At the moment this post is published I have had time to digest the latest PLMx conference organized by MarketKey. See the agenda here. For me it was a conference with mixed feelings this time and I will share more details a little further on.

At the moment this post is published I have had time to digest the latest PLMx conference organized by MarketKey. See the agenda here. For me it was a conference with mixed feelings this time and I will share more details a little further on.

Networking during the conference was excellent, good quality of conversations, however the number of people attending was smaller than previous conferences, perhaps due to too much diversification in the PI conferences?

There were several inspiring sessions and as I participated in three sessions myself, I missed a lot of potential exciting sessions that were in parallel at the same time. I believe four parallel tracks is too much and downloading the presentations later does not give you the real story. Now some of the notable sessions I attended:

Building a Better Urban Mobility Future

The first keynote session was meant to inspire us and think of solving issues differently. Lewis Horne from a Swedish automotive startup explained their different approach to designing an electrical vehicle. Not based on classical paradigms – you do not need a steering wheel – you can navigate differently. And switching the indicator on when going left or right is now a swipe. Of course these were not the only differences.

The first keynote session was meant to inspire us and think of solving issues differently. Lewis Horne from a Swedish automotive startup explained their different approach to designing an electrical vehicle. Not based on classical paradigms – you do not need a steering wheel – you can navigate differently. And switching the indicator on when going left or right is now a swipe. Of course these were not the only differences.

Unity will not certify for the highest safety classes like other vehicles as car safety rules are a lot based on mechanical / human handling and responses. A fully computerized and full of sensors has complete different dynamics. And a light city car does not ride on the high-speed way. Based on the first prototype there are already more than 1000 pre-orders but Unity does not have a manufacturing facility. This will be franchised. Unity used the Apple mode – focus on an unmatched user-experience instead of manufacturability. Let’s see what happens when the first Unity’s start riding – current target prices 20.000 Euro. Will it be the new hype for modern citizens?

Focus on quality – not on happy engineers

Not only the title of this paragraph but also other statements were made by Hilmer Brunn, head of global PLM from Mettler-Toledo related to their PLM implementation strategy. As Hilmer stated:

We should not focus to give engineers more time to design only. The job of engineering is more comprehensive than just creating designs. Engineers also need to solve issues that are related to their design – not leave it to the others.

Another interesting statement:

As long as you do not connect simulation to your design in 3D, you are actually working with 3D as if you do it with 2D. The value of 3D is more than just representation of geometry.

And the last quote I want to share from Hilmer was again related to engineering.

Engineering should consider themselves as a service provider of information to the rest of the company, providing the full information associated with a design, instead of behaving like extreme, intelligent people who need more resources to translate and complete their work.

Grand statements although during Q&A it became clear that also Mettler-Toledo did not have the magic bullet to get an organization work integrated.

Working towards a Model-Based Enterprise with PLM

I consider Model-Based practices as one of the essential needs for future PLM as this approach reduces the amount of derived information related to a product/ system. And it provides a digital continuity. In the last PDT conference in Gothenburg this topic was shared on a quit extensive matter. Have a read to fresh-up your memory here: The weekend after PDT Europe – part 1 and part 2

I consider Model-Based practices as one of the essential needs for future PLM as this approach reduces the amount of derived information related to a product/ system. And it provides a digital continuity. In the last PDT conference in Gothenburg this topic was shared on a quit extensive matter. Have a read to fresh-up your memory here: The weekend after PDT Europe – part 1 and part 2

The focus group which I moderated was with approximate 20 attendees and the majority was looking for getting a better understanding what model-based would mean for their organization. Therefore, the discussion was at the end more around areas where a few persons had the experience while others still tried to grasp the concepts. For me a point to take action related to education and in future posts I will go deeper into the basics.

PLMPulse Survey results and panel discussion

Nick Leeder presented the context of the PLMPulse survey and the results in a precise manner, where perhaps the result was not that surprising to the audience as many of us are involved in PLM. Two recurring points: PLM is still considered as an engineering tool and: The value related to PLM is most of the time not clear. You can register and download the full report from here.

Next Nick lead a panel discussion where people from the audience could participate. And here we got into a negative spiral where it became an inward-looking discussion why PLM has never been able to show the value and get out of the engineering domain. It was a someone said like an anonymous PLM meeting where members stood up and confessed they were also part of the group that could not change this behavior.

Was it the time of the day? Was it the mood of the audience? Too much old experiences? I believe it has to do with the fact that in PLM projects and conferences we focus too much on what we do and how we do things, not connecting it to tangible benefits that are recognized at the board level. And we will see an example later.

