You are currently browsing the tag archive for the ‘Business process’ tag.

Last week, I participated in the annual 3DEXPERIENCE User Conference, organized by the ENOVIA and NETVIBES brands. With approximately 250 attendees, the 2-day conference on the High-Tech Campus in Eindhoven was fully booked.

Last week, I participated in the annual 3DEXPERIENCE User Conference, organized by the ENOVIA and NETVIBES brands. With approximately 250 attendees, the 2-day conference on the High-Tech Campus in Eindhoven was fully booked.

My PDM/PLM career started in 1990 in Eindhoven.

First, I spent a significant part of my school life there, and later, I became a physics teacher in Eindhoven. Then, I got infected by CAD and data management, discovering SmarTeam, and the rest is history.

First, I spent a significant part of my school life there, and later, I became a physics teacher in Eindhoven. Then, I got infected by CAD and data management, discovering SmarTeam, and the rest is history.

As I wrote in my last year’s post, the 3DEXPERIENCE conference always feels like a reunion, as I have worked most of my time in the SmarTeam, ENOVIA, and 3DEXPERIENCE Eco-system.

Innovation Drivers in the Generative Economy

Stephane Declee and Morgan Zimmerman kicked off the conference with their keynote, talking about the business theme for 2024: the Generative Economy. Where the initial focus was on the Experience Economy and emotion, the Generative Economy includes Sustainability. It is a clever move as the word Sustainability, like Digital Transformation, has become such a generic term. The Generative Economy clearly explains that the aim is to be sustainable for the planet.

Stephane and Morgan talked about the importance of the virtual twin, which is different from digital twins. A virtual twin typically refers to a broader concept that encompasses not only the physical characteristics and behavior of an object or system but also its environment, interactions, and context within a virtual or simulated world. Virtual Twins are crucial to developing sustainable solutions.

Morgan concluded the session by describing the characteristics of the data-driven 3DEXPERIENCE platform and its AI fundamentals, illustrating all the facets of the mix of a System of Record (traditional PLM) and Systems of Record (MODSIM).

3DEXPERIENCE for All at automation.eXpress

Daniel Schöpf, CEO and founder of automation.eXpress GmbH, gave a passionate story about why, for his business, the 3DEXPERIENCE platform is the only environment for product development, collaboration and sales.

Automation.eXpress is a young but typical Engineering To Order company building special machinery and services in dedicated projects, which means that every project, from sales to delivery, requires a lot of communication.

Automation.eXpress is a young but typical Engineering To Order company building special machinery and services in dedicated projects, which means that every project, from sales to delivery, requires a lot of communication.

For that reason, Daniel insisted all employees to communicate using the 3DEXPERIENCE platform on the cloud. So, there are no separate emails, chats, or other siloed systems.

Everyone should work connected to the project and the product as they need to deliver projects as efficiently and fast as possible.

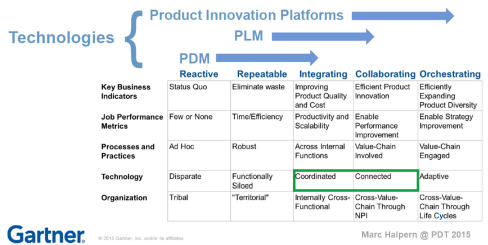

Daniel made this decision based on his 20 years of experience in traditional ways of working—the coordinated approach. Now, starting from scratch in a new company without a legacy, Daniel chose the connected approach, an ideal fit for his organization, and using the cloud solution as a scalable solution, an essential criterium for a startup company.

My conclusion is that this example shows the unique situation of an inspired leader with 20 years of experience in this business who does not choose ways of working from the past but starts a new company in the same industry, but now based on a modern platform approach instead of individual traditional tools.

My conclusion is that this example shows the unique situation of an inspired leader with 20 years of experience in this business who does not choose ways of working from the past but starts a new company in the same industry, but now based on a modern platform approach instead of individual traditional tools.

