In the last two weeks, I have had mixed discussions related to PLM, where I realized the two different ways people can look at PLM. Are implementing PLM capabilities driven by a cost-benefit analysis and a business case? Or is implementing PLM capabilities driven by strategy providing business value for a company?

In the last two weeks, I have had mixed discussions related to PLM, where I realized the two different ways people can look at PLM. Are implementing PLM capabilities driven by a cost-benefit analysis and a business case? Or is implementing PLM capabilities driven by strategy providing business value for a company?

Most companies I am working with focus on the first option – there needs to be a business case.

This observation is a pleasant passageway into a broader discussion started by Rob Ferrone recently with his article Money for nothing and PLM for free. He explains the PDM cost of doing business, which goes beyond the software’s cost. Often, companies consider the other expenses inescapable.

This observation is a pleasant passageway into a broader discussion started by Rob Ferrone recently with his article Money for nothing and PLM for free. He explains the PDM cost of doing business, which goes beyond the software’s cost. Often, companies consider the other expenses inescapable.

At the same time, Benedict Smith wrote some visionary posts about the potential power of an AI-driven PLM strategy, the most recent article being PLM augmentation – Panning for Gold.

At the same time, Benedict Smith wrote some visionary posts about the potential power of an AI-driven PLM strategy, the most recent article being PLM augmentation – Panning for Gold.

It is a visionary article about what is possible in the PLM space (if there was no legacy ☹), based on Robust Reasoning and how you could even start with LLM Augmentation for PLM “Micro-Tasks.

Interestingly, the articles from both Rob and Benedict were supported by AI-generated images – I believe this is the future: Creating an AI image of the message you have in mind.

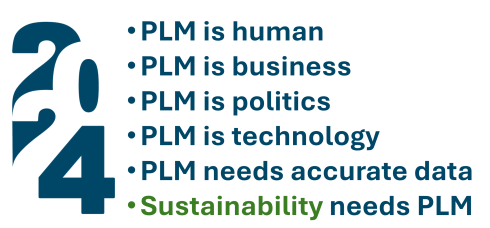

![]() When you have digested their articles, it is time to dive deeper into the different perspectives of value and costs for PLM.

When you have digested their articles, it is time to dive deeper into the different perspectives of value and costs for PLM.

From a system to a strategy

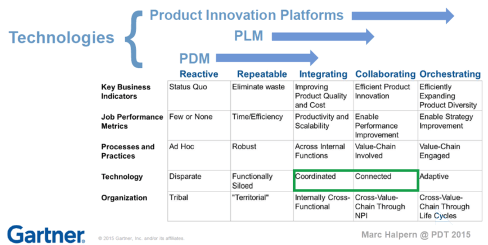

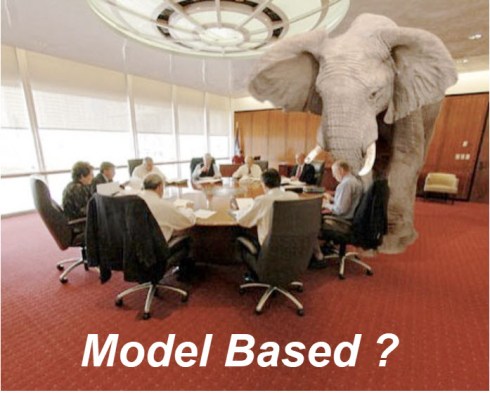

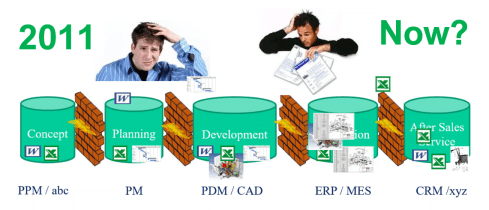

The biggest obstacle I have discovered is that people relate PLM to a system or, even worse, to an engineering tool. This 20-year-old misunderstanding probably comes from the fact that in the past, implementing PLM was more an IT activity – providing the best support for engineers and their data – than a business-driven set of capabilities needed to support the product lifecycle.

The biggest obstacle I have discovered is that people relate PLM to a system or, even worse, to an engineering tool. This 20-year-old misunderstanding probably comes from the fact that in the past, implementing PLM was more an IT activity – providing the best support for engineers and their data – than a business-driven set of capabilities needed to support the product lifecycle.

The System approach

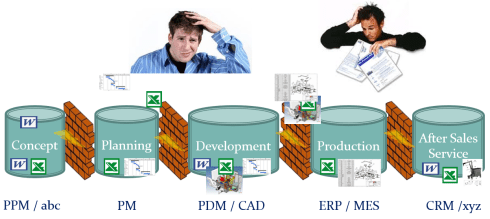

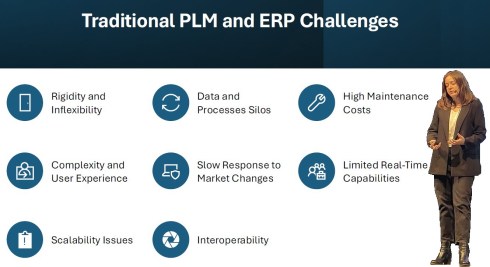

Traditional organizations are siloed, and initially, PLM always had the challenge of supporting product information shared throughout the whole lifecycle, where there was no conventional focus per discipline to invest in sharing – every discipline has its P&L – and sharing comes with a cost.

At the management level, the financial data coming from the ERP system drives the business. ERP systems are transactional and can provide real-time data about the company’s performance. C-level management wants to be sure they can see what is happening, so there is a massive focus on implementing the best ERP system.

At the management level, the financial data coming from the ERP system drives the business. ERP systems are transactional and can provide real-time data about the company’s performance. C-level management wants to be sure they can see what is happening, so there is a massive focus on implementing the best ERP system.

In some cases, I noticed that the investment in ERP was twenty times more than the PLM investment.

