You are currently browsing the category archive for the ‘Life Cycle Assessment’ category.

This blog post is especially written for our PLM Global Green Alliance LinkedIn members — a message from a “boomer” to the next generation of PLM enthusiasts.

This blog post is especially written for our PLM Global Green Alliance LinkedIn members — a message from a “boomer” to the next generation of PLM enthusiasts.

If you belong to that next generation, please read until the end and share your thoughts.

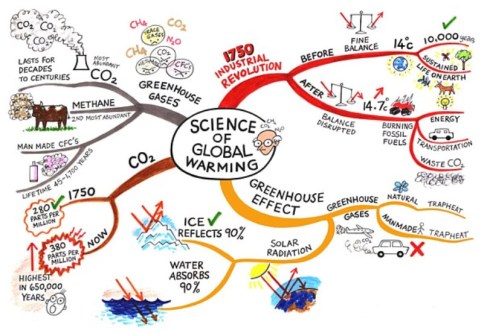

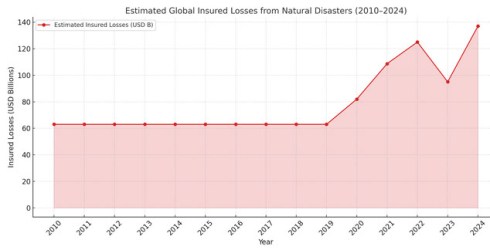

With last week’s announcement from the US government, no longer treating greenhouse gas emissions as a threat to the planet or climate.

We see a push to remove regulations that limit companies from continuing or expanding business without considering the broader consequences for other countries and future generations.

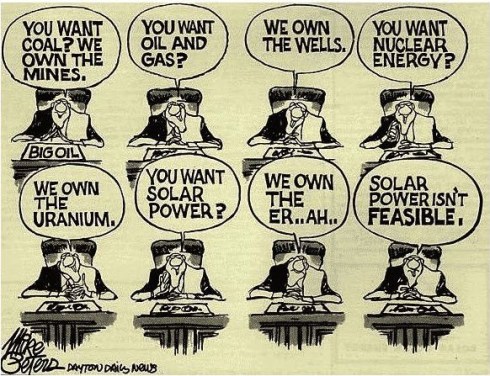

It feels like a short-term, greedy decision, largely influenced by those who benefit from fossil-carbon economies. Decisions like this make the energy transition harder, because the path of least resistance is always the easiest to follow.

Transitions are never simple. But when science is ignored, data is removed, and opinions replace facts, we are no longer supporting a transition — we are actively working against it.

My Story

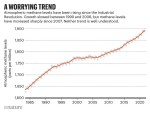

When I started working in the PLM domain in 1999, climate change already existed in the background of society. The 1972 Limits to Growth report by the Club of Rome had created waves long before, encouraging some people to rethink business and lifestyle choices.

When I started working in the PLM domain in 1999, climate change already existed in the background of society. The 1972 Limits to Growth report by the Club of Rome had created waves long before, encouraging some people to rethink business and lifestyle choices.

For me, however, it stayed outside my daily focus. I was at the beginning of my career, excited about the new challenges.

And important to notice that connecting to the internet with a 28k modem was the standard, a world without social media constantly reminding us of global issues.

I enjoyed my role as the “Flying Dutchman,” travelling around the world to support PLM implementations and discussions. Flying was simply part of the job. Real communication meant being in the same room; early phone and video calls were expensive, awkward, and often ineffective. PLM was — and still is — a human business.

I enjoyed my role as the “Flying Dutchman,” travelling around the world to support PLM implementations and discussions. Flying was simply part of the job. Real communication meant being in the same room; early phone and video calls were expensive, awkward, and often ineffective. PLM was — and still is — a human business.

Back then, the effects of carbon emissions and global warming felt distant, almost abstract. Only around 2014 did the conversation become more mainstream for me, helped by social media, before algorithms and bots began driving polarization.

In 2015, while writing about PLM and global warming, I realized something that still resonates today: even when we understand change is needed, we often stick to familiar habits, because investments in the future rarely deliver immediate ROI for ourselves or our shareholders.

The PLM Green Global Alliance

When Rich McFall approached me in 2019 with the idea of creating an alliance where people and companies could share ideas and experiences around sustainability in the PLM domain, I was immediately interested — for two reasons.

- First, there was a certain sense of responsibility related to my past activities as the Flying Dutchman. Not guilt — life is about learning and gaining insight — but awareness that I needed to change, even if the past could not be changed.

- Second, and more importantly, the PLM Green Global Alliance offered a way to contribute. It gave me a reason to act — for personal peace of mind and for future generations. Not only for my children or grandchildren, but for all those who will share this planet with them.

In the first years of the PGGA, we saw strong engagement from younger professionals. Over time, however, we noticed that career priorities often came first — which is understandable.

Like me at the start of my career, many focus first on building their future. Career and sustainability can coexist, but investing extra time in long-term change is not easy when daily responsibilities already demand so much.

Your Chance to Work on the Future

The real challenge lies with those willing to go the extra mile — staying focused on today’s business while also investing energy in the long-term future.

The real challenge lies with those willing to go the extra mile — staying focused on today’s business while also investing energy in the long-term future.

At the same time, I understand that not everyone is in a position to speak out or dedicate time to sustainability initiatives. Circumstances differ. For many, current responsibilities leave little space for additional commitments.

Still, for those willing to join us, we have two requests to better understand your expectations.

Two weeks ago, I connected with our 40 newest members of the PLM Green Global Alliance. We are now close to 1,600 members — up from around 1,500 in September 2025, as mentioned in Working on the Long Term.

That post was a gentle call to action. Seeing our PGGA membership continue to grow is encouraging — and naturally raises a question:

1. What motivates people to join the PGGA LinkedIn group?

So far, only a small number of the recent new members have completed a survey that was especially sent to them to explore changing priorities. Due to the low response, we extended the invitation to all members. We are curious about your expectations — and quietly hopeful about your involvement.

If you haven’t filled in the survey yet, please click here and share your feedback. The survey is anonymous unless you choose to leave your details for follow-up. We will share the results in approximately 2 weeks from now.

If you haven’t filled in the survey yet, please click here and share your feedback. The survey is anonymous unless you choose to leave your details for follow-up. We will share the results in approximately 2 weeks from now.

2. Design for Sustainability – your contribution?

Last year, Erik Rieger and Matthew Sullivan launched a new workgroup within the PLM Green Global Alliance focused on Design for Sustainability. While the initial energy was strong, changes in personal priorities meant the team could not continue at the pace they hoped. Since many new members have joined since last May, we decided to relaunch the initiative.