Augment Me Through Innovative Technology

Dr. Cara Antoine gave an inspiring keynote based on her own life experience and lessons learned from working in various industries, a major oil & gas company and major high-tech hardware and software brands. Currently, she is an EVP and the Chief Technology, Innovation & Portfolio Officer at Capgemini.

Dr. Cara Antoine gave an inspiring keynote based on her own life experience and lessons learned from working in various industries, a major oil & gas company and major high-tech hardware and software brands. Currently, she is an EVP and the Chief Technology, Innovation & Portfolio Officer at Capgemini.

She explained how a life-threatening infection that caused blindness in one of her eyes inspired her to find ways to augment herself to keep on functioning.

With that, she drew a parallel with humanity, who continuously have been augmenting themselves from the prehistoric day to now at an ever-increasing speed of change.

With that, she drew a parallel with humanity, who continuously have been augmenting themselves from the prehistoric day to now at an ever-increasing speed of change.

The current augmentation is the digital revolution. Digital technology is coming, and you need to be prepared to survive – it is Innovate of Abdicate.

Dr. Cara continued expressing the need to invest in innovation (me: it was not better in the past 😉 ) – and, of course, with an economic purpose; however, it should go hand in hand with social progress (gender diversity) and creating a sustainable planet (innovation is needed here).

Besides the focus on innovation drivers, Dr. Cara always connected her message to personal interaction. Her recently published book Make it Personal describes the importance of personal interaction, even if the topics can be very technical or complex.

Besides the focus on innovation drivers, Dr. Cara always connected her message to personal interaction. Her recently published book Make it Personal describes the importance of personal interaction, even if the topics can be very technical or complex.

I read the book with great pleasure, and it was one of the cornerstones of the panel discussion next.

It is all about people…

It might be strange to have a session like this in an ENOVIA/NETVIBES User Conference; however, it is another illustration that we are not just talking about technology and tools.

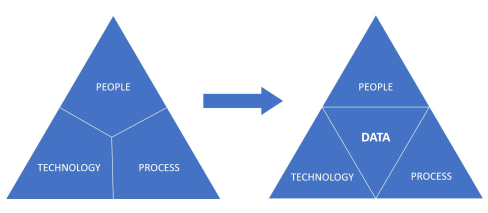

I was happy to introduce and moderate this panel discussion,also using the iconic Share PLM image, which is close to my heart.

I was happy to introduce and moderate this panel discussion,also using the iconic Share PLM image, which is close to my heart.

The panelists, Dr. Cara Antoine, Daniel Schöpf, and Florens Wolters, each actively led transformational initiatives with their companies.

We discussed questions related to culture, personal leadership and involvement and concluded with many insights, including “Create chemistry, identify a passion, empower diversity, and make a connection as it could make/break your relationship, were discussed.

And it is about processes.

Another trend I discovered is that cloud-based business platforms, like the 3DEXERIENCE platform, switch the focus from discussing functions and features in tools to establishing platform-based environments, where the focus is more on data-driven and connected processes.

Another trend I discovered is that cloud-based business platforms, like the 3DEXERIENCE platform, switch the focus from discussing functions and features in tools to establishing platform-based environments, where the focus is more on data-driven and connected processes.

Some examples:

Data Driven Quality at Suzlon Energy Ltd.

Florens Wolters, who also participated in the panel discussion “It is all about people ..” explained how he took the lead to reimagine the Sulon Energy Quality Management System using the 3DEXPERIENCE platform and ENOVIA from a disconnected, fragmented, document-driven Quality Management System with many findings in 2020 to a fully integrated data-driven management system with zero findings in 2023.

Florens Wolters, who also participated in the panel discussion “It is all about people ..” explained how he took the lead to reimagine the Sulon Energy Quality Management System using the 3DEXPERIENCE platform and ENOVIA from a disconnected, fragmented, document-driven Quality Management System with many findings in 2020 to a fully integrated data-driven management system with zero findings in 2023.