Why would you invest in PLM? Although the ERP engine will slow down without proper PLM, the complexity of PLM compared to ERP is a reason for management to look at the costs, as the PLM benefits are hard to grasp and depend on so much more than just execution.

Why would you invest in PLM? Although the ERP engine will slow down without proper PLM, the complexity of PLM compared to ERP is a reason for management to look at the costs, as the PLM benefits are hard to grasp and depend on so much more than just execution.

See also my old 2015 article: How do you measure collaboration?

As I mentioned, the Cost of Non-Quality, too many iterations, time lost by searching, material scrap, manufacturing delays or customer complaints – often are considered inescapable parts of doing business (like everyone else) – it happens all the time..

The strategy approach

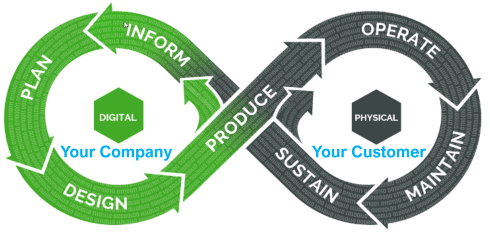

It is clear that when we accept the modern definition of PLM, we should be considering product lifecycle management as the management of the product lifecycle (as Patrick Hillberg says eloquently in our Share PLM podcast – see the image at the bottom of this post, too).

It is clear that when we accept the modern definition of PLM, we should be considering product lifecycle management as the management of the product lifecycle (as Patrick Hillberg says eloquently in our Share PLM podcast – see the image at the bottom of this post, too).

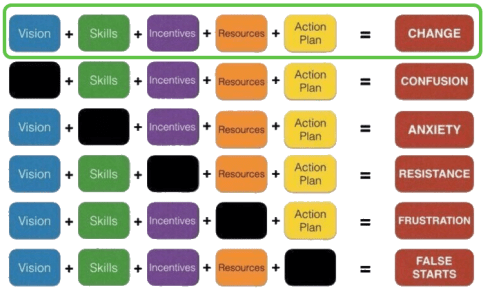

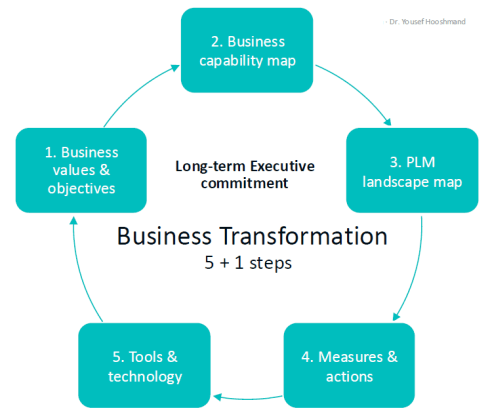

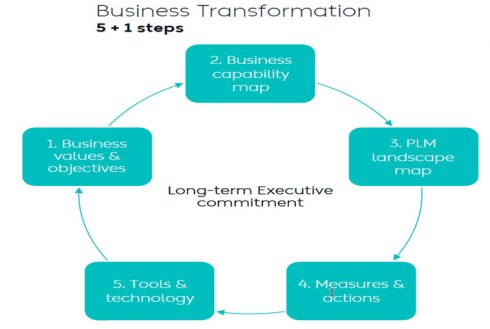

When you implement a strategy, it is evident that there should be a long(er) term vision behind it, which can be challenging for companies. Also, please read my previous article: The importance of a (PLM) vision.

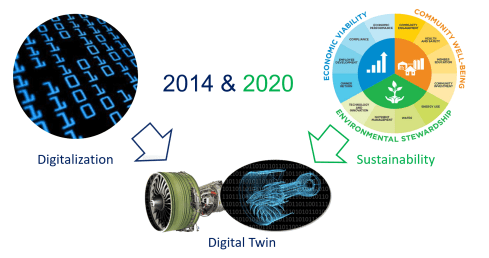

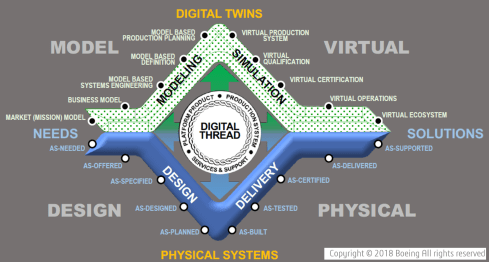

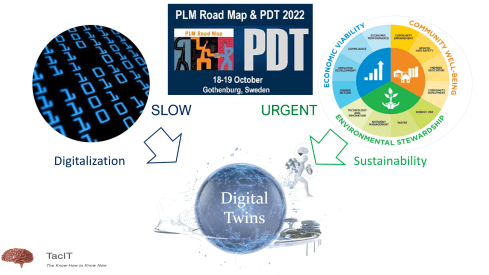

I cannot believe that, although perhaps not fully understood, the importance of a data-driven approach will be discussed at many strategic board meetings. A data-driven approach is needed to implement a digital thread as the foundation for enhanced business models based on digital twins and to ensure data quality and governance supporting AI initiatives.

I cannot believe that, although perhaps not fully understood, the importance of a data-driven approach will be discussed at many strategic board meetings. A data-driven approach is needed to implement a digital thread as the foundation for enhanced business models based on digital twins and to ensure data quality and governance supporting AI initiatives.

