You are currently browsing the category archive for the ‘Green Development’ category.

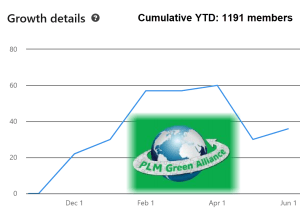

I am happy to see that the number of members of our PLM Green Global Alliance on LinkedIn has been growing fast recently.

I am happy to see that the number of members of our PLM Green Global Alliance on LinkedIn has been growing fast recently.

Early this year, we reached 1000 members; now, as of this post, we have almost 1200 members in our LinkedIn group—a growth of 20 % in less than half a year!

Each member of the #plmgreen alliance has a unique story and reason for joining.

I’m genuinely interested in learning more about your motivation. To kick off this conversation, I am sharing my journey, and I am eager to hear your thoughts, comments, and suggestions.

I’m genuinely interested in learning more about your motivation. To kick off this conversation, I am sharing my journey, and I am eager to hear your thoughts, comments, and suggestions.

Being aware this is again a long read, but I encourage you to read the article till the end.

Reading a 1500-word post was a 20th-century skill that helped people understand things with their nuances.

Let’s not lose this skill in the 21st century!

How it all started

Rich McFall reached out to me in late 2019, seeking individuals who shared our vision of establishing a platform for discussion and collaboration on green PLM. He was drawn to my 2015 blog post, ‘PLM and Global Warming,’ which I wrote six months before the famous Paris Agreement.

Rich McFall reached out to me in late 2019, seeking individuals who shared our vision of establishing a platform for discussion and collaboration on green PLM. He was drawn to my 2015 blog post, ‘PLM and Global Warming,’ which I wrote six months before the famous Paris Agreement.

In my 2015 blog post, I drew a parallel between the slow response to digital transformation in the PLM domain and our collective inaction against climate change.

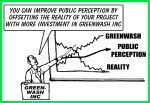

Despite the growing awareness of human-caused greenhouse gas emissions, there needed to be more urgency. This post was a call to action, not just for digital transformation in the PLM domain, but for our planet’s future. The cartoon below illustrates this mindset:

Both Rich and I felt that, when possible, we should use our energy and PLM-related skills to bring together a community of people who would take Climate Change and Sustainability seriously.

Rich’s focus was primarily on Climate Change and Greenhouse Gas emissions. – a hot topic in the US, where my passion and interest were related to Sustainability and the Circular Economy – two overlapping topics with a different impact, both parts of the UN Sustainable Development Goals (SDG) as formulated and adopted by all United Nations Member States in 2015.

Rich’s focus was primarily on Climate Change and Greenhouse Gas emissions. – a hot topic in the US, where my passion and interest were related to Sustainability and the Circular Economy – two overlapping topics with a different impact, both parts of the UN Sustainable Development Goals (SDG) as formulated and adopted by all United Nations Member States in 2015.

“Climate change creates fear and polarization, whereas the Circular Economy is more of a long-term concept, more complex to grasp, or implement, however crucial for the future of the planet.”

The start in 2020

When we started in early 2020, a few people were interested in contributing to the alliance—their names are at the bottom of this post. After several internal Zoom meetings, we decided to focus on different Green areas.

When we started in early 2020, a few people were interested in contributing to the alliance—their names are at the bottom of this post. After several internal Zoom meetings, we decided to focus on different Green areas.

The themes are available here: PLM Green Themes, i.e., Sustainability, the Circular Economy, Climate Change, Green Energy and Life Cycle Assessment.

In the beginning, the alliance was a small group of enthusiastic people supported by approximately 100 members in our LinkedIn group. As an organization of volunteers, we struggled with allocating time and resources to get the needed attention. In 2020, climate change and Sustainability were still niche topics in the PLM domain, and our audience was still small.

In the beginning, the alliance was a small group of enthusiastic people supported by approximately 100 members in our LinkedIn group. As an organization of volunteers, we struggled with allocating time and resources to get the needed attention. In 2020, climate change and Sustainability were still niche topics in the PLM domain, and our audience was still small.

Our interactive medium was the LinkedIn group, where comments and likes were easily shared. Our PLM Green Global Alliance website would be the place where we consolidate information—a challenging approach for us with limited skills and budget.

Starting the interviews in 2022

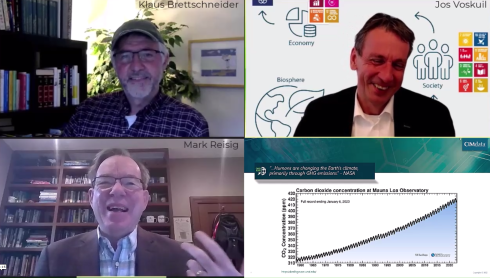

In 2022, we started interviewing PLM-related software vendors. Together with Klaus Brettschneider and, more recently, Mark Reisig, we were happy to discover what the major players in our PLM ecosystem were doing regarding Sustainability.

We spoke with SAP (Feb 2022 – Circular Economy), Autodesk (March 2020 – empowering engineers), Dassault Systemes (May 2022 – company targets & Virtual Twin), Sustaira (Sept 2022 – Connecting the dots – ESG reporting) and Aras (Oct 2022 – the need for a digital thread)

2023 – A year of transition

Besides the software vendors, consultancy firms started to address the need for more sustainable product development and understanding of what to do, and we spoke with CIMdata (April 2023 – the importance of sustainable business models) and Transition Technologies PSC (October 2023 – their GreenPLM offering on top of the PTC PLM suite)

However, as a PLM Green Global Alliance, we discovered that more and more companies were considering moving away from greenwashing and toward implementing actual measures, some of them driven by upcoming regulations and country initiatives.

However, as a PLM Green Global Alliance, we discovered that more and more companies were considering moving away from greenwashing and toward implementing actual measures, some of them driven by upcoming regulations and country initiatives.

It was also a significant year for the PLM Green Global Alliance, as besides receiving increasingly encouraging messages, both CIMdata and CIMPA joined the alliance as moderators.

![]() CIMdata, well known for its PLM consultancy and market analysis, started an additional consultancy practice related to PLM and Sustainability.

CIMdata, well known for its PLM consultancy and market analysis, started an additional consultancy practice related to PLM and Sustainability.

Mark Reisig, their lead consultant, joined us on the themes of Sustainability and Energy, also given his previous work career in that field.

CIMPA, a European PLM consultancy services company with roots in the aerospace industry, decided to support the alliance on the theme of the circular economy. Patrice Quencez and his team lead and moderate this activity.

CIMPA, a European PLM consultancy services company with roots in the aerospace industry, decided to support the alliance on the theme of the circular economy. Patrice Quencez and his team lead and moderate this activity.

Green in 2024 – what can we do?

Fear or Optimism? Fast and Slow!

One of the negative characteristics of the human mind is that we only want to act if it is indispensable. The brain’s evolutionary characteristic is to use the maximum amount of energy when there is a dangerous situation that forces us to act.

One of the negative characteristics of the human mind is that we only want to act if it is indispensable. The brain’s evolutionary characteristic is to use the maximum amount of energy when there is a dangerous situation that forces us to act.

There is enough proof for this theory, and it is the main reason why we continue bad habits. The best book to recommend is Thinking Fast and Slow by Daniel Kahneman.

Ask yourself:

- Should you study for the whole year or just before the exams?

- Would you start smoking knowing it is likely killing you in the long term?

- Would you save money for later, as then you might need it?

- Would you spend hours/days mastering a topic, or would you be an expert on social media with some easy facts and statistics?

- Would you act against climate change and overconsumption, knowing the reasons?

All the above questions illustrate that the majority of us (me too – there are no saints anymore) think fast, and media and marketing organizations know our weaknesses.