Solar Stratos

The food and drinks at the end of day 1 probably washed away the PLMPulse feedback session and Raphael Domjan inspired us with his SolarStratos project – a mission to develop a plane that can fly on solar energy on the heights of the stratosphere. Raphael is working hard with a team now to get there.

The food and drinks at the end of day 1 probably washed away the PLMPulse feedback session and Raphael Domjan inspired us with his SolarStratos project – a mission to develop a plane that can fly on solar energy on the heights of the stratosphere. Raphael is working hard with a team now to get there.

Designing an airplane, more a glider, that can take off en reach the stratosphere on solar energy requires solving a combination of so many different challenges. The first test flight reached an altitude of 500 m, but you can imagine challenges with the stratosphere – lack of oxygen / air pressure need to be solved. Raphael is looking for funding and you can find more details here. Back to the relative easy PLM challenges

The future of PLM Consultancy

Together with Oleg Shilovitsky we had a discussion related to the ways PLM could be realized in different manners thanks to changing technology. The dialogue started through our blogs – read it here. In this session there was a good dialogue with the audience and MarketKey promised to share the video recording of this session soon. Stay tuned to Oleg’s blog or my blog and you can watch it.

PLM in the context of digitization

This was my main personal contribution to the conference. Sharing insights why we have to approach PLM in a different manner. Not the classical linear engineering approach but as a mix of system of record and system of engagement. You can see the full presentation on SlideShare here.

My main conclusions are that PLM consultants / experts focus too much on what and how they do PLM, where the connection to WHY is missing. (See also my post PLM WHY?).

In addition I defended the statement that old and new PLM are incompatible and therefore you need to accept they will exist both in your organization. For a while or for a long time, depending on your product lifecycle. In order to reduce the gap between old and new PLM, there is a need for data governance, model-based ways of working, which allow the company to connect at some stages the old/record data and the new data. And don’t do pilots anymore experimenting new ways of working and then stop because the next step seems to be overwhelming. Start your projects in small, multidisciplinary teams and make them real. The only way to be faster in the future.

In addition I defended the statement that old and new PLM are incompatible and therefore you need to accept they will exist both in your organization. For a while or for a long time, depending on your product lifecycle. In order to reduce the gap between old and new PLM, there is a need for data governance, model-based ways of working, which allow the company to connect at some stages the old/record data and the new data. And don’t do pilots anymore experimenting new ways of working and then stop because the next step seems to be overwhelming. Start your projects in small, multidisciplinary teams and make them real. The only way to be faster in the future.

PLM in Manufacturing as Backbone of the Smart Factory

Susanne Lauda, Director, Global Advanced Manufacturing Technology, AGCO Corporation provided an overview related to AGCO’s new PLM journey and how they were benefiting from a digital thread towards manufacturing. It felt like a smooth vendor demo as everything looked nice and reasonable. It was all about the WHAT. However two points that brought the extra:

Susanne Lauda, Director, Global Advanced Manufacturing Technology, AGCO Corporation provided an overview related to AGCO’s new PLM journey and how they were benefiting from a digital thread towards manufacturing. It felt like a smooth vendor demo as everything looked nice and reasonable. It was all about the WHAT. However two points that brought the extra:

When moving to the new system the tried to bring in the data from an existing product into then new system. According to Susanne a waste of time as the data required so much rework – there was no real value added for that. This confirms again my statement that old and new PLM are incompatible and one should not try to unify everything again in one system.

Second, I got excited at the end when we discussed the WHY for PLM and the business value of PLM. Here Suzanne mentioned PLM started as a “must-do strategic” project. PLM lead to a reduction of time to market with almost 50 %. Suzanne did not give exact number, but you can imagine I have heard these numbers from other companies too. Why aren’t we able to connect these benefits in the mindset of the management to PLM ? Perhaps still too much engineering focused.

Next Susanne explained that they investigated the cost for quality for their manufacturing plants. What if something was produced wrong, the wrong parts were ordered, the delays to fix it, the changes needed to be made on the shop floor? These results were so high that people were even afraid to report them. This is the case at many companies I worked with – even their PLM consultants do not receive these numbers – you just have to imagine they are big.

At AGCO they were able to reduce the cost for quality in a significant manner and Susanne explain that PLM was a main contributor to that success. However, success always has many fathers – so if your PLM team does not claim loud (and we are modest people not used to talk finance) – the success will not be recognized.

