You are currently browsing the tag archive for the ‘PGGA’ tag.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago, in 2022, with the initial PLM vendors followed by additional software vendors and implementers who focus on Sustainability.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago, in 2022, with the initial PLM vendors followed by additional software vendors and implementers who focus on Sustainability.

The list is getting longer, and for some of them, we are now in the second round, learning what has happened in the field with their customers.

You can always read about these interviews on our PLM Green Global Alliance website or subscribe to the YouTube channel: @PLM_Global_Green_Alliance where we share the interview recordings.

This time, we spoke with Henrik Hulgaard from Configit. I spoke earlier with Henrik about Configuration Lifecycle Management – you can read our discussion here. Now, we talked about the relationship between Configit and Sustainability.

This time, we spoke with Henrik Hulgaard from Configit. I spoke earlier with Henrik about Configuration Lifecycle Management – you can read our discussion here. Now, we talked about the relationship between Configit and Sustainability.

Configit

![]() Configit is not a typical PLM or reporting software provider. They flourish on top of an existing (data-driven) infrastructure in order to provide consistency between all aspects of product design, manufacturing and usage.

Configit is not a typical PLM or reporting software provider. They flourish on top of an existing (data-driven) infrastructure in order to provide consistency between all aspects of product design, manufacturing and usage.

In their words:

“We build configuration solutions for manufacturing companies to master the challenges of getting configurable products and services to market faster and selling, manufacturing, and servicing them more effectively.”

We discussed how this is beneficial in the context of Sustainability with Henrik Hulgaard, their VP of Product Management.

Enjoy the 35-minute discussion below:

The slides shown during the interview, combined with additional company information, can be found HERE.

What we have learned

- Using Configit connected to your configurable products allows you to select the best performance for Sustainability if this is your motivation. It will enable companies to design and deliver configurable products where, in the end, in practice, the customer decides on the optimum configuration, fitting their purpose and ambition.

- Configurations and Modularity, which are building blocks of the circular economy, go hand in hand and cannot be considered standalone options.

- Even AI has entered the domain of configuration lifecycle management – we are in the early stages of learning more.

Want to learn more?

- The slide deck related to this interview

- The whitepaper: Sustainability transformation in manufacturing

- The Configit blog section

Conclusion

As a company, there are many ways to provide more sustainable products to your customers, such as by design and by customer choice. With Configit, companies can provide the most sustainable options for their manufacturing process or later support their customers to select the most sustainable options.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

The initial interview in 2022 focused on companies getting pushed by legislation related to plastic packaging and how they could collect and analyze their product data.

Now, two years later, we discussed a much broader scope, including the Circular Economy and even Circular Manufacturing in the automotive industry. You can read and listen to this interview following this link: The PGGA talking again with SAP on Sustainability.

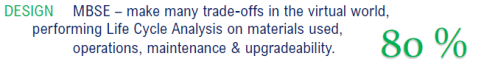

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

PTC

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

You could follow his movements through Europe on LinkedIn and his posting from the Munich workshop was fascinating. Besides meeting customers, there were also PTC partners like MakerSite, aPriori, and Transition Technologies PSC. All three companies have recently contributed to our PGGA series related to Sustainability.

Together with Dave, we spoke again with James Norman, who is responsible for driving PTC’s solutions and strategy for the digital and Sustainability transformation. He helped us make the connection between what’s happening in the field and what PTC is considering.

When listening to the interview, you will observe that in the PLM domain, so much has changed in the past two years.

Enjoy the 36 minutes of the interview and listen to what Dave has learned from the field, as reflected by James, on how PTC is addressing Sustainability.

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- The Corporate Sustainability Reporting Directive (CSRD) has forced companies to address Sustainability and the need for the digitalization of their processes (the digital thread)

- For Sustainability impact, do not focus just on the component properties; identify hot-spots when analyzing analyzing the impact of the product on the product level.

- As the OEM often only assembles the final product, the environmental impact is defined upstream in the supply chain.

- Modularity and Systems Thinking are crucial methodologies for implementing a Circular Economy.

- If you only consider the cradle-to-gate part of a product’s lifecycle, you might miss the big picture entirely. Even worse, you might implement design changes in the name of sustainability that result in outcomes far less sustainable than the original design. It’s crucial to look at the entire Product Service System/lifecycle to truly understand a product’s environmental impact

- We did not talk about Digital Twins and AI this time. Implementing a connected Digital Thread is, at this moment, the highest priority.

Want to learn more?

