You are currently browsing the tag archive for the ‘digital thread’ tag.

Our recent interviews this year with aPriori and SAP were with companies that had less of a focus on the traditional product design process and more of a focus on the (circular) manufacturing process. In these interviews the importance of working with connected data was discussed in a shared (digital) thread.

Our recent interviews this year with aPriori and SAP were with companies that had less of a focus on the traditional product design process and more of a focus on the (circular) manufacturing process. In these interviews the importance of working with connected data was discussed in a shared (digital) thread.

This time, we, Mark Reisig and Jos Voskuil, were excited to talk with Siemens, not only a well-known PLM vendor but also a manufacturer of products and, therefore, having a close understanding of what is needed and can be achieved with their software solutions.

Siemens

![]() As Siemens is such a broad enterprise; we were happy to speak with Ryan R. Rochelle, who focuses on Sustainable Production, Sustainable Manufacturing and Sustainable Industry within Siemens . In the interview we discussed the importance of digital twins and the feedback loops between design and manufacturing. Despite some flaws in the network connection, we are happy to share an informative interview.

As Siemens is such a broad enterprise; we were happy to speak with Ryan R. Rochelle, who focuses on Sustainable Production, Sustainable Manufacturing and Sustainable Industry within Siemens . In the interview we discussed the importance of digital twins and the feedback loops between design and manufacturing. Despite some flaws in the network connection, we are happy to share an informative interview.

Enjoy listening and watching the next 33 minutes, talking with Ryan Rochelle.

You can download the images shown during the interview HERE

What I have learned

- Like all PLM vendors in this domain, Siemens talks about the importance of a circular economy and the need for digital threads and digital twins, confirming the need for all of us to invest in the digitization of the product lifecycle.

- Siemens is in a unique position as both the industrial user and software provider of its PLM suite, therefore having a unique feedback loop on the usability and applicability of its software in its industry.

- In the area of sustainability, they learn from both customers and internal customers. They are customer zero. Here, they observe shifting in engineering activities to the left” to optimize processes, supply chain and manufacturing earlier . (<<PGGA>>: which aligns with our aPriori and Makersite interviews).

- Siemens, SiGreen’s solution is an example of this unique position, being be able to track the carbon footprint of products across the supply chain.

Want to learn more

- There is the Siemens Sustainable industries website

- How the Digital Enterprise helps attain sustainability

- The Journey to a Sustainability Lighthouse awarded by the World Economic Forum

Conclusion

We have been discussing the relationship between PLM and sustainability with relevant software vendors for over two years now. As we saw initially in 2022, a few companies were exploring the possibilities.

Now, with further regulations and advanced software capabilities, companies are starting to implement new capabilities to make their product development process and products more sustainable. Siemens, as a software provider and an industrial user of its tools, is leading this journey—is it time for your company to step up, too?

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

Now, I want to conclude on what I would call, in my terminology, the connected digital thread. This topic was already addressed when I reported on the federated PLM story from NIO (Yousef Hooshmand) and SAAB Aeronautics (Erik Herzog).

The Need for a Governance Digital Thread

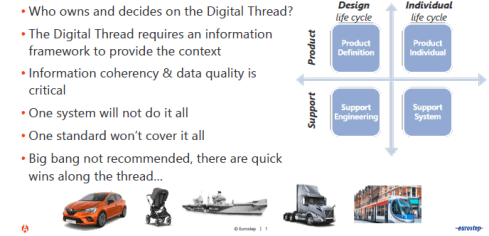

This time, my presentation was a memory refresher related to digital transformation in the PLM domain – moving from coordinated ways of working towards connected ways of working.

A typology that is also valid for the digital thread definition.

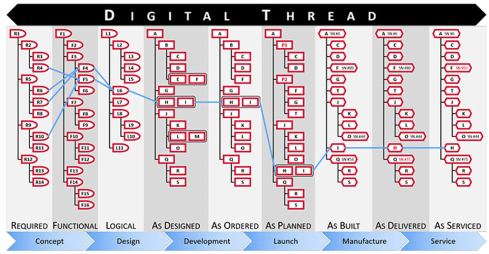

- A Coordinated Digital Thread is a digital thread that connects various artifacts in an enterprise. These relations are created and managed to support traceability and an impact analysis. The coordinated digital thread requires human interpretation to process the information. The image below from Aras is a perfect example of a coordinated digital thread.