If you are interested in contributing to the revival of Design for Sustainability, please take five minutes to complete the short survey. Your input will help shape the direction of the DfS working group and frame future discussions.

If you are interested in contributing to the revival of Design for Sustainability, please take five minutes to complete the short survey. Your input will help shape the direction of the DfS working group and frame future discussions.

Note: If you are worried about clicking on the links for the survey, you can always contact us directly (in private) to share your ambition

Conclusion

The outside world often pushes us to focus only on daily business. In some places, there is even active pressure to avoid long-term sustainability investments. Remember that pressure often comes from those invested in keeping the current system unchanged.

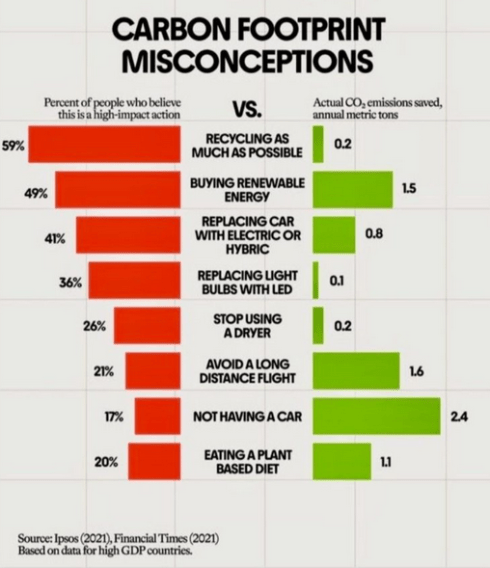

If you care about the future — your generation and those that follow — stay engaged. Small actions by millions of people can create meaningful change.

We look forward to your input and participation.

— says the boomer who still cares 😉

On November 11th, we celebrated our 5th anniversary of the PLM Green Global Alliance (PGGA) with a webinar where ♻️ Jos Voskuil (me) interviewed the five other PGGA core team members about developments and experiences in their focus domain, potentially allowing for a broader discussion.

On November 11th, we celebrated our 5th anniversary of the PLM Green Global Alliance (PGGA) with a webinar where ♻️ Jos Voskuil (me) interviewed the five other PGGA core team members about developments and experiences in their focus domain, potentially allowing for a broader discussion.

In our discussion, we focused on the trends and future directions of the PLM Green Global Alliance, emphasizing the intersection of Product Lifecycle Management (PLM) and sustainability.

Probably, November 11th was not the best day for broad attendance, and therefore, we hope that the recording of this webinar will allow you to connect and comment on this post.

Probably, November 11th was not the best day for broad attendance, and therefore, we hope that the recording of this webinar will allow you to connect and comment on this post.

Enjoy the discussion – watch it, or listen to it, as this time we did not share any visuals in the debate. Still, we hope to get your reflections and feedback on the interview related to the LinkedIn post.

The discussion centered on the trends and future directions of the PLM Green Global Alliance, with a focus on the intersection of Product Lifecycle Management (PLM) and sustainability.

Short Summary

♻️ Rich McFall shared his motivations for founding the alliance, highlighting the need for a platform that connects individuals committed to sustainability and addresses the previously limited discourse on PLM’s role in promoting environmental responsibility. He noted a significant variance in vendor engagement with sustainability, indicating that while some companies are proactive, others remain hesitant.

The conversation delved into the growing awareness and capabilities of how to perform a Life Cycle Assessment (LCA) with ♻️ Klaus Brettschneider, followed by the importance of integrating sustainability into PLM strategies, with ♻️ Mark Reisig discussing the ongoing energy transition and the growing investments in green technologies, particularly in China and Europe.

♻️ Evgeniya Burimskaya raised concerns about implementing circular economy principles in the aerospace industry, emphasizing the necessity of lifecycle analysis and the upcoming digital product passport requirements. The dialogue also touched on the Design for Sustainability initiative, led by ♻️ Erik Rieger, which aims to embed sustainability into the product design phase, necessitating a cultural shift in engineering education to prioritize sustainability.

Conclusion

We concluded with understanding the urgent realities of climate change, but also advocating for an optimistic mindset in the face of challenges – it is perhaps not as bad as it seems in the new media. There are significant investments in green energy, serving as a beacon of hope, which encourage people to remain committed to collaborative efforts in advancing sustainable practices.

We agreed on the long-term nature of behavioral change within organizations and the role of the Green Alliance in fostering this transformation, concluding with a positive outlook on the potential for future generations to drive necessary changes in sustainability.

Recently, we initiated the Design for Sustainability workgroup, an initiative from two of our PGGA members, Erik Rieger and Matthew Sullivan. You can find a recording of the kick-off here on our YouTube channel.

Recently, we initiated the Design for Sustainability workgroup, an initiative from two of our PGGA members, Erik Rieger and Matthew Sullivan. You can find a recording of the kick-off here on our YouTube channel.

Thanks to the launch of the Design for Sustainability workgroup, we were introduced to Dr. Elvira Rakova, founder and CEO of the startup company Direktin.

Her mission is to build the Digital Ecosystem of engineering tools and simulation for Compressed Air Systems. As typical PLM professionals with a focus on product design, we were curious to learn about developments in the manufacturing space. And it was an interesting discussion, almost a lecture.

Compressed air and Direktin

Dr. Elvira Rakova has been working with compressed air in manufacturing plants for several years, during which she has observed the inefficiency of how compressed air is utilized in these facilities. It is an available resource for all kinds of machines in the plant, often overdimensioned and a significant source of wasted energy.

Dr. Elvira Rakova has been working with compressed air in manufacturing plants for several years, during which she has observed the inefficiency of how compressed air is utilized in these facilities. It is an available resource for all kinds of machines in the plant, often overdimensioned and a significant source of wasted energy.

To address this waste of energy, linked to CO2 emissions, she started her company to help companies scale, dimension, and analyse their compressed air usage. A mix of software and consultancy to make manufacturing processes using compressed air responsible for less carbon emissions, and for the plant owners, saving significant money related to energy usage.

For us, it was an educational discussion, and we recommend that you watch or listen to the next 36 minutes

What I learned

- The use of compressed air and its energy/environmental impact were like dark matter to me.

I never noticed it when visiting customers as a significant source to become more sustainable. - Although the topic of compressed air seems easy to understand, its usage and impact are all tough to address quickly and easily, due to legacy in plants, lack of visibility on compressed air (energy usage) and needs and standardization among the providers of machinery.

- The need for data analysis is crucial in addressing the reporting challenges of Scope 3 emissions, and it is also increasingly important as part of the Digital Product Passport data to be provided. Companies must invest in the digitalization of their plants to better analyze and improve energy usage, such as in the case of compressed air.

