You are currently browsing the category archive for the ‘PLM’ category.

As promised I would come back to the results of my small questionnaire about PLM for the mid-market. Here are the answers:

What is your relation to PLM ?

| PLM consultant | 51 % |

| IT specialist | 21 % |

| Interested in PLM related to my work | 14 |

| PLM vendor | 9 % |

| Student | 5 % |

The answers show that the majority of readers are professionals directly involved with PLM, which is of course not strange for my blog. And good to see, the real majority is PLM consultant. At that time when I launched the questionnaire, I was not making a differentiation between independent consultants and PLM supplier specific consultants. And you need them both.

Do you believe PLM has a place in the mid-market?

| Yes, it is already happening | 57 % |

| Yes, it is a matter of time and education | 38 % |

| No, mid-market companies do not need PLM | 5 % |

| No, there is no place for a PLM system next to CAD and ERP | 0 % |

Of course it is a PLM blog, so this explains the 0 % for the last alternative. Also it is clear that the readers of this blog believe PLM has a place in the mid-market. Some remarks here were:

- It depends on product and maturity cycles and on whether this service is provided by the larger companies who the mid market company is supplying (IT enterprise architect)

- PLM is a strategy and can be implemented by any tool (Student)

Who should provide PLM functionality in the mid-market

| A special PLM provider | 72 % |

| A CAD supplier as extension of their data management | 14 % |

| A system integrator | 7 % |

| An IT supplier, like Microsoft, as part of their architecture | 5 % |

| An ERP supplier as extension of their BOM management | 2 % |

Good news, we are among PLM friends and believe it must be a PLM provider that will bring the PLM functionality to the market, not a CAD or IT-supplier. System integrators are the majority of the minority here. Some remarks here were:

- One size doesn’t fit all. A special solution need to be provided (PLM Consultant)

- For me, the best solutions for mid market involve low-cost of ownership, easy to use and limited but straight forward capabilities. ERP and CAD vendors are far from there from what I can see, but at least they are integrated with one or the other part. Cloud computing solutions would be the best, that could integrate with ERP and CAD would be the best. (PLM Consultant)

- Any one, who have technical sound knowledge, broad thinking and customized software tools like ERP and CAD (Student)

I would like to see more discussion about:

| PLM implementation experiences | 44 % |

| PLM basic principles / best practices | 34 % |

| PLM vendors and their specific coverage | 10 % |

| PLM selection guidelines | 8 % |

| PLM functions and features | 5 % |

It is clear that readers from this blog want to read PLM related topics vendor independent and I will focus on this the upcoming post about the two major responses: PLM implementation experiences and PLM basic principles and best practices. Some of the other requests were:

- How PLM can support inter-company collaboration at design time, manufacturing time and operational support time and how service oriented technologies have a role in this, especially when products can now be supported by 3rd party companies (not the OEM). (IT Enterprise Architect)

- As we have not came to final Point of PLM as it is vast field and will not be, so we will be discussing on different points (student)

Conclusion:

So I want to thank all of you who responded to this mini-questionnaire and as we are PLM supporters, I will focus in my upcoming post again on mid-market PLM experiences and practices.

This time I will conclude with an anecdote:

Some time ago a Christian PLM Sales professional died (let’s call him Jack) and according to his believe he faced Saint Peter at the gates of Heaven and Hell.

Saint Peter greeted Jack and said: “Jack, With your PLM Sales you have done good and bad things to the world and for that reason, I cannot decide if you should go to Heaven or to Hell. Therefore I allow you to make the choice yourself”.

Jack replied: “But Saint Peter, how can I make such an important decision for the rest of my eternal life. It is too difficult !”

Saint Peter replied: “No problem Jack, take a look at Heaven and Hell, take your time and then come back to tell me your decision”

Jack entered Heaven and he was surprised about the quietness and green atmosphere there. Angels were singing, people were eating from golden plates with the best food ever, people were reading poetry and everything was as peaceful as you could imagine. In the distance he could see God surrounded by some prophets talking about the long-term future. After some time Jack had seen it and went to Hell to have a view there.

And when he opened the gates of Hell, he was astonished. Everywhere he looked there were people partying, having fun. It reminded him off these sales kick-offs, he had in the past, exotic places with lots of fun. In the distance he could see the Devil as DJ playing the latest dance music – or was it DJ Tiësto ?

Jack did not hesitate and ran back to Saint Peter, no time to lose. “Saint Peter” he said “I want to go to Hell, no doubt and pity I did not know it before”

“So be it” said Saint Peter “go for it.”

And then once Jack entered Hell, it was suddenly all fire around him, people were screaming of pain and suffering and also Jack felt the first flames.

And then once Jack entered Hell, it was suddenly all fire around him, people were screaming of pain and suffering and also Jack felt the first flames.

“Devil!!” he screamed “what happened to what I have seen before?”

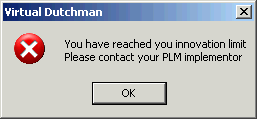

With a sarcastic voice the devil replied: “That ? That was a demo”

In my previous post (PLM Selection – Don’t do this) – I wrote about what not to do, if you want to make a PLM selection and many thanks for the responses and feedback I got on this post. It is obvious that a PLM selection is not as simple as purchasing a new car, but for the sake of the simplification, I will use it as a comparison once and a while in this post.

Understanding the need

All around you, people are driving cars and there are objectives you can only achieve in an efficient matter if you have the flexibility of car. In some countries, the governments are pushing people to public means of transport for obvious reasons. However this reduces the flexibility, and in general it fails due to our individual (read customer centric) needs.