The result: we only get attention when there is a message of fear

The result: we only get attention when there is a message of fear

An explanation of why good news channels have no subscribers, whereas bad/fake news and polarising messages create an emotion to act.

In our PLM Green Alliance Group, Rich started with a monthly news digest related to Climate change. In the beginning, it felt like only bad news and the climate changes and disasters were showing us the urgency to handle. Read the last Climate Change Chronicles here.

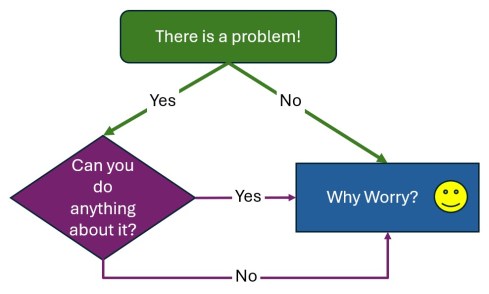

Bad news and fear might paralyze people. You might think the topic is too big for me to handle; therefore, let’s do nothing. Do you remember the diagram below?

Fortunately, many people believe that something needs to be done.

A recent UNDP survey shows that 80 percent of people globally want more decisive government climate action. Read the news here, and if you are interested in how your country compares to the rest of the world, check it here.

A recent UNDP survey shows that 80 percent of people globally want more decisive government climate action. Read the news here, and if you are interested in how your country compares to the rest of the world, check it here.

The good news is that the majority supports measures; the bad news is that the minority is the most vocal and influential by having the means and motives not to change the current status quo. And they have been organizing themselves for years.

Therefore, there is some optimism – we need to organize!

Looking back, particularly over the last 1½ years, there are reasons for optimism. Progress might not go as fast as desired, but if you are open to action and your newsfeed algorithm is also switched to positive, you will find encouraging messages.

For example, follow Assaad Razouk; his posts are often encouraging – not creating rage.

Read the monthly ESG Newsletters published by Vincent de la Mar from Sustaira and discover the positive trend. You can find his latest May newsletter here as an example: Sustainability & ESG Insights May ’24: Biden’s carbon market plans & how to get back on track to Paris Targets.

Following the progress within Europe – after the European Green Deal with all its aspects, recently, the Nature Restoration Law was signed, pushing companies to use more generative resources. The Nature Restoration Law and the European Green Deal are regulations pushing for a more circular economy as both the left side (regenerative) and right side (hardware) of the famous butterfly are addressed.

Conclusion

We are making progress, and I hope this post makes you realize that you need to worry about climate change and the Sustainability of our planet. My passion, and the passion of all the people listed below, is to support a movement and not to be silent.

Now, I am asking you to share your story. Which topics do we need to address first? Can you share examples or facts that illustrate—that with 1200 members, we should not be part of the silent majority but become a respected voice?

We’d like to express our exceptional gratitude to all those who supported us or are still supporting us at any stage of our PLM Green Global Alliance. Feel motivated to join this group of the non-silent majority.

In an alfabetical order: Xavier Adam, Zoe Bezpalko, Tom Boudeville, Klaus Brettschneider, Nina Dar, Stephane Declee, Dave Duncan, Stephan Fester, Bjorn Fidjeland, Ryan Flavelle, Matthias Fohrer, Roger L. Franz, Lionel Grealou, Jon den Hartog, Patrick Hilberg, Yousef Hooshmand, Hannes Lindfred, Ilan Madjar, Vincent de la Mar, James Norman, Rich McFall, Frank Popielas, Patrice Quencez, Mark Reisig, Audrey Reyniers, Erik Rieger, Ryan Rochelle, Mark Rushton, Neil D’Souza, Jonathan Thery, Oleg Shilovitsky, Florence Verzelen, Darren West ,Patrick Willemsen, Rafał Witkowski, Morgan Zimmermann.

Our recent interviews this year with aPriori and SAP were with companies that had less of a focus on the traditional product design process and more of a focus on the (circular) manufacturing process. In these interviews the importance of working with connected data was discussed in a shared (digital) thread.

Our recent interviews this year with aPriori and SAP were with companies that had less of a focus on the traditional product design process and more of a focus on the (circular) manufacturing process. In these interviews the importance of working with connected data was discussed in a shared (digital) thread.

This time, we, Mark Reisig and Jos Voskuil, were excited to talk with Siemens, not only a well-known PLM vendor but also a manufacturer of products and, therefore, having a close understanding of what is needed and can be achieved with their software solutions.

Siemens

![]() As Siemens is such a broad enterprise; we were happy to speak with Ryan R. Rochelle, who focuses on Sustainable Production, Sustainable Manufacturing and Sustainable Industry within Siemens . In the interview we discussed the importance of digital twins and the feedback loops between design and manufacturing. Despite some flaws in the network connection, we are happy to share an informative interview.

As Siemens is such a broad enterprise; we were happy to speak with Ryan R. Rochelle, who focuses on Sustainable Production, Sustainable Manufacturing and Sustainable Industry within Siemens . In the interview we discussed the importance of digital twins and the feedback loops between design and manufacturing. Despite some flaws in the network connection, we are happy to share an informative interview.

Enjoy listening and watching the next 33 minutes, talking with Ryan Rochelle.

You can download the images shown during the interview HERE

What I have learned

- Like all PLM vendors in this domain, Siemens talks about the importance of a circular economy and the need for digital threads and digital twins, confirming the need for all of us to invest in the digitization of the product lifecycle.

- Siemens is in a unique position as both the industrial user and software provider of its PLM suite, therefore having a unique feedback loop on the usability and applicability of its software in its industry.

- In the area of sustainability, they learn from both customers and internal customers. They are customer zero. Here, they observe shifting in engineering activities to the left” to optimize processes, supply chain and manufacturing earlier . (<<PGGA>>: which aligns with our aPriori and Makersite interviews).

- Siemens, SiGreen’s solution is an example of this unique position, being be able to track the carbon footprint of products across the supply chain.

Want to learn more

- There is the Siemens Sustainable industries website

- How the Digital Enterprise helps attain sustainability

- The Journey to a Sustainability Lighthouse awarded by the World Economic Forum

Conclusion

We have been discussing the relationship between PLM and sustainability with relevant software vendors for over two years now. As we saw initially in 2022, a few companies were exploring the possibilities.

Now, with further regulations and advanced software capabilities, companies are starting to implement new capabilities to make their product development process and products more sustainable. Siemens, as a software provider and an industrial user of its tools, is leading this journey—is it time for your company to step up, too?

We are happy to start the year with the next round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability. This year, we will speak with some new companies, and we will also revisit some of our previous guests to learn about their progress.

We are happy to start the year with the next round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability. This year, we will speak with some new companies, and we will also revisit some of our previous guests to learn about their progress.

Where we talked with Aras, Autodesk, CIMdata, Dassault Systèmes, PTC, SAP, Sustaira and Transition Technologies PSC, there are still a lot of software companies with an exciting portfolio related to sustainability.

Therefore, we are happy to talk this time with Makersite, a company whose AI-powered Product Lifecycle Intelligence software, according to their home page, brings together your cost, environment, compliance, and risk data in one place to make smarter, greener decisions powered by the deepest understanding of your supply chain. Let’s explore

Makersite

![]() We were lucky to have a stimulating discussion with Neil D’Souza, Makersite’s CEO and founder, who was active in the field of sustainability for almost twenty years, even before it became a cool (or disputed) profession.

We were lucky to have a stimulating discussion with Neil D’Souza, Makersite’s CEO and founder, who was active in the field of sustainability for almost twenty years, even before it became a cool (or disputed) profession.

It was an exciting dialogue where we enjoyed realistic answers without all the buzzwords and marketing terms often used in the new domain of sustainability. Enjoy the 39 minutes of interaction below:

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- Makersite’s mission, to enable manufacturers to make better products, faster, initially applied to economic parameters, can be easily extended with sustainability parameters.The power of Makersite is that it connects to enterprise systems and sources using AI, Machine Learning and algorithms to support reporting views on compliance, sustainability, costs and risk.