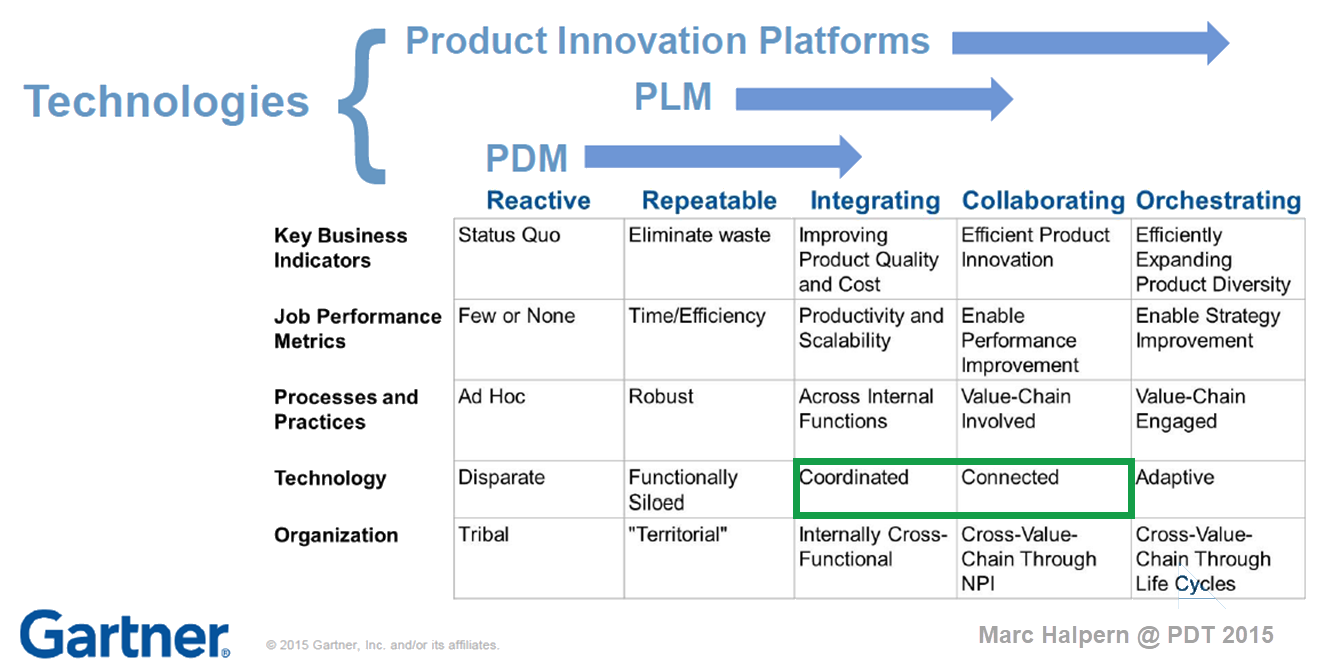

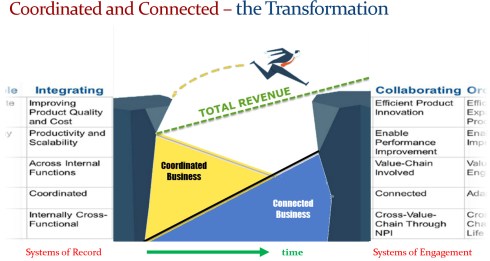

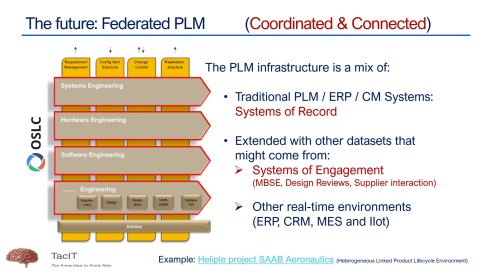

It is a process I have been preaching: From Coordinated to Coordinated and Connected.

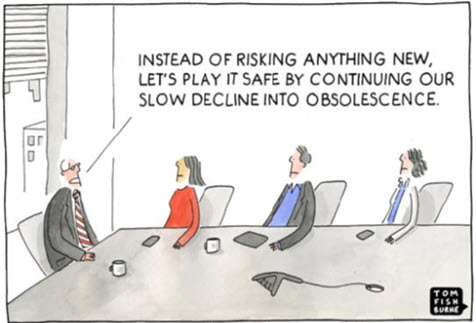

We can be sure that at the board level, strategy discussions should be about value creation, not about reducing costs or avoiding risks as the future strategy.

Understanding the (PLM) value

The biggest challenge for companies is to understand how to modernize their PLM infrastructure to bring value.

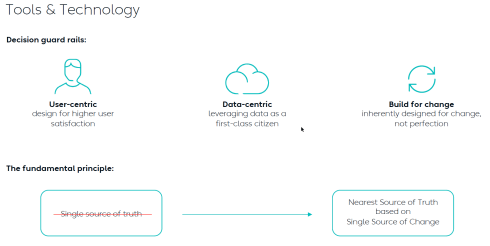

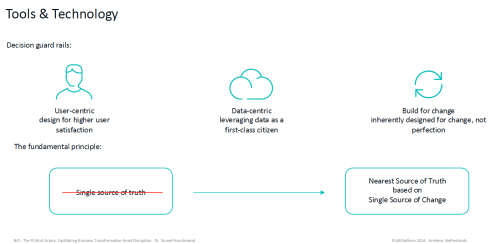

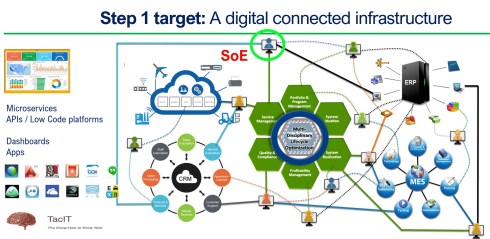

* Step 1 is obvious. Stop considering PLM as a system with capabilities, but investigate how you transform your infrastructure from a collection of systems and (document) interfaces towards a federated infrastructure of connected tools.

![]() Note: the paradigm shift from a Single Source of Truth (in my system) towards a Nearest Source of Truth and a Single Source of Change.

Note: the paradigm shift from a Single Source of Truth (in my system) towards a Nearest Source of Truth and a Single Source of Change.