PLM’s Place Within an Enterprise Application Architecture

![]() Peter Bilello from CIMData in the closing keynote speech gave an excellent summary and overview of where and which capabilities fit in an enterprise architecture and the positioning of a product innovation platform. A blueprint that can be used for companies to grasp the holistic view before jumping into the details of the tools.

Peter Bilello from CIMData in the closing keynote speech gave an excellent summary and overview of where and which capabilities fit in an enterprise architecture and the positioning of a product innovation platform. A blueprint that can be used for companies to grasp the holistic view before jumping into the details of the tools.

Conclusion

PLMx Hamburg 2018 was an event with valuable highlights for me and potential I missed several more due to the fact of parallel streams. I hope to catch-up with these sessions in the upcoming month and share interesting thoughts that I discover with you. What remains crucial I believe for all vendor-neutral events is to find new blood. New companies, new experiences that are focused on the future of PLM and connect to the WHY or the WHAT WE LEARNED values.

Perhaps an ambiguous title this time as it can be interpreted in various ways. I think that all these interpretations are one of the most significant problems with PLM. Ambiguity everywhere. Its definition, its value and as you might have noticed from the past two blog posts the required skill-set for PLM consultants.

Perhaps an ambiguous title this time as it can be interpreted in various ways. I think that all these interpretations are one of the most significant problems with PLM. Ambiguity everywhere. Its definition, its value and as you might have noticed from the past two blog posts the required skill-set for PLM consultants. In the past twenty years, companies have implemented PLM systems, where the primary focus was on the P (Product) only from Product Lifecycle Management. PLM systems have been implemented as an engineering tool, as an evolution of (Product Data Management).

In the past twenty years, companies have implemented PLM systems, where the primary focus was on the P (Product) only from Product Lifecycle Management. PLM systems have been implemented as an engineering tool, as an evolution of (Product Data Management).

During the upcoming PLMx 2018 Hamburg conference there will be a panel discussion where the survey results will be discussed. I am afraid that this debate will result again in a discussion where we will talk about the beauty and necessity of PLM and we wonder why PLM is not considered crucial for the enterprise.

During the upcoming PLMx 2018 Hamburg conference there will be a panel discussion where the survey results will be discussed. I am afraid that this debate will result again in a discussion where we will talk about the beauty and necessity of PLM and we wonder why PLM is not considered crucial for the enterprise.

We agreed on the fact that traditional consultancy practices related to PLM ranking and selection processes are out of time. The Forester Wave publication was the cause of our discussion. For two reasons:

We agreed on the fact that traditional consultancy practices related to PLM ranking and selection processes are out of time. The Forester Wave publication was the cause of our discussion. For two reasons:

Also, make a 5-10 years cost evaluation of your solution and take the risk of raising subscription fees into account. No vendor will drop the price unless forced by the outside world. The initial benefits will be paid back later because of the other business model.

Also, make a 5-10 years cost evaluation of your solution and take the risk of raising subscription fees into account. No vendor will drop the price unless forced by the outside world. The initial benefits will be paid back later because of the other business model.

I believe we still need consultants to help companies to tell and coach them towards new ways of working related to the current digitization. Twenty years old concepts won’t work anymore. Consultants need a digital mindset and think holistic. Fitting technology and tools will be there in the future.

I believe we still need consultants to help companies to tell and coach them towards new ways of working related to the current digitization. Twenty years old concepts won’t work anymore. Consultants need a digital mindset and think holistic. Fitting technology and tools will be there in the future. In my earlier post;

In my earlier post;  I agree with Oleg and Joe. PLM ranking does not make sense for companies to select a PLM solution. They are more an internal PLM show, useful for the organizing consultancy companies to conduct, but at the end, it is a discussion about who has the biggest and most effective button. Companies need to sell themselves and differentiate.

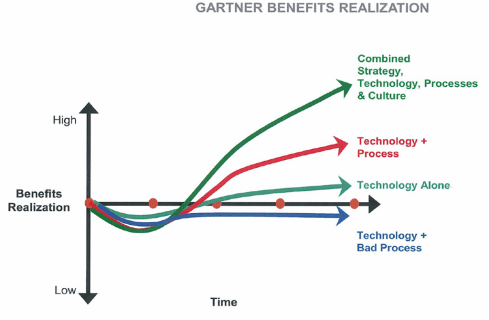

I agree with Oleg and Joe. PLM ranking does not make sense for companies to select a PLM solution. They are more an internal PLM show, useful for the organizing consultancy companies to conduct, but at the end, it is a discussion about who has the biggest and most effective button. Companies need to sell themselves and differentiate. ses, a strategy is future-oriented and not about consolidating the current status quo. Therefore I believe a PLM implementation is always done in the context of a business transformation, which is most of the time not only related to PLM – it is about People, Processes and then the tools.

ses, a strategy is future-oriented and not about consolidating the current status quo. Therefore I believe a PLM implementation is always done in the context of a business transformation, which is most of the time not only related to PLM – it is about People, Processes and then the tools.