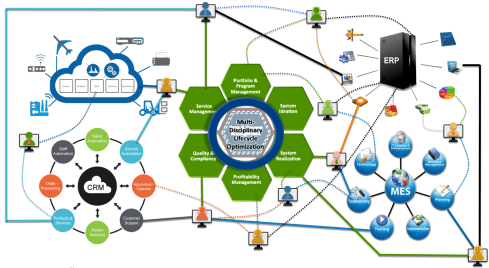

- The Connected Digital Thread is the digital thread where the artifacts are datasets stored in a federated infrastructure of databases. A connected digital thread provides real-time access to data through applications or dashboards for users. The real-time access makes the connected digital thread a solution for real-time, multidisciplinary collaboration activities.

The image above illustrates the connected digital thread as an infrastructure on top of five potential business platforms, i.e., the IoT platform, the CRM platform, the ERP platform, the MES platform and ultimately, the Product Innovation Platform.

Note: These platforms are usually a collection of systems that logically work together efficiently.

The importance of the Connected Digital Thread

When looking at the benefits of the Connected Digital Thread, the most essential feature is that it allows people in an organization to have all relevant data and its context available for making changes, analysis and design choices.

Due to the rich context, people can work proactively and reduce the number of iterations and fixes later.

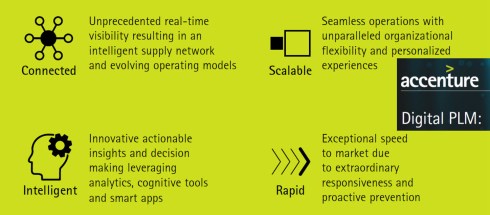

The above image from Accenture (2014) describing the business benefits can be divided into two categories:

- The top, Connected and Scalable describing capabilities

- The bottom, Intelligent and Rapid, describes the business impact

The connected digital thread for governance

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

The PLM system will be one of the sources; other sources can be fragmented in an organization. Bringing them together manually in one report is a significant human effort, time-consuming and not supporting the business.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

According to a recent KPMG report, only a quarter of companies are ready for ESG Reporting Requirements.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

The Connected Digital Thread and the Digital Product Passport

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

The DPP is based on the GS1 infrastructure, originating from the retail industry. Each product will have a unique ID (UID based on ISO/IEC 15459:2015), and this UID will provide digital access to product information, containing information about the product’s used materials, its environmental impact, and recycle/reuse–ability.

It will serve both for regulatory compliance and as an information source for consumers to make informed decisions about the products they buy. The DPP aims to stimulate and enforce a more circular economy.

![]() Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

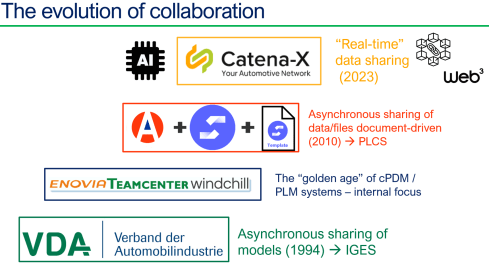

The Connected Digital Thread and Catena-X

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

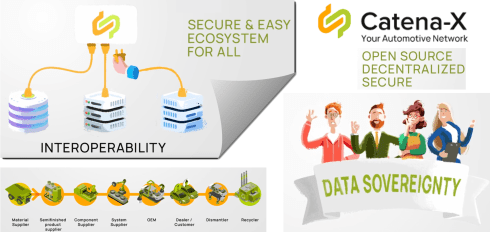

A new exciting trend is the potential rise of not-for-profit infrastructure for a particular industry. Where the GS1-based infrastructure is designed to provide visibility on sustainable targets and decisions, Catena-X is focusing on the automotive industry.

Catena-X is the establishment of a data-driven value chain for the German automotive industry and is now in the process of expanding to become a global network.

It is a significant building block in what I would call the connected or even adaptive enterprise, using a data-driven infrastructure to let information flow through the whole value chain.

