You are currently browsing the category archive for the ‘Circulair Economy’ category.

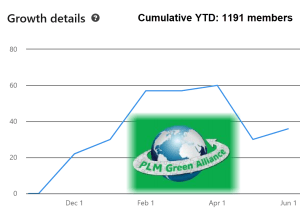

I am happy to see that the number of members of our PLM Green Global Alliance on LinkedIn has been growing fast recently.

I am happy to see that the number of members of our PLM Green Global Alliance on LinkedIn has been growing fast recently.

Early this year, we reached 1000 members; now, as of this post, we have almost 1200 members in our LinkedIn group—a growth of 20 % in less than half a year!

Each member of the #plmgreen alliance has a unique story and reason for joining.

I’m genuinely interested in learning more about your motivation. To kick off this conversation, I am sharing my journey, and I am eager to hear your thoughts, comments, and suggestions.

I’m genuinely interested in learning more about your motivation. To kick off this conversation, I am sharing my journey, and I am eager to hear your thoughts, comments, and suggestions.

Being aware this is again a long read, but I encourage you to read the article till the end.

Reading a 1500-word post was a 20th-century skill that helped people understand things with their nuances.

Let’s not lose this skill in the 21st century!

How it all started

Rich McFall reached out to me in late 2019, seeking individuals who shared our vision of establishing a platform for discussion and collaboration on green PLM. He was drawn to my 2015 blog post, ‘PLM and Global Warming,’ which I wrote six months before the famous Paris Agreement.

Rich McFall reached out to me in late 2019, seeking individuals who shared our vision of establishing a platform for discussion and collaboration on green PLM. He was drawn to my 2015 blog post, ‘PLM and Global Warming,’ which I wrote six months before the famous Paris Agreement.

In my 2015 blog post, I drew a parallel between the slow response to digital transformation in the PLM domain and our collective inaction against climate change.

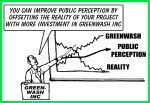

Despite the growing awareness of human-caused greenhouse gas emissions, there needed to be more urgency. This post was a call to action, not just for digital transformation in the PLM domain, but for our planet’s future. The cartoon below illustrates this mindset:

Both Rich and I felt that, when possible, we should use our energy and PLM-related skills to bring together a community of people who would take Climate Change and Sustainability seriously.

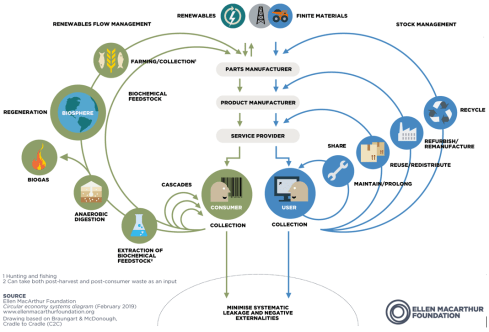

Rich’s focus was primarily on Climate Change and Greenhouse Gas emissions. – a hot topic in the US, where my passion and interest were related to Sustainability and the Circular Economy – two overlapping topics with a different impact, both parts of the UN Sustainable Development Goals (SDG) as formulated and adopted by all United Nations Member States in 2015.

Rich’s focus was primarily on Climate Change and Greenhouse Gas emissions. – a hot topic in the US, where my passion and interest were related to Sustainability and the Circular Economy – two overlapping topics with a different impact, both parts of the UN Sustainable Development Goals (SDG) as formulated and adopted by all United Nations Member States in 2015.

“Climate change creates fear and polarization, whereas the Circular Economy is more of a long-term concept, more complex to grasp, or implement, however crucial for the future of the planet.”

The start in 2020

When we started in early 2020, a few people were interested in contributing to the alliance—their names are at the bottom of this post. After several internal Zoom meetings, we decided to focus on different Green areas.

When we started in early 2020, a few people were interested in contributing to the alliance—their names are at the bottom of this post. After several internal Zoom meetings, we decided to focus on different Green areas.

The themes are available here: PLM Green Themes, i.e., Sustainability, the Circular Economy, Climate Change, Green Energy and Life Cycle Assessment.

In the beginning, the alliance was a small group of enthusiastic people supported by approximately 100 members in our LinkedIn group. As an organization of volunteers, we struggled with allocating time and resources to get the needed attention. In 2020, climate change and Sustainability were still niche topics in the PLM domain, and our audience was still small.

In the beginning, the alliance was a small group of enthusiastic people supported by approximately 100 members in our LinkedIn group. As an organization of volunteers, we struggled with allocating time and resources to get the needed attention. In 2020, climate change and Sustainability were still niche topics in the PLM domain, and our audience was still small.

Our interactive medium was the LinkedIn group, where comments and likes were easily shared. Our PLM Green Global Alliance website would be the place where we consolidate information—a challenging approach for us with limited skills and budget.

Starting the interviews in 2022

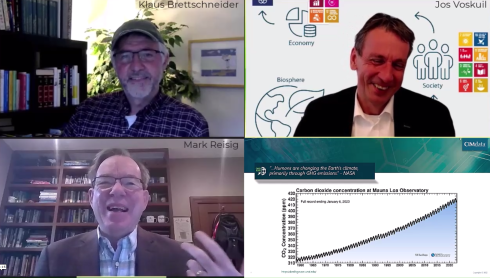

In 2022, we started interviewing PLM-related software vendors. Together with Klaus Brettschneider and, more recently, Mark Reisig, we were happy to discover what the major players in our PLM ecosystem were doing regarding Sustainability.

We spoke with SAP (Feb 2022 – Circular Economy), Autodesk (March 2020 – empowering engineers), Dassault Systemes (May 2022 – company targets & Virtual Twin), Sustaira (Sept 2022 – Connecting the dots – ESG reporting) and Aras (Oct 2022 – the need for a digital thread)

2023 – A year of transition

Besides the software vendors, consultancy firms started to address the need for more sustainable product development and understanding of what to do, and we spoke with CIMdata (April 2023 – the importance of sustainable business models) and Transition Technologies PSC (October 2023 – their GreenPLM offering on top of the PTC PLM suite)

However, as a PLM Green Global Alliance, we discovered that more and more companies were considering moving away from greenwashing and toward implementing actual measures, some of them driven by upcoming regulations and country initiatives.

However, as a PLM Green Global Alliance, we discovered that more and more companies were considering moving away from greenwashing and toward implementing actual measures, some of them driven by upcoming regulations and country initiatives.

It was also a significant year for the PLM Green Global Alliance, as besides receiving increasingly encouraging messages, both CIMdata and CIMPA joined the alliance as moderators.

![]() CIMdata, well known for its PLM consultancy and market analysis, started an additional consultancy practice related to PLM and Sustainability.

CIMdata, well known for its PLM consultancy and market analysis, started an additional consultancy practice related to PLM and Sustainability.

Mark Reisig, their lead consultant, joined us on the themes of Sustainability and Energy, also given his previous work career in that field.

CIMPA, a European PLM consultancy services company with roots in the aerospace industry, decided to support the alliance on the theme of the circular economy. Patrice Quencez and his team lead and moderate this activity.

CIMPA, a European PLM consultancy services company with roots in the aerospace industry, decided to support the alliance on the theme of the circular economy. Patrice Quencez and his team lead and moderate this activity.

Green in 2024 – what can we do?

Fear or Optimism? Fast and Slow!