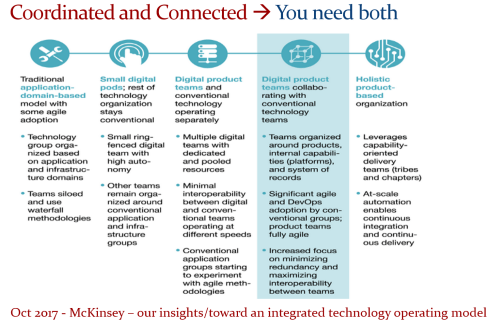

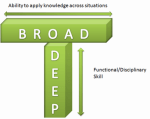

* Step 2 is education. A data-driven approach creates new opportunities and impacts how companies should run their business. Different skills are needed, and other organizational structures are required, from disciplines working in siloes to hybrid organizations where people can work in domain-driven environments (the Systems of Record) and product-centric teams (the System of Engagement). AI tools and capabilities will likely create an effortless flow of information within the enterprise.

* Step 3 is building a compelling story to implement the vision. Implementing new ways of working based on new technical capabilities requires also organizational change. If your organization keeps working similarly, you might gain some percentage of efficiency improvements.

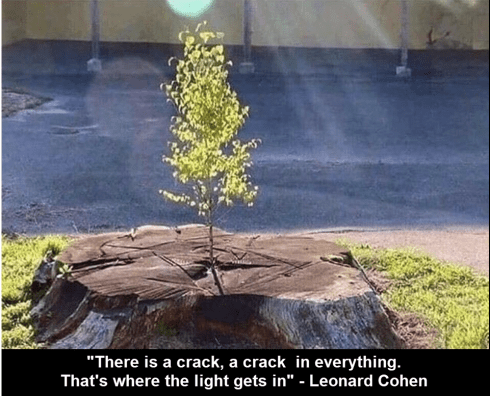

The real benefits come from doing things differently, and technology allows you to do it differently. However, this requires people to work differently, too, and this is the most common mistake in transformational projects.

The real benefits come from doing things differently, and technology allows you to do it differently. However, this requires people to work differently, too, and this is the most common mistake in transformational projects.

Companies understand the WHY and WHAT but leave the HOW to the middle management.

People are squeezed into an ideal performance without taking them on the journey. For that reason, it is essential to build a compelling story that motivates individuals to join the transformation. Assisting companies in building compelling story lines is one of the areas where I specialize.

People are squeezed into an ideal performance without taking them on the journey. For that reason, it is essential to build a compelling story that motivates individuals to join the transformation. Assisting companies in building compelling story lines is one of the areas where I specialize.

Feel free to contact me to explore the opportunity for your business.

It is not the technology!

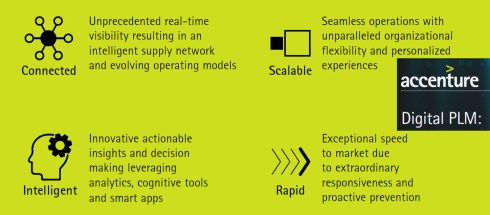

With the upcoming availability of AI tools, implementing a PLM strategy will no longer depend on how IT understands the technology, the systems and the interfaces needed.

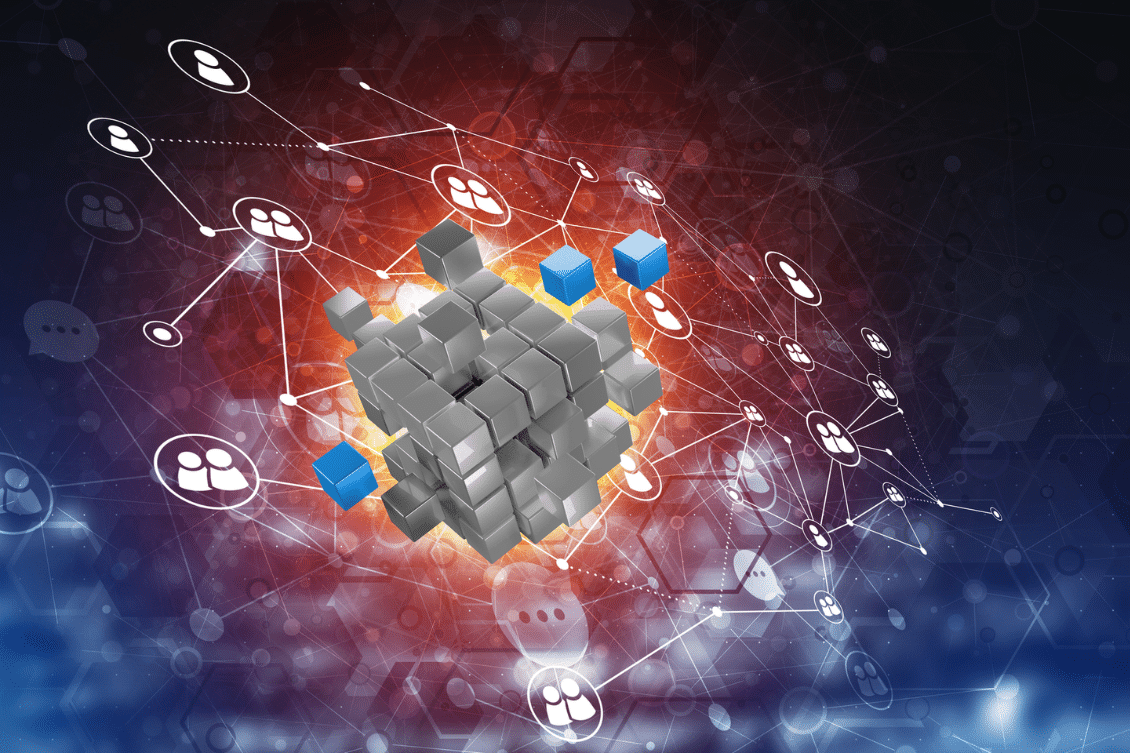

As Yousef Hooshmand‘s above image describes, a federated infrastructure of connected (SaaS) solutions will enable companies to focus on accurate data (priority #1) and people creating and using accurate data (priority #1). As you can see, people and data in modern PLM are the highest priority.

