Analysis part, here, a model-based, data-driven infrastructure is the most efficient way to run virtual analysis, using digital twin concepts at each stage of the product lifecycle.

Virtual models for design, manufacturing and operations allow your company to make trade-off studies with low cost before committing to the physical world. 80 % of the environmental impact of a product comes from decisions in the virtual world.

Once you have your digital twins for each phase of the product lifecycle, you can benchmark your models with data reported from the physical world. All these interactions can be found in the beautiful Boeing diamond below, which I discussed before – Read A digital twin for everybody.

Conclusion

Efficient and sustainable life cycle assessment and analysis will come from connected information sources. The old document-driven paradigm is too costly and too slow to maintain. In particular, when the scope is not only a subset of your product, it is your full product and its full lifecycle with LCA. Another stepping stone towards the near future. Where are you?

Stepping-stone 1: From Model-Based Definition to an efficient Model-Based, Data-driven Enterprise

Stepping-stone 2: For RoHS compliance to an efficient and sustainable Model-Based, data-driven enterprise.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…