For PLM this is somehow the same. Many companies require an implementation of the PLM vision to achieve their goals and being more customer-centric. Of course there are lots of standard tools available which bring you from A to B, but then you have to walk from B to C in order to get connected again for the next part. Not efficient and not connected. The challenges of public transport as an analogy for connectivity in a tool based environment.

For PLM this is somehow the same. Many companies require an implementation of the PLM vision to achieve their goals and being more customer-centric. Of course there are lots of standard tools available which bring you from A to B, but then you have to walk from B to C in order to get connected again for the next part. Not efficient and not connected. The challenges of public transport as an analogy for connectivity in a tool based environment.

So let’s assume which PLM to look for is similar to which car to select. From your needs and budget you will narrow down the search.

Do you need a bus, a jeep, a van, a sports car, an SUV, etc, etc?

You can write down all the features and functions that you can imagine to do with your new car on a checklist and send this list out to somebody (a car consultant?) to do the verification with all the known car manufacturers. (You use a car consultant as it is too time consuming and you are not the expert in this area)

From the previous post we learned this is waste of time and budget, except for the consultant. I am pretty sure that most of the companies are aware of their pains and if they would invest in understanding the PLM vision, without jumping immediately into products, they would be able to create a shortlist of needs based on their main characteristics:

- What is my main businesses process (ETO – BTO – CTO – MTS – etc) and where do I want to be in the long term?

- Am I using a single CAD platform or do I require a multi-CAD strategy?

- Do I go with the flow (low risk/lower costs/less different) or do I want to be outside the flow (develop new practices / new technology / differentiate)

- Is my company really independent in its processes and data or are we depending on specific collaboration. For example in a supply chain or conglomerate of companies?

For those questions, to formalize the company’s strategy and dependencies between business goals and organization, it is not as easy as buying a car. Often external help is needed, as inside your company it is very rare that you will find someone, who can spend the time to collect this knowledge (or has this broad knowledge) and to bring it back to the company in an ‘objective’ manner.

That’s the role of an independent PLM consultant. I underlined the word independent as you can read some remarks in the footnote of this post on what independent means in this context.

There must be hundreds of independent PLM consultants, who can assist a company formalizing their PLM needs, without jumping and starting to talk immediately from the point of view of a specific product. Complementary you have the dependent PLM consultants and also there you will find good expertise. Their knowledge and focus however is more to fit you in their product range – good once you have made your choice.

Or you might say: “I do not need this consultant. Let’s spent some money on reports from known independent PLM consultancy firms”. They have general reports about PLM and for each of the major PLM vendors, they will have a specific, sponsored reports explaining the PLM capabilities of these platforms. Again look at the footnote of what it means independent.

Narrowing down the choice

Finish the first phase would mean in car selection terminology, you understood now where to look – it will be:

- An electrical car (new technology, sustainable, short distances required so far)

going for the future – knowing the future is open - A high-end tuned CAR (a big investment, but now you can enjoy)

as long as you do not get in or out a personal crisis - the mid-range CAR (everyone uses this car, it is price effective)

but you do not want to be like everyone - the nano (it is cheap – it is a car)

understanding this car does not fit expansion of the family - the MPV – (it can do everything – even consume fuel)

never comfortable but it serves all - leasing /renting CAR capacity (drive immediately – the on-line CAR)

you have to get rid of the idea that you need to own it - a free CAR (drive now – pay later – the Open Source car)

freedom comes with other obligations in the long term

Evaluating the need

Now that you have narrowed down the selection, you are able to go into the details. And then the second most important option of the selection process comes: how does this PLM product/partner fit to my company.

Now that you have narrowed down the selection, you are able to go into the details. And then the second most important option of the selection process comes: how does this PLM product/partner fit to my company.

In car terminology, you would do a test drive. You step into the car and you drive and experience. In PLM this is impossible, it is software applied to your company, it is business and people change. So your choice will be more based on feeling comfortable with the future

You might want to start with some basic PLM functionality, which suits best at your current situation, and gradually you extend the PLM coverage (as you own and should have the vision) inside the company.

So what I have seen companies are doing? They invite 3 to 5 suppliers of a PLM system to come and do a benchmark. Sometime they have a predefined scenario which everyone should follow; sometimes they allow the vendor to suggest best practices. I do not believe in this approach as I wrote in one of my older posts – I called it the academic approach.

I believe a PLM implementation requires a partner who understands your business, has experience in your business and is available and affordable to consult and work with.

Here there is not the unique need any more for independent consultants, as most of the PLM vendors have their consultants with product specific experience in your market. Only be aware of the following:

- In this stage you are in a sales process – so each vendor will explain how easy and fast to implement, how easy to understand and how unique they are. Check here with customers.

- They will use FUD (Fear, Uncertainty and Doubt) and it is very difficult to understand the reality here. Here an independent consultant or customer reference can help to understand the reality

- If the PLM supplier is selling hammers, for sure everywhere in your organizations there nails will pop up

The main goal is to find a partner for the future, which you trust, from whom you feel they understand your business without immediately selling product features or customizations.

The main goal is to find a partner for the future, which you trust, from whom you feel they understand your business without immediately selling product features or customizations.

In my analogy with the car selection process, I live in a small village where we have one real car dealer for the mid-market from a certain French brand. The car dealer claims 60 % of the people in our village drive a car from this brand, due to the local support (I am sure it is less but it is visible)

Part of their sales process is to explain that if you consider another brand you might get stuck in the village on a snowy morning without support when you urgently need it (horror stories and all the other FUD). And if you want an electrical car, they will explain you that you do not want an electrical car as from insiders (unknown to us), they learned that they are not reliable, not cost-effective, where their brand is in the top of most of the lists.