Therefore, I look forward to participating in the upcoming Share PLM Summit on 27-28 May in Jerez.

It will be a breakthrough – where traditional PLM conferences focus on technology and best practices. This conference will focus on how we can involve and motivate people. Regardless of which industry you are active in, it is a universal topic for any company that wants to transform.

Conclusion

Returning to this article’s introduction, modern PLM is an opportunity to transform the business and make it future-proof. It needs to be done for sure now or in the near future. Therefore PLM initiatives should be considered from the value point first instead of focusing on the costs. How well are you connected to your management’s vision to make PLM a value discussion?

Enjoy the podcast – several topics discuss relate to this post.

In the last two weeks, I had some interesting observations and discussions related to the need to have a (PLM) vision. I placed the word PLM between brackets, as PLM is no longer an isolated topic in an organization. A PLM strategy should align with the business strategy and vision.

In the last two weeks, I had some interesting observations and discussions related to the need to have a (PLM) vision. I placed the word PLM between brackets, as PLM is no longer an isolated topic in an organization. A PLM strategy should align with the business strategy and vision.

So far my impression is that most companies implement their digital enhancements (treads/graphs) in a bottom-up approach, not driven by a management vision but more like band-aids or places where it fits well, without a strategy or vision.

So far my impression is that most companies implement their digital enhancements (treads/graphs) in a bottom-up approach, not driven by a management vision but more like band-aids or places where it fits well, without a strategy or vision.

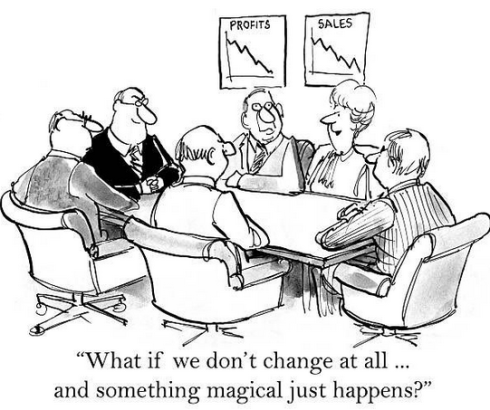

Based on these findings, there will be classical efficiency plans, i.e., cutting costs somewhere, dropping some non-performing products, or investing in new technology that they cannot resist. Still, minor process changes and fundamental organizational changes are not expected.

Based on these findings, there will be classical efficiency plans, i.e., cutting costs somewhere, dropping some non-performing products, or investing in new technology that they cannot resist. Still, minor process changes and fundamental organizational changes are not expected. Everyone is happy when the company feels stable and profitable, even if the margins are under pressure. The challenge for this type of company without a vision is that they navigate in the dark when the outside world changes – like nowadays.

Everyone is happy when the company feels stable and profitable, even if the margins are under pressure. The challenge for this type of company without a vision is that they navigate in the dark when the outside world changes – like nowadays.

Many current discussions in the PLM domain are about structures and data connectivity, Bills of Materials (BOM), or Bills of Information(BOI) combined with the new term Digital Thread as a Service (DTaaS) introduced by

Many current discussions in the PLM domain are about structures and data connectivity, Bills of Materials (BOM), or Bills of Information(BOI) combined with the new term Digital Thread as a Service (DTaaS) introduced by

MBD is a common practice in aerospace and particularly in the automotive industry. Other industries are struggling to introduce MBD, either because the OEM is not ready or willing to share information in a different format than 3D + 2D drawings, or their supplier consider MBD too complex for them compared to their current document-driven approach.

MBD is a common practice in aerospace and particularly in the automotive industry. Other industries are struggling to introduce MBD, either because the OEM is not ready or willing to share information in a different format than 3D + 2D drawings, or their supplier consider MBD too complex for them compared to their current document-driven approach. As I wrote, learning to work with MBD is a stepping stone in understanding a modern model-based and data-driven enterprise. See my 2022 post:

As I wrote, learning to work with MBD is a stepping stone in understanding a modern model-based and data-driven enterprise. See my 2022 post:

In addition, an interesting article from Nicolas Figay might help you understand the value for a broader audience. Read his article:

In addition, an interesting article from Nicolas Figay might help you understand the value for a broader audience. Read his article:

These discussions are more challenging to follow as you need a broader and long-term vision, as implementing solutions/changes takes much longer than buying tools.

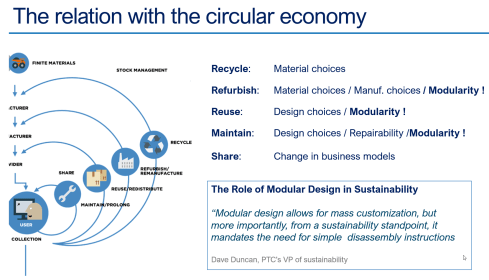

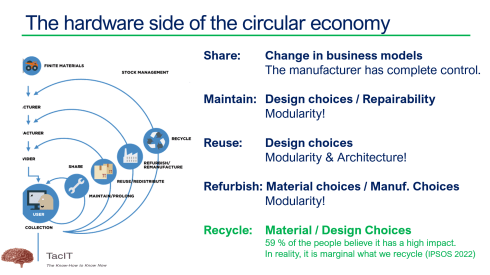

These discussions are more challenging to follow as you need a broader and long-term vision, as implementing solutions/changes takes much longer than buying tools. Modularity is a design principle that breaks a system into smaller, independent, and interchangeable components, or modules, that function together as a whole. Each module performs a specific task and can be developed, tested, and maintained separately, improving flexibility and scalability.

Modularity is a design principle that breaks a system into smaller, independent, and interchangeable components, or modules, that function together as a whole. Each module performs a specific task and can be developed, tested, and maintained separately, improving flexibility and scalability. In the hardware world, this is different. Often, companies have a history of delivering a specific (hardware) solution, and the product has been improved by adding features and options where the top products remain the company’s flagships.