One of the negative characteristics of the human mind is that we only want to act if it is indispensable. The brain’s evolutionary characteristic is to use the maximum amount of energy when there is a dangerous situation that forces us to act.

One of the negative characteristics of the human mind is that we only want to act if it is indispensable. The brain’s evolutionary characteristic is to use the maximum amount of energy when there is a dangerous situation that forces us to act.

There is enough proof for this theory, and it is the main reason why we continue bad habits. The best book to recommend is Thinking Fast and Slow by Daniel Kahneman.

Ask yourself:

- Should you study for the whole year or just before the exams?

- Would you start smoking knowing it is likely killing you in the long term?

- Would you save money for later, as then you might need it?

- Would you spend hours/days mastering a topic, or would you be an expert on social media with some easy facts and statistics?

- Would you act against climate change and overconsumption, knowing the reasons?

All the above questions illustrate that the majority of us (me too – there are no saints anymore) think fast, and media and marketing organizations know our weaknesses.

The result: we only get attention when there is a message of fear

The result: we only get attention when there is a message of fear

An explanation of why good news channels have no subscribers, whereas bad/fake news and polarising messages create an emotion to act.

In our PLM Green Alliance Group, Rich started with a monthly news digest related to Climate change. In the beginning, it felt like only bad news and the climate changes and disasters were showing us the urgency to handle. Read the last Climate Change Chronicles here.

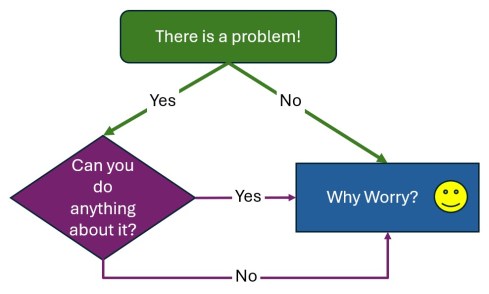

Bad news and fear might paralyze people. You might think the topic is too big for me to handle; therefore, let’s do nothing. Do you remember the diagram below?

Fortunately, many people believe that something needs to be done.

A recent UNDP survey shows that 80 percent of people globally want more decisive government climate action. Read the news here, and if you are interested in how your country compares to the rest of the world, check it here.

A recent UNDP survey shows that 80 percent of people globally want more decisive government climate action. Read the news here, and if you are interested in how your country compares to the rest of the world, check it here.

The good news is that the majority supports measures; the bad news is that the minority is the most vocal and influential by having the means and motives not to change the current status quo. And they have been organizing themselves for years.

Therefore, there is some optimism – we need to organize!

Looking back, particularly over the last 1½ years, there are reasons for optimism. Progress might not go as fast as desired, but if you are open to action and your newsfeed algorithm is also switched to positive, you will find encouraging messages.

For example, follow Assaad Razouk; his posts are often encouraging – not creating rage.

Read the monthly ESG Newsletters published by Vincent de la Mar from Sustaira and discover the positive trend. You can find his latest May newsletter here as an example: Sustainability & ESG Insights May ’24: Biden’s carbon market plans & how to get back on track to Paris Targets.

Following the progress within Europe – after the European Green Deal with all its aspects, recently, the Nature Restoration Law was signed, pushing companies to use more generative resources. The Nature Restoration Law and the European Green Deal are regulations pushing for a more circular economy as both the left side (regenerative) and right side (hardware) of the famous butterfly are addressed.

Conclusion

We are making progress, and I hope this post makes you realize that you need to worry about climate change and the Sustainability of our planet. My passion, and the passion of all the people listed below, is to support a movement and not to be silent.

Now, I am asking you to share your story. Which topics do we need to address first? Can you share examples or facts that illustrate—that with 1200 members, we should not be part of the silent majority but become a respected voice?

We’d like to express our exceptional gratitude to all those who supported us or are still supporting us at any stage of our PLM Green Global Alliance. Feel motivated to join this group of the non-silent majority.

In an alfabetical order: Xavier Adam, Zoe Bezpalko, Tom Boudeville, Klaus Brettschneider, Nina Dar, Stephane Declee, Dave Duncan, Stephan Fester, Bjorn Fidjeland, Ryan Flavelle, Matthias Fohrer, Roger L. Franz, Lionel Grealou, Jon den Hartog, Patrick Hilberg, Yousef Hooshmand, Hannes Lindfred, Ilan Madjar, Vincent de la Mar, James Norman, Rich McFall, Frank Popielas, Patrice Quencez, Mark Reisig, Audrey Reyniers, Erik Rieger, Ryan Rochelle, Mark Rushton, Neil D’Souza, Jonathan Thery, Oleg Shilovitsky, Florence Verzelen, Darren West ,Patrick Willemsen, Rafał Witkowski, Morgan Zimmermann.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

The initial interview in 2022 focused on companies getting pushed by legislation related to plastic packaging and how they could collect and analyze their product data.

Now, two years later, we discussed a much broader scope, including the Circular Economy and even Circular Manufacturing in the automotive industry. You can read and listen to this interview following this link: The PGGA talking again with SAP on Sustainability.

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

PTC

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

You could follow his movements through Europe on LinkedIn and his posting from the Munich workshop was fascinating. Besides meeting customers, there were also PTC partners like MakerSite, aPriori, and Transition Technologies PSC. All three companies have recently contributed to our PGGA series related to Sustainability.

Together with Dave, we spoke again with James Norman, who is responsible for driving PTC’s solutions and strategy for the digital and Sustainability transformation. He helped us make the connection between what’s happening in the field and what PTC is considering.

When listening to the interview, you will observe that in the PLM domain, so much has changed in the past two years.

Enjoy the 36 minutes of the interview and listen to what Dave has learned from the field, as reflected by James, on how PTC is addressing Sustainability.

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- The Corporate Sustainability Reporting Directive (CSRD) has forced companies to address Sustainability and the need for the digitalization of their processes (the digital thread)

- For Sustainability impact, do not focus just on the component properties; identify hot-spots when analyzing analyzing the impact of the product on the product level.

- As the OEM often only assembles the final product, the environmental impact is defined upstream in the supply chain.

- Modularity and Systems Thinking are crucial methodologies for implementing a Circular Economy.

- If you only consider the cradle-to-gate part of a product’s lifecycle, you might miss the big picture entirely. Even worse, you might implement design changes in the name of sustainability that result in outcomes far less sustainable than the original design. It’s crucial to look at the entire Product Service System/lifecycle to truly understand a product’s environmental impact

- We did not talk about Digital Twins and AI this time. Implementing a connected Digital Thread is, at this moment, the highest priority.

Want to learn more?

- There is the PTC Impact Report

- Dave Duncan’s article: Join PTC on Our Sustainability Journey

- A customer story: How Cummins Prioritizes Sustainability for New Product Designs

Conclusion

I enjoyed the dialogue with Dave and James and the progress we all have made towards understanding what is needed to ensure a sustainable future for our planet. So much has changed in two years.

PLM plays a crucial role in the discussion of a circular economy, the need for modularity, and sustainability reporting. All of these elements require a digital infrastructure related to the products we manufacture or use.

In addition, I was impressed by Dave’s pragmatic approach, who was in the hot spots of European manufacturing companies to understand their needs instead of telling them about their should-be dreams.

![]() I attended the PDSVISION forum for the first time, a two-day PLM event in Gothenburg organized by PTC’s largest implementer in the Nordics, also active in North America, the UK, and Germany.