It is one of the best examples of a Connected Digital Thread covering an end-to-end value chain.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

So Sustainability and Digitization go hand in hand.

Why a Digital Thread makes a lot of sense

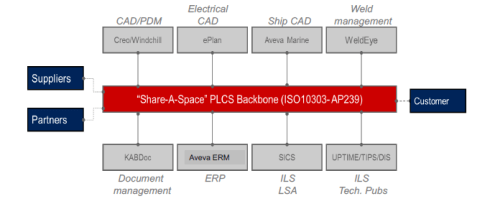

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

Eurostep, recently acquired by BAE Systems, is known for its collaboration hub or information backbone, ShareAspace. The interesting trend here is switching from a traditional PLM infrastructure to an asset-centric one.

This approach makes a lot of sense for complex assets with a long lifecycle, as the development phase is usually done with a consortium of companies. Still, the owner/operator wants to maintain a digital twin of the asset – for maintenance and upgrades.

A standards-based backbone makes much sense in such an environment due to the various data formats. This setup also means we are looking at a Coordinated Digital Thread at this stage, not a Connected Digital Thread.

Mattias concluded with the question of who owns and who decides on the coordinated digital thread – a discussion also valid in the construction industry when discussing Building Information Management (BIM) and a Common Data Environment(CDE).

I believe software vendors can provide the Coordinated Digital Thread option when they can demonstrate and provide a positive business case for their solution. Still, it will be seen as an overhead to connect the dots.

For a Connected Digital Thread, I think it might be provided as an infrastructure like the World Wide Web (W3C) organization. Here, the business case is much easier to demonstrate as it is really a digital highway.

Such an infrastructure could be provided by not-for-profit organizations like GS1 (Digital Product Passport/Retail), Catena-X (Automotive) and others (Gaia-X).

![]() For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

AI

And then there was AI. During the conference, people spoke more about AI than Sustainability topics, illustrating that our audience is more interested in understanding the next hype instead of feeling the short-term need to address climate change and planet sustainability.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

And we closed the conference with a roundtable discussion: AI, PLM and the Digital Thread: Why should we care about AI?

From the roundtable, I concluded that we are all convinced AI will have a significant impact in the upcoming years and are all in the early phases of the AI hype.

Will AI introduction go faster than digital transformation?

Conclusion

The conference gave me confidence that digital transformation in the PLM domain has reached the next level. Many sessions were related to collaboration concepts outside the traditional engineering domain – coordinated and connected digital threads.

The connected digital thread is the future, and as we saw it, it heralds the downfall of monolithic PLM. The change is needed for business efficiency AND compliance with more and more environmental regulations.

I am looking forward to seeing the pace of progress here next year.

Again, a “The weekend after …” post related to my favorite event to which I have contributed since 2014.

Expectations were high this time from my side, in particular because we would have a serious discussion related to connected digital threads and federated PLM.

More about these topics in my post next week as all content is not yet available for sharing.

The conference was sold out this time, and during the breaks, you had to navigate through the people to find your network opportunities. Also, the participation of the main PLM players as sponsors illustrated that everyone wanted to benefit from this opportunity to meet and learn from their industry peers.

The conference was sold out this time, and during the breaks, you had to navigate through the people to find your network opportunities. Also, the participation of the main PLM players as sponsors illustrated that everyone wanted to benefit from this opportunity to meet and learn from their industry peers.

Looking back to the conference, there were two noticeable streams.

- The stream where people share their current PLM experiences, traditionally the A&D action groups moderated by CIMdata, is part of this stream. This part I will cover in this post.

- There were forward-looking presentations related to standards, ontologies, and federated PLM—all with an AI flavor. This part I will cover in my next post(s).

The connection between all these sessions was the Digital Thread. The conference’s theme was: The Digital Thread in a Heterogeneous, Extended Enterprise Reality. Let’s start the review with the highlights from the first stream.

Digital Thread: Why Should We Care?

As usual, Peter Bilello from CIMdata kicked off the conference by setting the scene. Peter started by clarifying the two definitions of the Digital Thread.

- The first is a communication framework that allows a connected data flow and integrated view of an asset’s data (i.e., its Digital Twin) throughout its lifecycle across traditionally siloed functional perspectives.