In the hardware world, this is different. Often, companies have a history of delivering a specific (hardware) solution, and the product has been improved by adding features and options where the top products remain the company’s flagships.

If you reached this point of the article, my question is now to reflect on your business or company. Modularity is, for many companies, a dream (or vision) and will become, for most companies, a must to provide a sustainable business.

If you reached this point of the article, my question is now to reflect on your business or company. Modularity is, for many companies, a dream (or vision) and will become, for most companies, a must to provide a sustainable business. IMPORTANT:

IMPORTANT:

The implementations became too much a highly customized environment, not necessarily thought-through as every customer worked differently based on their (paper) history. Thanks to learning from the discussions in the field supporting stalled implementations, I was also assigned to develop templates (e.g. SmarTeam Design Express) and standard methodology (the FDA toolkit), as the mid-market customers requested. The focus was on standard processes.

The implementations became too much a highly customized environment, not necessarily thought-through as every customer worked differently based on their (paper) history. Thanks to learning from the discussions in the field supporting stalled implementations, I was also assigned to develop templates (e.g. SmarTeam Design Express) and standard methodology (the FDA toolkit), as the mid-market customers requested. The focus was on standard processes. In 2010, I wrote

In 2010, I wrote

The technology was there, the usability was not there. Many implementations of a PLM system go through a critical stage. Are companies willing to change their methodology and habits to align with common best practices, or do they still want to implement their unique ways of working (from the past)?

The technology was there, the usability was not there. Many implementations of a PLM system go through a critical stage. Are companies willing to change their methodology and habits to align with common best practices, or do they still want to implement their unique ways of working (from the past)? I have seen companies that created a task or issue for every single activity a person should do. Managers loved the (demo) dashboard. It never lead to success as the approach created frustration at the end user level as their To-Do list grew and grew.

I have seen companies that created a task or issue for every single activity a person should do. Managers loved the (demo) dashboard. It never lead to success as the approach created frustration at the end user level as their To-Do list grew and grew. Another example of the micro-management mindset is when I worked with a company that had the opposite definition of Version and Revision in their current terminology. Initially, they insisted that the new PLM system should support this, meaning everywhere in the interface where Revisions was mentioned should be Version and the reverse for Version and Revision.

Another example of the micro-management mindset is when I worked with a company that had the opposite definition of Version and Revision in their current terminology. Initially, they insisted that the new PLM system should support this, meaning everywhere in the interface where Revisions was mentioned should be Version and the reverse for Version and Revision.

At that time, I saw a few companies linking their digital transformation to implementing a new PLM system. Those were the days the PLM vendors were battling for the big enterprise deals, sometimes motivated by an IT mindset that unifying the existing PDM/PLM systems would fulfill the digital dream. Science was not winning, but emotion. Read

At that time, I saw a few companies linking their digital transformation to implementing a new PLM system. Those were the days the PLM vendors were battling for the big enterprise deals, sometimes motivated by an IT mindset that unifying the existing PDM/PLM systems would fulfill the digital dream. Science was not winning, but emotion. Read

In the past two years, I have been reading and digesting much news related to AI, particularly generative AI.

In the past two years, I have been reading and digesting much news related to AI, particularly generative AI.

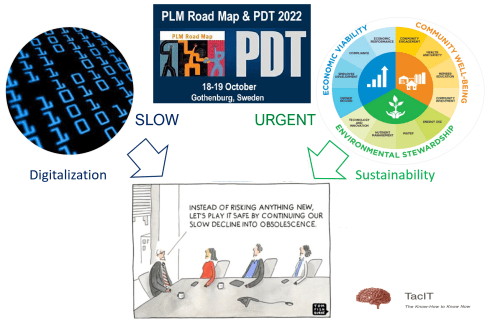

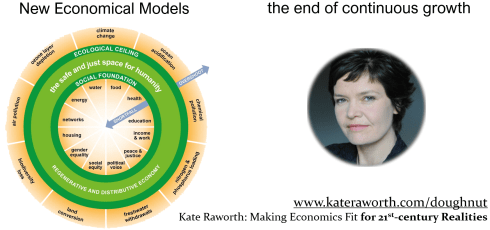

Due to sustainability regulations, digital transformation has gotten a push in the right direction. GHG (Greenhouse Gas) reporting, ESG (Environmental Social Governance) reporting, CSRD (Corporate Sustainability Reporting Directive), and the DPP (Digital Product Passport) have all created the need for companies to create digital threads for information that historically did not exist or was locked in documents.

Due to sustainability regulations, digital transformation has gotten a push in the right direction. GHG (Greenhouse Gas) reporting, ESG (Environmental Social Governance) reporting, CSRD (Corporate Sustainability Reporting Directive), and the DPP (Digital Product Passport) have all created the need for companies to create digital threads for information that historically did not exist or was locked in documents.

The challenge of regulations is that they limit someone’s freedom. Regulations are there to create an equal playing field for all and ensure society makes progress. Be it traffic regulations, business regulations or environmental regulations. The challenge is not to over-regulate and create a

The challenge of regulations is that they limit someone’s freedom. Regulations are there to create an equal playing field for all and ensure society makes progress. Be it traffic regulations, business regulations or environmental regulations. The challenge is not to over-regulate and create a  I have learned to always look at the WHY. Why are companies doing business in a certain manner, why are people behaving in a certain manner even against common logic?

I have learned to always look at the WHY. Why are companies doing business in a certain manner, why are people behaving in a certain manner even against common logic?

Still it is a transformational change in the way you work and this is a challenge for an existing workforce. They reached their status by being an expert in a certain discipline, by mastering specific skills. Now the needed expertise is changing (

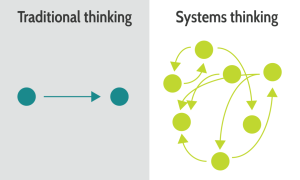

Still it is a transformational change in the way you work and this is a challenge for an existing workforce. They reached their status by being an expert in a certain discipline, by mastering specific skills. Now the needed expertise is changing ( We cannot just produce product or consume like crazy if we care about future generations. It is not longer only about the money, it is about next generations and the environment – if you care. This complexity pushes us toward Systems Thinking – many topics are connected – addressing a single topic does not solve the rest.