It is an illustration that a modern data-driven approach in a connected environment brings higher value to the organization as all stakeholders in the addressed solution work within an integrated, real-time environment. No time is wasted to search for related information.

It is an illustration that a modern data-driven approach in a connected environment brings higher value to the organization as all stakeholders in the addressed solution work within an integrated, real-time environment. No time is wasted to search for related information.

Of course, there is the organizational change management needed to convince people not to work in their favorite siloes system, which might be dedicated to the job, but not designed for a connected future.

Of course, there is the organizational change management needed to convince people not to work in their favorite siloes system, which might be dedicated to the job, but not designed for a connected future.

The image to the left was also a part of the “It is all about people”- session.

Enterprise Virtual Twin at Renault Group

The presentation of Renault was also an exciting surprise. Last year, they shared the scope of the Renaulution project at the conference (see also my post: The week after the 3DEXPERIENCE conference 2023).

The presentation of Renault was also an exciting surprise. Last year, they shared the scope of the Renaulution project at the conference (see also my post: The week after the 3DEXPERIENCE conference 2023).

Here, Renault mentioned that they would start using the 3DEXPERIENCE platform as an enterprise business platform instead of a traditional engineering tool.

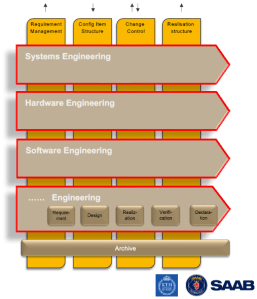

Their presentation today, which was related to their Engineering Virtual Twin, was an example of that. Instead of using their document-based SCR (Système de Conception Renault – the Renault Design System) with over 1000 documents describing processes connected to over a hundred KPI, they have been modeling their whole business architecture and processes in UAF using a Systems of System Approach.

The image above shows Franck Gana, Renault’s engineering – transformation chief officer, explaining the approach. We could write an entire article about the details of how, again, the 3DEXPERIENCE platform can be used to provide a real-time virtual twin of the actual business processes, ensuring everyone is working on the same referential.

Bringing Business Collaboration to the Next Level with Business Experiences

To conclude this section about the shifting focus toward people and processes instead of system features, Alizée Meissonnier Aubin and Antoine Gravot introduced a new offering from 3DS, the marketplace for Business Experiences.

According to the HBR article, workers switch an average of 1200 times per day between applications, leading to 9 % of their time reorienting themselves after toggling.

1200 is a high number and a plea for working in a collaboration platform instead of siloed systems (the Systems of Engagement, in my terminology – data-driven, real-time connected). The story has been told before by Daniel Schöpf, Florens Wolters and Franck Gana, who shared the benefits of working in a connected collaboration environment.

The announced marketplace will be a place where customers can download Business Experiences.

There is was more ….

There were several engaging presentations and workshops during the conference. But, as we reach 1500 words, I will mention just two of them, which I hope to come back to in a later post with more detail.

- Delivering Sustainable & Eco Design with the 3DS LCA Solution

Valentin Tofana from Comau, an Italian multinational company in the automation and committed to more sustainable products. In the last context Valentin shared his experiences and lessons learned starting to use the 3DS LifeCycle Assessment tools on the 3DEXPERIENCE platform.

Valentin Tofana from Comau, an Italian multinational company in the automation and committed to more sustainable products. In the last context Valentin shared his experiences and lessons learned starting to use the 3DS LifeCycle Assessment tools on the 3DEXPERIENCE platform.

This session gave such a clear overview that we will come back with the PLM Green Global Alliance in a separate interview. - Beyond PLM. Productivity is the Key to Sustainable Business

Neerav MEHTA from L&T Energy Hydrocarbon demonstrated how they currently have implemented a virtual twin of the plant, allowing everyone to navigate, collaborate and explore all activities related to the plant.I was promoting this concept in 2013 also for Oil & Gas EPC companies, at that time, an immense performance and integration challenge. (PLM for all industries) Now, ten years later, thanks to the capabilities of the 3DEXPERIENCE platform, it has become a workable reality. Impressive.