In my terminology, the connected digital thread. - The second is a network of connected information sources around the product lifecycle supporting traceability and decision-making.

In my terminology, the coordinated digital thread is the most straightforward digital thread to achieve.

Peter recommends starting a digital thread by connecting at the beginning of product conceptualization, creating an environment where one can analyze the performance of the product portfolio and the product features and capabilities that need to be planned or how they perform in the field.

In addition, when defining the products, connect them with regulatory requirement databases as they have must-have requirements. A topic I addressed in my session too, besides the existing regulatory requirements, it is expected that in the upcoming years, due to environmental regulations, these requirements will increase, and it will be necessary to have them integrated with your digital thread.

Digital Threads require data governance and are the basis for the various digital twins. Peter discussed the multiple applications of the digital twin, primarily a relation between a virtual asset and a physical asset, except in the early concept phase.

The digital thread is still in the early phase of implementation at companies. A CIMdata survey showed that companies still focus primarily on implementing traditional PDM capabilities, although as the image above shows, there is a growing interest in short-term digital twin/thread implementations.

People, Process & Technology:

The Pillars of Digital Transformation Success

The second keynote was from Christine McMonagle, Director of Digital Engineering Systems at Textron Systems a services and products supplier for the Aerospace and Defense industry. Christine leads the digital evolution in Textron Systems and presents nicely how a digital transformation should start from the people.Traditionally this industry has enough budget on the OEM level and therefore companies will not take a revolutionary approach when it comes to digital transformation.

The second keynote was from Christine McMonagle, Director of Digital Engineering Systems at Textron Systems a services and products supplier for the Aerospace and Defense industry. Christine leads the digital evolution in Textron Systems and presents nicely how a digital transformation should start from the people.Traditionally this industry has enough budget on the OEM level and therefore companies will not take a revolutionary approach when it comes to digital transformation.

Having your people at all levels involved and make them understand the need for change is crucial. A change does not happen top-down. You must educate people and understand what is possible and achievable to change – in the right direction. One of her concluding slides highlights the main points.

In the Q&A there to Christine’s sessions there was an interesting question related to the involvement of Human Resources (HR) in this project. There was a laugh that said it all – like in most companies HR is not focusing on organizational change, they focus more on operational issues – the Human is considered a Resource.

In the Q&A there to Christine’s sessions there was an interesting question related to the involvement of Human Resources (HR) in this project. There was a laugh that said it all – like in most companies HR is not focusing on organizational change, they focus more on operational issues – the Human is considered a Resource.

Between the regular sessions there were short sessions from sponsors: Altium, Contact Software, Dassault Systemes, ESI, inensia, Modular Management , PTC, SAP, Share PLM and Sinequa could pitch their value offering.

The Share PLM session, shortly after Christine’s presentation was a nice continuation of the focus on people. I loved the Share PLM image to the left explaining why people do not engage with our dreams.

Learn how LEONI is achieving Digital Continuity in the Automotive Industry.

Tobias Bauer, head of Product Data Standardization at LEONI talked about their FLOW project. FLOW is an acronym for Future Leoni Operating World. LEONI, well-known in the automotive industry produces cable and network solutions, including cable harnesses.

Tobias Bauer, head of Product Data Standardization at LEONI talked about their FLOW project. FLOW is an acronym for Future Leoni Operating World. LEONI, well-known in the automotive industry produces cable and network solutions, including cable harnesses.

Recently it has gone through a serious financial crisis and the need for restructuring. This makes it always challenging for a “visionary” PLM project. Tobias mentioned that after disappointing engagements with consultancy firms, they decided on a bottom-up approach to analyze existing processes using BPML. They agreed on a to-be state, fixing bottlenecks and streamlining the flow of information.

Tobias presented a smooth product data flow between their PLM system (PTC Windchill) and ERP (SAP S/4 HANA), clearly stating that the PLM system has become the controlled source of managing product changes.

Their key achievements reported so far were:

- related to BOM creation and routing (approx. 10x faster – from 2-3 days to ¼ day),

- better data consistency (fewer manual steps)

- complete traceability between the systems with PLM as the change management backbone.