- Compliance and sustainability are the areas where I see a significant need for companies to invest. It is not a revolutionary business change but an extension of scope.We discussed this in the context of the stage-gate process, where sustainability parameters should be added at each gate.

- Neil has an exciting podcast, Five Lifes to Fifty, where he discusses the path to sustainable products with co-hosts Shelley Metcalfe and Jim Fava, and recently, they discussed sustainability in the context of the stage-gate process.

- Again, to move forward with sustainability, it is about creating the base and caring about the data internally to understand what’s happening, and from there, enable value engineering, including your supplier where possible (IP protection remains a topic) – confirming digital transformation (the connected way of working) is needed for business and sustainability.

Want to learn more?

Here are some links to the topics discussed in our meeting:

- The Website – Makersite.io

- Makersite data foundation – makersite-data-foundation

- Makersite demo video – makersite-platform-demo

- Neil’s LinkedIn – neilsaviodsouza

Conclusions

With Makersite, we discovered an experienced company that used its experience in cost, compliance and risk analysis, including supply chains, to extend it to the domain of sustainability. As their technology partners page shows, they can be complementary in many industries and enterprises.

We will see another complementary solution soon in our following interview. Stay tuned.

Another year passed, and as usual, I took the time to look back. I always feel that things are going so much slower than expected. But that’s reality – there is always friction, and in particular, in the PLM domain, there is so much legacy we cannot leave behind.

Another year passed, and as usual, I took the time to look back. I always feel that things are going so much slower than expected. But that’s reality – there is always friction, and in particular, in the PLM domain, there is so much legacy we cannot leave behind.

It is better to plan what we can do in 2024 to be prepared for the next steps or, if lucky, even implement the next steps in progress.

In this post, I will discuss four significant areas of attention (AI – DATA – PEOPLE – SUSTAINABILITY) in an alphabetic order, not prioritized.

Here are some initial thoughts. In the upcoming weeks I will elaborate further on them and look forward to your input.

AI (Artificial Intelligence)

![]() Where would I be without talking about AI?

Where would I be without talking about AI?

When you look at the image below, the Gartner Hype Cycle for AI in 2023, you see the potential coming on the left, with Generative AI at the peak.

Part of the hype comes from the availability of generative AI tools in the public domain, allowing everyone to play with them or use them. Some barriers are gone, but what does it mean? Many AI tools can make our lives easier, and there is for sure no threat if our job does not depend on standard practices.

AI and People

When I was teaching physics in high school, it was during the introduction of the pocket calculator, which replaced the slide rule.You need to be skilled to uyse the slide rule, now there was a device that gave immediate answers. Was this bad for the pupils?

When I was teaching physics in high school, it was during the introduction of the pocket calculator, which replaced the slide rule.You need to be skilled to uyse the slide rule, now there was a device that gave immediate answers. Was this bad for the pupils?

If you do not know a slide rule, it was en example of new technology replacing old tools, providing more time for other details. Click on the image or read more about the slide rule here on Wiki.

![]() Or today you would ask the question about the slide rule to ChatGPT? Does generative AI mean the end of Wikipedia? Or does generative AI need the common knowledge of sites like Wikipedia?

Or today you would ask the question about the slide rule to ChatGPT? Does generative AI mean the end of Wikipedia? Or does generative AI need the common knowledge of sites like Wikipedia?

AI can empower people in legacy environments, when working with disconnected systems. AI will be a threat for to people and companies that rely on people and processes to bring information together without adding value. These activities will disappear soon and you must consider using this innovative approach.

During the recent holiday period, there was an interesting discussion about why companies are reluctant to change and implement better solution concepts. Initially launched by Alex Bruskin here on LinkedIn , the debate spilled over into the topic of TECHNICAL DEBT , well addressed here by Lionel Grealou.

During the recent holiday period, there was an interesting discussion about why companies are reluctant to change and implement better solution concepts. Initially launched by Alex Bruskin here on LinkedIn , the debate spilled over into the topic of TECHNICAL DEBT , well addressed here by Lionel Grealou.

![]() Both articles and the related discussion in the comments are recommended to follow and learn.

Both articles and the related discussion in the comments are recommended to follow and learn.

AI and Sustainability

![]() Similar to the introduction of Bitcoin using blockchain technology, some people are warning about the vast energy consumption required for training and interaction with Large Language Models (LLM), as Sasha Luccioni explains in her interesting TED talk when addressing sustainability.

Similar to the introduction of Bitcoin using blockchain technology, some people are warning about the vast energy consumption required for training and interaction with Large Language Models (LLM), as Sasha Luccioni explains in her interesting TED talk when addressing sustainability.

She proposes that tech companies should be more transparent on this topic, the size and the type of the LLM matters, as the indicative picture below illustrates.

Carbon Emissions of LLMs compared

In addition, I found an interesting article discussing the pros and cons of AI related to Sustainability. The image below from the article Risks and Benefits of Large Language Models for the Environment illustrates nicely that we must start discussing and balancing these topics.

![]() To conclude, in discussing AI related to sustainability, I see the significant advantage of using generative AI for ESG reporting.

To conclude, in discussing AI related to sustainability, I see the significant advantage of using generative AI for ESG reporting.

ESG reporting is currently a very fragmented activity for organizations, based on (marketing) people’s goodwill and currently these reports are not always be evidence-based.

Data

The transformation from a coordinated, document-driven enterprise towards a hybrid coordinated/connected enterprise using a data-driven approach became increasingly visible in 2023. I expect this transformation to grow faster in 2024 – the momentum is here.

The transformation from a coordinated, document-driven enterprise towards a hybrid coordinated/connected enterprise using a data-driven approach became increasingly visible in 2023. I expect this transformation to grow faster in 2024 – the momentum is here.

We saw last year that the discussions related to Federated PLM nicely converged at the PLM Roadmap / PDT Europe conference in Paris. I shared most of the topics in this post: The week after PLM Roadmap / PDT Europe 2023. In addition, there is now the Heliple Federated PLM LinkedIn group with regular discussions planned.

We saw last year that the discussions related to Federated PLM nicely converged at the PLM Roadmap / PDT Europe conference in Paris. I shared most of the topics in this post: The week after PLM Roadmap / PDT Europe 2023. In addition, there is now the Heliple Federated PLM LinkedIn group with regular discussions planned.

In addition, if you read here Jan Bosch’s reflection on 2023, he mentions (quote):

… 2023 was the year where many of the companies in the center became serious about the use of data. Whether it is historical analysis, high-frequency data collection during R&D, A/B testing or data pipelines, I notice a remarkable shift from a focus on software to a focus on data. The notion of data as a product, for now predominantly for internal use, is increasingly strong in the companies we work with

I am a big fan of Jan’s posting; coming from the software world, he describes the same issues that we have in the PLM world, except he does not carry the hardware legacy that much and, therefore, acts faster than us in the PLM world.

I am a big fan of Jan’s posting; coming from the software world, he describes the same issues that we have in the PLM world, except he does not carry the hardware legacy that much and, therefore, acts faster than us in the PLM world.

An interesting illustration of the slow pace to a data-driven environment is the revival of the PLM and ERP integration discussion. Prof. Jörg Fischer and Martin Eigner contributed to the broader debate of a modern enterprise infrastructure, not based on systems (PLM, ERP, MES, ….) but more on the flow of data through the lifecycle and an organization.

It is a great restart of the debate, showing we should care more about data semantics and the flow of information.

The articles: The Future of PLM & ERP: Bridging the Gap. An Epic Battle of Opinions! and Is part master in PLM and ERP equal or not) combined with the comments to these posts, are a must read to follow this change towards a more connected flow of information.