So what replaces the test drive?

I assume if you have gone through the selection of a partner, who speaks the same language, has a clear vision and has shown the capability to deliver (through references and the interaction you had so far), you have only a short-list of one or maybe two candidates.

So what is usual the case – the purchasing department starts to negotiate with both candidates (and sometimes invite a third supplier as this is company policy) and they try to squeeze out each of the PLM suppliers to the maximum for the full project scope till both sides have the feeling there is a base for a partnership .

How did you engage with your partner 😉 ?

My recommendation is to discuss with both candidates your possible roadmap. Let them explain in detail what should be done as the first small step and have them propose from there the next following steps. The first step should be with a clear budget, time (max 2 – 3 month) and effort specification – internal and external; the other steps roughly budgeted for costs and efforts

Then you have to make your choice, you do this first step, making sure it is reversible or it can be a single step. It is a verification of your first step (call it engagement / a test drive for a month) and from there you evaluate if you continue for the big step or rethink your first choice.

As choosing a PLM platform is a long term relation – at least 5 – 10 years – you need to use the engagement phase to meet the family and learn and understand the future.

Again the independent consultant?

Yes, when writing down the above paragraphs, I realized again that it is easier said than done. If you are not experienced with the PLM market guiding this process will be difficult and time consuming if you do it once in your life. So also in the selection phase an independent consultant can assist you with the selection process, the most logical roadmap for your company and interface with the PLM suppliers, knowing their strengths & weaknesses

Conclusion

PLM selection is not such a complex process where you need to understand all the details upfront. It is based on common sense, not equal to buying a car but also not rocket science. The independent consultant fits well in this approach, in cases where you did not have the time or people to build the expertise internally to define a PLM vision, justification and selection

Looking forward to your feedback

- not influenced or controlled in any way by other people, events or things

- free; autonomous, self-governing, sovereign; self-reliant, self-sufficient

The above definition says it all – not influenced or controlled. However being independent does not mean you have the knowledge of all products and technologies that exist. So an independent consultant should assist with the common best practices of PLM, independent of the software.

The same for the comments on PLM Research – see the LinkedIn post in case you are group member – The Trouble with PLM Research .

An interesting discussion as also these PLM research organizations work with a certain state of mind – there is no single PLM definition according to the PLM suppliers – and each of the PLM research companies have to deal with their understanding of what these supplier can do, meanwhile keeping their business also alive.

Which means in order to have good relationships with the PLM supplier, they need to be in a good relation and due that relation they sometimes write some biased reports about a single PLM supplier who sponsored the white paper. Nothing wrong with this approach as long as you understand the context of this information.

If you think you have the need for PLM, as everyone around you has PLM and you are sure you need it also, how do you select a PLM system?

If you are not familiar with PLM, PLM (Product Lifecycle Management) stands for a vision and a combination of best practices, industry dependent, that allow you as a company to be more innovative, faster too market, more customer centric and also with a higher quality and efficiency. The result: you are doing better as the competition – more margin, market share etc, etc

Next the implementation of this vision can be done by implementing pieces of the PLM vision on top of the existing systems already in your company. Extending the capabilities of your CAD system with some macros ; programming some capabilities around SharePoint to make information available and combined with Excel macros and an import in our ERP system, you believe you are doing PLM as you implemented parts of the PLM vision, mainly the efficiency part.

And then we get stuck, we would like to be more customer centric. Which macro to write for that? Or we want to connect our 3D designs to be used in a virtual prototype environment so we do not have to make the first real prototype to understand where to improve. Here the local reseller or IT-provider mentions it goes beyond his expertise (if he is fair).

And then we get stuck, we would like to be more customer centric. Which macro to write for that? Or we want to connect our 3D designs to be used in a virtual prototype environment so we do not have to make the first real prototype to understand where to improve. Here the local reseller or IT-provider mentions it goes beyond his expertise (if he is fair).

For the full PLM vision, we see that the major PLM vendors have an integrated story, where all best practices and capabilities are connected and available on demand. Of course there is a discussion between themselves who has the best vision, the best integration between all these modules and who is the most efficient, but this is normal in a competitive world. You will find out the details during your selection process, but let’s agree you want all these benefits now or in the future, so the first conclusion is, you need to implement a PLM system in your company, and not small pieces of PLM capabilities in different systems and infrastructure.

And now comes the do not do this part, which I encountered in the past two months several times and from which I thought this approach was already considered by people, knowledgeable in this are as leading to failure.

The content below might lead to dissatisfaction in the near or longer future and the writer warns you NOT to use the methodology below

The company starts collecting requirements from all departments to assure they can implement the new vision. And as collecting requirements is a lot of work, they hire an external consulting company to do this work. The consultant(s) go and talk with all the different departments and at the end they collected a list of 100+ requirements, which after discussing them with the management are completed with another 50 requirements to assure the company is not going to select the wrong PLM system.

Then the company sends this book to all the known PLM vendors, telling them to respond within a timely matter (two – four ) weeks. And questions will be answered only through a very formal process via the consultancy company.