Neerav MEHTA from L&T Energy Hydrocarbon demonstrated how they currently have implemented a virtual twin of the plant, allowing everyone to navigate, collaborate and explore all activities related to the plant.I was promoting this concept in 2013 also for Oil & Gas EPC companies, at that time, an immense performance and integration challenge. (PLM for all industries) Now, ten years later, thanks to the capabilities of the 3DEXPERIENCE platform, it has become a workable reality. Impressive.

Conclusion

Again, I learned a lot during these days, seeing the architecture of the 3DEXPERIENCE platform growing (image below). In addition, more and more companies are shifting their focus to real-time collaboration processes in the cloud on a connected platform. Their testimonies illustrate that to be sustainable in business, you have to augment yourself with digital.

Note: Dassault Systemes did not cover any of the cost for me attending this conference. I picked the topics close to my heart and got encouraged by all the conversations I had.

Those who have read my blog posts over the years will have seen the image to the left.

Those who have read my blog posts over the years will have seen the image to the left.

The people, processes and tools slogan points to the best practice of implementing (PLM and CM) systems.

Theoretically, a PLM implementation will move smoothly if the company first agrees on the desired processes and people involved before a system implementation using the right tools.

Too often, companies start from their historical landscape (the tools – starting with a vendor selection) and then try to figure out the optimal usage of their systems. The best example of this approach is the interaction between PDM(PLM) and ERP.

PDM and ERP

Historically ERP was the first enterprise system that most companies implemented. For product development, there was the PDM system, an engineering tool, and for execution, there was the ERP system. Since ERP focuses on the company’s execution, the system became the management’s favorite.

Historically ERP was the first enterprise system that most companies implemented. For product development, there was the PDM system, an engineering tool, and for execution, there was the ERP system. Since ERP focuses on the company’s execution, the system became the management’s favorite.

The ERP system and its information were needed to run and control the company. Unfortunately, this approach has introduced the idea that the ERP system should also be the source of the part information, as it was often the first enterprise system for a company. The PDM system was often considered an engineering tool only. And when we talk about a PLM system, who really implements PLM as an enterprise system or was it still an engineering tool?

This is an example of Tools, Processes, and People – A BAD PRACTICE.

Imagine an engineer who wants to introduce a new part needed for a product to deliver. In many companies at the beginning of this century, even before starting the exercise, the engineer had to request a part number from the ERP system. This is implementation complexity #1.

Imagine an engineer who wants to introduce a new part needed for a product to deliver. In many companies at the beginning of this century, even before starting the exercise, the engineer had to request a part number from the ERP system. This is implementation complexity #1.

Next, the engineer starts developing versions of the part based on the requirements. Ultimately the engineer might come to the conclusion this part will never be implemented. The reserved part number in ERP has been wasted – what to do?

It sounds weird, but this was a reality in discussions on this topic until ten years ago.

Next, as the ERP system could only deal with 7 digits, what about part number reuse? In conclusion, it is a considerable risk that reused part numbers can lead to errors. With the introduction of the PLM systems, there was the opportunity to bridge the gap between engineering and manufacturing. Now it is clear for most companies that the engineer should create the initial part number.

Next, as the ERP system could only deal with 7 digits, what about part number reuse? In conclusion, it is a considerable risk that reused part numbers can lead to errors. With the introduction of the PLM systems, there was the opportunity to bridge the gap between engineering and manufacturing. Now it is clear for most companies that the engineer should create the initial part number.

Only when the conceptual part becomes approved to be used for the realization of the product, an exchange with the ERP system will be needed. Using the same part number or not, we do not care if we can map both identifiers between these environments and have traceability.

It took almost 10 years from PDM to PLM until companies agreed on this approach, and I am curious about your company’s status.

Meanwhile, in the PLM world, we have evolved on this topic. The part and the BOM are no longer simple entities. Instead, we often differentiate between EBOM and MBOM, and the parts in those BOMs are not necessarily the same.