- There is the PTC Impact Report

- Dave Duncan’s article: Join PTC on Our Sustainability Journey

- A customer story: How Cummins Prioritizes Sustainability for New Product Designs

Conclusion

I enjoyed the dialogue with Dave and James and the progress we all have made towards understanding what is needed to ensure a sustainable future for our planet. So much has changed in two years.

PLM plays a crucial role in the discussion of a circular economy, the need for modularity, and sustainability reporting. All of these elements require a digital infrastructure related to the products we manufacture or use.

In addition, I was impressed by Dave’s pragmatic approach, who was in the hot spots of European manufacturing companies to understand their needs instead of telling them about their should-be dreams.

Our first PGGA interview with PLM-related software vendors was two years ago with SAP. At that time, Sustainability became more visible in corporate strategies, and regulations were imminent.

Our first PGGA interview with PLM-related software vendors was two years ago with SAP. At that time, Sustainability became more visible in corporate strategies, and regulations were imminent.

This time, Klaus Brettschneider and I want to learn what has happened related to Sustainability. Is there visible progress in their organizations and customer base? And what is hot now?

And we were positively surprised by a conversation going in many directions.

SAP

The interview was again with Darren West. Darren is the product expert for SAP’s Circular Economy solutions and this time, Stephan Fester supported him. Stephan is co-leading the SAP Global Circular Manufacturing Practice and, therefore, is well-connected to the field. Last year, in particular, working in discrete manufacturing and discussing circular manufacturing.

The interview was again with Darren West. Darren is the product expert for SAP’s Circular Economy solutions and this time, Stephan Fester supported him. Stephan is co-leading the SAP Global Circular Manufacturing Practice and, therefore, is well-connected to the field. Last year, in particular, working in discrete manufacturing and discussing circular manufacturing.

Thanks to the expertise of our guests, the discussion went in various directions, with circularity as the central theme.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

But also, we discussed the Digital Product Passport. Catena-X, what is it, and what is it targeting?

We also discussed how to deal with the scarcity of materials and materials harvesting. The interview could not be complete without mentioning AI.

Enjoy the 35-minute interview with Darren and Stephan on our YouTube channel.

The slides shown in this recording can be found here: PGGA talking again with SAP.

What we have learned

- Regulations heavily push SAP customers and require adequate reporting tools, not only for finance and material use but also for sustainability KPIs

- The Responsible Design & Production module launched two years ago is already in use with 60+ customers, showing the importance of having data-driven decision support for plastic packaging – to be extended to the product. Of course, as a PLM community, we are interested in understanding the next steps toward the product.

- The insights from Stephan Fester on circular manufacturing can be a logical evolution of the linear product process, as Stephan’s image shows.

- Great insights on Catena-X as an independent network for data sharing in the global network

Want to learn more?

Events and Shows:

- SAP at Hannover Messe – April 22-26, 2024 – event information

- SAP Sapphire, Orlando, USA – June 3-5, 2024 – event information

- SAP Sapphire, Barcelona, Spain – June 11-13, 2024 – event information

Websites:

- Circular Manufacturing at Scale – Microsite

- SAP Responsible Design and Production – product page

- SAP Circular Economy page

- SAP Sustainability home page

Conclusion

It was a great discussion with a company that is quite active in supporting its customers on a sustainable journey. The journey is complex and has many aspects, as Darren and Stephan shared in this dialogue. The good news is that SAP’s customers are actively implementing measures and processes – going circular is happening!

Join the PDSFORUM next month and join me to get inspired an participate in a Think Thank session on day 2 related to designing more sustainable products. Will we meet there?

About a year ago we started the PLM Global Green Alliance, further abbreviated as the PGGA. Rich McFall, the main driver behind the PGGA started the website, The PLM Green Alliance, to have a persistent place to share information.

About a year ago we started the PLM Global Green Alliance, further abbreviated as the PGGA. Rich McFall, the main driver behind the PGGA started the website, The PLM Green Alliance, to have a persistent place to share information.

Also, we launched the PLM Global Alliance LinkedIn group to share our intentions and create a community of people who would like to share knowledge through information or discussion.

Our mission statement is:

The mission of the new PLM Green Alliance is to create global connection, communication, and community between professionals who use, develop, market, or support Product Lifecycle Management (PLM) related technologies and software solutions that have value in addressing the causes and consequences of climate change due to human-generated greenhouse gas emissions. We are motivated by the technological challenge to help create a more sustainable and green future for our economies, industries, communities, and all life forms on our planet that depend on healthy ecosystems.