This type of questions you will find (and they are real):

- There should be a control for the renaming of CAD-parts and links

- It should be possible to search from the top to the bottom in the structure with all documents

- It should be possible to work with the following formats (3 common and 15 rare formats mentioned)

- It should be able to drag and drop information from one structure to the other

- The system should protect the users to make an error

- The system should run integrated with our ERP system (xyz mentioned)

- The system should be able to identify and manage project risk to support product and process changes throughout the product lifecycle

And one of my favorites:

- The system shall be able to create, update, maintain and process main and typical sorts and types of documents and their source data. Both “tabular” data (lists/datasheets) and graphic (diagrams, etc.) data, as well as text data (technical reports, etc.) are understood in this requirement. However see also requirement 18 and requirement 54. The scope and types of documents should be possible to be modified in an easy way for various projects and various stages of development documentation for those projects

And the management added:

- The implementer should come with a detailed implementation plan and budget

- The implementer should guarantee the budget stays with xxx range

- The implementer should provide 3 references of similar companies and tools.

The RFP document is usually a 20 to 50 page document – the amount of pages seems to have a correlation with the amount of money spent to consultancy. The total assembly costs for this document: 400 to 1000 man-hours (do your math for the initial costs)

The RFP document is usually a 20 to 50 page document – the amount of pages seems to have a correlation with the amount of money spent to consultancy. The total assembly costs for this document: 400 to 1000 man-hours (do your math for the initial costs)

Then the RFP document is sent to 5 or more potential suppliers, who need to answer for each requirement in detail if:

- It is standard in the system

- It can be done through configuring the system, explain.

- It can be done through customization, please specify

- It is not supported

Each vendor spends at least 500 man-hours to answer all these questions as much as possible with yes, it is standard. An although not understanding the requirements at all at some points, they only give positive answers, trying to stay away from the “It is not supported answer”.

Each vendor spends at least 500 man-hours to answer all these questions as much as possible with yes, it is standard. An although not understanding the requirements at all at some points, they only give positive answers, trying to stay away from the “It is not supported answer”.

So after at least 2500 (5 times 500) man-hours the company assisted by the consultant(s) think the know who to invite for the next stage of the PLM selection.

Did they make the right choice?

My statement is perhaps yes. So far they have wasted 3000 man-hours or more in the world just to be busy and come to a result which an experienced independent PLM consultant could do in a few days:

If you are this type of company – look at these vendors: company A, company B and perhaps company C for your PLM solution as you are in this industry, this IT-platform and this maturity – let’s discuss with them what we want to achieve

Next the real PLM selection process starts, here the investment and research should begin – and I would do this different. In my next post I will explain my approach.

Do you agree and would you do it different?

I am looking forward to your feedback.

In my previous post (PLM for the mid-market – your opinion) I started a very small questionnaire – if you did not have the time (takes less than 5 minutes) or encouragement (please, please) to answer the 4 anonymous questions, please go there. End of October I promised to publish the results in this blog.

In my previous post (PLM for the mid-market – your opinion) I started a very small questionnaire – if you did not have the time (takes less than 5 minutes) or encouragement (please, please) to answer the 4 anonymous questions, please go there. End of October I promised to publish the results in this blog.

Direct link to the questionnaire: http://www.enquetemaken.be/toonenquete.php?id=48804

The past two years I have been blogging about PLM, with a special focus on the mid-market. My previous post was about PLM selection (which PLM to choose) and thanks to Oleg (How To Choose PLM? (Visual guide)) this became a broader discussion. It made me realize that although we are all talking about PLM, I am not sure if we all have the same opinion about the mid-market.

The past two years I have been blogging about PLM, with a special focus on the mid-market. My previous post was about PLM selection (which PLM to choose) and thanks to Oleg (How To Choose PLM? (Visual guide)) this became a broader discussion. It made me realize that although we are all talking about PLM, I am not sure if we all have the same opinion about the mid-market.

To be aligned my previous definition of the mid-market:

Mid market company: For me the definition of a mid-market company does not have to do with revenue or the amount of people working for this company. I characterize a mid-market company as a company, where everyone has a focus on the company’s primary process. There is no strategic layer of people, who are analyzing the current business and defining new strategies for the future. In addition, the IT-staff is minimal, more seen as an overhead than as strategic. Mid-market companies have their strength in being flexible and reacting fast on changes, which might contradict with a long term strategic approach.

Now I am curious about your opinion. Therefore I published a small questionnaire on a Belgium website, to get a quick feedback and I am looking forward to your response. Although I do not consider it as scientific research, your (anonymous) response will enable me review my opinion and to focus on some specific topics.

Please take the time so answers this questionnaire from the link below:

PLM for the mid-market – your opinion

Thanks for your feedback and I will publish the results end of October

Jos Voskuil

As a follow-up of my holiday thoughts, I want to discuss this time the various interpretations of PLM that exist. Of course we have the ‘official’ definitions of the consultancy companies like CIMdata and 2PLM ( I took an American and European example). They describe clearly that it is a business approach, not necessary a set of technologies and tools to implement.

As a follow-up of my holiday thoughts, I want to discuss this time the various interpretations of PLM that exist. Of course we have the ‘official’ definitions of the consultancy companies like CIMdata and 2PLM ( I took an American and European example). They describe clearly that it is a business approach, not necessary a set of technologies and tools to implement.

Then we have the PLM vendors, where Dassault Systems and Siemens claim their visionary leadership. Looking at their websites, it is hard to find an explicit message. They both claim PLM brings innovation (how ?) , where Dassault Systemes has a strong message around 3D and virtual product development and Siemens focuses more on efficiency and better collaboration benefits. I am not going in depth into PTC and Aras or other PLM vendors as I am only taking two examples per type of company, but look at their websites and find out how (and if) they describe PLM as a business approach.

Then we have the PLM vendors, where Dassault Systems and Siemens claim their visionary leadership. Looking at their websites, it is hard to find an explicit message. They both claim PLM brings innovation (how ?) , where Dassault Systemes has a strong message around 3D and virtual product development and Siemens focuses more on efficiency and better collaboration benefits. I am not going in depth into PTC and Aras or other PLM vendors as I am only taking two examples per type of company, but look at their websites and find out how (and if) they describe PLM as a business approach.