Meanwhile, in the PLM world, we have evolved on this topic. The part and the BOM are no longer simple entities. Instead, we often differentiate between EBOM and MBOM, and the parts in those BOMs are not necessarily the same.

In this context, I like Prof. Dr. Jörg W. Fischer‘s framing:

EBOM is the specification, and MBOM is the realization.

(Leider schreibt Er viel auf Deutsch).

An interesting discussion initiated by Jörg last week was again about the interaction between PLM and ERP. The article is an excellent example of how potentially mainstream enterprises are thinking. PLM = Siemens, ERP = SAP – an illustration of the “tools first” mindset before the ideal process is defined.

An interesting discussion initiated by Jörg last week was again about the interaction between PLM and ERP. The article is an excellent example of how potentially mainstream enterprises are thinking. PLM = Siemens, ERP = SAP – an illustration of the “tools first” mindset before the ideal process is defined.

There was nothing wrong with that in the early days, as connectivity between different systems was difficult and expensive. Therefore people with a 20 year of experience might still rely on their systems infrastructure instead of data flow.

But enough about the bad practice – let’s go to people, processes, (data), and Tools

People, Processes, Data and Tools?

I got inspired by this topic, seeing this post two weeks ago from Juha Korpela, claiming:

Okay, so maybe a hot take, maybe not, but: the old “People, Process, Technology” trinity is one of the most harmful thinking patterns you can have. It leaves out a key element: Data.

His full post was quite focused on data, and I liked the ” wrapping post” from Dr. Nicolas Figay here, putting things more in perspective from his point of view. The reply made me think about how this discussion fits into the PLM digital transformation discussion. How would it work in the two major themes I use to explain the digital transformation in the PLM landscape?

For incidental readers of my blog, these are the two major themes I am using:

- From Coordinated to Connected, based on the famous diagram from Marc Halpern (image below). The coordinated approach based on documents (files) requires a particular timing (processes) and context (Bills of Information) – it is the traditional and current PLM approach for most companies. On the other hand, the Connected approach is based on connected datasets (here, we talk about data – not files). These connected datasets are available in different contexts, in real-time, to be used by all kinds of applications, particularly modeling applications. Read about it in the series: The road to model-based and connected PLM.

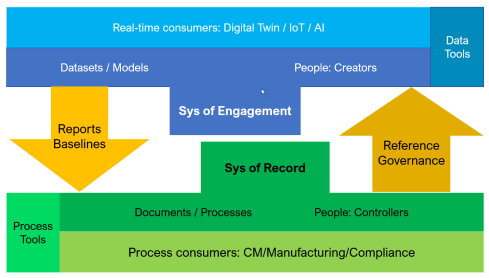

. - The need to split PLM, thinking in System(s) of Record and Systems of Engagement. (example below) The idea behind this split is driven by the observation that companies need various Systems of Record for configuration management, change management, compliance and realization. These activities sound like traditional PLM targets and could still be done in these systems. New in the discussion is the System of Engagement which focuses on a specific value stream in a digitally connected manner. Here data is essential.I discussed the coexistence of these two approaches in my post Time to Split PLM. A post on LinkedIn with many discussions and reshares illustrating the topic is hot. And I am happy to discuss “split PLM architectures” with all of you.

These two concepts discuss the processes and the tools, but what about the people? Here I came to a conclusion to complete the story, we have to imagine three kinds of people. And this will not be new. We have the creators of data, the controllers of data and the consumers of data. Let’s zoom in on their specifics.

A new representation?

I am looking for a new simplifaction of the people, processes, and tools trinity combined with data; I got inspired by the work Don Farr did at Boeing, where he worked on a new visual representation for the model-based enterprise. You might have seen the image on the left before – click on it to see it in detail.

I am looking for a new simplifaction of the people, processes, and tools trinity combined with data; I got inspired by the work Don Farr did at Boeing, where he worked on a new visual representation for the model-based enterprise. You might have seen the image on the left before – click on it to see it in detail.