I attended the PDSVISION forum for the first time, a two-day PLM event in Gothenburg organized by PTC’s largest implementer in the Nordics, also active in North America, the UK, and Germany.

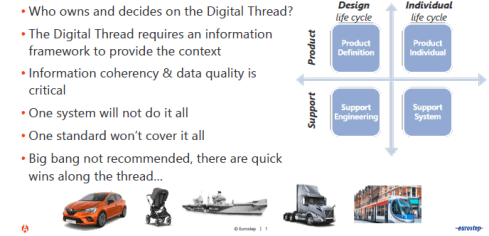

The theme of the conference: Master your Digital Thread – a hot topic, as it has been discussed in various events, like the recent PLM Roadmap/PDT Europe conference in November 2023.

The event drew over 200 attendees, showing the commitment of participants, primarily from the Nordics, to knowledge sharing and learning.

The diverse representation included industry leaders like Vestas, pioneers in Sustainable Energy, and innovative startups like CorPower Ocean, who are dedicated to making wave energy reliable and competitive. Notably, the common thread among these diverse participants was their focus on sustainability, a growing theme in PLM conferences and an essential item on every board’s strategic agenda.

I enjoyed the structure and agenda of the conference. The first day was filled with lectures and inspiring keynotes. The second day was a day of interactive workshops divided into four tracks, which were of decent length so we could really dive into the topics. As you can imagine, I followed the sustainability track.

Here are some of my highlights of this conference.

Catching the Wind: A Digital Thread From Design to Service

Simon Saandvig Storbjerg, unfortunately remote, gave an overview of the PLM-related challenges that Vestas is addressing. Vestas, the undisputed market leader in wind energy, is indirectly responsible for 231 million tonnes of CO2 per year.

Simon Saandvig Storbjerg, unfortunately remote, gave an overview of the PLM-related challenges that Vestas is addressing. Vestas, the undisputed market leader in wind energy, is indirectly responsible for 231 million tonnes of CO2 per year.

One of the challenges of wind power energy is the growing complexity and need for variants. With continuous innovation and the size of the wind turbine, it is challenging to achieve economic benefits of scale.

As an example, Simon shared data related to the Lost Production Factor, which was around 5% in 2009 and reduced to 2% in 2017 and is now growing again. This trend is valid not only for Vestas but also for all wind turbine manufacturers, as variability is increasing.

Vestas is introducing modularity to address these challenges. I reported last year about their modularity journey related to the North European Modularity biannual meeting held at Vestas in Ringkøbing – you can read the post here.

Simon also addressed the importance of Model-Based Definition (MBD), which is crucial if you want to achieve digital continuity between engineering and manufacturing. In particular, in this industry, MBD is a challenge to involve the entire value chain, despite the fact that the benefits are proven and known. Change in people skills and processes remains a challenge.

The Future of Product Design and Development

The session led by PTC from Mark Lobo, General Manager for the PLM Segment, and Brian Thompson, General Manager of the CAD Segment, brought clarity to the audience on the joint roadmap of Windchill and Creo.

The session led by PTC from Mark Lobo, General Manager for the PLM Segment, and Brian Thompson, General Manager of the CAD Segment, brought clarity to the audience on the joint roadmap of Windchill and Creo.

Mark and Brian highlighted the benefits of a Model-Based Enterprise and Model-Based Definition, which are musts if you want to be more efficient in your company and value chain.

Mark and Brian highlighted the benefits of a Model-Based Enterprise and Model-Based Definition, which are musts if you want to be more efficient in your company and value chain.

The WHY is known, see the benefits described in the image, and requires new ways of working, something organizations need to implement anyway when aiming to realize a digital thread or digital twin.

In addition, Mark addressed PTC’s focus on Design for Sustainability and their partner network. In relation to materials science, the partnership with Ansys Granta MI is essential. It was presented later by Ansys and discussed on day two during one of the sustainability workshops.

Mark and Brian elaborated on the PTC SaaS journey – the future atlas platform and the current status of WindChill+ and Creo+, addressing a smooth transition from existing customers to a new future architecture.

And, of course, there was the topic of Artificial Intelligence.

Mark explained that PTC is exploring AI in various areas of the product lifecycle, like validating requirements, optimizing CAD models, streamlining change processes on the design side but also downstream activities like quality and maintenance predictions, improved operations and streamlined field services and service parts are part of the PTC Copilot strategy.

Mark explained that PTC is exploring AI in various areas of the product lifecycle, like validating requirements, optimizing CAD models, streamlining change processes on the design side but also downstream activities like quality and maintenance predictions, improved operations and streamlined field services and service parts are part of the PTC Copilot strategy.

PLM combined with AI is for sure a topic where the applicability and benefits can be high to improve decision-making.

PLM Data Merge in the PTC Cloud: The Why & The How

Mikael Gustafson from Xylem, a leading Global Water Solutions provider, described their recently completed project: merging their on-premise Windchill instance TAPIR and their cloud Windchill XGV into a single environment.

Mikael Gustafson from Xylem, a leading Global Water Solutions provider, described their recently completed project: merging their on-premise Windchill instance TAPIR and their cloud Windchill XGV into a single environment.

TAPIR stands for Technical Administration, Part Information Repository and is very much part-centric and used in one organization. XGV stands for Xylem Global Vault, and it is used in 28 organizations with more of a focus on CAD data (Creo and AutoCAD). Two different siloes are to be joined in one instance to build a modern, connected, data-driven future or, as Mikael phrased it: “A step towards a more manageable Virtual Product“.

It was a severe project involving a lot of resources and time, again showing the challenges of migrations. I am planning to publish a blog post, the draft title “Migration Migraine,” as this type of migration is prevalent in many places because companies want to implement a single PLM backbone beyond (mechanical) engineering.

It was a severe project involving a lot of resources and time, again showing the challenges of migrations. I am planning to publish a blog post, the draft title “Migration Migraine,” as this type of migration is prevalent in many places because companies want to implement a single PLM backbone beyond (mechanical) engineering.

What I liked about the approach was its focus on assessing the risks and prioritizing a mitigation strategy if necessary. As the list below shows, even the COVID-19 pandemic was challenging the project.

Often, big migration projects fail due to optimism or by assessing some of the risks at the start and then giving it a go.

When failures happen, there is often the blame game: Was it the software, the implementer, or the customer (past or present) that caused the troubles? Mediating in such environments has been a long time my mission as the “Flying Dutchman,” and from my experience, it is not about the blame game; it is, most of the time, too high expectations and not enough time or resources to fully control this journey.

When failures happen, there is often the blame game: Was it the software, the implementer, or the customer (past or present) that caused the troubles? Mediating in such environments has been a long time my mission as the “Flying Dutchman,” and from my experience, it is not about the blame game; it is, most of the time, too high expectations and not enough time or resources to fully control this journey.

As Michael said, Xylem was successful, and during the go-live, only a few non-critical issues popped up.

When asked what he would do differently with the project’s hindsight, Mikael mentioned he would do the migrations not as a big project but as smaller projects.

When asked what he would do differently with the project’s hindsight, Mikael mentioned he would do the migrations not as a big project but as smaller projects.

I can relate a lot to this answer as, by experience, the “one-time” migration projects have created a lot of stress for the company, and only a few of them were successful.