For a PLM definition at SAP you have to dig a little deeper and I got even more surprised when searching through the Oracle web site. Here it was difficult to find a generic PLM message. There was the list of acquisitions (which make me wonder if this means they are all integrated) and there was the list of industries and only when drilling down into the industries, you will find PLM related information. Here I still have the feeling that these companies understand there is a need for PLM, but that it is not in their veins, they want to manage product data as a ‘single version of the truth’ – which is not a bad idea and I will come back on that later – but they want to manage different data.

For a PLM definition at SAP you have to dig a little deeper and I got even more surprised when searching through the Oracle web site. Here it was difficult to find a generic PLM message. There was the list of acquisitions (which make me wonder if this means they are all integrated) and there was the list of industries and only when drilling down into the industries, you will find PLM related information. Here I still have the feeling that these companies understand there is a need for PLM, but that it is not in their veins, they want to manage product data as a ‘single version of the truth’ – which is not a bad idea and I will come back on that later – but they want to manage different data.

Also upcoming are the generic PLM on-line solutions (Arena and PLM+), which for me still are somehow a contradiction to what consultancy companies describe as PLM. Instead of a bussiness approach it is an IT-solution. In parallel there are more dedicated on-line solutions that support a specific business process (where PLM practices are embedded) – like for Apparel, CPG.

Also upcoming are the generic PLM on-line solutions (Arena and PLM+), which for me still are somehow a contradiction to what consultancy companies describe as PLM. Instead of a bussiness approach it is an IT-solution. In parallel there are more dedicated on-line solutions that support a specific business process (where PLM practices are embedded) – like for Apparel, CPG.

For these type of solutions, I have a more positive opinion as they are lowering the threshold to implement PLM in a certain industry. However the biggest skepticism I have for these types of solutions is the degrees of flexibility it will offer the implementing company to be different from standard best practices. As all companies have their uniqueness in being competitive, will they be able to support this ?

And then there was the press release from Zero Wait-State which struck me:

Zero Wait-State is launching a new website that will provide a central location for Product Lifecycle Management software and partner reviews. This site will be a valuable resource for companies trying to assess different PLM solutions and which partners to work with. The site will be driven by users and allow them to share their experiences with different software products and implementation partners.

Zero Wait-State is launching a new website that will provide a central location for Product Lifecycle Management software and partner reviews. This site will be a valuable resource for companies trying to assess different PLM solutions and which partners to work with. The site will be driven by users and allow them to share their experiences with different software products and implementation partners.

See the full press release here: Zero Wait-State Announces New Website for PLM and Service Provider Reviews.

I believe in these times of product selection and reviews certainly a good initiative. Where do we find vendor independent reviews of various PLM products ? Bringing PLM to social communities.

But ……

Here I want to take a step back. What is the essence of PLM and how do you know as a company you want to implement PLM ?

The majority of mid-market companies are not looking for a PLM system. Most of the mid-market companies have the impression that PLM is complex and expensive and typical mid-market vendors like Autodesk or SolidWorks are not pushing PLM (try for fun to search for PLM on their websites).

So will a mid-market company be able to select a PLM product through communities in the same manner as you select a consumer product ?

I believe the main challenge for a PLM implementation is not the software, but the business change.

In a company where most people are thinking (and rewarded) departmental, it is difficult to implement a new system that affects all departments. Creating the single version of the truth for product data is one of the basics for PLM. Try to get an agreement with sales, engineering, production and service who will be responsible for which part of the BOM. SAP’s single version of the truth is much more a statement from an IT-infrastructure point of view not focusing and pushing a change of business processes.

I believe, and this is also based on discussions and comments from colleagues focusing on the mid-market, that many mid-market companies are implementing basics of PLM, not always using a ‘certified’ PLM system or PLM vendor, but a pragmatic solution (customization / piece of software) which connects parts of the product information. These solutions are usually extensions on top of the CAD data management environment or the ERP system.

And here PLM vendors have a mission. Provide building blocks (services) that allow mid-market companies to connect data between departments based on known standard authoring tools. For classical PLM industries (Automotive/Aero/Fabrication & Assembly) the major CAD systems and virtual product development plus analysis software are major disciplines to manage. Other industries also have their authoring tools. Connecting them through services and provide an easy to implement backbone for product information. This should be not a big-boom effect in the mid-market, but more an evolution – moving to PLM 2.0 or beyond ?

Will this come from PLM providers or IT-providers ?

Conclusion:

For the mid-market it is not about which PLM, but more about who can provide a gradual business change from sequential and departmental business processes towards company-wide processes, where people share and collaborate around the single version of data. So which PLM should be called which provider …..

I am looking forward to your opinion.

As today it was again ‘Black Saturday”, the day that the French and German roads are filled with cars and traffic jams above100 km length, it was a moment for me to reflect in the middle of my summer holiday. I do not want to make other continents jealous, but the summer holiday is important (and long), still time for some thoughts.

PLM is dead, long live Social / User focused PLM ?

In one of my old 2008 posts, PLM in 2050, I predicted that PLM would no longer exist at that time, as companies would no longer focus on individual systems, but on full coverage of business processes, through integrated and federated data sources. I see this trend coming from two major PLM vendors (Dassault Systems / Siemens) with their 3DLive / HD PLM concepts. These concepts are trying to provide a unique user experience, where in an intuitive manner, a user in a specific role can obtain relevant data, analyze and simulate it in a virtual environment. Here the PLM vendors are really taking the lead to become the main platform for product development processes. Will the name PLM disappear at a certain stage ?