- In the end, we concluded that for sustainability, it is all about digital partnerships connecting the design world and the manufacturing world and for that reason, Elvira is personally motivated to join and support the Design for Sustainability workgroup

Want to learn more?

- Another educational webinar: Design Review Culture and Sustainability

- Explore the Direktin website to learn more

Conclusions

The PLM Green Global Alliance is not only about designing products; we have also seen lifecycle assessments for manufacturing, as discussed with Makersite and aPriori. These companies focused more on traditional operations in a manufacturing plant. Through our lecture/discussion on the use of compressed air in manufacturing plants, we identified a new domain that requires attention.

Just before or during the summer holidays, we were pleased to resume our interview series on PLM and Sustainability, where the PLM Green Global Alliance interviews PLM-related software vendors and service organizations, discussing their sustainability missions and offerings.

Just before or during the summer holidays, we were pleased to resume our interview series on PLM and Sustainability, where the PLM Green Global Alliance interviews PLM-related software vendors and service organizations, discussing their sustainability missions and offerings.

Following recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for Sustainability working group (with multiple vendors & service partners), we now have the opportunity to catch up with Sustaira after almost three years.

In 2022, Sustaira was a startup company focused on building and providing data-driven, efficient support for sustainability reporting and analysis based on the Mendix platform, while engaging with their first potential customers. What has happened in those three years?

In 2022, Sustaira was a startup company focused on building and providing data-driven, efficient support for sustainability reporting and analysis based on the Mendix platform, while engaging with their first potential customers. What has happened in those three years?

SUSTAIRA

Sustaira provides a sustainability management software platform that helps organizations track, manage, and report their environmental, social, and governance (ESG) performance through customizable applications and dashboards.

Sustaira provides a sustainability management software platform that helps organizations track, manage, and report their environmental, social, and governance (ESG) performance through customizable applications and dashboards.

We spoke again with Vincent de la Mar, founder and CEO of Sustaira, and it was pretty clear from our conversation that they have evolved and grown in their business and value proposition for businesses. As you will discover by listening to the interview, they are not, per se, in the PLM domain.

Enjoy the 35-minute interview below.

Slides shown during the interview, combined with additional company information, can be found HERE.

What we have learned

- Sustaira is a modular, AI-driven sustainability platform. It offers approximately 150 “sustainability accelerators,” which are either complete Software as a Service (SaaS) products (such as carbon accounting, goal/KPI tracking, and disclosures) or adaptable SaaS products that allow for complete configuration of data models, logic, and user interfaces.

- Their strategy is based on three pillars:

- providing an end-to-end sustainability platform (Ports of Jersey),

- filling gaps in an enterprise architecture and business needs (Science-Based Target Initiatives)

- Co-creating new applications with partners (BCAF with Siemens Financial Services)

- The company has a pragmatic view on AI and thanks to its scalable, data-driven Mendix platform, it can bring integrated value compared to niche applications that might become obsolete due to changing regulations and practices (e.g., dedicated CSRD apps)

- The Sustainability Global Alliance, in partnership with Capgemini, is a strategic alliance that benefits both parties, with a focus on AI & Sustainability.

- The strong partnership with Siemens Digital Solutions.

- Their monthly Sustainability and ESG Insights newsletter, also published in our PGGA group, already has 55.000 subscribers.

Want to learn more?

The following links provide more information related to Sustaira:

- About Sustaira:

- Sustaira’s sustainability marketplace

- Siemens and Sustaira partnership

- Capgemini and Sustaira partnership

- Customer Case Stories

- The Sustainability Insights LinkedIn Newsletter

- Navigating CSRD

- Content Hub (requires registration)

Conclusion

It was great to observe how Sustaira has grown over the past three years, establishing a broad portfolio of sustainability-related solutions for various types of businesses. Their relationship with Siemens Digital Solutions enables them to bring value and add capabilities to the Siemens portfolio, as their platform can be applied to any company that needs a complementary data-driven service related to sustainability insights and reporting.

Follow the news around this event – click on the image to learn more.

Within the PLM Green Global Alliance (PGGA), we had an internal kick-off meeting related to the topic of Design for Sustainability. As you might have seen on our website, Erik Rieger, PLM Evangelist and now working for PTC, took the initiative to start this focus group.

Within the PLM Green Global Alliance (PGGA), we had an internal kick-off meeting related to the topic of Design for Sustainability. As you might have seen on our website, Erik Rieger, PLM Evangelist and now working for PTC, took the initiative to start this focus group.

You might know Erik from a previous interview from the PGGA where we discussed TTPSC’s ecoPLM offering based on Windchill: PLM and Sustainability: talking about ecoPLM.

When Erik announced the Design for Sustainability initiative, it was Matthew Sullivan from CIMPA PLM Service who immediately contacted Erik to work together on this initiative.

When Erik announced the Design for Sustainability initiative, it was Matthew Sullivan from CIMPA PLM Service who immediately contacted Erik to work together on this initiative.

And again, you might know CIMPA PLM services from our recent interview with them related to regulations and best practices related to sustainability in the aerospace industry (CSRD, LCA, DPP, AI and more): PLM and Sustainability: talking with CIMPA.

Erik and Matthew decided to participate in an introductory interview, during which they shared their background, passion, and goals related to Design for Sustainability.

Watch the episode here:

Why Design for Sustainability?

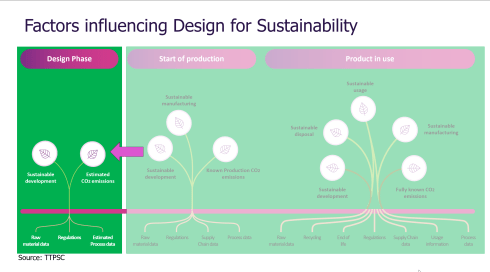

Design for Sustainability (DfS) is an approach to designing products, services, systems, and experiences that prioritize environmental, social, and economic sustainability throughout their entire lifecycle. It means creating things in a way that reduces negative impacts on the planet and people while still being functional, profitable, and desirable.

In theory, this should be one of the key areas in which our PGGA members can have a common discussion.

As Erik mentions, it is estimated that 80 % of the environmental impact is defined during the design phase. This is a number that has been coming back in several of our PGGA discussions with all the other software vendors.

More on Design for Sustainability

Just after the recording, Dave Duncan, head of Sustainability at PTC, published the eBook Product Sustainability for Dummies. An excellent book that brings all aspects of sustainability and products together in an easy-to-digest manner. There is also a chapter on Design for Sustainability in the eBook.