Starting being coordinated and then connected

Several sessions were held where companies shared their PLM journey, to be mapped along the maturity slide (slide 8) I shared in my session: The Why, What and How of Digital Transformation in the PLM domain. You can review the content here on SlideShare.

There was Evolabel, a company starting its PLM journey because they are suffering from ineffective work procedures, information islands and the increasing complexity of its products.

Evolabel realized it needed PLM to realize its market ambition: To be a market leader within five years. For Evolabel, PLM is a must that is repeatable and integrated internally.

Evolabel realized it needed PLM to realize its market ambition: To be a market leader within five years. For Evolabel, PLM is a must that is repeatable and integrated internally.

They shared how they first defined the required understanding and mindset for the needed capabilities before implementing them. In my terminology, they started to implement a coordinated PLM approach.

Teddy Svenson from JBT, a well-known manufacturer of food-tech solutions, described their next step in PLM. From an old AS/400 system with very little integration to PDM to a complete PLM system with parts, configurations, and change management.

Teddy Svenson from JBT, a well-known manufacturer of food-tech solutions, described their next step in PLM. From an old AS/400 system with very little integration to PDM to a complete PLM system with parts, configurations, and change management.

It is not an easy task but a vital stepping stone for future development and a complete digital thread, from sales to customer care. In my terminology, they were upgrading their technology to improve their coordinated approach to be ready for the next digital evolution.

![]() There were several other presentations on Day One – See the agenda here I cannot cover them all given the limited size of this blog post.

There were several other presentations on Day One – See the agenda here I cannot cover them all given the limited size of this blog post.

The Workshops

As I followed the Sustainability track, I cannot comment much on the other track; however, given the presenters and the topics, they all appeared to be very pragmatic and interactive – given the format.

Achieving sustainability goals by integrating material intelligence into the design process

![]() In the sustainability track, we started with Manuelle Clavel from Ansys Granta, who explained in detail how material data and its management are crucial for designing better-performing, more sustainable, and compliant products.

In the sustainability track, we started with Manuelle Clavel from Ansys Granta, who explained in detail how material data and its management are crucial for designing better-performing, more sustainable, and compliant products.

With the importance of compliance with (upcoming) regulations and the usage of material characteristics in the context of more sustainable products and being able to perform a Life Cycle Assessment, it is crucial to have material information digitally available, both in the CAD design environment as well in the PLM environment.

For me, a dataset of material properties is an excellent example of how it is used in a connected enterprise. You do not want to copy the information from system to system; it needs to be connected and available in real-time.

How can we design more sustainable products?

Together with Martin Lundqvist from QCM, I conducted an interactive session. We started with the need for digitalization, then looked at RoHS and REACH compliance and discussed the upcoming requirements of the Digital Product Passport.

We closed the session with a dialogue on the circular economy.

From the audience, we learned that many companies are still early in understanding the implementation of sustainability requirements and new processes. However, some were already quite advanced and acting. In particular, it is essential to know if your company is involved with batteries (DPP #1) or is close to consumers.

Conclusion

The PDSFORUM was for me an interesting experience for meeting companies at all different stages of their PLM journey. All sessions I attended were realistic, and the solutions were often pragmatic. In my day-to-day life, inspiring companies to understand a digital and sustainable future, you sometimes forget the journey everyone is going through.

Thanks, PDVISION, for inviting me to speak and learn at this conference.

and some sad news …..

I was sorry to learn that last week, Dr. Ken Versprille suddenly passed away. I know Ken, as shown in the picture – a passionate moderator and timekeeper of the PLM Roadmap / PDT conferences, well prepared for the details. May his spirit live through the future conferences – the next one already on May 8-9th in Washington, DC.

Our recent interviews this year with aPriori and SAP were with companies that had less of a focus on the traditional product design process and more of a focus on the (circular) manufacturing process. In these interviews the importance of working with connected data was discussed in a shared (digital) thread.

Our recent interviews this year with aPriori and SAP were with companies that had less of a focus on the traditional product design process and more of a focus on the (circular) manufacturing process. In these interviews the importance of working with connected data was discussed in a shared (digital) thread.

This time, we, Mark Reisig and Jos Voskuil, were excited to talk with Siemens, not only a well-known PLM vendor but also a manufacturer of products and, therefore, having a close understanding of what is needed and can be achieved with their software solutions.

Siemens

![]() As Siemens is such a broad enterprise; we were happy to speak with Ryan R. Rochelle, who focuses on Sustainable Production, Sustainable Manufacturing and Sustainable Industry within Siemens . In the interview we discussed the importance of digital twins and the feedback loops between design and manufacturing. Despite some flaws in the network connection, we are happy to share an informative interview.

As Siemens is such a broad enterprise; we were happy to speak with Ryan R. Rochelle, who focuses on Sustainable Production, Sustainable Manufacturing and Sustainable Industry within Siemens . In the interview we discussed the importance of digital twins and the feedback loops between design and manufacturing. Despite some flaws in the network connection, we are happy to share an informative interview.

Enjoy listening and watching the next 33 minutes, talking with Ryan Rochelle.

You can download the images shown during the interview HERE

What I have learned

- Like all PLM vendors in this domain, Siemens talks about the importance of a circular economy and the need for digital threads and digital twins, confirming the need for all of us to invest in the digitization of the product lifecycle.

- Siemens is in a unique position as both the industrial user and software provider of its PLM suite, therefore having a unique feedback loop on the usability and applicability of its software in its industry.

- In the area of sustainability, they learn from both customers and internal customers. They are customer zero. Here, they observe shifting in engineering activities to the left” to optimize processes, supply chain and manufacturing earlier . (<<PGGA>>: which aligns with our aPriori and Makersite interviews).

- Siemens, SiGreen’s solution is an example of this unique position, being be able to track the carbon footprint of products across the supply chain.

Want to learn more

- There is the Siemens Sustainable industries website

- How the Digital Enterprise helps attain sustainability

- The Journey to a Sustainability Lighthouse awarded by the World Economic Forum

Conclusion

We have been discussing the relationship between PLM and sustainability with relevant software vendors for over two years now. As we saw initially in 2022, a few companies were exploring the possibilities.

Now, with further regulations and advanced software capabilities, companies are starting to implement new capabilities to make their product development process and products more sustainable. Siemens, as a software provider and an industrial user of its tools, is leading this journey—is it time for your company to step up, too?

Our first PGGA interview with PLM-related software vendors was two years ago with SAP. At that time, Sustainability became more visible in corporate strategies, and regulations were imminent.

Our first PGGA interview with PLM-related software vendors was two years ago with SAP. At that time, Sustainability became more visible in corporate strategies, and regulations were imminent.

This time, Klaus Brettschneider and I want to learn what has happened related to Sustainability. Is there visible progress in their organizations and customer base? And what is hot now?

And we were positively surprised by a conversation going in many directions.

SAP

The interview was again with Darren West. Darren is the product expert for SAP’s Circular Economy solutions and this time, Stephan Fester supported him. Stephan is co-leading the SAP Global Circular Manufacturing Practice and, therefore, is well-connected to the field. Last year, in particular, working in discrete manufacturing and discussing circular manufacturing.

The interview was again with Darren West. Darren is the product expert for SAP’s Circular Economy solutions and this time, Stephan Fester supported him. Stephan is co-leading the SAP Global Circular Manufacturing Practice and, therefore, is well-connected to the field. Last year, in particular, working in discrete manufacturing and discussing circular manufacturing.