While writing this post, Andreas Lindenthal expanded the discussion with his post: PLM and Configuration Management Best Practices: Part Traceability and Revisions. Again thanks to data-driven approaches, there is an extending support for the entire product lifecycle. Product Lifecycle Management, Configuration Management and AIM (Asset Information Management) have come together.

![]() PLM and CM are more and more overlapping as I discussed some time ago with Martijn Dullaart, Maxime Gravel and Lisa Fenwick in the The future of Configuration Management. This topic will be “hot”in 2024.

PLM and CM are more and more overlapping as I discussed some time ago with Martijn Dullaart, Maxime Gravel and Lisa Fenwick in the The future of Configuration Management. This topic will be “hot”in 2024.

People

From the people’s perspective towards AI, DATA and SUSTAINABILITY, there is a noticeable divide between generations. Of course, for the sake of the article, I am generalizing, assuming most people do not like to change their habits or want to reprogram themselves.

From the people’s perspective towards AI, DATA and SUSTAINABILITY, there is a noticeable divide between generations. Of course, for the sake of the article, I am generalizing, assuming most people do not like to change their habits or want to reprogram themselves.

Unfortunate, we have to adapt our skills as our environment is changing. Most of my generation was brought up with the single source of truth idea, documented and supported by science papers.

In my terminology, information processing takes place in our head by combining all the information we learned or collected through documents/books/newspapers – the coordinated approach.

For people living in this mindset, AI can become a significant threat, as their brain is no longer needed to make a judgment, and they are not used to differentiate between facts and fake news as they were never trained to do so

For people living in this mindset, AI can become a significant threat, as their brain is no longer needed to make a judgment, and they are not used to differentiate between facts and fake news as they were never trained to do so

The same is valid for practices like the model-based approach, working data-centric, or considering sustainability. It is not in the DNA of the older generations and, therefore, hard to change.

The older generation is mostly part of an organization’s higher management, so we are returning to the technical debt discussion.

Later generations that grew up as digital natives are used to almost real-time interaction, and when applied consistently in a digital enterprise, people will benefit from the information available to them in a rich context – in my terminology – the connected approach.

AI is a blessing for people living in this mindset as they do not need to use old-fashioned methods to acquire information.

AI is a blessing for people living in this mindset as they do not need to use old-fashioned methods to acquire information.

“Let ChatGPT write my essay.”

However, their challenge could be what I would call “processing time”. Because data is available, it does not necessarily mean it is the correct information. For that reason it remains important to spend time digesting the impact of information you are reading – don’t click “Like”based on the tittle, read the full article and then decide.

Experience is what you get, when you don’t get what you expect.

meaning you only become experienced if you learn from failures.

Sustainability

Unfortunately, sustainability is not only the last topic in alphabetic order, as when you look at the image below, you see that discussions related to sustainability are in a slight decline at C-level at the moment.

Unfortunately, sustainability is not only the last topic in alphabetic order, as when you look at the image below, you see that discussions related to sustainability are in a slight decline at C-level at the moment.

I share this observation in my engagements when discussing sustainability with the companies I interact with.

The PLM software and services providers are all on a trajectory of providing tools and an infrastructure to support a transition to a more circular economy and better traceability of materials and carbon emissions.

The PLM software and services providers are all on a trajectory of providing tools and an infrastructure to support a transition to a more circular economy and better traceability of materials and carbon emissions.

In the PLM Global Green Alliance, we talked with Aras, Autodesk, Dassault Systems, PTC, SAP, Sustaira, TTPSC(Green PLM) and more to come in 2024. The solution offerings in the PLM domain are available to start, now the people and processes.

For sure, AI tools will help companies to get a better understanding of their sustainability efforts. As mentioned before AI could help companies in understanding their environmental impact and build more accurate ESG reports.

Next, being DATA-driven will be crucial. As discussed during the latest PLM Roadmap/PDT Europe conference: The Need for a Governance Digital Thread.

And regarding PEOPLE, the good news is that younger generations want to take care of their future. They are in a position to choose the company to work for or influence companies by their consumer behavior. Unfortunately, climate disasters will remind us continuously in the upcoming decades that we are in a critical phase.

With the PLM Global Green Alliance, we strive to bring people together with a PLM mindset, sharing news and information on how to move forward to a sustainable future.

![]() Mark Reisig (CIMdata – moderator for Sustainability & Energy) and Patrice Quencez (CIMPA – moderator for the Circular Economy) joined the PGGA last year and you will experience their inputs this year.

Mark Reisig (CIMdata – moderator for Sustainability & Energy) and Patrice Quencez (CIMPA – moderator for the Circular Economy) joined the PGGA last year and you will experience their inputs this year.

Conclusion

As you can see from this long post, there is so much to learn. The topics described are all actual, and each topic requires education, experience (success & failures) combined with understanding of the technology concepts. Make sure you consider all of them, as focusing on a single topic will not make move faster forward – they are all related. Please share your experiences this year—Happy New Year of Learning.

It might have been silent in the series of PLM and Sustainability … interviews where we as PLM Green Global Alliance core team members, talk with software vendors, implementers and consultants and their relation to PLM and sustainability. The interviews are still in a stage of exploring what is happening at this moment. More details per vendor or service provider next year.

It might have been silent in the series of PLM and Sustainability … interviews where we as PLM Green Global Alliance core team members, talk with software vendors, implementers and consultants and their relation to PLM and sustainability. The interviews are still in a stage of exploring what is happening at this moment. More details per vendor or service provider next year.

Our last interview was in April this year when we spoke with Mark Reisig, Green Energy Practice Director & Executive Consultant at CIMdata. You can find the interview here, and at that time, I mentioned the good news is that sustainability is no longer a software discussion.

As companies are planning or pushed by regulations to implement sustainable strategies, it becomes clear that education and guidance are needed beyond the tools.

This trend is also noticeable in our PLM Green Global Alliance community, which has grown significantly in the past half year. While writing this post, we have 862 members, not all as active as we hoped. Still, there is more good news related to dedicated contributors and more to come in the next PGGA update.

This time, we want to share the interview with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services.

This time, we want to share the interview with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services.

I met them during the LiveWorx conference in Boston in May – you can read more about the conference in my post: The weekend after LiveWorx 2023. Here we decided to follow-up on GreenPLM/

GreenPLM

![]() The label “GreenPLM” is always challenging as it could be considered green-washing. However, in this case, GreenPLM is an additional software offering that can be implemented on top of a PLM system, enabling people to make scientifically informed decisions for a more sustainable, greener product.

The label “GreenPLM” is always challenging as it could be considered green-washing. However, in this case, GreenPLM is an additional software offering that can be implemented on top of a PLM system, enabling people to make scientifically informed decisions for a more sustainable, greener product.

For GreenPLM, Rafal’s and Erik’s experiences are based on implementing GreenPLM on top of the PTC Windchill suite. Listen for the next 34 minutes to an educative session and learn.

You can download the slides shown in the recording here.

What I learned

- It was more a general educative session related to the relation PLM and Sustainability, focusing on the importance of design decisions – the 80 % impact number.

- Erik considers sustainability not a disruption for designers; they already work within cost, quality and time parameters. Now, sustainability is the fourth dimension to consider.

- Erik’s opinion is also reflected in the pragmatic approach of GreenPLM as an additional extension of Windchill using PTC Navigate and OSLC standards.

- GreenPLM is more design-oriented than Mendix-based Sustaira, a sustainability platform we discussed in this series – you can find the recording here.

Want to learn more?

Here are some links related to the topics discussed in our meeting:

Conclusions

With GreenPLM, it is clear that the focus of design for sustainability is changing from a vision (led by software vendors and environmental regulations) towards implementations in the field. Pragmatic and an extension of the current PLM infrastructure. System integrators like Transition Technologies are the required bridge between vision and realization. We are looking for more examples from the field.