Additional you see startups and also some of the major PLM vendors experimenting with community concepts, social media. Moving towards a “Facebook’- like environment for product development and collaboration processes. The idea behind this direction is partly driven by the fact that the old generation of workforce slowly moves towards retirement where the new generation is not motivated to follow up the same working processes and procedures. The old generation moved from paper-based, manual processes to terminal-like screens, email and excel sheets.

If the new generation of employees will benefit from Facebook like environments is the question. Product development and collaboration requires a lot of boring data entry, even if we have a unique user experience. In addition, I was reading a preview of some research done with American and Dutch students, stating that study results from those students active on Facebook are significant lower as the result of student not active on Facebook, although they spend the same time on internet. I haven’t found the original source – here is a Dutch link. Curious to learn who will develop and bring better products to the market in the future with modern social PLM ?

ALM based on PLM is underestimated by owner /operators

As I have been active the past two years in some Asset Lifecycle Management projects based on PLM, I also feel that many owner/operators do not have the understanding or guts to change the way they are working. Understandable from their point of view – as long as the errors and risks are acceptable, why change the way the whole industry is working ?

As I have been active the past two years in some Asset Lifecycle Management projects based on PLM, I also feel that many owner/operators do not have the understanding or guts to change the way they are working. Understandable from their point of view – as long as the errors and risks are acceptable, why change the way the whole industry is working ?

In the nuclear industry you see the awareness growing. People know the risks of a nuclear disaster (after Chernobyl) and as we need more energy resources, nuclear energy with enhanced containment of risks is a natural way to go.

Perhaps after the BP disaster in the Mexican gulf, where apparently to the various reports, people were taking the wrong decisions due to inaccurate data or due to lack of information (could not be found in time) ALM based on PLM could be considered. However, investing even a few millions and changing the company’s way of working will never be approved by the BP management, as it will never happen a second time. It is all about being proactive (which is not a natural behavior) or being reactive and trying to control the damage. Here I have no predictions for 2050, I only believe that the proactive companies have a higher chance of survival – no matter which industry

But now my holiday activities call me back – for those not blessed by a holiday, here an overview of some of the relevant posts from the past year/

PLM and Organization

How to get users excited for PLM ?

Some users do not like the single version of the truth

Implementing PLM requires a vision

What not to do in a bottom up PLM implementation ?

Culture change in a mid-sized company a management responsibility !

PLM selection

PLM for mid-market a mission impossible ?

Who decides for PLM in a mid-market company ?

More on who decides for PLM in a mid-market company

The academic conclusion on who decides for PLM in a mid-market company

Free PLM does not help companies

ALM

Asset Lifecycle Management based on PLM experiences

Asset Lifecycle Management using a PLM system

Tutorials

and if these links are not enough – look at my favorite blogs:

The past month I have been very busy in a specific area where PLM is not yet as understood. Where PLM is a ‘must have’ for companies developing and manufacturing products, in the world of Asset Development and Asset Management not many companies are yet aware of the benefits PLM can bring. I wrote about it in one of my previous posts . I will share some of my experiences here and I must thank Stephen Porter for mentioning my blog in his review (and pushing me to write today – even during the soccer championships in South Africa.

The past month I have been very busy in a specific area where PLM is not yet as understood. Where PLM is a ‘must have’ for companies developing and manufacturing products, in the world of Asset Development and Asset Management not many companies are yet aware of the benefits PLM can bring. I wrote about it in one of my previous posts . I will share some of my experiences here and I must thank Stephen Porter for mentioning my blog in his review (and pushing me to write today – even during the soccer championships in South Africa.

PLM benefits for Owner / Operators

I had discussions with a few owner/operators in the past week and as they all came from different industries (nuclear power generation / gas distribution / chemical processing), the details might differ but the values a PLM system can bring is for all of them the same.

When talking to Owner/Operators there are a few standard situations you observe:

- The usage of a transactional system (MRO / ERP /SCADA) which is managing the operational and financial activities as job scheduling and purchasing. Main dominant players in this area are Maximo and SAP. Most Owner / Operators believe that this is the only main system they need.This looks very similar to what we see in the typical manufacturing companies. They all have an ERP system, and specially in the mid-market these companies are not looking for another major IT-system.

The problem with only the transactional system as the core system for the company is that there is no natural storage for product or process information that can change (the Intellectual Property of the company). Transactional systems use pointers to actual product or process information that they require. But where do they store other and historical information ?

- The challenge to manage in parallel data for maintenance, rework and innovation projects. As the transactional system provides data for the operational environment, these companies are used to copy out data to their project environment avoiding not released project data can be seen in the operational environment. Another situation in relation to the engineering projects is that the owner / operator usually outsources the engineering work to EPC contractors and only coordinates the activities taking ownership of the data only after the new installation is under operation

The two owner / operators I met in the past month were in two different stages. The first one had already many years of experience in maintaining the plant operational and there they understood that the SAP PM module could not help them managing all required plant information around scheduled maintenance projects. Having already four different document management systems in place, the biggest challenge remained to coordinate the different baselines for the various projects scheduled for the annual maintenance. At the end they developed the concept where the PLM system is the owner of all plant related information, based on an Asset Structure in PLM and the PLM system ‘pushes’ the right information to SAP when the changes become operational.