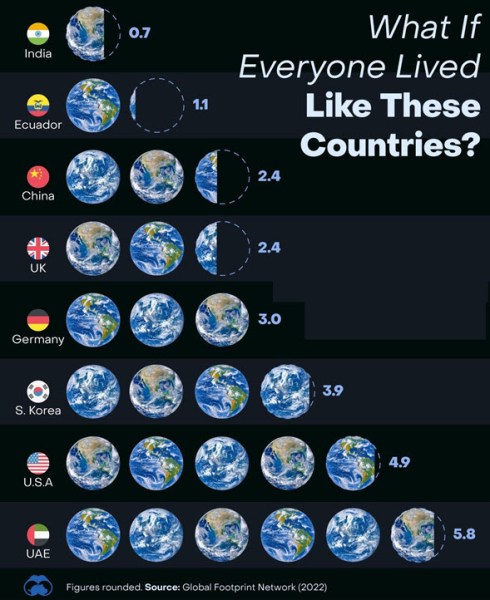

We cannot just produce product or consume like crazy if we care about future generations. It is not longer only about the money, it is about next generations and the environment – if you care. This complexity pushes us toward Systems Thinking – many topics are connected – addressing a single topic does not solve the rest. Historically Europe has been a stable democracy since the second world war and the European Union has been able to establish quite a unified voice step by step. Of course the European Union was heavily influenced by the Automotive and Agricultural lobby. Still the European Green Deal was established with great consensus in the middle instead of focusing on the extremes. A multi-party parliament guarantees a balanced outcome. However type of democracy is still very sensitive for influences from lobbyist and external forces.

Historically Europe has been a stable democracy since the second world war and the European Union has been able to establish quite a unified voice step by step. Of course the European Union was heavily influenced by the Automotive and Agricultural lobby. Still the European Green Deal was established with great consensus in the middle instead of focusing on the extremes. A multi-party parliament guarantees a balanced outcome. However type of democracy is still very sensitive for influences from lobbyist and external forces. The US has been leading the world in polarization. With two major parties fighting always for the 51 % majority vote, there is no place for consensus. The winner takes it all. And although we call it a democracy, you need to have a lot of money to be elected and money is the driving power behind the elections. The WHY in most cases in the US is about short term money making, although I found an interesting point related to Elon Musk.

The US has been leading the world in polarization. With two major parties fighting always for the 51 % majority vote, there is no place for consensus. The winner takes it all. And although we call it a democracy, you need to have a lot of money to be elected and money is the driving power behind the elections. The WHY in most cases in the US is about short term money making, although I found an interesting point related to Elon Musk. In

In  Here we are not talking about a democracy anymore and they might seem the biggest enemy for the climate. However they have a long-term strategy. While keeping the world addicted to fossil fuels, they invest heavily in solar and hydrogen and once the western world understands the energy transition is needed, they are far ahead in experience and remain a main energy supplier.

Here we are not talking about a democracy anymore and they might seem the biggest enemy for the climate. However they have a long-term strategy. While keeping the world addicted to fossil fuels, they invest heavily in solar and hydrogen and once the western world understands the energy transition is needed, they are far ahead in experience and remain a main energy supplier. With 1.4 billion inhabitants and not a democracy either, China has a different mission. Initially as the manufacturing hub for the planet they needed huge amount of energy and therefore they are listed as the most polluting country in the world.

With 1.4 billion inhabitants and not a democracy either, China has a different mission. Initially as the manufacturing hub for the planet they needed huge amount of energy and therefore they are listed as the most polluting country in the world. It is a pity to mention Russia as with their war-economy and reliance on fossil fuels, they are on a path towards oblivion. Even if they would win a few other wars, innovation is gone and fossil is ending. It will be a blessing for humanity. I hope they will find a new long-term strategy.

It is a pity to mention Russia as with their war-economy and reliance on fossil fuels, they are on a path towards oblivion. Even if they would win a few other wars, innovation is gone and fossil is ending. It will be a blessing for humanity. I hope they will find a new long-term strategy.

As I wrote in a recent post, “

As I wrote in a recent post, “

The title of the paragraph covers topics from the previous paragraphs and it was also the theme from a recent post shared through LinkedIn from Lionel Grealou:

The title of the paragraph covers topics from the previous paragraphs and it was also the theme from a recent post shared through LinkedIn from Lionel Grealou:

The challenge seen in this discussion is that:

The challenge seen in this discussion is that:

It is a topic I want to explore this year and see how to connect it to companies in my ecosystem. It is an unknown phenomenon as most of them struggle with a data-driven foundation and skills and focus on the right AI applications.

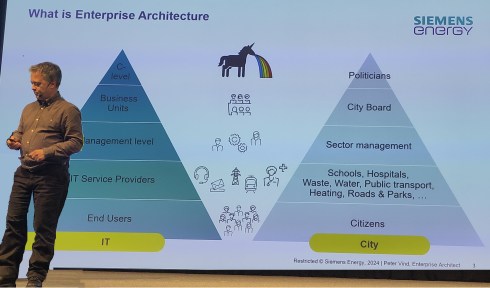

It is a topic I want to explore this year and see how to connect it to companies in my ecosystem. It is an unknown phenomenon as most of them struggle with a data-driven foundation and skills and focus on the right AI applications. A potential interesting trend als related to AI I want to clarify further is the modern enterprise architecture . Over the past two years, we have seen a growing understanding that we should not think in systems connected through interfaces but towards a digitally connected infrastructure where APIs, low-code platforms or standardized interfaces will be responsible for real-time collaboration.