Just after the recording, Dave Duncan, head of Sustainability at PTC, published the eBook Product Sustainability for Dummies. An excellent book that brings all aspects of sustainability and products together in an easy-to-digest manner. There is also a chapter on Design for Sustainability in the eBook.

Note: Dave Duncan is a recognized PGGA leader in PLM and Sustainability, as we reported last year.

Read the post here: Leaders in PLM and Sustainability – December 2024

A call for action

We hope you watched and enjoyed the interview with Erik and Matthew as an inspiration to become active in this Design for Sustainability discussion group.

The intention is, as mentioned, to share experiences and discuss challenges within the group. It will be a private group where people can discuss openly to avoid any business conflicts. The plan is to start with an initial kick-off Zoom meeting in June the date still to be fixed.

The intention is, as mentioned, to share experiences and discuss challenges within the group. It will be a private group where people can discuss openly to avoid any business conflicts. The plan is to start with an initial kick-off Zoom meeting in June the date still to be fixed.

If you are interested in joining this exciting discussion group, please contact Erik Rieger, who will be the focal point for this group. We are looking forward to your contribution, and now is the time to prepare and act.

Join us in the discussion

Most times in this PLM and Sustainability series, Klaus Brettschneider and Jos Voskuil from the PLM Green Global Alliance core team speak with PLM related vendors or service partners.

Most times in this PLM and Sustainability series, Klaus Brettschneider and Jos Voskuil from the PLM Green Global Alliance core team speak with PLM related vendors or service partners.

This year we have been speaking with Transition Technologies PSC, Configit, aPriori, Makersite and the PLM Vendors PTC, Siemens and SAP.

Where the first group of companies provided complementary software offerings to support sustainability – “the fourth dimension”– the PLM vendors focused more on the solutions within their portfolio.

This time we spoke with , CIMPA PLM services, a company supporting their customers with PLM and Sustainability challenges, offering an end-to-end support.

What makes them special is that they are also core partner of the PLM Global Green Alliance, where they moderate the Circular Economy theme – read their introduction here: PLM and Circular Economy.

CIMPA PLM services

We spoke with Pierre DAVID and Mahdi BESBES from CIMPA PLM services. Pierre is an environmental engineer and Mahdi is a consulting manager focusing on parts/components traceability in the context of sustainability and a circular economy. Many of the activities described by Pierre and Mahdi were related to the aerospace industry.

We spoke with Pierre DAVID and Mahdi BESBES from CIMPA PLM services. Pierre is an environmental engineer and Mahdi is a consulting manager focusing on parts/components traceability in the context of sustainability and a circular economy. Many of the activities described by Pierre and Mahdi were related to the aerospace industry.

We had an enjoyable and in-depth discussion of sustainability, as the aerospace industry is well-advanced in traceability during the upstream design processes. Good digital traceability is an excellent foundation to extend for sustainability purposes.

CSRD, LCA, DPP, AI and more

A bunch of abbreviations you will have to learn. We went through the need for a data-driven PLM infrastructure to support sustainability initiatives, like Life Cycle Assessments and more. We zoomed in on the current Corporate Sustainability Reporting Directive(CSRD) highlighting the challenges with the CSRD guidelines and how to connect the strategy (why we do the CSRD) to its execution (providing reports and KPIs that make sense to individuals).

In addition, we discussed the importance of using the proper methodology and databases for lifecycle assessments. Looking forward, we discussed the potential of AI and the value of the Digital Product Passport for products in service.

Enjoy the 37 minutes discussion and you are always welcome to comment or start a discussion with us.

What we learned

- Sustainability initiatives are quite mature in the aerospace industry and thanks to its nature of traceability, this industry is leading in methodology and best practices.

- The various challenges with the CSRD directive – standardization, strategy and execution.

- The importance of the right databases when performing lifecycle analysis.

- CIMPA is working on how AI can be used for assessing environmental impacts and the value of the Digital Product Passport for products in service to extend its traceability

Want to learn more?

Here are some links related to the topics discussed in our meeting:

- CIMPA’s theme page on the PLM Green website: PLM and Circular Economy

- CIMPA’s commitments towards A sustainable, human and guiding approach

- Sopra Steria, CIMPA’s parent company: INSIDE #8 magazine

Conclusion

The discussion was insightful, given the advanced environment in which CIMPA consultants operate compared to other manufacturing industries. Our dialogue offered valuable lessons in the aerospace industry, that others can draw on to advance and better understand their sustainability initiatives

I am sharing another follow-up interview about PLM and Sustainability with a software vendor or implementer. Last year, in November 2023, Klaus Brettschneider and Jos Voskuil from the PLM Green Global Alliance core team spoke with Transition Technologies PSC about their GreenPLM offering and their first experiences in the field.

I am sharing another follow-up interview about PLM and Sustainability with a software vendor or implementer. Last year, in November 2023, Klaus Brettschneider and Jos Voskuil from the PLM Green Global Alliance core team spoke with Transition Technologies PSC about their GreenPLM offering and their first experiences in the field.

As we noticed with most first interviews, sustainability was a topic of discussion in the PLM domain, but it was still in the early discovery phases for all of us.

![]() Last week, we spoke again with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services. The exciting part of this discussion is that system integrators are usually more directly connected to their customers in the field and, therefore, can be the source of understanding of what is happening.

Last week, we spoke again with Erik Rieger and Rafał Witkowski, both working for Transition Technologies PSC, a global IT solution integrator in the PLM world known for their PTC implementation services. The exciting part of this discussion is that system integrators are usually more directly connected to their customers in the field and, therefore, can be the source of understanding of what is happening.

ecoPLM and more

Where Erik is a and he is a long term PLM expert and Rafal is the PLM Practice Lead for Industrial Sustainability. In the interview below they shared their experiences with a first implementation pilot in the field, the value of their _ecoPLM offering in the context of the broader PTC portfolio. And of course we discussed topics closely related to these points and put them into a broader context of sustainably.

Enjoy the 34 minutes discussion and you are always welcome to comment or start a discussion with us.

The slides shown in this presentation and some more can be downloaded HERE.

What I learned

- The GreenPLM offering has changed its name into ecoPLM as TT PSC customers are focusing on developing sustainable products, with currently supporting designer to understand the carbon footprint of their products.

- They are actually in a MVP approach with a Tier 1 automotive supplier to validate and improve their solution and more customers are adding Design for Sustainability to their objective, besides Time to Market, Quality and Cost.

- Erik will provide a keynote speech at the Green PLM conference on November 14th in Berlin – The conference is targeting a German speaking audience although the papers are in English. You can still register and find more info here

- TT PSC is one of the partners completing the PTC sustainability offering and working close with their product management.