The two owner / operators I met in the past month were in two different stages. The first one had already many years of experience in maintaining the plant operational and there they understood that the SAP PM module could not help them managing all required plant information around scheduled maintenance projects. Having already four different document management systems in place, the biggest challenge remained to coordinate the different baselines for the various projects scheduled for the annual maintenance. At the end they developed the concept where the PLM system is the owner of all plant related information, based on an Asset Structure in PLM and the PLM system ‘pushes’ the right information to SAP when the changes become operational.

The other owner / operator was in the early stage. They were planning to have a process to become operational. Their understanding is that they need only one system that provides them all the time the actual information and if needed also all the history and approvals of each of the components. For sure the actual information needs to be managed in a transactional system (SCADA) and for sure the SCADA vendor will say they can manage all information in their system. The pity for this owner / operator is that once they need historical data, or need to manage complex maintenance projects, they have lost the opportunity to do it right from the beginning.

The other owner / operator was in the early stage. They were planning to have a process to become operational. Their understanding is that they need only one system that provides them all the time the actual information and if needed also all the history and approvals of each of the components. For sure the actual information needs to be managed in a transactional system (SCADA) and for sure the SCADA vendor will say they can manage all information in their system. The pity for this owner / operator is that once they need historical data, or need to manage complex maintenance projects, they have lost the opportunity to do it right from the beginning.

Of course there is also a significant difference between the two owner operators.. The first owner / operator is situated in the Nordics, where the cost of labor is high. This means investing in IT-solutions to assure people are working with the right information brings a much faster ROI as compared to the owner / operator from South Europe. Sometime the labor cost can be one-third or less in comparison to the Nordic countries.

Of course there is also a significant difference between the two owner operators.. The first owner / operator is situated in the Nordics, where the cost of labor is high. This means investing in IT-solutions to assure people are working with the right information brings a much faster ROI as compared to the owner / operator from South Europe. Sometime the labor cost can be one-third or less in comparison to the Nordic countries.

The owner/operator in the South Europe will initially not focus on efficiency and reducing labor costs. Due to the economical crisis unemployment is also high, so working with less people – improving by investments in IT are also not a popular measure.

But for all owner/operators a main consideration should be to remain competitive also over 10 – 20 years. Short term strategy is not good for this type of companies

Conclusion so far:

PLM concepts are bringing competitive benefits for Owner/Operator, despite the fact that they do not develop products. The value is based on bringing a single version of the truth (no island systems) and working in a single environment for the as-built and the to-be environment, without data conversions or transitions

next post I will talk about Asset Development and the PLM benefits

Last weeks have been busy weeks and I have seen various PLM candidates all around Europe. As these companies were mid-market companies, I noticed again how difficult it is for these companies to follow the ideal path towards PLM.

Last weeks have been busy weeks and I have seen various PLM candidates all around Europe. As these companies were mid-market companies, I noticed again how difficult it is for these companies to follow the ideal path towards PLM.

For those reading my blog frequently they might remember my definition of mid-market and PLM. For newer readers I will give my definitions again, as everyone has their own definition.

Mid market company: For me the definition of a mid-market company does not have to do with revenue or the amount of people working for this company. I characterize a mid-market company as a company, where everyone has a focus on the company’s primary process. There is no strategic layer of people, who are analyzing the current business and defining new strategies for the future. In addition, the IT-staff is minimal, more seen as an overhead than as strategic. Mid-market companies have their strength in being flexible and reacting fast on changes, which might contradict with a long term strategic approach.

As what happens if you are only in a reactive mode – it can be too late.

PLM: For me PLM is not a product but a vision or business approach based on a collection of best practices (per industry). Main characteristics of PLM are centralizing all product knowledge (IP) throughout all the lifecycle stages and a focus on best practices and immediate visibility on all lifecycle stages. Combining concept, planning, development, production planning and after sales / service into one integrated process. It is more than concurrent engineering, it is about sharing data and ownership of data through different departments. And this means business transformation, breaking through traditional barriers. Of course PLM vendors have a slight different definition in order to differentiate themselves from other vendors. For example more focus on a virtual product definition (CAD PLM vendors) or a focus on efficiency and one single platform (ERP PLM vendors)

Who will initiate this change ?

And these two definitions already raise the questions I want to reflect here as I experienced again in two recent visits that the pain to move to PLM is here.

First what is the result of a reactive mode, even when it is a quick reaction ?

A reactive mode leads to a situation where a company will never be able to differentiate rapidly from their competition. As every change takes time to implement, it is logically that a real business change will not be implemented as a quick reaction. The company needs to have a long term vision. And this is one of the things I noticed talking with mid-market companies. Ask these questions: “Where do you want to be in five years from now” and “How do you make sure you achieve these goals (if goals exist)” and often you find the company is depending on the business instinct of the founder(s) and has no real answers for the long term future.

A reactive mode leads to a situation where a company will never be able to differentiate rapidly from their competition. As every change takes time to implement, it is logically that a real business change will not be implemented as a quick reaction. The company needs to have a long term vision. And this is one of the things I noticed talking with mid-market companies. Ask these questions: “Where do you want to be in five years from now” and “How do you make sure you achieve these goals (if goals exist)” and often you find the company is depending on the business instinct of the founder(s) and has no real answers for the long term future.

This is of course a result of the typical mid-market company, they have no internal people who will step outside the daily hectic and work on a change. And being reactive always means you are (a little) behind. And this was the situation in one of the companies that I have met recently. There was an initial understanding of the values that PLM could bring, but when talking about some of the basic principles of PLM, the answers was: In our company ERP is God. This means real PLM has no chance – you do not want to fight against God.

This is of course a result of the typical mid-market company, they have no internal people who will step outside the daily hectic and work on a change. And being reactive always means you are (a little) behind. And this was the situation in one of the companies that I have met recently. There was an initial understanding of the values that PLM could bring, but when talking about some of the basic principles of PLM, the answers was: In our company ERP is God. This means real PLM has no chance – you do not want to fight against God.