The last point I would call the coordinated Digital Thread. The image below shows their current IT landscape in a simplified manner.

This solution might seem obvious for neutral PLM academics or experts, but it is an achievement to do this in an environment with SAP implemented. The eBOM-mBOM discussion is one of the most frequent held discussions – sometimes a battle.

Often, companies use their IT systems first and listen to the vendor’s experts to build integrations instead of starting from the natural business flow of information.

Aerospace & Defense Action groups outcomes

As usual, several Aerospace & Defense (A&D) action groups reported their progress during this conference. The A&D action groups are facilitated by CIMdata, and per topic, various OEMs and suppliers in the A&D industry study and analyze a particular topic, often inviting software vendors to demonstrate and discuss their capabilities with them.

Their activities and reports can be found on the A&D PLM Action page here; In the remainder of this post I will share briefly the ones presented. For a real deep dive in the topics I recommend to find the proceedings per topic on the A&D action page.

The Promise and Reality of the Digital Thread

James Roche CIMdata presented insights from industry research on The Promise and Reality of the Digital Thread. A total of 90 persons completed an in-depth survey about the status and implementation of digital thread concepts in their company. It is clear that the digital thread is still in its early days in this industry, and it is mainly about the coordinated digital thread. The image below reflects the highlights of the survey.

A&D Industry Digital Twin and Digital Thread Standards

Robert Rencher from Boeing explained the progress of their Digital Twin/Digital Thread project, where they had investigated the applicable standards to support a Digital Twin/Digital Thread (Phase 4 out of 7 currently planned). The image below shows that various standards may apply depending on business perspectives.

Their current findings are:

- Digital twin standards overlap, which is most likely a function of standards bodies representing their respective standards as an ongoing development from a historical perspective.

- The limited availability of mature digital twin/thread standards requires greater attention by standards organizations.

- The concept of the digital twin continues to evolve. This dynamic will be a challenge to standards bodies.

- The digital twin and the digital thread are distinct aspects of digital transformation. The corresponding digital twin and digital thread standards will be distinctly different.

- Coordinating the development of the respective standards between the digital twin/thread is needed.

- The digital twin’s organization, definition, and enablement depend on data and information provided by the digital thread.

Roadmap for Enabling Global Collaboration

Robert Gutwein (Pratt & Whitney Canada) and Agnes Gourillon-Jandot (Safran Aircraft Engines) reported their progress on the Global Collaboration project. Collaboration is challenged as exchange methods can vary, as well as dealing with the validation of exchanged information and governing the exchange of information in the context of IP protection.

One of the focal points was to introduce an approach to define standardized supplier agreements that anticipate modern model-based exchanges and collaboration methods.

Robert & Agnes presented the 8-step guideline for the aerospace industry in specific terms, explicitly mentioning the ISO44001 standard as being generic for all industries. An impression of the eight steps and sub-steps can be found below:

The 8-step approach will be supported by a 3rd-party Collaboration Management System (CMS app), which is not mandatory but recommended for use. When an interaction depends on a specific tool, it cannot become an ISO standard. The purpose of the methodology and app is to assist participants to ensure the collaboration aspect between stakeholders contains all the necessary steps & and people.

Model-based OEM/Supplier Collaboration Needs in Aviation Industry

Hartmut Hintze, working at Airbus Operations, presented the latest findings of the MBSE Data Interoperability working group and presented the model-based OEM/Supplier collaboration requirements and standards that need to be supported by the PLM/MBSE solution providers in the future. This collaboration goes beyond sharing CAD models, as you can see from the supplier engagement framework below:

As there are no standards-based tools, their first focus was looking into methodologies for model and behavior exchanges based on use cases. The use cases are then used to verify the state-of-the-art abilities of the various tools. At this moment, there is a focus on SysML V2 as a potential game-changer due to its new API support. As a relative novice on SysML, I cannot explain this topic in more simple words. I recommend that experts visit their presentations on the AD PAG publications page here.