- A customer quote: “Sustainability makes PLM sexy again”

Want to learn more?

Here are some links related to the topics discussed in our meeting:

- YouTube: ecoPLM: your roadmap for eco-friendly product development

- ecoPLM – a sustainable product development website

- YouTube: Win the Net-Zero Race with PLM (and PTC)

Conclusions

We are making great progress in the support to design and deliver more sustainable products – sustainability goes beyond marketing as Rafal Witkowski mentioned – the journey has started. What do you see in your company?

It was a great pleasure to attend my favorite vendor-neutral PLM conference this year in Gothenburg—approximately 150 attendees, where most have expertise in the PLM domain.

It was a great pleasure to attend my favorite vendor-neutral PLM conference this year in Gothenburg—approximately 150 attendees, where most have expertise in the PLM domain.

We had the opportunity to learn new trends, discuss reality, and meet our peers.

The theme of the conference was:Value Drivers for Digitalization of the Product Lifecycle, a topic I have been discussing in my recent blog posts, as we need help and educate companies to understand the importance of digitalization for their business.

The two-day conference covered various lectures – view the agenda here – and of course the topic of AI was part of half of the lectures, giving the attendees a touch of reality.

The two-day conference covered various lectures – view the agenda here – and of course the topic of AI was part of half of the lectures, giving the attendees a touch of reality.

In this first post, I will cover the main highlight of Day 1.

Value Drivers for Digitalization of the Product Lifecycle

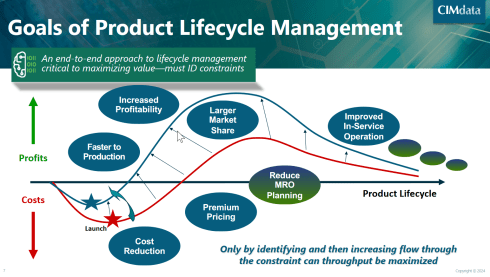

As usual, the conference started with Peter Bilello, president & CEO of CIMdata, stressing again that when implementing a PLM strategy, the maximum result comes from a holistic approach, meaning look at the big picture, don’t just focus on one topic.

As usual, the conference started with Peter Bilello, president & CEO of CIMdata, stressing again that when implementing a PLM strategy, the maximum result comes from a holistic approach, meaning look at the big picture, don’t just focus on one topic.

It was interesting to see again the classic graph (below) explaining the benefits of the end-to-end approach – I believe it is still valid for most companies; however, as I shared in my session the next day, implementing concepts of a Products Service System will require more a DevOp type of graph (more next week).

Next, Peter went through the CIMdata’s critical dozen with some updates. You can look at the updated 2024 image here.

Some of the changes: Digital Thread and Digital Twin are merged– as Digital Twins do not run on documents. And instead of focusing on Artificial Intelligence only, CIMdata introduced Augmented Intelligence as we should also consider solutions that augment human activities, not just replace them.

Some of the changes: Digital Thread and Digital Twin are merged– as Digital Twins do not run on documents. And instead of focusing on Artificial Intelligence only, CIMdata introduced Augmented Intelligence as we should also consider solutions that augment human activities, not just replace them.

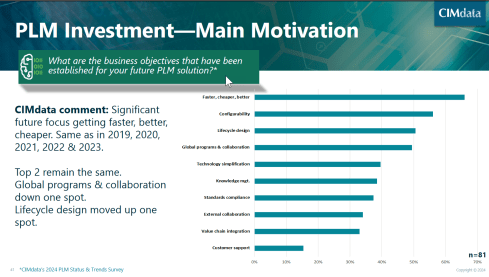

Peter also shared the results of a recent PLM survey where companies were asked about their main motivation for PLM investments. I found the result a little discouraging for several reasons:

The number one topic is still faster, cheaper and better – almost 65 % of the respondents see this as their priority. This number one topic illustrates that Sustainability has not reached the level of urgency, and perhaps the topic can be found in standards compliance.

Many of the companies with Sustainability in their mission should understand that a digital PLM infrastructure is the foundation for most initiatives, like Lifecycle Analysis (LCA). Sustainability is more than part of standards compliance, if it was mentioned anyway.

Many of the companies with Sustainability in their mission should understand that a digital PLM infrastructure is the foundation for most initiatives, like Lifecycle Analysis (LCA). Sustainability is more than part of standards compliance, if it was mentioned anyway.

The second disappointing observation for the understanding of PLM is that customer support is mentioned only by 15 % of the companies. Again, connecting your products to your customers is the first step to a DevOp approach, and you need to be able to optimize your product offering to what the customer really wants.

Digital Transformation of the Value Chain in Pharma

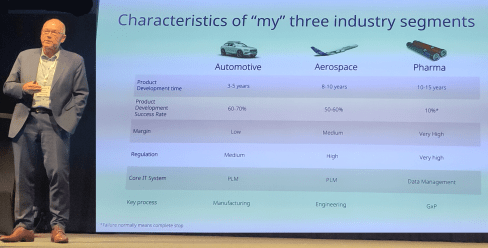

The second keynote was from Anders Romare, Chief Digital and Information Officer at Novo Nordisk. Anders has been participating in the PDT conference in the past. See my 2016 PLM Roadmap/PDT Europe post, where Anders presented on behalf of Airbus: Digital Transformation through an e2e PLM backbone.

Anders started by sharing some of the main characteristics of the companies he has been working for. Volvo, Airbus and now Novo Nordisk. It is interesting to compare these characteristics as they say a lot about the industry’s focus. See below:

Anders is now responsible for digital transformation in Novo Nordisk, which is a challenge in a heavily regulated industry.

One of the focus areas for Novo Nordisk in 2024 is also Artificial Intelligence, as you can see from the image to the left (click on it for the details).

One of the focus areas for Novo Nordisk in 2024 is also Artificial Intelligence, as you can see from the image to the left (click on it for the details).

As many others in this conference, Anders mentioned AI can only be applicable when it runs on top of accurate data.

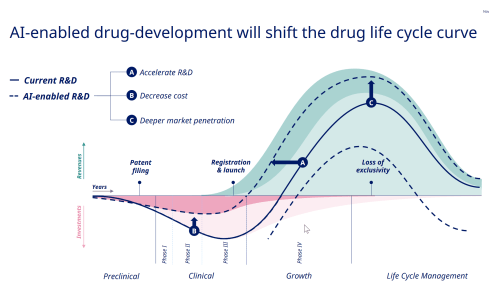

Understanding the potential of AI, they identified 59 areas where AI can create value for the business, and it is interesting to compare the traditional PLM curve Peter shared in his session with the potential AI-enabled drug-development curve as presented by Anders below:

Next, Anders shared some of the example cases of this exploration, and if you are interested in the details, visit their tech.life site.