Two more weeks to go – don’t miss this opportunity when you are in Europe

Click on the image to see the full and interesting agenda/

During May and June, I wrote a guest chapter for the next edition of John Stark’s book Product Lifecycle Management (Volume 2): The Devil is in the Details.

During May and June, I wrote a guest chapter for the next edition of John Stark’s book Product Lifecycle Management (Volume 2): The Devil is in the Details.

The book is considered a standard in the academic world when studying aspects of PLM.

Looking into the table of contents through the above link, it shows that understanding PLM in its full scope is broad. I wrote about it recently: PLM is Complex (and we have to accept it?), and Roger Tempest and others are still fighting to get the job as PLM Professional recognized Associate Yourself With Professional PLM.

To make the scope broader, John invited me to write a chapter about PLM and Sustainability, which is an actual topic in many organizations. As sustainability is my dedicated topic in the PLM Global Green Alliance (PGGA) core team, I was happy to accept this challenge.

To make the scope broader, John invited me to write a chapter about PLM and Sustainability, which is an actual topic in many organizations. As sustainability is my dedicated topic in the PLM Global Green Alliance (PGGA) core team, I was happy to accept this challenge.

This activity is challenging because writing a chapter on a current topic might make it outdated soon. For the same reason, I never wanted to write a PLM book as I wrote in my 2014 post: Did you notice PLM is changing?

The book, with the additional chapter, will be available later this year. I want to share with you in this post the topics I addressed in this chapter. Perhaps relevant for your organization or personal interests. Also, I am looking forward to learning if I missed any topics.

The book, with the additional chapter, will be available later this year. I want to share with you in this post the topics I addressed in this chapter. Perhaps relevant for your organization or personal interests. Also, I am looking forward to learning if I missed any topics.

Introduction

The chapter starts with defining the context. PLM is considered a strategy supported by a connected IT infrastructure, and for the definition of sustainability, I refer to the relevant SDGs as described on our PGGA theme page: PLM and Sustainability

Next, I discuss two major concepts indissoluble connected with sustainability.

The Circular Economy

On a planet with limited resources and still a growing consumption of raw materials, we need to follow the concepts of the circular economy in our businesses and lives. The circular economy section addresses mainly the hardware side of the butterfly as, here, PLM practices have the most significant impact.

The circular economy requires collaboration among various stakeholders, including businesses, governments and consumers. It involves rethinking production processes and establishing new consumption patterns. Policies and regulations will push for circular economy patterns, as seen in the following paragraphs.

Systems Thinking

A significant change in bringing products to the market will be the need to change how we look at our development processes. Historically, many of these processes were linear and only focused on time to market, cost and quality. Now, we have to look into other dimensions, like environmental impact, usage and impact on the planet. As I wrote in the past Systems Thinking – a must-have skill in the 21st century?

Systems Thinking is a cognitive approach that emphasizes understanding complex problems by considering interconnections, feedback loops, and emergent properties. It provides a holistic perspective and explores multiple viewpoints.

Systems Thinking guides problem-solving and decision-making and requires you to treat a solution with a mindset of a system interacting with other systems.

Regulations

More sustainable products and services will be driven primarily by existing and upcoming regulations. In this section, I refer to the success of the CFC (ChloroFluorCarbon) emission reduction, leading to slowly fixing the hole in the Ozon layer. Current regulations like WEEE, RoHS and REACH are already relevant for many companies, and compliance with these regulations is a good exercise for more stringent regulations related to Carbon emissions and upcoming related to the Digital Product Passport.

Making regulatory compliance a part of the concept phase ensures no late changes are needed to become compliant, saving time and costs. In addition, making regulatory compliance as much as possible with a data-driven approach reduces the overhead required to prove regulatory compliance. Both topics are part of a PLM strategy.

![]() In this context, see Lionel Grealou’s article 5 Brand Value Benefits at the Intersection of Sustainability and Product Compliance. The article has also been shared in our PGGA LinkedIn group.

In this context, see Lionel Grealou’s article 5 Brand Value Benefits at the Intersection of Sustainability and Product Compliance. The article has also been shared in our PGGA LinkedIn group.

Business

On the business side, the Greenhouse Gas Protocol is explained. How companies will have to report their Scope 1 and Scope 2 emissions and, ultimately, Scope 3 – see the image below for the details.

GHG reporting will support companies, investors and consumers to decide where to prioritize and put their money.

Ultimately, companies have to be profitable to survive in their business. The ESG framework is relevant in this context as it will allow investors to put their money not only based on short-term gains (as expected) but also on Environmental or Social parameters. There are a lot of discussions related to the ESG framework, as you might have read in Vincent de la Mar’s monthly newsletter, Sustainability & ESG Insights, which is also published in our PGGA group – a link below..

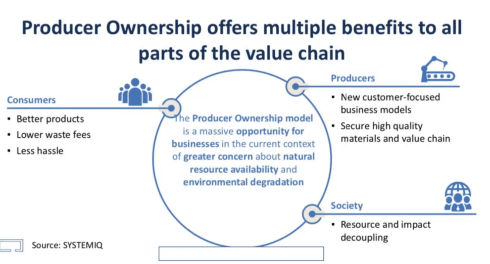

Besides ESG guidelines, there is also the drive by governments and consumers to push for a Product as a Service economy. Instead of owning products, consumers would pay for the usage of these products.

The concept is not new when considering lease cars, EV scooters, or streaming services like Spotify and Netflix. In the CIMdata PLM Roadmap/PDT Fall 2021 conference, we heard Kenn Webster explaining: In the future, you will own nothing & you will be happy.

Changing the business to a Product as a Service is not something done overnight. It requires repairable, upgradeable products. And business related, it requires a connected ecosystem of all stakeholders – the manufacturer, the finance company, and the operating entities.

Digital Transformation

All the subjects discussed before require real-time reporting and analysis combined with data access to compliance-related databases. More in the section related to Life Cycle Assessment. As I discussed last year in several conferences, a sustainability initiative starts with data-driven and model-based approaches during the concept phase, but when manufacturing and operating (connected) products in the field. You can read the entire story here: Sustainability and Data-Driven PLM – the Perfect Storm.

Life Cycle Analysis

Special attention is given in this chapter to Life Cycle Analysis, which seems to be a popular topic among PLM vendors. Here, they can provide tools to make a lifecycle assessment, and you can read an impression of these tools in a guest blog from Roger L. Franz titled PLM Tools to Design for Sustainability – PLM Green Global Alliance.

However, Lifecycle Analysis is not as simple. Looking at the ISO 14040 framework, which describes – having the right goals and scope in mind, allows you to do an LCA where the Product Category Rules (PCS) will enable companies to compare their products with others.

PCRs include the description of the product category, the goal of the LCA, functional units, system boundaries, cut-off criteria, allocation rules, impact categories, information on the use phase, units, calculation procedures, requirements for data quality, and other information on the lifecycle Inventory Phase.

So be aware there is more to do than installing a tool.

Digital Twin

This section describes the importance of implementing a digital twin for the design phase, allowing companies to develop, test and analyze their products and services first virtually. Trade-off studies on virtual products are much cheaper, and when they are done in a data-driven, model-based environment, it will be the most efficient environment. In my terminology, setting up such a collaboration environment might be considered a System of Engagement.

This section describes the importance of implementing a digital twin for the design phase, allowing companies to develop, test and analyze their products and services first virtually. Trade-off studies on virtual products are much cheaper, and when they are done in a data-driven, model-based environment, it will be the most efficient environment. In my terminology, setting up such a collaboration environment might be considered a System of Engagement.