Happy New Year to all of you. A new year comes traditionally with good intentions for the upcoming year. I would like to share my PLM intentions for this year with you and look forward to your opinion. I shared some of my 2017 thoughts in my earlier post:

Happy New Year to all of you. A new year comes traditionally with good intentions for the upcoming year. I would like to share my PLM intentions for this year with you and look forward to your opinion. I shared some of my 2017 thoughts in my earlier post:

To my understanding we are still in the early phases of discovering the ideal architecture and practices for a digital enterprise. PLM Vendors and technology companies show us the impressive potential as-if the future already exists already now. Have a reality check from Marc Halpern (Gartner) in this article on engineering.com –

To my understanding we are still in the early phases of discovering the ideal architecture and practices for a digital enterprise. PLM Vendors and technology companies show us the impressive potential as-if the future already exists already now. Have a reality check from Marc Halpern (Gartner) in this article on engineering.com –  Although my curiosity is focused on future PLM, there is still a journey to go for companies that have just started with PLM. Before even thinking of a digital enterprise, there is first a need to understand and implement PLM as an infrastructure outside the engineering department.

Although my curiosity is focused on future PLM, there is still a journey to go for companies that have just started with PLM. Before even thinking of a digital enterprise, there is first a need to understand and implement PLM as an infrastructure outside the engineering department. The most prominent challenge for most companies however is how to transform their existing business towards a modern digital business where new processes and business opportunities need to be implemented inside an existing enterprise. These new processes and business opportunities are not just simple extensions of the current activities, they need new ways of working like delivering incremental results through agile and multidisciplinary teams. And these ways of working combined with never-existing-before interactivity with the market and the customer.

The most prominent challenge for most companies however is how to transform their existing business towards a modern digital business where new processes and business opportunities need to be implemented inside an existing enterprise. These new processes and business opportunities are not just simple extensions of the current activities, they need new ways of working like delivering incremental results through agile and multidisciplinary teams. And these ways of working combined with never-existing-before interactivity with the market and the customer. How to convince management that these changes are needed and do not happen without their firm support? It is easier to do nothing and push for small incremental changes. But will this be fast enough? Probably not as you can read from research done by strategic consultancy firms. There is a lot of valuable information available if you invest time in research. But spending time is a challenge for management.

How to convince management that these changes are needed and do not happen without their firm support? It is easier to do nothing and push for small incremental changes. But will this be fast enough? Probably not as you can read from research done by strategic consultancy firms. There is a lot of valuable information available if you invest time in research. But spending time is a challenge for management.

This mindset is also applicable to manufacturing companies. Where in the past companies were trying to optimize and standardize their processes driven by efficiency and predictability, now due to the dynamics of a globally connected world, businesses need to become extremely flexible however still reliable and profitable.

This mindset is also applicable to manufacturing companies. Where in the past companies were trying to optimize and standardize their processes driven by efficiency and predictability, now due to the dynamics of a globally connected world, businesses need to become extremely flexible however still reliable and profitable. Digital transformation is one of the buzz words pointing to the transition process. Companies need to go through a change to become flexible for the future and deliver products or solutions for the individual customer. Currently companies invest in digital transformation, most of the time in areas that bring direct visibility to the outside world or their own management, not necessarily delivering profitable results as a recent article from McKinsey illustrated:

Digital transformation is one of the buzz words pointing to the transition process. Companies need to go through a change to become flexible for the future and deliver products or solutions for the individual customer. Currently companies invest in digital transformation, most of the time in areas that bring direct visibility to the outside world or their own management, not necessarily delivering profitable results as a recent article from McKinsey illustrated:  Software vendors in various domains are all contributing to support a modern digital product innovation management future. But where to start? Is it the product innovation platform? Is it about federated solutions? Model-Based? Graph-databases? There are even people who want to define the future of PLM. We can keep throwing pieces of the puzzle on the table, but all these pieces will not lead to a single solved puzzle. There will be different approaches based on your industry and your customers. Therefore, continuous learning and investing time to understand the digital future is crucial. This year’s PDT Europe conference was an excellent event to learn and discuss the themes around a model-based lifecycle enterprise. You can read my reviews here: The weekend after PDT Europe 2017