When talking about the engineering framing of PLM, it was interesting to learn from Anders, who had a long history in PLM before Novo Nordisk, when he replied to a question from the audience that he would never talk about PLM at the management level. It’s very much aligned with my Don’t mention the P** word post.

A Strategy for the Management of Large Enterprise PLM Platforms

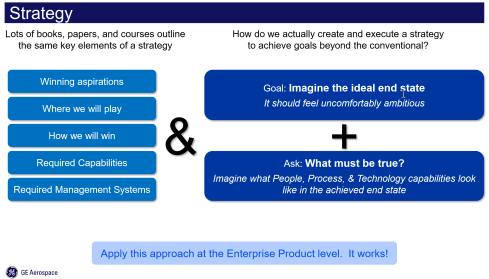

One of the highlights for me on Day 1 was Jorgen Dahl‘s presentation. Jorgen, a senior PLM director at GE Aerospace, shared their story towards a single PLM approach needed due to changes in businesses. And addressing the need for a digital thread also comes with an increased need for uptime.

I like his strategy to execution approach, as shown in the image below, as it contains the most important topics. The business vision and understanding, the imagination of the end status and What must be True?

In my experience, the three blocks are iteratively connected. When describing the strategy, you might not be able to identify the required capabilities and management systems yet.

But then, when you start to imagine the ideal end state, you will have to consider them. And for companies, it is essential to be ambitious – or, as Jorgen stated, uncomfortable ambitious. Go for the 75 % to almost 100 % to be true. Also, asking What must be True is an excellent way to allow people to be involved and creatively explore the next steps.

Note: This approach does not provide all the details, as it will be a multiyear journey of learning and adjusting towards the future. Therefore, the strategy must be aligned with the culture to avoid continuous top-down governance of the details. In that context, Jorgen stated:

“Culture is what happens when you leave the room.”

It is a more positive statement than the famous Peter Drucker’s quote: “Culture eats strategy for breakfast.”

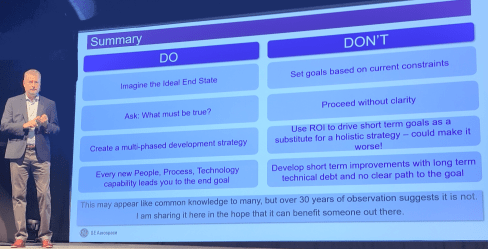

Jorgen’s concluding slide mentions potential common knowledge, although I believe the way Jorgen used the right easy-to-digest points will be helpful for all organizations to step back, look at their initiatives, and compare where they can improve.

How a Business Capability Model and Application Portfolio Management Support Through Changing Times

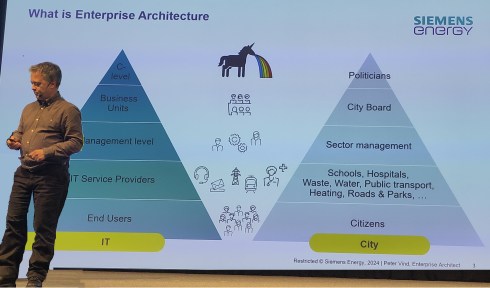

Peter Vind‘s presentation was nicely connected to the presentation from Jorgen Dahl. Peter, who is an enterprise architect at Siemens Energy, started by explaining where the enterprise architect fits in an organization and comparing it to a city.

In his entertaining session, he mentioned he has to deal with the unicorns at the C-level, who, like politicians in a city, sometimes have the most “innovative” ideas – can they be realized?

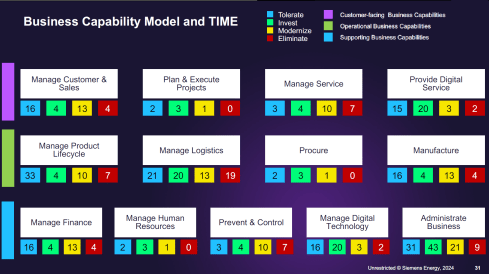

Peter explained how they used Business Capability Modeling when Siemens Energy went through various business stages. First, the carve-out from Siemens AG and later the merger with Siemens Gamesa. Their challenge is to understand which capabilities remain, which are new or overlapping, both during the carve-out and merging process.

The business capability modeling leads to a classification of the applications used at different levels of the organization, such as customer-facing, operational, or supporting business capabilities.

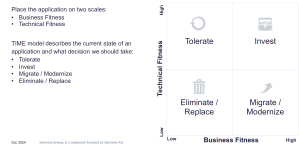

Next, for the lifecycle of the applications, the TIME approach was used, meaning that each application was mapped to business fitness and technical fitness. Click on the diagram to see the details.

The result could look like the mapping shown below – a comprehensive overview of where the action is

It is a rational approach; however, Peter mentioned that we also should be aware of the HIPPOs in an organization. If there is a HiPPO (Highest Paid Person’s Opinion) in play, you might face a political battle too.

It was a great educational session illustrating the need for an Enterprise Architect, the value of business capabilities modeling and the TIME concept.

And some more …

There were several other exciting presentations during day 1; however, as not all presentations are publicly available, I cannot discuss them in detail; I just looked at my notes.

Driving Trade Compliance and Efficiency

Peter Sandeck, Director of Project Management at TE Connectivity shared what they did to motivate engineers to endorse their Jurisdiction and Classification Assessment (JCA) process. Peter showed how, through a Minimal Viable Product (MVP) approach and listening to the end-users, they reached a higher Customer Satisfaction (CSAT) score after several iterations of the solution developed for the JCA process.

Peter Sandeck, Director of Project Management at TE Connectivity shared what they did to motivate engineers to endorse their Jurisdiction and Classification Assessment (JCA) process. Peter showed how, through a Minimal Viable Product (MVP) approach and listening to the end-users, they reached a higher Customer Satisfaction (CSAT) score after several iterations of the solution developed for the JCA process.

This approach is an excellent example of an agile method in which engineers are involved. My remaining question is still – are the same engineers in the short term also pushed to make lifecycle assessments? More work; however, I believe if you make it personal, the same MVP approach could work again.

Value of Model-Based Product Architecture

Jussi Sippola, Chief Expert, Product Architecture Management & Modularity at Wärtsilä, presented an excellent story related to the advantages of a more modular product architecture. Where historically, products were delivered based on customer requirements through the order fulfillment process, now there is in parallel the portfolio management process, defining the platform of modules, features and options.

Jussi Sippola, Chief Expert, Product Architecture Management & Modularity at Wärtsilä, presented an excellent story related to the advantages of a more modular product architecture. Where historically, products were delivered based on customer requirements through the order fulfillment process, now there is in parallel the portfolio management process, defining the platform of modules, features and options.