Conclusions

The theme of the conference was related to the Digital Thread – and as you will discover it is valid for everyone. Learn to see the difference between the coordinated Digital Thread and the connected Digital Tread.This time, a lot of information about the Aerospace and Defense Action Groups (AD PAG), which are a fundamental part of this conference. The A&D industry has always been leading in advanced PLM concepts. However, more advanced concepts will come in my next post when touching the connected Digital Thread in the context of federated PLM and let’s not forget AI.

Last week I shared my first review of the PLM Roadmap / PDT Fall 2020 conference, organized by CIMdata and Eurostep. Having digested now most of the content in detail, I can state this was the best conference of 2020. In my first post, the topics I shared were mainly the consultant’s view of digital thread and digital twin concepts.

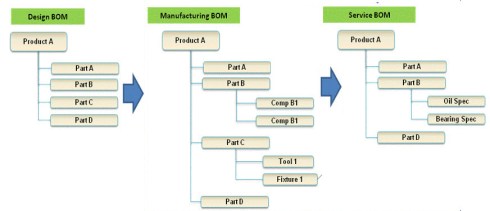

This time, I want to focus on the content presented by the various Aerospace & Defense working groups who shared their findings, lessons-learned (so far) on topics like the Multi-view BOM, Supply Chain Collaboration, MBSE Data interoperability.

This time, I want to focus on the content presented by the various Aerospace & Defense working groups who shared their findings, lessons-learned (so far) on topics like the Multi-view BOM, Supply Chain Collaboration, MBSE Data interoperability.

These sessions were nicely wrapped with presentations from Alberto Ferrari (Raytheon), discussing the digital thread between PLM and Simulation Lifecycle Management and Jeff Plant (Boeing) sharing their Model-Based Engineering strategy.

I believe these insights are crucial, although there might be people in the field that will question if this research is essential. Is not there an easier way to achieve to have the same results?

Nicely formulated by Ilan Madjar as a comment to my first post:

Ilan makes a good point about simplifying the ideas to the masses to make it work. The majority of companies probably do not have the bandwidth to invest and understand the future benefits of a digital thread or digital twins.

This does not mean that these topics should not be studied. If your business is in a small, simple eco-system and wants to work in a connected mode, you can choose a vendor and a few custom interfaces.

This does not mean that these topics should not be studied. If your business is in a small, simple eco-system and wants to work in a connected mode, you can choose a vendor and a few custom interfaces.

However, suppose you work in a global industry with an extensive network of partners, suppliers, and customers.

In that case, you cannot rely on ad-hoc interfaces or a single vendor. You need to invest in standards; you need to study common best practices to drive methodology, standards, and vendors to align.

This process of standardization is so crucial if you want to have a sustainable, connected enterprise. In the end, the push from these companies will lead to standards, allowing the smaller companies to ad-here or connect to.

The future is about Connected through Standards, as discussed in part 1 and further in this post. Let’s go!

Global Collaboration – Defining a baseline for data exchange processes and standards

Katheryn Bell (Pratt & Whitney Canada) presented the progress of the A&D Global Collaboration workgroup. As you can see from the project timeline, they have reached the phase to look towards the future.

Katheryn mentioned the need to standardize terminology as the first point of attention. I am fully aligned with that point; without a standardized terminology framework, people will have a misunderstanding in communication.

This happens even more in the smaller businesses that just pick sometimes (buzz) terms without a full understanding.

Several years ago, I talked with a PLM-implementer telling me that their implementation focus was on systems engineering. After some more explanations, it appeared they were making an attempt for configuration management in reality. Here the confusion was massive. Still, a standard, common terminology is crucial in our domain, even if it seems academic.

Several years ago, I talked with a PLM-implementer telling me that their implementation focus was on systems engineering. After some more explanations, it appeared they were making an attempt for configuration management in reality. Here the confusion was massive. Still, a standard, common terminology is crucial in our domain, even if it seems academic.

The group has been analyzing interoperability standards, standards for long-time archival and retrieval (LOTAR), but also has been studying the ISO 44001 standard related to Collaborative business relationship management systems

In the Q&A session, Katheryn explained that the biggest problem to solve with collaboration was the risk of working with the wrong version of data between disciplines and suppliers.

In the Q&A session, Katheryn explained that the biggest problem to solve with collaboration was the risk of working with the wrong version of data between disciplines and suppliers.