Software vendors in various domains are all contributing to support a modern digital product innovation management future. But where to start? Is it the product innovation platform? Is it about federated solutions? Model-Based? Graph-databases? There are even people who want to define the future of PLM. We can keep throwing pieces of the puzzle on the table, but all these pieces will not lead to a single solved puzzle. There will be different approaches based on your industry and your customers. Therefore, continuous learning and investing time to understand the digital future is crucial. This year’s PDT Europe conference was an excellent event to learn and discuss the themes around a model-based lifecycle enterprise. You can read my reviews here: The weekend after PDT Europe 2017

Of course if you are aiming for a full digital enterprise, and I think you should, do not waste time fixing the past. In some situations, I learned that an external consultant recommended the company to rename their old meaningful part numbers to the new non-intelligent part numbering scheme. There are two mistakes here. Renumbering is too costly, as all referenced information should be updated. And secondly as long as the old part numbers have a unique ID for the enterprise, there is no need to change. The connectivity of information should not depend on how the unique ID is formatted.

Of course if you are aiming for a full digital enterprise, and I think you should, do not waste time fixing the past. In some situations, I learned that an external consultant recommended the company to rename their old meaningful part numbers to the new non-intelligent part numbering scheme. There are two mistakes here. Renumbering is too costly, as all referenced information should be updated. And secondly as long as the old part numbers have a unique ID for the enterprise, there is no need to change. The connectivity of information should not depend on how the unique ID is formatted.

Approximate four years ago new concepts related to digitalization for PLM became more evident. How could a digital continuity connect the various disciplines around the product lifecycle and therefore provide end-to-end visibility and traceability? When speaking of end-to-end visibility most of the time companies talked about the way they designed and delivered products, visibility of what is happening stopped most of the time after manufacturing. The diagram to the left, showing a typical Build To Order organization illustrates the classical way of thinking. There is an R&D team working on Innovation, typically a few engineers and most of the engineers are working in Sales Engineering and Manufacturing Preparation to define and deliver a customer specific order. In theory, once delivered none of the engineers will be further involved, and it is up to the Service Department to react to what is happening in the field.

Approximate four years ago new concepts related to digitalization for PLM became more evident. How could a digital continuity connect the various disciplines around the product lifecycle and therefore provide end-to-end visibility and traceability? When speaking of end-to-end visibility most of the time companies talked about the way they designed and delivered products, visibility of what is happening stopped most of the time after manufacturing. The diagram to the left, showing a typical Build To Order organization illustrates the classical way of thinking. There is an R&D team working on Innovation, typically a few engineers and most of the engineers are working in Sales Engineering and Manufacturing Preparation to define and deliver a customer specific order. In theory, once delivered none of the engineers will be further involved, and it is up to the Service Department to react to what is happening in the field.

Modern business is about having customer or market involvement in the whole lifecycle of the product. And as products become more and more a combination of hardware and software, it is the software that allows the manufacturer to provide incremental innovation to their products. However, to innovate in a manner that is matching or even exceeding customer demands, information from the outside world needs to travel as fast as possible through an organization. In case this is done in isolated systems and documents, the journey will be cumbersome and too slow to allow a company to act fast enough. Here digitization comes in, making information directly available as data elements instead of documents with their own file formats and systems to author them. The ultimate dream is a digital enterprise where date “flows”, advocated already by some manufacturing companies for several years.

Modern business is about having customer or market involvement in the whole lifecycle of the product. And as products become more and more a combination of hardware and software, it is the software that allows the manufacturer to provide incremental innovation to their products. However, to innovate in a manner that is matching or even exceeding customer demands, information from the outside world needs to travel as fast as possible through an organization. In case this is done in isolated systems and documents, the journey will be cumbersome and too slow to allow a company to act fast enough. Here digitization comes in, making information directly available as data elements instead of documents with their own file formats and systems to author them. The ultimate dream is a digital enterprise where date “flows”, advocated already by some manufacturing companies for several years. This post is a rewrite of an article I wrote on LinkedIn two years ago and modified it to my current understanding. When you are following my blog, in particular, the posts related to the business change needed to transform a company towards a data-driven digital enterprise, one of the characteristics of digital is about the real-time availability of information. This has an impact on everyone working in such an organization. My conversations are in the context of PLM (Product Lifecycle Management) however I assume my observations are valid for other domains too.