Jussi mentioned that they were able to reduce the number of parts by 50 % while still maintaining the same level of customer capabilities. In addition, thanks to modularity, they were able to reduce the production lead time by 40 % – essential numbers if you want to remain competitive.

Conclusion

Day 1 was a day where we learned a lot as an audience, and in addition, the networking time and dinner in the evening were precious for me and, I assume, also for many of the participants. In my next post, we will see more about new ways of working, the AI dream and Sustainability.

This is a guest post from one of our active members of the PLM Green Global Alliance, Roger L. Franz.

This is a guest post from one of our active members of the PLM Green Global Alliance, Roger L. Franz.

Roger is supporting industry inquiries on regulated substances, sustainable product design and life cycle management, including carbon footprint.

He is a recognized authority on supply chain reporting for compliance with worldwide regulations. Roger brings decades of experience with engineering tools and enterprise IT systems.

Introduction.

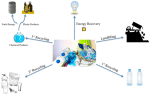

More than just unsightly “plastic pollution,” the volume of consumer plastics and lack of closed-loop recovery have created a significant micro- and nano-plastics problem. These invisible plastic particles are found around the world, including in animal and human tissues.

For several reasons, including a much smaller volume of plastic used in electrotechnical products compared to consumer plastics and the generally longer life of hardware compared to the rapid turnover of consumer goods and packaging, the microplastics problem is not typically tagged as a major electronics problem- or at least not yet. Now is the time to be proactive.

The United Nations Environment Programme has posted summaries of recent discussions on using life cycle assessment (LCA) to address the global problem of plastic pollution. These Life Cycle Initiative areas relate to plastic products, chemicals of concern in plastic products, and plastic product design. The documents are about possible approaches to managing plastics with recommendations but are not detailed prescriptions, methods, or regulations.

The United Nations Environment Programme has posted summaries of recent discussions on using life cycle assessment (LCA) to address the global problem of plastic pollution. These Life Cycle Initiative areas relate to plastic products, chemicals of concern in plastic products, and plastic product design. The documents are about possible approaches to managing plastics with recommendations but are not detailed prescriptions, methods, or regulations.

While the studies did not specifically mention electrotechnical products, this industry will need to accelerate focus on engineering design tools and engineering plastics choices to avoid significantly adding on to the consumer plastic product problems.

Within the UNEP product design discussion, the section on “General considerations on possible approaches to product design, focusing on recyclability and reusability” included the following important point, which bears repeating: Product design approaches should include eco-design and circularity principles.

Product design approaches should include

eco-design and circularity principles.

But what does this mean? In the following discussion, we hope to break these approaches down into more tangible design choices. Even within the electrotechnical product category, there are many product variations, so no claim is made here to cover all of them.

Options for lower carbon footprint plastics already exist to some extent. Except for packaging, electronic components and products are typically made with engineering resins rather than the common consumer plastic “recycling arrow” types. Alternative types of lower carbon footprint engineering resins may be available to use rather than others with higher carbon footprints.

Many plastic manufacturers are currently conducting LCA to quantify the cradle-to-gate carbon footprint of their materials. Different polymer types have inherent differences in carbon footprint due to their different monomeric starting materials and manufacturing processes.

For many plastics, these flows are detailed by Plastics Europe. Polycarbonate, ABS, and several Polyamides, for example, are included. What is missing in these publicly available sources, as well as LCA inventory databases themselves, are many other engineering plastics; for example, while consumer PET is widely modeled, PBT (Polybutylene terephthalate) is not. These are just some of the data gaps that need to be resolved.

For many plastics, these flows are detailed by Plastics Europe. Polycarbonate, ABS, and several Polyamides, for example, are included. What is missing in these publicly available sources, as well as LCA inventory databases themselves, are many other engineering plastics; for example, while consumer PET is widely modeled, PBT (Polybutylene terephthalate) is not. These are just some of the data gaps that need to be resolved.

More sustainable feedstock is a good option since a given end polymer may be made from different monomeric chemicals, so the more sustainable plastic performs exactly like its classic version because it is the same. One of the growing alternatives includes feedstocks based on renewable, bio-based sources.

These need some evaluation, again using LCA, to ensure they are free of downsides like increased water use, eutrophication, and chemical pollution due to the use of herbicides, pesticides, fertilizers, and so on. Marketing claims of being a “green material” will need backup data! For guidelines on acceptable environmental benefits claims, refer to the US FTC Green Guides.

These need some evaluation, again using LCA, to ensure they are free of downsides like increased water use, eutrophication, and chemical pollution due to the use of herbicides, pesticides, fertilizers, and so on. Marketing claims of being a “green material” will need backup data! For guidelines on acceptable environmental benefits claims, refer to the US FTC Green Guides.

Reducing the amount of plastic by design is not only a good practice for sustainability, it also saves money. Some designs using parts with enough material to be modeled using generative design may be able to reduce the amount of material while reducing material usage and weight. Reducing factory scrap from injection molding processes leaving sprues in runners and use of captive regrind are other good options.

Choosing manufacturers using renewable fuels– and even benefits like reduction of water use during processing- is another area of choice for sustainability. Local sourcing is also a way to reduce the overall carbon footprint of a material by reducing the contribution of transportation.

Identify large plastic parts. Historical guidelines on eco-design have actually been around for years.

One good example is the ECMA 341 Standard, “Environmental Design Considerations for ICT & CE Products (4th Edition / December 2010), which says, “All plastic parts weighing 25 g or more and with a flat area of 200 mm2 or more are marked with the type of polymer, copolymer, polymer blends or alloys in conformance with ISO 11469.” This practice enables the identification of plastic types of large parts, while in practice, the ability to sort becomes less useful when a variety of goods are mixed in a production recycling facility. Success here depends either on manual sorting or more sophisticated methods like infrared spectroscopy to be effective. Some equipment recyclers have such capability.

One good example is the ECMA 341 Standard, “Environmental Design Considerations for ICT & CE Products (4th Edition / December 2010), which says, “All plastic parts weighing 25 g or more and with a flat area of 200 mm2 or more are marked with the type of polymer, copolymer, polymer blends or alloys in conformance with ISO 11469.” This practice enables the identification of plastic types of large parts, while in practice, the ability to sort becomes less useful when a variety of goods are mixed in a production recycling facility. Success here depends either on manual sorting or more sophisticated methods like infrared spectroscopy to be effective. Some equipment recyclers have such capability.