The second crucial digital twin mentioned is the digital twin from a product in operation where performance can be monitored and usage can be optimized for a minimal environmental impact. Suppose a company is able to create a feedback loop between its products in the field and its product innovation platform. In that case, it can benchmark its design models and update the product behavior for better performance.

The manufacturing digital twin is also discussed in the context of environmental impact, as choosing the right processes and resources can significantly affect scope 3 emissions.

The chapter finishes with the story of a fictive company, WePack, where we can follow the impact and implementations of the topics described in this chapter.

Conclusion

As I described in the introduction, the topic of PLM and Sustainability is relatively new and constantly evolving. What do you think? Did I miss any dimensions?

Feel free to contribute to our PLM Global Green Alliance LinkedIn group.

Last week I enjoyed visiting LiveWorx 2023 on behalf of the PLM Global Green Alliance. PTC had invited us to understand their sustainability ambitions and meet with the relevant people from PTC, partners, customers and several of my analyst friends. It felt like a reunion.

Last week I enjoyed visiting LiveWorx 2023 on behalf of the PLM Global Green Alliance. PTC had invited us to understand their sustainability ambitions and meet with the relevant people from PTC, partners, customers and several of my analyst friends. It felt like a reunion.

In addition, I used the opportunity to understand better their Velocity SaaS offering with OnShape and Arena. The almost 4-days event, with approximately 5000 attendees, was massive and well-organized.

So many people were excited that this was again an in-person event after four years.

With PTC’s broad product portfolio, you could easily have a full agenda for the whole event, depending on your interests.

I was personally motivated that I had a relatively full schedule focusing purely on Sustainability, leaving all these other beautiful end-to-end concepts for another time.

Here are some of my observations

Jim Heppelman’s keynote

The primary presentation of such an event is the keynote from PTC’s CEO. This session allows you to understand the company’s key focus areas.

My takeaways:

- Need for Speed: Software-driven innovation, or as Jim said, Software is eating the BOM, reminding me of my recent blog post: The Rise and Fall of the BOM. Here Jim was referring to the integration with ALM (CodeBeamer) and IoT to have full traceability of products. However, including Software also requires agile ways of working.

- Need for Speed: Agile ways of working – the OnShape and Arena offerings are examples of agile working methods. A SaaS solution is easy to extend with suppliers or other stakeholders. PTC calls this their Velocity offering, typical Systems of Engagement, and I spoke later with people working on this topic. More in the future.

- Need for Speed: Model-based digital continuity – a theme I have discussed in my blog post too. Here Jim explains the interaction between Windchill and ServiceMax, both Systems of Record for product definition and Operation.

- Environmental Sustainability: introducing Catherine Kniker, PTC’s Chief Strategy and Sustainability Officer, announcing that PTC has committed to Science Based Targets, pledging near-term emissions reductions and long-term net-zero targets – see image below and more on Sustainability in the next section.

- A further investment in a SaaS architecture, announcing CREO+ as a SaaS solution supporting dynamic multi-user collaboration (a System of Engagement)

- A further investment in the partnership with Ansys fits the needs of a model-based future where modeling and simulation go hand in hand.

You can watch the full session Path to the Future: Products in the Age of Transformation here.

Sustainability

The PGGA spoke with Dave Duncan and James Norman last year about PTC’s sustainability initiatives. Remember: PLM and Sustainability: talking with PTC. Therefore, Klaus Brettschneider and I were happy to meet Dave and James in person just before the event and align on understanding what’s coming at PTC.

The PGGA spoke with Dave Duncan and James Norman last year about PTC’s sustainability initiatives. Remember: PLM and Sustainability: talking with PTC. Therefore, Klaus Brettschneider and I were happy to meet Dave and James in person just before the event and align on understanding what’s coming at PTC.

We agreed there is no “sustainability super app”; it is more about providing an open, digital infrastructure to connect data sources at any time of the product lifecycle, supporting decision-making and analysis. It is all about reliable data.

Product Sustainability 101

On Tuesday, Dave Duncan gave a great introductory session, Product Sustainability 101, addressing Business Drivers and Technical Opportunities. Dave started by explaining the business context aiming at greenhouse gas (GHG) reduction based on science-based targets, describing the content of Scope 1, Scope 2 and Scope 3 emissions.

The image above, which came back in several presentations later that week, nicely describes the mapping of lifecycle decisions and operations in the context of the GHG protocol.

Design for Sustainability (DfS)

On Wednesday, I started with a session moderated by James Norman titled Design for Sustainability: Harnessing Innovation for a Resilient Future. The panel consisted of Neil D’Souza (CEO Makersite), Tim Greiner (MD Pure Strategies), Francois Lamy (SVP Product Management PTC) and Asheen Phansey (Director ESG & Sustainability at PagerDuty). You can find the topic discussed below:

Some of the notes I took:

- No specific PLM modules are needed, LCA needs to become an additional practice for companies, and they rely on a connected infrastructure.

- Where to start? First, understand the current baseline based on data collection – what is your environmental impact? Next, decide where to start

- The importance of Design for Service – many companies design products for easy delivery, not for service. Being able to service products better will extend their lifetime, therefore reducing their environmental impact (manufacturing/decommissioning)

- There Is a value chain for carbon data. In addition, suppliers significantly impact reaching net zero, as many OEMs have an Assembly To Order process, and most of the emissions are done during part manufacturing.

DfS: an example from Cummins

Next, on Wednesday, I attended the session from David Genter from Cummins, who presented their Design for Sustainability (DfS) project.

Next, on Wednesday, I attended the session from David Genter from Cummins, who presented their Design for Sustainability (DfS) project.

Dave started by sharing their 2030 sustainability goals:

- On Facilities and Operations: A reduction of 50 % of GHG emissions, reducing water usage by 30 %, reducing waste by 25 % and reducing organic compound emissions by 50%

- Reducing Scope 3 emissions for new products by 25%

- In general, reducing Scope 3 emissions by 55M metric tons.

The benefits for products were documented using a standardized scorecard (example below) to ensure the benefits are real and not based on wishful thinking.

Many motivated people wanted to participate in the project, and the ultimate result demonstrated that DfS has both business value for Cummins and the environment.

The project has been very well described in this whitepaper: How Cummins Made Changes to Optimize Product Designs for the Environment – a recommended case study to read.

Tangible Strategies for Improving Product Sustainability

The session was a dialogue between Catherine Kniker and Dave Duncan, discussing the strategies to move forward with Sustainability.

They reiterated the three areas where we as a PLM community can improve: Material choice and usage, Addressing Energy Emissions and Reducing Waste. And it is worth addressing them all, as you can see below – it is not only about carbon reduction.

It was an informative dialogue going through the different aspects of where we, as an engineering/ PLM community, can contribute. You can watch their full dialog here: Tangible Strategies for Improving Product Sustainability.

Conclusion

It was encouraging to see that at such an event as LiveWorx, you could learn about Sustainability and discuss Sustainability with the audience and PTC partners. And as I mentioned before, we need to learn to measure (data-driven / reliable data), and we need to be able to work in a connected infrastructure (digital thread) to allow design, simulation, validation and feedback to go hand in hand. It requires adapting a business strategy, not just a tactical solution. With the PLM Global Green Alliance, we are looking forward to following up on these.

NOTE: PTC covered the expenses associated with my participation in this event but did not in any way influence the content of this post – I made my tour fully independent through the conference and got encouraged by all the conversations I had.

We are happy to start the year with the next PLM Global Green Alliances (PGGA) series round: PLM and Sustainability.

Last year we spoke mainly with the prominent PLM software editors (Aras, Autodesk, Dassault Systèmes, PTC, SAP) and Sustaira (Sustainability platform – Siemens partner).

This time we talked with Mark Reisig, Sustainability and Green Energy Practice Director & Executive Consultant from CIMdata. The good news is that discussing a PLM strategy and Sustainability is no longer a software discussion.