Thanks to the expertise of our guests, the discussion went in various directions, with circularity as the central theme.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

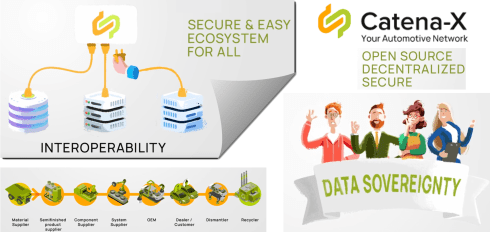

But also, we discussed the Digital Product Passport. Catena-X, what is it, and what is it targeting?

We also discussed how to deal with the scarcity of materials and materials harvesting. The interview could not be complete without mentioning AI.

Enjoy the 35-minute interview with Darren and Stephan on our YouTube channel.

The slides shown in this recording can be found here: PGGA talking again with SAP.

What we have learned

- Regulations heavily push SAP customers and require adequate reporting tools, not only for finance and material use but also for sustainability KPIs

- The Responsible Design & Production module launched two years ago is already in use with 60+ customers, showing the importance of having data-driven decision support for plastic packaging – to be extended to the product. Of course, as a PLM community, we are interested in understanding the next steps toward the product.

- The insights from Stephan Fester on circular manufacturing can be a logical evolution of the linear product process, as Stephan’s image shows.

- Great insights on Catena-X as an independent network for data sharing in the global network

Want to learn more?

Events and Shows:

- SAP at Hannover Messe – April 22-26, 2024 – event information

- SAP Sapphire, Orlando, USA – June 3-5, 2024 – event information

- SAP Sapphire, Barcelona, Spain – June 11-13, 2024 – event information

Websites:

- Circular Manufacturing at Scale – Microsite

- SAP Responsible Design and Production – product page

- SAP Circular Economy page

- SAP Sustainability home page

Conclusion

It was a great discussion with a company that is quite active in supporting its customers on a sustainable journey. The journey is complex and has many aspects, as Darren and Stephan shared in this dialogue. The good news is that SAP’s customers are actively implementing measures and processes – going circular is happening!

Join the PDSFORUM next month and join me to get inspired an participate in a Think Thank session on day 2 related to designing more sustainable products. Will we meet there?

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

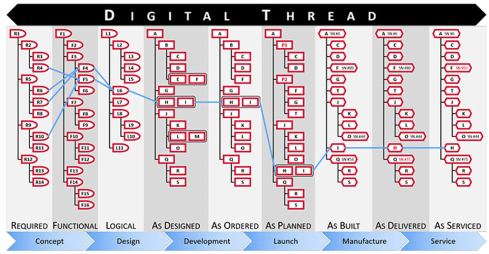

Now, I want to conclude on what I would call, in my terminology, the connected digital thread. This topic was already addressed when I reported on the federated PLM story from NIO (Yousef Hooshmand) and SAAB Aeronautics (Erik Herzog).

The Need for a Governance Digital Thread

This time, my presentation was a memory refresher related to digital transformation in the PLM domain – moving from coordinated ways of working towards connected ways of working.

A typology that is also valid for the digital thread definition.

- A Coordinated Digital Thread is a digital thread that connects various artifacts in an enterprise. These relations are created and managed to support traceability and an impact analysis. The coordinated digital thread requires human interpretation to process the information. The image below from Aras is a perfect example of a coordinated digital thread.

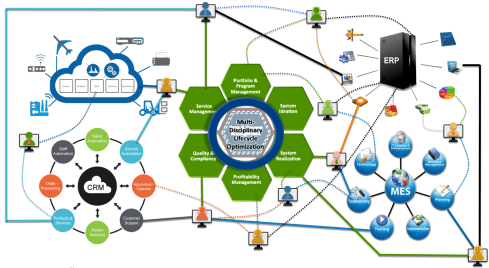

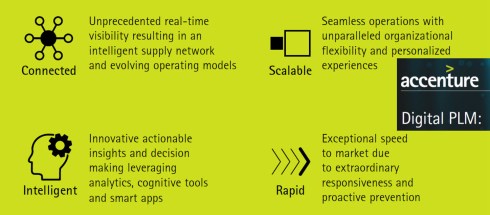

- The Connected Digital Thread is the digital thread where the artifacts are datasets stored in a federated infrastructure of databases. A connected digital thread provides real-time access to data through applications or dashboards for users. The real-time access makes the connected digital thread a solution for real-time, multidisciplinary collaboration activities.

The image above illustrates the connected digital thread as an infrastructure on top of five potential business platforms, i.e., the IoT platform, the CRM platform, the ERP platform, the MES platform and ultimately, the Product Innovation Platform.

Note: These platforms are usually a collection of systems that logically work together efficiently.

The importance of the Connected Digital Thread

When looking at the benefits of the Connected Digital Thread, the most essential feature is that it allows people in an organization to have all relevant data and its context available for making changes, analysis and design choices.

Due to the rich context, people can work proactively and reduce the number of iterations and fixes later.

The above image from Accenture (2014) describing the business benefits can be divided into two categories:

- The top, Connected and Scalable describing capabilities

- The bottom, Intelligent and Rapid, describes the business impact

The connected digital thread for governance

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

The PLM system will be one of the sources; other sources can be fragmented in an organization. Bringing them together manually in one report is a significant human effort, time-consuming and not supporting the business.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

According to a recent KPMG report, only a quarter of companies are ready for ESG Reporting Requirements.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

The Connected Digital Thread and the Digital Product Passport

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

The DPP is based on the GS1 infrastructure, originating from the retail industry. Each product will have a unique ID (UID based on ISO/IEC 15459:2015), and this UID will provide digital access to product information, containing information about the product’s used materials, its environmental impact, and recycle/reuse–ability.

It will serve both for regulatory compliance and as an information source for consumers to make informed decisions about the products they buy. The DPP aims to stimulate and enforce a more circular economy.

![]() Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

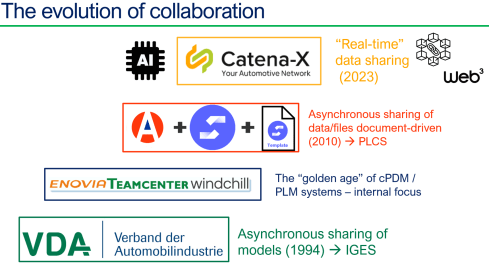

The Connected Digital Thread and Catena-X

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

A new exciting trend is the potential rise of not-for-profit infrastructure for a particular industry. Where the GS1-based infrastructure is designed to provide visibility on sustainable targets and decisions, Catena-X is focusing on the automotive industry.

Catena-X is the establishment of a data-driven value chain for the German automotive industry and is now in the process of expanding to become a global network.

It is a significant building block in what I would call the connected or even adaptive enterprise, using a data-driven infrastructure to let information flow through the whole value chain.

It is one of the best examples of a Connected Digital Thread covering an end-to-end value chain.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

So Sustainability and Digitization go hand in hand.

Why a Digital Thread makes a lot of sense

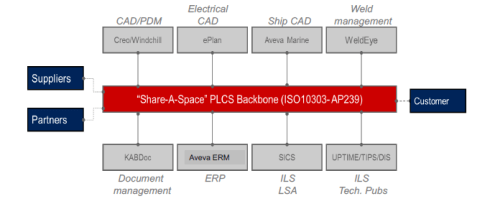

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

Eurostep, recently acquired by BAE Systems, is known for its collaboration hub or information backbone, ShareAspace. The interesting trend here is switching from a traditional PLM infrastructure to an asset-centric one.