Keep it clean. More useful guidance from ECMA 341 is to avoid the following: non-recyclable composites; coatings and surface finishes on plastic parts; adhesive-backed stickers or foams on plastic parts; if stickers are required, they should be separable; and metal inserts in plastic parts unless easily removable with common tools. These are common sense from a clean recycling stream perspective and should not be difficult to implement.

Closing the end-of-life loop. Recycling is imperfect, and as far as this author has seen, is rarely in place for engineering plastics.

Processes under development to decompose plastics back to new monomer feedstocks, called chemical recycling or tertiary recycling. This approach is achieving some success with a limited number of materials, mostly for high-volume consumer plastics rather than engineering types.

Processes under development to decompose plastics back to new monomer feedstocks, called chemical recycling or tertiary recycling. This approach is achieving some success with a limited number of materials, mostly for high-volume consumer plastics rather than engineering types.

LCA is needed to validate that achieving plastic circularity this way with the necessary processing energy and chemicals will have a net environmental benefit. The obvious problem with all approaches is that plastics were never designed for the environment in the first place.

Selecting More Sustainable Additives is another area where product engineers have some choices. There are thousands of possible additives used in plastic, usually specified for a given grade and end application. These include flame retardants, processing aids, fillers, colorants, ultraviolet stabilizers, plasticizers for flexibility, and so on and on. While these choices are primarily the responsibility of the resin manufacturer, pressure from regulators and industry demand can influence the use of more sustainable additives.

Whenever possible, new products should avoid regulated substances by design, which may include Substances of Very High Concern (SVHC) as defined by the European Chemicals Agency (ECHA) and, more recently, polyfluorinated substances called PFAS. This is easier said than done but definitely belongs on the checklist of ecodesign considerations.

Besides plastics? While the present discussion is about plastics, choices of using altogether different materials may be possible in some cases.

High-volume hardware is probably unable to use alternative materials like wood, glass, bamboo, etc. Historically, though, until the rise of both solid-state and plastic technology in the 1950s, radios and televisions featured wooden cases and consoles. Miniaturization in the solid-state era brought in mostly plastic housings. One recent example that the author worked on was an audio teleconferencing system that featured either oak or walnut to blend with the executive conference room.

High-volume hardware is probably unable to use alternative materials like wood, glass, bamboo, etc. Historically, though, until the rise of both solid-state and plastic technology in the 1950s, radios and televisions featured wooden cases and consoles. Miniaturization in the solid-state era brought in mostly plastic housings. One recent example that the author worked on was an audio teleconferencing system that featured either oak or walnut to blend with the executive conference room.

While the intent was not specifically to avoid using plastic, it is an interesting example to think outside the plastic box. Wood avoids many of the issues with plastics, but of course, the plastics in the circuitry content remain to be addressed.

Other large household electrical/electronic goods are likely to use recyclable steel and/or stainless steel cabinets. And if you consider an automobile to be an electronic product, these metals come into play in high volume in automobile shredder residue. Using metal rather than plastic housings may be possible for some products; for example, aluminum may be used for personal communications and IT devices, bringing a tradeoff between initial cost and the potential advantage of aluminum being more highly recyclable for use in new equipment than any plastic.

Only LCA can quantify the tradeoffs. We should also mention toys, which increasingly incorporate some electronics and use colored plastics extensively.

New material technology. One of the many emerging material technologies is Engineered Wood. The cited research hardly suggests that a wood-based material could be a drop-in, for example, injection molded thermoplastics, but the possibility is most intriguing. However, just having a material of natural origins is not automatically a panacea for replacing plastics. Quite the contrary, significant cautions remain; for example,

“Chemical and thermal modifications are usually applied to adapt the wood structure and impart necessary functionalities. Most of these treatments use substantial amounts of chemicals, energy, and water. They also innocently incorporate unwanted chemically bonded structures into the wood and generate a large amount of waste products which are harmful to the environment. This brings a dilemma where an entirely sustainable and green material is converted to a non-environmentally friendly material”

(El Akban et. al, Green Chemistry, 2021).

For now, the point is that reconsidering classical synthetic polymers in the light of more natural and renewable materials may have an interesting future.

Modularity. The ease of disassembly into “modules” is often listed as an eco-design practice that improves circularity, but the present author is skeptical about providing practical details. More specific guidance requires each manufacturer to know how its products can be disassembled at their end of life and where such disassembly would lead in terms of reuse, remanufacturing, or material recovery. In the context of plastics, a large plastic housing that can be easily disassembled into a single clean material is more likely to be sent to a recycler rather than reused as a “module” in other products.

It is unfortunate that software tools to make early design choices for disassembly began to be developed 25 years ago but have gone by the wayside since. The author had personal experience with such a “Green Design Advisor” tool that modeled a product assembly from its raw materials and showed how disassembly into environmentally and economically viable recovery fractions could be optimized.

One example that is probably still true today is that an epoxy circuit board and its components would be a “module” to be submitted to size a reduction, separation, and metal recovery process. Such a tool could also model the choice of a plastic housing vs. a metal alloy and the impacts of circular recovery of the material choices. Disassembly modeling tools for product designers is an area that needs significant development now, while software using artificial intelligence (AI) claims to be the answer. We shall see.

In conclusion, it must be recognized that most plastics were never designed for the environment in the first place. While there is currently no 100% perfect alternative, engineers do have options to improve the life cycle sustainability of tomorrow’s products.

- Select lower PCF plastics and avoid regulated additives.

- Reduce the amount of plastics if possible and keep larger parts free of different materials.

- Consider materials other than plastics.

- Be aware of new developments in both sources of plastic and end-of-life options.

Roger L. Franz / RogerLFranz@gmail.com – Sept. 2024

Although scientists engaged in a discussion about the scientific evidence, there were no significant economic forces behind the scenes influencing the scientific research.

Although scientists engaged in a discussion about the scientific evidence, there were no significant economic forces behind the scenes influencing the scientific research.

We look forward to having

We look forward to having

Part of this challenge is the lack of education among top management, who are primarily focused on efficiency gains rather than adopting new approaches or mitigating risk.

Part of this challenge is the lack of education among top management, who are primarily focused on efficiency gains rather than adopting new approaches or mitigating risk. However, first and foremost, the most critical factor in driving sustainability within organizations is the people. Where companies are challenged in creating a green image, including the introduction of the Chief Sustainability Officer (CSO), there has always been resistance from existing business leaders, who prioritize money and profitability.

However, first and foremost, the most critical factor in driving sustainability within organizations is the people. Where companies are challenged in creating a green image, including the introduction of the Chief Sustainability Officer (CSO), there has always been resistance from existing business leaders, who prioritize money and profitability.

And recently, we saw the

And recently, we saw the

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…