My motivation

My personal motivation to support and join the PGGA was driven by the wish to combine my PLM-world with interest to create a more sustainable society for anyone around the world. It is a challenging combination. For example, PLM is born in the Aerospace and Defense industries, probably not the most sustainable industries.

My personal motivation to support and join the PGGA was driven by the wish to combine my PLM-world with interest to create a more sustainable society for anyone around the world. It is a challenging combination. For example, PLM is born in the Aerospace and Defense industries, probably not the most sustainable industries.

Having worked with some companies in the Apparel and Retail industry, I have seen that these industries care more about their carbon footprint. Perhaps because they are “volume-industries” closely connected to their consumers, these industries actively build practices to reduce their carbon footprint and impact societies. The sense or non-sense of recycling is such a topic to discuss and analyze.

At that time, I got inspired by a session during the PLM Roadmap / PDT 2019 conference.

Graham Aid‘s from the Ragn-Sells group was a call to action. Sustainability and a wealthy economy go together; however, we have to change our habits & think patterns. You can read my review from this session in this blog post: The weekend after PLM Roadmap / PDT 2019 – Day 1

Many readers of this post have probably never heard of the Ragn-Sells group or followed up on a call for action. I have the same challenge. Being motivated beyond your day-to-day business (the old ways of working) and giving these activities priority above exploring and learning more about applying sustainability in my PLM practices.

Many readers of this post have probably never heard of the Ragn-Sells group or followed up on a call for action. I have the same challenge. Being motivated beyond your day-to-day business (the old ways of working) and giving these activities priority above exploring and learning more about applying sustainability in my PLM practices.

And then came COVID-19.

I think most of you have seen the image on the left, which started as a joke. However, looking back, we all have seen that COVID-19 has led to a tremendous push for using digital technologies to modernize existing businesses.

I think most of you have seen the image on the left, which started as a joke. However, looking back, we all have seen that COVID-19 has led to a tremendous push for using digital technologies to modernize existing businesses.

Personally, I was used to traveling every 2 – 3 weeks to a customer, now I have left my home office only twice for business. Meanwhile, I invested in better communication equipment and a place to work. And hé, it remains possible to work and communicate with people.

Onboarding new people, getting to know new people takes more social interaction than a camera can bring.

In the PGGA LinkedIn community, we had people joining from all over the world. We started to organize video meetings to discuss their expectations and interest in this group with some active members.

In the PGGA LinkedIn community, we had people joining from all over the world. We started to organize video meetings to discuss their expectations and interest in this group with some active members.

We learned several things from these calls.

First of all, finding a single timeslot that everyone worldwide could participate in is a challenge. A late Friday afternoon is almost midnight in Asia and morning in the US. And is Friday the best day – we do not know yet.

For that reason, we are probably moving to the PLM Green Alliance website and combine this environment with a space for discussion outside the LinkedIn scope. More to come on the PGGA website.

Finally, we will organize video discussion sessions to ask the participants to prepare themselves for a discussion. Any member of the PGGA can bring in the discussion topics.

Finally, we will organize video discussion sessions to ask the participants to prepare themselves for a discussion. Any member of the PGGA can bring in the discussion topics.

It might be a topic you want to clarify or better understand.

What’s next

For December 4th, we have planned a discussion meeting related to the Exponential Roadmap 2019 report, where 36 solutions to halve carbon emission by 2030 are discussed. In our video discussion, we want to focus on the chapter: Digital Industries.

For December 4th, we have planned a discussion meeting related to the Exponential Roadmap 2019 report, where 36 solutions to halve carbon emission by 2030 are discussed. In our video discussion, we want to focus on the chapter: Digital Industries.

We believe that this topic comes closest to our PLM domain and hopes that participants will share their thinking and potential activities within their companies.

You can download the Exponential Roadmap here or by clicking on the image. More details about the PLM Global Green Alliance you will find in the LinkedIn group. If you want to participate, let us know.

You can download the Exponential Roadmap here or by clicking on the image. More details about the PLM Global Green Alliance you will find in the LinkedIn group. If you want to participate, let us know.

The PGGA website will be the place where more and more information will be collected per theme, to help you understand what is happening worldwide and the place where you can contribute to let us know what is happening at your side.

Conclusion

The PLM Global Green Alliance exists now for a year with 192 members. With approximately five percent active members, we have the motivation to grow our efforts and value. We learned from COVID-19 there is a need to become proactive as the costs of prevention are always lower than the costs of (trying) fixing afterward.

And each of us has the challenge to behave a little differently than before.

Will you be one of them ?

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…