Of course, such errors can lead to huge costs if they are discovered late (or too late). As some of the big OEMs work with thousands of suppliers, you can imagine it is not an issue easily discovered in a more ad-hoc environment.

The move to a standardized Technical Data Package based on a Model-Based Definition is one of these initiatives in this domain to reduce these types of errors.

You can find the proceedings from the Global Collaboration working group here.

Connect, Trace, and Manage Lifecycle of Models, Simulation and Linked Data: Is That Easy?

I loved Alberto Ferrari‘s (Raytheon) presentation how he described the value of a model-based digital thread, positioning it in a targeted enterprise.

I loved Alberto Ferrari‘s (Raytheon) presentation how he described the value of a model-based digital thread, positioning it in a targeted enterprise.

Click on the image and discover how business objectives, processes and models go together supported by a federated infrastructure.

Alberto’s presentation was a kind of mind map from how I imagine the future, and it is a pity if you have not had the chance to see his session.

Alberto also focused on the importance of various simulation capabilities combined with simulation lifecycle management. For Alberto, they are essential to implement digital twins. Besides focusing on standards, Alberto pleas for a semantic integration, open service architecture with the importance of DevSecOps.

Enough food for thought; as Alberto mentioned, he presented the corporate vision, not the current state.

More A&D Action Groups

There were two more interesting specialized sessions where teams from the A&D action groups provided a status update.

Brandon Sapp (Boeing) and Ian Parent (Pratt & Whitney) shared the activities and progress on Minimum Model-Based Definition (MBD) for Type Design Certification.

Brandon Sapp (Boeing) and Ian Parent (Pratt & Whitney) shared the activities and progress on Minimum Model-Based Definition (MBD) for Type Design Certification.

As Brandon mentioned, MBD is already a widely used capability; however, MBD is still maturing and evolving. I believe that is also one of the reasons why MBD is not yet accepted in mainstream PLM. Smaller organizations will wait; however, can your company afford to wait?

More information about their progress can be found here.

Mark Williams (Boeing) reported from the A&D Model-Based Systems Engineering action group their first findings related to MBSE Data Interoperability, focusing on an Architecture Model Exchange Solution. A topic interesting to follow as the promise of MBSE is that it is about connected information shared in models. As Mark explained, data exchange standards for requirements and behavior models are mature, readily available in the tools, and easily adopted. Exchanging architecture models has proven to be very difficult. I will not dive into more details, respecting the audience of this blog.

Mark Williams (Boeing) reported from the A&D Model-Based Systems Engineering action group their first findings related to MBSE Data Interoperability, focusing on an Architecture Model Exchange Solution. A topic interesting to follow as the promise of MBSE is that it is about connected information shared in models. As Mark explained, data exchange standards for requirements and behavior models are mature, readily available in the tools, and easily adopted. Exchanging architecture models has proven to be very difficult. I will not dive into more details, respecting the audience of this blog.

For those interested in their progress, more information can be found here

Model-Based Engineering @ Boeing

In this conference, the participation of Boeing was significant through the various action groups. As the cherry on the cake, there was Jeff Plant‘s session, giving an overview of what is happening at Boeing. Jeff is Boeing’s director of engineering practices, processes, and tools.

In his introduction, Jeff mentioned that Boeing has more than 160.000 employees in over 65 countries. They are working with more than 12.000 suppliers globally. These suppliers can be manufacturing, service or technology partnerships. Therefore you can imagine, and as discussed by others during the conference, streamlined collaboration and traceability are crucial.

The now-famous MBE Diamond symbol illustrates the model-based information flows in the virtual world and the physical world based on the systems engineering approach. Like Katheryn Bell did in her session related to Global Collaboration, Jeff started explaining the importance of a common language and taxonomy needed if you want to standardize processes.

The now-famous MBE Diamond symbol illustrates the model-based information flows in the virtual world and the physical world based on the systems engineering approach. Like Katheryn Bell did in her session related to Global Collaboration, Jeff started explaining the importance of a common language and taxonomy needed if you want to standardize processes.

Zoom in on the Boeing MBE Taxonomy, you will discover the clarity it brings for the company.