I wrote the first time about this new representation in my post: The weekend after CIMdata Roadmap / PDT Europe 2018

Related to Configuration Management, Martijn Dullaart and Martin Haket have also worked on a diagram with their peers to depict the scope of CM and Impact Analysis. The image leads to the post with my favorite quote: Communication is merely an exchange of information, but connections tell the story.

Related to Configuration Management, Martijn Dullaart and Martin Haket have also worked on a diagram with their peers to depict the scope of CM and Impact Analysis. The image leads to the post with my favorite quote: Communication is merely an exchange of information, but connections tell the story.

Below I share my first attempt to combine the people, process and tools trinity with the concepts of document and data, system(s) of record and system(s) of engagement. Trying to build the story. Look if you recognize the aspects of the discussion above, and feel free to develop enhancements.

I look forward to your suggestions. Like the understanding that we have to split PLM thinking, as it impacts how we look at implementations.

Conclusion

Digital transformation in the PLM domain is forcing us to think differently. There will still be processes based on people collecting, interpreting and combining information. However, there will also be a new domain of connected data interpreted by models and algorithms, not necessarily depending on processes.

Therefore we need to work on new representations that can be used to tell this combined story. What do you think? How can we improve?

I don’t know if it is the time of the year, but suddenly there is again in the PLM world a discussion which is related to the theme of flexibility (or the lack of flexibility). And I do not refer to some of the PLM supplier lock-in situations discussed recently. In a group discussion on LinkedIn we talked about the two worlds of PLM-ERP and that somehow here we have status quo do to the fact companies won’t change the way they manage their BOM if they are not forced to do or see the value.

Stephen Porter from Zero Wait-State in his blog wrote an interesting post about using PLM to model business processes and I liked his thoughts. Here the topic, flexibility was brought into the discussion by me.

Then Mark Lind from Aras responded to this post and referred to his post on Out-Of-The-Box (OOTB) PLM which ended in a call for flexibility.

Then Mark Lind from Aras responded to this post and referred to his post on Out-Of-The-Box (OOTB) PLM which ended in a call for flexibility.

However, reading this post I wanted to bring some different viewpoints to Mark’s post and as my response became too long, I decided to post it in my blog. So please read Stephen’s post, read Mark’s post and keep the word flexibility in the back of your mind.

My European view

As I have been involved in several OOTB-attempts with various PDM / PLM suppliers, I tend to have somehow a different opinion about the purpose of OOTB.

It is all about what you mean with OOTB and what type and size of company you are talking about. My focus is not on the global enterprises – they are too big to even consider OOTB (too many opinions – too much politics).

But the mid-market companies, which in Europe practice a lot of PLM, without having a PLM system, are my major target. They improve their business with tools fitting in their environment, and when they decide to use a PLM system; it is often close related to their CAD or ERP system.

In this perspective, Mark’s statement:

Now stop and think… the fundamental premise of OOTB enterprise software is that there’s an exact match between your corporate processes and the software. If it’s not an exact match, then get ready to customize (and it won’t be OOTB anymore). This is why the concept of OOTB enterprise PLM is absurd.

I see it as a simplification – yes customers want to use OOTB systems, but as soon as you offer flexibility, customers want to adapt it. And the challenge of each product is to support as much as possible different scenarios (through configuration, through tuning (you can call it macros or customization) Microsoft Excel is still the best tool in this area

But let’s focus on PLM. Marc’s next statement:

It doesn’t matter if we’re talking about Industry Accelerators or so called ‘best practice’ templates

Again is simplifying the topic. Most of the companies I have been working with had no standard processes or PLM practices as much of the work was done outside a controlled system. And in situations that there was no Accelerator or Best Practice, you were trapped in a situation where people started to discuss their processes and to-be practices (losing time, concluding the process was not so easy as they thought, and at the end blame the PLM system as it takes so long to implement – and you need someone or something to blame). Also her Stephen promotes the functionality in PLM to assist modeling these processes.