This approach makes a lot of sense for complex assets with a long lifecycle, as the development phase is usually done with a consortium of companies. Still, the owner/operator wants to maintain a digital twin of the asset – for maintenance and upgrades.

A standards-based backbone makes much sense in such an environment due to the various data formats. This setup also means we are looking at a Coordinated Digital Thread at this stage, not a Connected Digital Thread.

Mattias concluded with the question of who owns and who decides on the coordinated digital thread – a discussion also valid in the construction industry when discussing Building Information Management (BIM) and a Common Data Environment(CDE).

I believe software vendors can provide the Coordinated Digital Thread option when they can demonstrate and provide a positive business case for their solution. Still, it will be seen as an overhead to connect the dots.

For a Connected Digital Thread, I think it might be provided as an infrastructure like the World Wide Web (W3C) organization. Here, the business case is much easier to demonstrate as it is really a digital highway.

Such an infrastructure could be provided by not-for-profit organizations like GS1 (Digital Product Passport/Retail), Catena-X (Automotive) and others (Gaia-X).

![]() For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

AI

And then there was AI. During the conference, people spoke more about AI than Sustainability topics, illustrating that our audience is more interested in understanding the next hype instead of feeling the short-term need to address climate change and planet sustainability.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

And we closed the conference with a roundtable discussion: AI, PLM and the Digital Thread: Why should we care about AI?

From the roundtable, I concluded that we are all convinced AI will have a significant impact in the upcoming years and are all in the early phases of the AI hype.

Will AI introduction go faster than digital transformation?

Conclusion

The conference gave me confidence that digital transformation in the PLM domain has reached the next level. Many sessions were related to collaboration concepts outside the traditional engineering domain – coordinated and connected digital threads.

The connected digital thread is the future, and as we saw it, it heralds the downfall of monolithic PLM. The change is needed for business efficiency AND compliance with more and more environmental regulations.

I am looking forward to seeing the pace of progress here next year.

It might have been silent in the series of PLM and Sustainability … interviews where we as PLM Green Global Alliance core team members, talk with software vendors, implementers and consultants and their relation to PLM and sustainability. The interviews are still in a stage of exploring what is happening at this moment. More details per vendor or service provider next year.

It might have been silent in the series of PLM and Sustainability … interviews where we as PLM Green Global Alliance core team members, talk with software vendors, implementers and consultants and their relation to PLM and sustainability. The interviews are still in a stage of exploring what is happening at this moment. More details per vendor or service provider next year.

Our last interview was in April this year when we spoke with Mark Reisig, Green Energy Practice Director & Executive Consultant at CIMdata. You can find the interview here, and at that time, I mentioned the good news is that sustainability is no longer a software discussion.

As companies are planning or pushed by regulations to implement sustainable strategies, it becomes clear that education and guidance are needed beyond the tools.

This trend is also noticeable in our PLM Green Global Alliance community, which has grown significantly in the past half year. While writing this post, we have 862 members, not all as active as we hoped. Still, there is more good news related to dedicated contributors and more to come in the next PGGA update.

This time, we want to share the interview with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services.

This time, we want to share the interview with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services.

I met them during the LiveWorx conference in Boston in May – you can read more about the conference in my post: The weekend after LiveWorx 2023. Here we decided to follow-up on GreenPLM/

GreenPLM

![]() The label “GreenPLM” is always challenging as it could be considered green-washing. However, in this case, GreenPLM is an additional software offering that can be implemented on top of a PLM system, enabling people to make scientifically informed decisions for a more sustainable, greener product.

The label “GreenPLM” is always challenging as it could be considered green-washing. However, in this case, GreenPLM is an additional software offering that can be implemented on top of a PLM system, enabling people to make scientifically informed decisions for a more sustainable, greener product.

For GreenPLM, Rafal’s and Erik’s experiences are based on implementing GreenPLM on top of the PTC Windchill suite. Listen for the next 34 minutes to an educative session and learn.

You can download the slides shown in the recording here.

What I learned

- It was more a general educative session related to the relation PLM and Sustainability, focusing on the importance of design decisions – the 80 % impact number.

- Erik considers sustainability not a disruption for designers; they already work within cost, quality and time parameters. Now, sustainability is the fourth dimension to consider.

- Erik’s opinion is also reflected in the pragmatic approach of GreenPLM as an additional extension of Windchill using PTC Navigate and OSLC standards.

- GreenPLM is more design-oriented than Mendix-based Sustaira, a sustainability platform we discussed in this series – you can find the recording here.

Want to learn more?

Here are some links related to the topics discussed in our meeting:

Conclusions

With GreenPLM, it is clear that the focus of design for sustainability is changing from a vision (led by software vendors and environmental regulations) towards implementations in the field. Pragmatic and an extension of the current PLM infrastructure. System integrators like Transition Technologies are the required bridge between vision and realization. We are looking for more examples from the field.

Two more weeks to go – don’t miss this opportunity when you are in Europe

Click on the image to see the full and interesting agenda/

We are happy to start the year with the next PLM Global Green Alliances (PGGA) series round: PLM and Sustainability.

Last year we spoke mainly with the prominent PLM software editors (Aras, Autodesk, Dassault Systèmes, PTC, SAP) and Sustaira (Sustainability platform – Siemens partner).

This time we talked with Mark Reisig, Sustainability and Green Energy Practice Director & Executive Consultant from CIMdata. The good news is that discussing a PLM strategy and Sustainability is no longer a software discussion.

This time we talked with Mark Reisig, Sustainability and Green Energy Practice Director & Executive Consultant from CIMdata. The good news is that discussing a PLM strategy and Sustainability is no longer a software discussion.

With CIMdata’s sustainability offering introduced last year, it becomes clear that the topic of sustainability reached a broader level than the tools.

CIMdata

CIMdata is well known in the PLM domain, focusing on Market Analysis, Education, Research & Strategic Management Consulting, all related to PLM.

CIMdata is well known in the PLM domain, focusing on Market Analysis, Education, Research & Strategic Management Consulting, all related to PLM.

Last year, Mark joined CIMdata as Green Energy Practice Director & Executive Consultant. Listening to Mark, you will discover he has an exciting background, starting with the “Keeling Curve”, his early interest in oceanography and wind turbines, working with GE later in his career and many years active in the PLM domain.

Learn more from the 40 minutes discussion with Mark below.

You can download the slides shown during the recording HERE

What we have learned

CIMdata has been discussing and promoting a circular economy already for a long time. A sustainable future and a circular economy have been a theme in many of the PLM Roadmap & PDT conferences. It is a logical relation as implementing a circular strategy depends significantly on the product design approach.

CIMdata has been discussing and promoting a circular economy already for a long time. A sustainable future and a circular economy have been a theme in many of the PLM Roadmap & PDT conferences. It is a logical relation as implementing a circular strategy depends significantly on the product design approach. CIMdata also combines Sustainability with the need to digitize the processes and data handled. A data-driven approach will allow companies to measure (and estimate) better their environmental impact.

CIMdata also combines Sustainability with the need to digitize the processes and data handled. A data-driven approach will allow companies to measure (and estimate) better their environmental impact.- CIMdata believes sustainability must be embedded in PLM for companies to reduce their product carbon footprint, and they must have greater visibility into their supply chain.