A potential interesting trend als related to AI I want to clarify further is the modern enterprise architecture . Over the past two years, we have seen a growing understanding that we should not think in systems connected through interfaces but towards a digitally connected infrastructure where APIs, low-code platforms or standardized interfaces will be responsible for real-time collaboration.

The second post, more recent, summarized the experiences I had with several customer engagements. The title says it all: “

The second post, more recent, summarized the experiences I had with several customer engagements. The title says it all: “

I also follow

I also follow  Of course, Oleg Shilovitsky’s impressive and continuous flow of posts related to modern PLM concepts is amazing—just browse through his

Of course, Oleg Shilovitsky’s impressive and continuous flow of posts related to modern PLM concepts is amazing—just browse through his

Sustainability should be on everyone’s agenda. From the interactions on LinkedIn, you can see that we prefer to discuss terms like

Sustainability should be on everyone’s agenda. From the interactions on LinkedIn, you can see that we prefer to discuss terms like

Congratulations if you have shown you can resist the psychological and emotional pressure and did not purchase anything in the context of Black Friday. However, we must not forget that another big part of the world cannot afford this behavior, as they do not have the means to do so – ultimate Black Friday might be their dream and a fast track to more enormous challenges.

Congratulations if you have shown you can resist the psychological and emotional pressure and did not purchase anything in the context of Black Friday. However, we must not forget that another big part of the world cannot afford this behavior, as they do not have the means to do so – ultimate Black Friday might be their dream and a fast track to more enormous challenges.

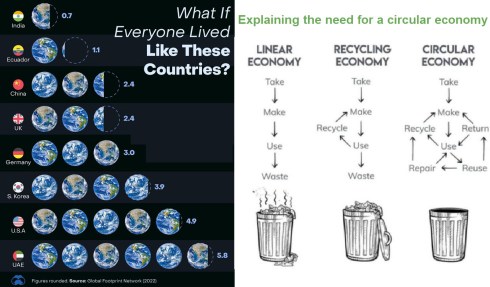

Or we need more planets, and I understand a brilliant guy is already working on it. Let’s go to Mars and enjoy life there.

Or we need more planets, and I understand a brilliant guy is already working on it. Let’s go to Mars and enjoy life there.

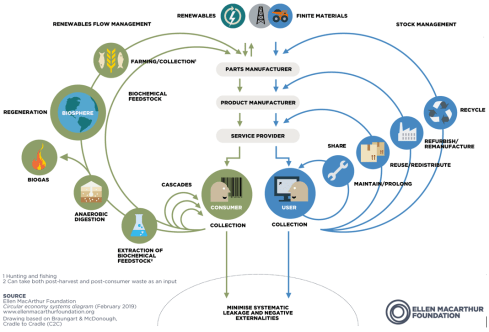

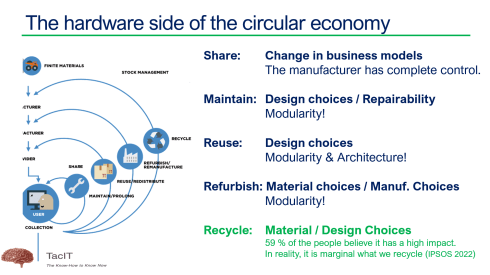

It is important to note that the recycle loop is the most overestimated loop, where we might contribute to recycling (glass, paper, plastic) in our daily lives; however, other materials, like composites often with embedded electronics, have a much more significant impact.

It is important to note that the recycle loop is the most overestimated loop, where we might contribute to recycling (glass, paper, plastic) in our daily lives; however, other materials, like composites often with embedded electronics, have a much more significant impact.

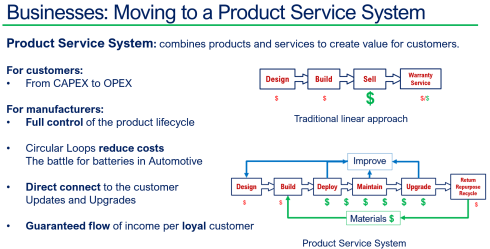

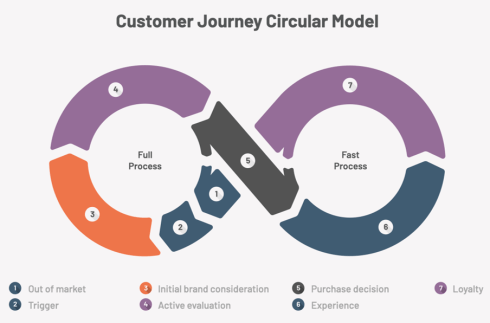

My presentation focused on three steps that manufacturing companies need to consider now and in the future when moving to a Product Service System.

My presentation focused on three steps that manufacturing companies need to consider now and in the future when moving to a Product Service System.

As an upcoming bonus and a must, companies need to use AI to run their Product Service System as it will improve customer knowledge and trends.

As an upcoming bonus and a must, companies need to use AI to run their Product Service System as it will improve customer knowledge and trends.

Step 2: From product to experience can already significantly impact organizations. The traditional salesperson’s role will disappear and be replaced by excellence in marketing, services and product management.

Step 2: From product to experience can already significantly impact organizations. The traditional salesperson’s role will disappear and be replaced by excellence in marketing, services and product management. When scaling up slowly, the company might be able to finance this transition themselves. Another option, already happening, is for a third party to finance the Product Service System – think about car leasing, power by the hour, or some industrial equipment vendors.

When scaling up slowly, the company might be able to finance this transition themselves. Another option, already happening, is for a third party to finance the Product Service System – think about car leasing, power by the hour, or some industrial equipment vendors.

But we must abandon the old business models and habits – there will be a lot of resistance to change before people are forced to change. This change can take generations as the outside world will not change without a reason, and the established ones will fight for their privileges.

But we must abandon the old business models and habits – there will be a lot of resistance to change before people are forced to change. This change can take generations as the outside world will not change without a reason, and the established ones will fight for their privileges.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…