I was not aware of the ISO 23247 standard concerning the Digital Twin framework for manufacturing, aiming to apply industry standards to the model-based definition of products and process planning. A standard certainly to follow as it brings standardization on top of existing standards.

As Jeff noted: A practical standard for implementation in a company of any size. In my opinion, mandatory for a sustainable, connected infrastructure.

Jeff presented the slide below, showing their standardization internally around federated platforms.

This slide resembles a lot the future platform vision I have been sharing since 2017 when discussing PLM’s future at PLM conferences, when explaining the differences between Coordinated and Connected – see also my presentation here on Slideshare.

You can zoom in on the picture to see the similarities. For me, the differences were interesting to observe. In Jeff’s diagram, the product lifecycle at the top indicates the platform of (central) interest during each lifecycle stage, suggesting a linear process again.

You can zoom in on the picture to see the similarities. For me, the differences were interesting to observe. In Jeff’s diagram, the product lifecycle at the top indicates the platform of (central) interest during each lifecycle stage, suggesting a linear process again.

In reality, the flow of information through feedback loops will be there too.

The second exciting detail is that these federated architectures should be based on strong interoperability standards. Jeff is urging other companies, academics and vendors to invest and come to industry standards for Model-Based System Engineering practices. The time is now to act on this domain.

The second exciting detail is that these federated architectures should be based on strong interoperability standards. Jeff is urging other companies, academics and vendors to invest and come to industry standards for Model-Based System Engineering practices. The time is now to act on this domain.

It reminded me again of Marc Halpern’s message mentioned in my previous post (part 1) that we should be worried about vendor alliances offering an integrated end-to-end data flow based on their solutions. This would lead to an immense vendor-lock in if these interfaces are not based on strong industry standards.

Therefore, don’t watch from the sideline; it is the voice (and effort) of the companies that can drive standards.

Finally, during the Q&A part, Jeff made an interesting point explaining Boeing is making a serious investment, as you can see from their participation in all the action groups. They have made the long-term business case.

Finally, during the Q&A part, Jeff made an interesting point explaining Boeing is making a serious investment, as you can see from their participation in all the action groups. They have made the long-term business case.

The team is confident that the business case for such an investment is firm and stable, however in such long-term investment without direct results, these projects might come under pressure when the business is under pressure.

The virtual fireside chat

The conference ended with a virtual fireside chat from which I picked up an interesting point that Marc Halpern was bringing in. Marc mentioned a survey Gartner has done with companies in fast-moving industries related to the benefits of PLM. Companies reported improvements in accuracy and product development. They did not see so much a reduced time to market or cost reduction. After analysis, Gartner believes the real issue is related to collaboration processes and supply chain practices. Here lead times did not change, nor the number of changes.

Marc believes that this topic will be really showing benefits in the future with cloud and connected suppliers. This reminded me of an article published by McKinsey called The case for digital reinvention. In this article, the authors indicated that only 2 % of the companies interview were investing in a digital supply chain. At the same time, the expected benefits in this area would have the most significant ROI.

Marc believes that this topic will be really showing benefits in the future with cloud and connected suppliers. This reminded me of an article published by McKinsey called The case for digital reinvention. In this article, the authors indicated that only 2 % of the companies interview were investing in a digital supply chain. At the same time, the expected benefits in this area would have the most significant ROI.

The good news, there is consistency, and we know where to focus for early results.

Conclusion

It was a great conference as here we could see digital transformation in action (groups). Where vendor solutions often provide a sneaky preview of the future, we saw people working on creating the right foundations based on standards. My appreciation goes to all the active members in the CIMdata A&D action groups as they provide the groundwork for all of us – sooner or later.

I discovered I am getting tired as I am missing face-to-face interaction with people. Working from home, having video calls, is probably a very sustainable way of working. However, non-planned social interaction, meeting each other at the coffee machine, or during the breaks at a conference or workshop, is also crucial for informal interaction.

I discovered I am getting tired as I am missing face-to-face interaction with people. Working from home, having video calls, is probably a very sustainable way of working. However, non-planned social interaction, meeting each other at the coffee machine, or during the breaks at a conference or workshop, is also crucial for informal interaction.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…