Mark mentions that focusing on a sustainable business model (product & business) is crucial for survival in the upcoming years, and this has increasingly landed at the board level of companies.

Mark mentions that focusing on a sustainable business model (product & business) is crucial for survival in the upcoming years, and this has increasingly landed at the board level of companies.- The major change has to be driven by the business. PLM vendors will not drive the change; they will align their portfolio offerings based on the market needs.

- It was clear Mark has a lot of experience in wind energy throughout his whole lifecycle 😊

Want to learn more

Mark already pointed to several valuable resources in our discussion to learn more. Here are the most important links related to CIMdata

- Sustainability and Green Energy Consulting Practice

Recent webinar: The Green Energy Transition and Sustainability from January 23, 2023

Recent webinar: The Green Energy Transition and Sustainability from January 23, 2023- Upcoming webinar: Meeting Sustainability and Green Energy Transition Objectives: The Industrial Perspective, April 27, 2023, 11:00 AM EDT

Conclusions

Last year we discussed sustainability with the software vendors and their product offerings. They all mentioned the importance of a data-driven approach and education. CIMdata has broadened the available sustainability offering for companies by providing additional education and strategy support.

Education at all levels is essential to make sustainable decisions. Sustainable for the company’s business and, above all, sustainable for the planet.

I will be @Livework in Boston, aiming to discuss PLM and Sustainability on behalf of the PGGA with PTC thought leaders. Will you be there too?

I was happy to present and participate at the 3DEXEPRIENCE User Conference held this year in Paris on 14-15 March. The conference was an evolution of the previous ENOVIA User conferences; this time, it was a joint event by both the ENOVIA and the NETVIBES brand.

I was happy to present and participate at the 3DEXEPRIENCE User Conference held this year in Paris on 14-15 March. The conference was an evolution of the previous ENOVIA User conferences; this time, it was a joint event by both the ENOVIA and the NETVIBES brand.

The conference was, for me, like a reunion. As I have worked for over 25 years in the SmarTeam, ENOVIA and 3DEXPERIENCE eco-system, now meeting people I have worked with and have not seen for over fifteen years.

My presentation: Sustainability Demands Virtualization – and it should happen fast was based on explaining the transformation from a coordinated (document-driven) to a connected (data-driven) enterprise.

There were 100+ attendees at the conference, mainly from Europe, and most of the presentations were coming from customers, where the breakout sessions gave the attendees a chance to dive deeper into the Dassault Systèmes portfolio.

Here are some of my impressions.

The power of ENOVIA and NETVIBES

I had a traditional view of the 3DEXPERIENCE platform based on my knowledge of ENOVIA, CATIA and SIMULIA, as many of my engagements were in the domain of MBSE or a model-based approach.

I had a traditional view of the 3DEXPERIENCE platform based on my knowledge of ENOVIA, CATIA and SIMULIA, as many of my engagements were in the domain of MBSE or a model-based approach.

However, at this conference, I discovered the data intelligence side that Dassault Systèmes is bringing with its NETVIBES brand.

Where I would classify the ENOVIA part of the 3DEXPERIENCE platform as a traditional System of Record infrastructure (see Time to Split PLM?).

I discovered that by adding NETVIBES on top of the 3DEXPERIENCE platform and other data sources, the potential scope had changed significantly. See the image below:

As we can see, the ontologies and knowledge graph layer make it possible to make sense of all the indexed data below, including the data from the 3DEXPERIENCE Platform, which provides a modern data-driven layer for its consumers and apps.

The applications on top of this layer, standard or developed, can be considered Systems of Engagement.

My curiosity now: will Dassault Systèmes keep supporting the “old” system of record approach – often based on BOM structures (see also my post: The Rise and Fall of the BOM) combined with the new data-driven environment? In that case, you would have both approaches within one platform.

My curiosity now: will Dassault Systèmes keep supporting the “old” system of record approach – often based on BOM structures (see also my post: The Rise and Fall of the BOM) combined with the new data-driven environment? In that case, you would have both approaches within one platform.

The Virtual Twin versus the Digital Twin

It is interesting to notice that Dassault Systèmes consistently differentiates between the definition of the Virtual Twin and the Digital Twin.

According to the 3DS.com website:

Digital Twins are simply a digital form of an object, a virtual version.

Unlike a digital twin prototype that focuses on one specific object, Virtual Twin Experiences let you visualize, model and simulate the entire environment of a sophisticated experience. As a result, they facilitate sustainable business innovation across the whole product lifecycle.

Understandably, Dassault Systemes makes this differentiation. With the implementation of the Unified Product Structure, they can connect CAD geometry as datasets to other non-CAD datasets, like eBOM and mBOM data.

The Unified Product Structure was not the topic of this event but is worthwhile to notice.

REE Automotive

![]() The presentation from Steve Atherton from REE Automotive was interesting because here we saw an example of an automotive startup that decided to go pure for the cloud.

The presentation from Steve Atherton from REE Automotive was interesting because here we saw an example of an automotive startup that decided to go pure for the cloud.

REE Automotive is an Israeli technology company that designs, develops, and produces electric vehicle platforms. Their mission is to provide a modular and scalable electric vehicle platform that can be used by a wide range of industries, including delivery and logistics, passenger cars, and autonomous vehicles.

Steve Atherton is the PLM 3DExperience lead for REE at the Engineering Centre in Coventry in the UK, where they have most designers. REE also has an R&D center in Tel Aviv with offshore support from India and satellite offices in the US

Steve Atherton is the PLM 3DExperience lead for REE at the Engineering Centre in Coventry in the UK, where they have most designers. REE also has an R&D center in Tel Aviv with offshore support from India and satellite offices in the US

REE decided from the start to implement its PLM backbone in the cloud, a logical choice for such a global spread company.

The cloud was also one of the conference’s central themes, and it was interesting to see that a startup company like REE is pushing for an end-to-end solution based on a cloud solution. So often, you see startups choosing traditional systems as the senior members of the startup to take their (legacy) PLM knowledge to their next company.

The cloud was also one of the conference’s central themes, and it was interesting to see that a startup company like REE is pushing for an end-to-end solution based on a cloud solution. So often, you see startups choosing traditional systems as the senior members of the startup to take their (legacy) PLM knowledge to their next company.

The current challenge for REE is implementing the manufacturing processes (EBOM- MBOM) and complying as much as possible with the out-of-the-box best practices to make their cloud implementation future-proof.

Groupe Renault

Olivier Mougin, Head of PLM at Groupe RENAULT, talked about their Renaulution Virtual Twin (RVT) program. Renault has always been a strategic partner of Dassault Systèmes.

Olivier Mougin, Head of PLM at Groupe RENAULT, talked about their Renaulution Virtual Twin (RVT) program. Renault has always been a strategic partner of Dassault Systèmes.

I remember them as one of the first references for the ENOVIA V6 backbone.

The Renaulution Virtual Twin ambition: from engineering to enterprise platform, is enormous, as you can see below:

Each of the three pillars has transformational aspects beyond traditional ways of working. For each pillar, Olivier explained the business drivers, expected benefits, and why a new approach is needed. I will not go into the details in this post.

However, you can see the transformation from an engineering backbone to an enterprise collaboration platform – The Renaulution!.

Ahmed Lguaouzi, head of marketing at NETVIBES, enforced the extended power of data intelligence on top of an engineering landscape as the target architecture.