This post is a rewrite of an article I wrote on LinkedIn two years ago and modified it to my current understanding. When you are following my blog, in particular, the posts related to the business change needed to transform a company towards a data-driven digital enterprise, one of the characteristics of digital is about the real-time availability of information. This has an impact on everyone working in such an organization. My conversations are in the context of PLM (Product Lifecycle Management) however I assume my observations are valid for other domains too.

And here we started the discussion. “Why do you want to escalate to a manager?” Escalation will only give more disruption and stress for the persons involved. Isn´t the person qualified enough to make a decision what is important?

And here we started the discussion. “Why do you want to escalate to a manager?” Escalation will only give more disruption and stress for the persons involved. Isn´t the person qualified enough to make a decision what is important? The ultimate conclusion of our discussion was: Implementing a modern PLM environment brings first of all almost 100 % visibility, the single version of the truth. This new capability breaks down silos, a department cannot hide activities behind their departmental wall anymore. Digital PLM allows horizontal multidisciplinary collaboration without the need going through the management hierarchy.

The ultimate conclusion of our discussion was: Implementing a modern PLM environment brings first of all almost 100 % visibility, the single version of the truth. This new capability breaks down silos, a department cannot hide activities behind their departmental wall anymore. Digital PLM allows horizontal multidisciplinary collaboration without the need going through the management hierarchy. Last week I posted my first review of the PDT Europe conference. You can read the details here:

Last week I posted my first review of the PDT Europe conference. You can read the details here:  Now back to the conference. Day 2 started with a remote session from Simon Floyd. Simon is Microsoft’s Managing Director for Manufacturing Industry Architecture Enterprise Services and a frequent speaker at PDT. Simon shared with us Microsoft’s viewpoint of a Digital Twin, the strategy to implement a Digit Twin, the maturity status of several of their reference customers and areas these companies are focusing. From these customers it was clear most companies focused on retrieving data in relation to maintenance, providing analytics and historical data. Futuristic scenarios like using the digital twin for augmented reality or design validation. As I discussed in the earlier post, this relates to my observations, where creating a digital thread between products in operations is considered as a quick win. Establishing an end-to-end relationship between products in operation and their design requires many steps to fix. Read my post:

Now back to the conference. Day 2 started with a remote session from Simon Floyd. Simon is Microsoft’s Managing Director for Manufacturing Industry Architecture Enterprise Services and a frequent speaker at PDT. Simon shared with us Microsoft’s viewpoint of a Digital Twin, the strategy to implement a Digit Twin, the maturity status of several of their reference customers and areas these companies are focusing. From these customers it was clear most companies focused on retrieving data in relation to maintenance, providing analytics and historical data. Futuristic scenarios like using the digital twin for augmented reality or design validation. As I discussed in the earlier post, this relates to my observations, where creating a digital thread between products in operations is considered as a quick win. Establishing an end-to-end relationship between products in operation and their design requires many steps to fix. Read my post:

Sustainability and the circular economy has been a theme at PDT for some years now too. In his keynote speech, Torbjörn Holm from Eurostep took us through the global megatrends (Hay group 2030) and the technology trends (Gartner 2018) and mapped out that technology would be a good enabler to discuss several of the global trends.

Sustainability and the circular economy has been a theme at PDT for some years now too. In his keynote speech, Torbjörn Holm from Eurostep took us through the global megatrends (Hay group 2030) and the technology trends (Gartner 2018) and mapped out that technology would be a good enabler to discuss several of the global trends. Rebecca Ihrfors, CIO from the Swedish Defense Material Administration (FMV) shared her plans on transforming the IT landscape to harmonize the current existing environments and to become a broker between industry and the armed forces (FM). As now many of the assets come with their own data sets and PDM/PLM environments, the overhead to keep up all these proprietary environments is too expensive and fragmented. FWM wants to harmonize the data they retrieve from industry and the way they offer it to the armed forces in a secure way. There is a need for standards and interoperability.

Rebecca Ihrfors, CIO from the Swedish Defense Material Administration (FMV) shared her plans on transforming the IT landscape to harmonize the current existing environments and to become a broker between industry and the armed forces (FM). As now many of the assets come with their own data sets and PDM/PLM environments, the overhead to keep up all these proprietary environments is too expensive and fragmented. FWM wants to harmonize the data they retrieve from industry and the way they offer it to the armed forces in a secure way. There is a need for standards and interoperability.

Principle 1 The bimodal strategy as the image shows.

Principle 1 The bimodal strategy as the image shows.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…