Again is simplifying the topic. Most of the companies I have been working with had no standard processes or PLM practices as much of the work was done outside a controlled system. And in situations that there was no Accelerator or Best Practice, you were trapped in a situation where people started to discuss their processes and to-be practices (losing time, concluding the process was not so easy as they thought, and at the end blame the PLM system as it takes so long to implement – and you need someone or something to blame). Also her Stephen promotes the functionality in PLM to assist modeling these processes.

PLM is a learning process for companies and with learning I mean, understanding that the way of working can be different and change is difficult. That’s why a second, new PLM implementation in the same company is often more easy to do. At this stage a customer is able to realize which customizations were nice to have but did not contribute to the process and which customizations now could be replaced by standard capabilities (or configured capabilities). A happy target for PLM vendors where the customer changes from PLM vendor as they claim the success of the second implementation. However I have seen also re-implementations with the same software and the same vendor with the same results: faster implementation, less customization and more flexibility.

I fully agree with Marc’s statement that PLM implementations should be flexible and for me this means during implementations make sure you stay close to the PLM standards (yes there are no ‘official’ standards but every PLM implementation is around a similar data model.)

As the metadata and the created files represent the most value for the customer, this is where you should focus. Processes to change, review, collaborate or approve information should always be flexible as they will change. And when you implement these processes to speed up time-to-market or communication between departments/partners, do an ROI and risk analysis if you need to customize.

I still see the biggest problem for PLM is that people believe it is an IT-project, like their ERP project in the past. Looking at PLM in the same way does not reflect the real PLM challenge of being flexible to react. This is one of my aversions against SAP PLM – these two trigrams just don’t go together – SAP is not flexible – PLM should be flexible.

Therefore this time a short blog post or long response, looking forward to your thoughts

As a follow-up of my holiday thoughts, I want to discuss this time the various interpretations of PLM that exist. Of course we have the ‘official’ definitions of the consultancy companies like CIMdata and 2PLM ( I took an American and European example). They describe clearly that it is a business approach, not necessary a set of technologies and tools to implement.

As a follow-up of my holiday thoughts, I want to discuss this time the various interpretations of PLM that exist. Of course we have the ‘official’ definitions of the consultancy companies like CIMdata and 2PLM ( I took an American and European example). They describe clearly that it is a business approach, not necessary a set of technologies and tools to implement.

Then we have the PLM vendors, where Dassault Systems and Siemens claim their visionary leadership. Looking at their websites, it is hard to find an explicit message. They both claim PLM brings innovation (how ?) , where Dassault Systemes has a strong message around 3D and virtual product development and Siemens focuses more on efficiency and better collaboration benefits. I am not going in depth into PTC and Aras or other PLM vendors as I am only taking two examples per type of company, but look at their websites and find out how (and if) they describe PLM as a business approach.

Then we have the PLM vendors, where Dassault Systems and Siemens claim their visionary leadership. Looking at their websites, it is hard to find an explicit message. They both claim PLM brings innovation (how ?) , where Dassault Systemes has a strong message around 3D and virtual product development and Siemens focuses more on efficiency and better collaboration benefits. I am not going in depth into PTC and Aras or other PLM vendors as I am only taking two examples per type of company, but look at their websites and find out how (and if) they describe PLM as a business approach.

For a PLM definition at SAP you have to dig a little deeper and I got even more surprised when searching through the Oracle web site. Here it was difficult to find a generic PLM message. There was the list of acquisitions (which make me wonder if this means they are all integrated) and there was the list of industries and only when drilling down into the industries, you will find PLM related information. Here I still have the feeling that these companies understand there is a need for PLM, but that it is not in their veins, they want to manage product data as a ‘single version of the truth’ – which is not a bad idea and I will come back on that later – but they want to manage different data.