This time we talked with Mark Reisig, Sustainability and Green Energy Practice Director & Executive Consultant from CIMdata. The good news is that discussing a PLM strategy and Sustainability is no longer a software discussion.

With CIMdata’s sustainability offering introduced last year, it becomes clear that the topic of sustainability reached a broader level than the tools.

CIMdata

CIMdata is well known in the PLM domain, focusing on Market Analysis, Education, Research & Strategic Management Consulting, all related to PLM.

CIMdata is well known in the PLM domain, focusing on Market Analysis, Education, Research & Strategic Management Consulting, all related to PLM.

Last year, Mark joined CIMdata as Green Energy Practice Director & Executive Consultant. Listening to Mark, you will discover he has an exciting background, starting with the “Keeling Curve”, his early interest in oceanography and wind turbines, working with GE later in his career and many years active in the PLM domain.

Learn more from the 40 minutes discussion with Mark below.

You can download the slides shown during the recording HERE

What we have learned

CIMdata has been discussing and promoting a circular economy already for a long time. A sustainable future and a circular economy have been a theme in many of the PLM Roadmap & PDT conferences. It is a logical relation as implementing a circular strategy depends significantly on the product design approach.

CIMdata has been discussing and promoting a circular economy already for a long time. A sustainable future and a circular economy have been a theme in many of the PLM Roadmap & PDT conferences. It is a logical relation as implementing a circular strategy depends significantly on the product design approach. CIMdata also combines Sustainability with the need to digitize the processes and data handled. A data-driven approach will allow companies to measure (and estimate) better their environmental impact.

CIMdata also combines Sustainability with the need to digitize the processes and data handled. A data-driven approach will allow companies to measure (and estimate) better their environmental impact.- CIMdata believes sustainability must be embedded in PLM for companies to reduce their product carbon footprint, and they must have greater visibility into their supply chain.

Mark mentions that focusing on a sustainable business model (product & business) is crucial for survival in the upcoming years, and this has increasingly landed at the board level of companies.

Mark mentions that focusing on a sustainable business model (product & business) is crucial for survival in the upcoming years, and this has increasingly landed at the board level of companies.- The major change has to be driven by the business. PLM vendors will not drive the change; they will align their portfolio offerings based on the market needs.

- It was clear Mark has a lot of experience in wind energy throughout his whole lifecycle 😊

Want to learn more

Mark already pointed to several valuable resources in our discussion to learn more. Here are the most important links related to CIMdata

- Sustainability and Green Energy Consulting Practice

Recent webinar: The Green Energy Transition and Sustainability from January 23, 2023

Recent webinar: The Green Energy Transition and Sustainability from January 23, 2023- Upcoming webinar: Meeting Sustainability and Green Energy Transition Objectives: The Industrial Perspective, April 27, 2023, 11:00 AM EDT

Conclusions

Last year we discussed sustainability with the software vendors and their product offerings. They all mentioned the importance of a data-driven approach and education. CIMdata has broadened the available sustainability offering for companies by providing additional education and strategy support.

Education at all levels is essential to make sustainable decisions. Sustainable for the company’s business and, above all, sustainable for the planet.

I will be @Livework in Boston, aiming to discuss PLM and Sustainability on behalf of the PGGA with PTC thought leaders. Will you be there too?

![]() In this post, I want to explain why Model-Based Systems Engineering (MBSE) and Sustainability are closely connected. I would claim sustainability in our PLM domain will depend on MBSE.

In this post, I want to explain why Model-Based Systems Engineering (MBSE) and Sustainability are closely connected. I would claim sustainability in our PLM domain will depend on MBSE.

Can we achieve Sustainability without MBSE? Yes, but it will be costly and slow. And as all businesses want to be efficient and agile, they should consider MBSE.

What is MBSE?

The abbreviation MBSE stands for Model-Based Systems Engineering, a specialized manner to perform Systems Engineering. Look at the Wikipedia definition in short:

MBSE is a technical approach to systems engineering that focuses on creating and exploiting domain models as the primary means of information exchange rather than on document-based information exchange.

Model-Based fits in the digital transformation scope of PLM – from a document-based approach to a data-driven, model-based one. In 2018, I focused on facets of the model-based enterprise and related to MBSE in this post: Model-Based: System Engineering (MBSE).

My conclusion in that post was:

Model-Based Systems Engineering might have been considered as a discipline for the automotive and aerospace industry only. As products become more and more complex, thanks to IoT-based applications and software, companies should consider evaluating the value of model-based systems engineering for their products/systems.

I drew this conclusion before I focused on sustainability and systems thinking. Implementing sustainability concepts, like the Circular Economy, require more complex engineering efforts, justifying a Model-Based Systems Engineering approach. Let’s have a look.

If you want to learn more about why we need MBSE, look at this excellent keynote speech lecture from Zhang Xin Guo at the Incose 2018 conference below:

The Mission / the stakeholders

A company might deliver products to the market with the best price/quality ratio and regulatory compliance, perceived and checked by the market. This approach is purely focusing on economic parameters.

There is no need for a system engineering approach as the complexity is manageable. The mission is more linear, a “job to do,” and a limited number of stakeholders are involved in this process.

… with sustainability

Once we start to include sustainability in our product’s mission, we need a systems engineering approach, as several factors will push for different considerations. The most obvious considerations are the choice of materials and the optimizing the production process (reducing carbon emissions).

Once we start to include sustainability in our product’s mission, we need a systems engineering approach, as several factors will push for different considerations. The most obvious considerations are the choice of materials and the optimizing the production process (reducing carbon emissions).

However, the repairability/serviceability of the product should be considered with a more extended lifetime vision.

What about upgradeability and reusing components? Will the customer pay for these extra sustainable benefits?

Probably Yes, when your customer has a long-term vision, as the overall lifecycle costs of the product will be lower.

Probably Yes, when your customer has a long-term vision, as the overall lifecycle costs of the product will be lower.

Probably No if none of your competitors delivers non-sustainable products much cheaper.

As long as regulations will not hurt traditional business models, there might be no significant change.

However, the change has already started. Higher energy prices will impact the production of specific resources and raise costs. In addition, energy-intensive manufacturing processes will lead to more expensive materials. Combined with raising carbon taxes, this will be a significant driver for companies to reconsider their product offering and manufacturing processes.

However, the change has already started. Higher energy prices will impact the production of specific resources and raise costs. In addition, energy-intensive manufacturing processes will lead to more expensive materials. Combined with raising carbon taxes, this will be a significant driver for companies to reconsider their product offering and manufacturing processes.

The more expensive it becomes to create new products, the more attractive repairable and upgradable products will become. And this brings us to the concept of the circular economy, which is one of the pillars of sustainability.

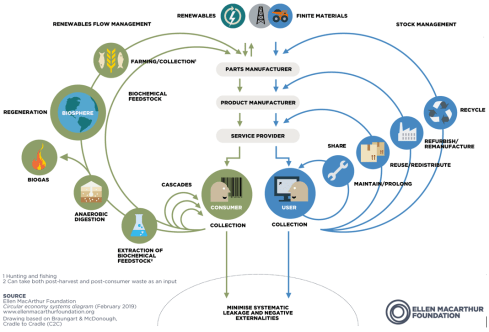

In short, looking at the diagram – the vertical flow from renewables and finite materials from part to product to product in service leads ultimately to wasted resources if there are no feedback loops. This is the traditional product delivery process that most companies are using.

In short, looking at the diagram – the vertical flow from renewables and finite materials from part to product to product in service leads ultimately to wasted resources if there are no feedback loops. This is the traditional product delivery process that most companies are using.

You can click on the image to the left to zoom in on the details.