Renault’s ambition is enormous – the ultimate dream of digital transformation for a company with a great legacy. The mission will challenge Renault and Dassault Systèmes to implement this vision, which can become a lighthouse for others.

3DS PLM Journey at MIELE

An exciting session close to my heart was the digital transformation story from MIELE, explained by André Lietz, head of the IT Products PLM @ Miele. As an old MIELE dishwasher owner, I was curious to learn about their future.

An exciting session close to my heart was the digital transformation story from MIELE, explained by André Lietz, head of the IT Products PLM @ Miele. As an old MIELE dishwasher owner, I was curious to learn about their future.

Miele has been a family-owned business since 1899, making high-end domestic and commercial equipment. They are a typical example of the power of German mid-market companies. Moreover, family-owned gives them stability and the opportunity to develop a multi-year transformation roadmap without being distracted by investor demands every few years.

André, with his team, is responsible for developing the value chain inside the product development process (PDP), the operation of nearly 90 IT applications, and the strategic transformation of the overarching PLM Mission 2027+.

André, with his team, is responsible for developing the value chain inside the product development process (PDP), the operation of nearly 90 IT applications, and the strategic transformation of the overarching PLM Mission 2027+.

As the slide below illustrates, the team is working on four typical transformation drivers:

- Providing customers with connected, advanced products (increasing R&D complexity)

- Providing employees with a modern, digital environment (the war for digital talent)

- Providing sustainable solutions (addressing the whole product lifecycle)

- Improving internal end-to-end collaboration and information visibility (PLM digital transformation)

André talked about their DELMIA pilot plant/project and its benefits to connect the EBOM and MBOM in the 3DEXPERIENCE platform. From my experience, this is a challenging topic, particularly in German companies, where SAP dominated the BOM for over twenty years.

I am curious to learn more about the progress in the upcoming years. The vision is there; the transformation is significant, but they have the time to succeed! This can be another digital transformation example.

I am curious to learn more about the progress in the upcoming years. The vision is there; the transformation is significant, but they have the time to succeed! This can be another digital transformation example.

And more …

Besides some educational sessions by Dassault Systemes (Laurent Bertaud – NETVIBES data science), there were also other interesting customer testimonies from Fernando Petre (IAR80 – Fly Again project), Christian Barlach (ISC Sustainable Construction) and Thelma Bonello (Methode Electronics – end-to-end BOM infrastructure). All sessions helped to get a better understanding about what is possible and what is done in the domain of PLM.

Conclusion

I learned a lot during these days, particularly the virtual twin strategy and the related capabilities of data intelligence. As the event was also a reunion for me with many people from my network, I discovered that we all aim at a digital transformation. We have a mission and a vision. The upcoming years will be crucial to implement the mission and realizing the vision. It will be the early adopters like Renault pushing Dassault Systèmes to deliver. I hope to stay tuned. You too?

NOTE: Dassault Systèmes covered some of the expenses associated with my participation in this event but did not in any way influence the content of this post.

![]() In this post, I want to explain why Model-Based Systems Engineering (MBSE) and Sustainability are closely connected. I would claim sustainability in our PLM domain will depend on MBSE.

In this post, I want to explain why Model-Based Systems Engineering (MBSE) and Sustainability are closely connected. I would claim sustainability in our PLM domain will depend on MBSE.

Can we achieve Sustainability without MBSE? Yes, but it will be costly and slow. And as all businesses want to be efficient and agile, they should consider MBSE.

What is MBSE?

The abbreviation MBSE stands for Model-Based Systems Engineering, a specialized manner to perform Systems Engineering. Look at the Wikipedia definition in short:

MBSE is a technical approach to systems engineering that focuses on creating and exploiting domain models as the primary means of information exchange rather than on document-based information exchange.

Model-Based fits in the digital transformation scope of PLM – from a document-based approach to a data-driven, model-based one. In 2018, I focused on facets of the model-based enterprise and related to MBSE in this post: Model-Based: System Engineering (MBSE).

My conclusion in that post was:

Model-Based Systems Engineering might have been considered as a discipline for the automotive and aerospace industry only. As products become more and more complex, thanks to IoT-based applications and software, companies should consider evaluating the value of model-based systems engineering for their products/systems.

I drew this conclusion before I focused on sustainability and systems thinking. Implementing sustainability concepts, like the Circular Economy, require more complex engineering efforts, justifying a Model-Based Systems Engineering approach. Let’s have a look.

If you want to learn more about why we need MBSE, look at this excellent keynote speech lecture from Zhang Xin Guo at the Incose 2018 conference below:

The Mission / the stakeholders

A company might deliver products to the market with the best price/quality ratio and regulatory compliance, perceived and checked by the market. This approach is purely focusing on economic parameters.

There is no need for a system engineering approach as the complexity is manageable. The mission is more linear, a “job to do,” and a limited number of stakeholders are involved in this process.

… with sustainability

Once we start to include sustainability in our product’s mission, we need a systems engineering approach, as several factors will push for different considerations. The most obvious considerations are the choice of materials and the optimizing the production process (reducing carbon emissions).

Once we start to include sustainability in our product’s mission, we need a systems engineering approach, as several factors will push for different considerations. The most obvious considerations are the choice of materials and the optimizing the production process (reducing carbon emissions).

However, the repairability/serviceability of the product should be considered with a more extended lifetime vision.

What about upgradeability and reusing components? Will the customer pay for these extra sustainable benefits?

Probably Yes, when your customer has a long-term vision, as the overall lifecycle costs of the product will be lower.

Probably Yes, when your customer has a long-term vision, as the overall lifecycle costs of the product will be lower.

Probably No if none of your competitors delivers non-sustainable products much cheaper.

As long as regulations will not hurt traditional business models, there might be no significant change.

However, the change has already started. Higher energy prices will impact the production of specific resources and raise costs. In addition, energy-intensive manufacturing processes will lead to more expensive materials. Combined with raising carbon taxes, this will be a significant driver for companies to reconsider their product offering and manufacturing processes.

However, the change has already started. Higher energy prices will impact the production of specific resources and raise costs. In addition, energy-intensive manufacturing processes will lead to more expensive materials. Combined with raising carbon taxes, this will be a significant driver for companies to reconsider their product offering and manufacturing processes.

The more expensive it becomes to create new products, the more attractive repairable and upgradable products will become. And this brings us to the concept of the circular economy, which is one of the pillars of sustainability.

In short, looking at the diagram – the vertical flow from renewables and finite materials from part to product to product in service leads ultimately to wasted resources if there are no feedback loops. This is the traditional product delivery process that most companies are using.

In short, looking at the diagram – the vertical flow from renewables and finite materials from part to product to product in service leads ultimately to wasted resources if there are no feedback loops. This is the traditional product delivery process that most companies are using.

You can click on the image to the left to zoom in on the details.

The renewable loop on the left side of the diagram is the usage of renewables during production and the use of the product. The more we use renewables instead of fossil fuels, the more sustainable this loop will be. This is the area where engineers should use simulations to find the optimal manufacturing processes and product behavior. Again click on the image to zoom in on the details.

The renewable loop on the left side of the diagram is the usage of renewables during production and the use of the product. The more we use renewables instead of fossil fuels, the more sustainable this loop will be. This is the area where engineers should use simulations to find the optimal manufacturing processes and product behavior. Again click on the image to zoom in on the details.