For a PLM definition at SAP you have to dig a little deeper and I got even more surprised when searching through the Oracle web site. Here it was difficult to find a generic PLM message. There was the list of acquisitions (which make me wonder if this means they are all integrated) and there was the list of industries and only when drilling down into the industries, you will find PLM related information. Here I still have the feeling that these companies understand there is a need for PLM, but that it is not in their veins, they want to manage product data as a ‘single version of the truth’ – which is not a bad idea and I will come back on that later – but they want to manage different data.

Also upcoming are the generic PLM on-line solutions (Arena and PLM+), which for me still are somehow a contradiction to what consultancy companies describe as PLM. Instead of a bussiness approach it is an IT-solution. In parallel there are more dedicated on-line solutions that support a specific business process (where PLM practices are embedded) – like for Apparel, CPG.

Also upcoming are the generic PLM on-line solutions (Arena and PLM+), which for me still are somehow a contradiction to what consultancy companies describe as PLM. Instead of a bussiness approach it is an IT-solution. In parallel there are more dedicated on-line solutions that support a specific business process (where PLM practices are embedded) – like for Apparel, CPG.

For these type of solutions, I have a more positive opinion as they are lowering the threshold to implement PLM in a certain industry. However the biggest skepticism I have for these types of solutions is the degrees of flexibility it will offer the implementing company to be different from standard best practices. As all companies have their uniqueness in being competitive, will they be able to support this ?

And then there was the press release from Zero Wait-State which struck me:

Zero Wait-State is launching a new website that will provide a central location for Product Lifecycle Management software and partner reviews. This site will be a valuable resource for companies trying to assess different PLM solutions and which partners to work with. The site will be driven by users and allow them to share their experiences with different software products and implementation partners.

Zero Wait-State is launching a new website that will provide a central location for Product Lifecycle Management software and partner reviews. This site will be a valuable resource for companies trying to assess different PLM solutions and which partners to work with. The site will be driven by users and allow them to share their experiences with different software products and implementation partners.

See the full press release here: Zero Wait-State Announces New Website for PLM and Service Provider Reviews.

I believe in these times of product selection and reviews certainly a good initiative. Where do we find vendor independent reviews of various PLM products ? Bringing PLM to social communities.

But ……

Here I want to take a step back. What is the essence of PLM and how do you know as a company you want to implement PLM ?

The majority of mid-market companies are not looking for a PLM system. Most of the mid-market companies have the impression that PLM is complex and expensive and typical mid-market vendors like Autodesk or SolidWorks are not pushing PLM (try for fun to search for PLM on their websites).

So will a mid-market company be able to select a PLM product through communities in the same manner as you select a consumer product ?

I believe the main challenge for a PLM implementation is not the software, but the business change.

In a company where most people are thinking (and rewarded) departmental, it is difficult to implement a new system that affects all departments. Creating the single version of the truth for product data is one of the basics for PLM. Try to get an agreement with sales, engineering, production and service who will be responsible for which part of the BOM. SAP’s single version of the truth is much more a statement from an IT-infrastructure point of view not focusing and pushing a change of business processes.

I believe, and this is also based on discussions and comments from colleagues focusing on the mid-market, that many mid-market companies are implementing basics of PLM, not always using a ‘certified’ PLM system or PLM vendor, but a pragmatic solution (customization / piece of software) which connects parts of the product information. These solutions are usually extensions on top of the CAD data management environment or the ERP system.

And here PLM vendors have a mission. Provide building blocks (services) that allow mid-market companies to connect data between departments based on known standard authoring tools. For classical PLM industries (Automotive/Aero/Fabrication & Assembly) the major CAD systems and virtual product development plus analysis software are major disciplines to manage. Other industries also have their authoring tools. Connecting them through services and provide an easy to implement backbone for product information. This should be not a big-boom effect in the mid-market, but more an evolution – moving to PLM 2.0 or beyond ?

Will this come from PLM providers or IT-providers ?

Conclusion:

For the mid-market it is not about which PLM, but more about who can provide a gradual business change from sequential and departmental business processes towards company-wide processes, where people share and collaborate around the single version of data. So which PLM should be called which provider …..

I am looking forward to your opinion.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…