The renewable loop on the left side of the diagram is the usage of renewables during production and the use of the product. The more we use renewables instead of fossil fuels, the more sustainable this loop will be. This is the area where engineers should use simulations to find the optimal manufacturing processes and product behavior. Again click on the image to zoom in on the details.

The renewable loop on the left side of the diagram is the usage of renewables during production and the use of the product. The more we use renewables instead of fossil fuels, the more sustainable this loop will be. This is the area where engineers should use simulations to find the optimal manufacturing processes and product behavior. Again click on the image to zoom in on the details.

The right side of the loop, related to the materials, is where we see the options for repairable, serviceable, upgradeable, and even further refurbishment and recycling to avoid leakage of precious materials. This is where mechanical engineers should dominate the activities. Focussing on each of the loops and how to enable them in the product. Click on the image to see the relevant loops.

The right side of the loop, related to the materials, is where we see the options for repairable, serviceable, upgradeable, and even further refurbishment and recycling to avoid leakage of precious materials. This is where mechanical engineers should dominate the activities. Focussing on each of the loops and how to enable them in the product. Click on the image to see the relevant loops.

Looking at the circular economy diagram, it is clear that we are no longer talking about a linear process – it has become the implementation of a system. Systems Engineering or MBSE?

The benefits of MBSE

Developing products with the circular economy in mind is no longer a “job to do,” a simple linear exercise. Instead, if we walk down the systems engineering V-shape, there are a lot of modeling exercises to perform before we reach the final solution.

To illustrate the benefits of MBSE, let’s walk through the following scenario.

A well-known company sells lighting projects for stadiums and public infrastructure. Their current business model is based on reliable lighting equipment with a competitive price and range of products.

A well-known company sells lighting projects for stadiums and public infrastructure. Their current business model is based on reliable lighting equipment with a competitive price and range of products.

Most of the time, their contracts have clauses about performance/cost and maintenance. The company sells the products when they win the deal and deliver spare parts when needed.

Their current product design is quite linear – without systems engineering.

Now this company has decided to change its business model towards Product As A Service, or in their terminology LaaS (Lightening as a Service). For a certain amount per month, they will provide lighting to their customers, a stadium, a city, and a road infrastructure.

To implement this business model, this is how they used a Model-Based Systems Engineering approach.

Modeling the Mission

Before even delivering any products, the process starts with describing and analyzing the business model needed for Lightening as a Service.

Then, with modeling estimates about the material costs, there are exercises about the resources required to maintain the service, the potential market, and the possible price range.

It is the first step of using a model to define the mission of the service. After that, the model can be updated, adjusted, and used for a better go-to-market approach when the solution becomes more mature.

Part of the business modeling is also the intention to deliver serviceable and upgradeable products. As the company now owns the entire lifecycle, this is the cheapest way to guarantee a continuous or improved service over time.

Modeling the Functions

Providing Lighting as a Service also means you must be in touch with your installations in real time. Power consumption needs to be measured and analyzed in real-time for (predictive) maintenance, and the light-providing service should be as cheap as possible during operation.

Therefore LED technology is the most reliable, and connectivity functions need to be implemented in the solution. The functional design ensures installation, maintenance and service can be done in a connected manner (cheapest in operation – beneficial for the business).

Modeling the Logical components

As an owner of the solution, the design of the logical components of the lighting solution is also crucial. How to address various lighting demands efficiently? Modularity is one of the first topics to address. With modular components, it is possible to build customer-specific solutions with a reduced engineering effort. However, the work needs to be done by generically designing the solutions and focusing on the interfaces.

Such a design starts with a logical process and flow diagrams combined with behavior modeling. Without already having a physical definition, we can analyze the components’ behavior within an electrical scheme. Decisions on whether specific scenarios will be covered by hardware or software can be analyzed here. The company can define the lower-level requirements for the physical component by using virtual trade-offs on the logical models.

At this stage, we have used business modeling, functional modeling and logical modeling to understand our solution’s behavior.

Modeling the Physical product

The final stage of the solution design is to implement the logical components into a physical solution. The placement of components and interfaces between the components becomes essential. For the physical design, there are still a lot of sustainability requirements to verify:

- Repairability and serviceability – are the components reachable and replaceable? Reducing the lifecycle costs of the solution

- Upgradeability – are there components that can behave differently due to software choices, or are there components that can be replaced with improved functionality. Reducing the cost of creating entirely new solutions.

- Reuse & recyclable – are the materials used in the solution recyclable or reusable, reducing the cost of new materials or reducing the cost of dumping waste.

- RoHS/ REACH compliance

The image below from Zhang Xin Guo’s presentation nicely demonstrates the iterative steps before reaching a physical product

Before committing to a hardware implementation, the virtual product can be analyzed, behavior can be simulated, and it carbon impact can be calculated for the various potential variants.

Before committing to a hardware implementation, the virtual product can be analyzed, behavior can be simulated, and it carbon impact can be calculated for the various potential variants.

The manufacturing process and energy usage during operation are also a part of the carbon impact calculation. The best performing virtual solution, including its simulations models, can be chosen for the realization to ensure the most environmentally friendly solution.

The digital twin for follow-up

Once the solution has been realized, the company still has a virtual model of the solution. By connecting the physical product’s observed and measured behavior, the virtual side’s modeling can be improved or used to identify improvement candidates – maintenance or upgrades. At this stage, the virtual twin is the actual twin of the physical solution. Without going deeper into the digital twin at this stage, I hope you also realize MBSE is a starting point for implementing digital twins serving sustainability outcomes.

The image below, published by Boeing, illustrates the power of the connected virtual and physical world and the various types of modeling that help to assess the optimal solution.

Conclusion

For sustainability, it all starts with the design. The design decisions for the product contribute for 80 % to the carbon footprint of the solution. Afterward, optimization is possible within smaller margins. MBSE is the recommended approach to get a trustworthy understanding and follow-up of the product’s environmental impact.

What do you think can we create sustainable products without MBSE?

We are happy to close the year with the first round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability.

We are happy to close the year with the first round of the PLM Global Green Alliances (PGGA) series: PLM and Sustainability.

We interviewed PLM-related software vendors in this series, discussing their sustainability mission and offering.

We talked with SAP, Autodesk, Dassault Systèmes, Sustaira and Aras and now with PTC. It was an exciting discussion, looking back at their Lifecycle Analysis (LCA) history and ending with a cliffhanger about what’s coming next year.

PTC

The discussion was with Dave Duncan, VP Sustainability at PTC, focusing on industrial Sustainability as well as PTC’s internal footprint reduction programs, joined by James Norman, who globally leads PTC’s Community of Practice for PLM and Design-for-Sustainability.

The discussion was with Dave Duncan, VP Sustainability at PTC, focusing on industrial Sustainability as well as PTC’s internal footprint reduction programs, joined by James Norman, who globally leads PTC’s Community of Practice for PLM and Design-for-Sustainability.

Interesting to notice from this discussion, listen to the introduction of Dave and James and their history with Sustainability long before it became a buzzword and then notice how long it takes till digital thread and digital twin are mentioned – enjoy the 38 minutes of interaction below

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- It was interesting to learn that just before the financial crisis in 2008, PTC invested (together with James Norman) in lifecycle analysis. But, unfortunately, a focus on restoring the economy silenced this activity until (as Dave Duncan says) a little more than six months ago, when Sustainability is almost in the top 3 of every company’s agenda.

- Regulation and financial reporting are the current drivers for companies to act related to Sustainability.

- The digital thread combined with the notion of relying on data quality are transformational aspects.

- Another transformational aspect is connecting sustainability as an integrated part of product development instead of a separate marketing discipline.

- Early next year, we will learn more about the realization of the PTC Digital Twin.

Want to learn more

Here are some links to the topics discussed in our meeting:

- The Innovators Program

- The Cummins Case Study

- The PTC Digital Twin description

- The PTC ServiceMax announcement

Conclusions