And now the discussion who can initiate the change towards PLM

Now another example of a mid-market company that had a long term PLM vision but got trapped in their own approach. The company has been growing fast and like many European companies, production is done in China. And this causes collaboration issues around communication and quality between Europe and China as the company only knows CAD data management and ERP. The engineering manager was assigned to solve these issues.He did not get a full strategic assignment to look at the complete picture, but the management pushes him to solve the current pains, having the PLM wishes still in mind.

Now another example of a mid-market company that had a long term PLM vision but got trapped in their own approach. The company has been growing fast and like many European companies, production is done in China. And this causes collaboration issues around communication and quality between Europe and China as the company only knows CAD data management and ERP. The engineering manager was assigned to solve these issues.He did not get a full strategic assignment to look at the complete picture, but the management pushes him to solve the current pains, having the PLM wishes still in mind.

And solving the current pains lead again to function / feature comparison with a short term justification, believing that in the future all will fit in the PLM vision, as the potential resellers for the new solution said: “Yes we can”. Have you ever heard a reseller say “No we cannot”

The result, the engineering manager has to make a decision based on the ‘blue eyes’ of the reseller as he does not get the mandate and power from his management to analyze and decide on a PLM strategy for the long term. For one of the resellers talking about the details of PLM was even more a disadvantage as it creates an impression that PLM is complex. It is easier to sell a dream. A similar situation as I described in my posts: Who decides for PLM in a mid-market company

My conclusion

Although I am aware that many mid-market companies implement basics of PLM, it is frustrating to see that lack of priority and understanding of the management in mid-market companies blocks the growth to full benefits for PLM. The management is not to blame, as most PLM messages either come from the high-end PLM vendors or from product resellers both not packaged for the mid-market. See PLM for the mid-market – a mission impossible ?

PLM is a cross-departmental solution and the management should look for partners who can explain the business values and share best practices for mid-market companies business wise.

The partner is 50 % of the success for a PLM implementation.

Do you recoginize similar situations ? How would you address them ?

My PLM blog cloud based on Wordie – see the virtualdutchman blog cloud

Two weeks ago I received through the PLM group on LinkedIn, the following question from Nathalie: “Do you know any specific examples of what some companies have done to get their users ready, excited or more committed to the new PLM system?”

Two weeks ago I received through the PLM group on LinkedIn, the following question from Nathalie: “Do you know any specific examples of what some companies have done to get their users ready, excited or more committed to the new PLM system?”

When digging in my mind and planning to give a quick answer, I realized it was an interesting question with a contradiction embedded: users and excitement for a new PLM system.

This week I was attending the SmarTeam User Group meeting in the Netherlands, where an excellent presentation was given by Simon and Hessel from a Dutch company called Meyn (Poultry processing) about their PLM implementation. They shared their excitement !

Combined with an interesting discussion on Oleg’s blog with Frank, I believe I have the ingredients to answer the above question more complete.

PLM is not exiting for users

I think this is fact number one. When you go to tradeshows or PLM exhibitions, you see usually only 3D CAD demos, nobody tries to demonstrate PLM functions and features in detail. As a side step, I believe the best PLM system should be almost invisible for the user. Users want to work in their own environment with applications like CAD, Excel (BOM handling apps), Office, FEA tools, Simulation tools and more.

I think this is fact number one. When you go to tradeshows or PLM exhibitions, you see usually only 3D CAD demos, nobody tries to demonstrate PLM functions and features in detail. As a side step, I believe the best PLM system should be almost invisible for the user. Users want to work in their own environment with applications like CAD, Excel (BOM handling apps), Office, FEA tools, Simulation tools and more.

ERP has a more clear value proposal, if you want to define and schedule your manufacturing and manage the financial transactions, everyone has accepted that you need ERP. User acceptance is not relevant, users have to work with the provided interface as otherwise production or accounting will fail, there is no alternative.

In contrary, the clear value and definition of PLM are not clear to user. For that reason these users do not get excited when confronted with PLM. They have been surviving without implementing PLM, so they believe there is an alternative.

But we know there are PLM benefits?

My previous post – PLM in the mid-market a mission impossible? – lead to a discussion with Oleg and Frank coming with anew and interesting view point. Frank mentioned that in the German area, many mid-market companies do PLM without purchasing an enterprise PLM system from the known vendors.

The discussion focused on granularity, as all of us believed that a set-by-step approach towards PLM best practices, driven by people who understand the company very well, is the key to success. For this approach you need people inside the customer’s organization who can formulate the vision assisted by consultants working very dedicated in that industry. It requires a different type of consultant as those active in the big enterprise projects.

The discussion focused on granularity, as all of us believed that a set-by-step approach towards PLM best practices, driven by people who understand the company very well, is the key to success. For this approach you need people inside the customer’s organization who can formulate the vision assisted by consultants working very dedicated in that industry. It requires a different type of consultant as those active in the big enterprise projects.

Instead of implementing PLM as a standard process, in this approach the customer drives and leads the activities where they see benefits in their overall business process. To achieve this, the company must have has a clear vision, where they want to be in the next 5 – 10 years.

Next implementations steps should fit in this strategy and prioritized based on different parameters and these steps are not always with a focus on PLM.

And here lies the key for successful PLM implementations.

The implementation might be based on an academic approach around a core PLM data model and best practices. Mid-market offerings are around an OOTB (Out-Of-The-Box) quick implementation – the PLM system/implementer leads.

The implementation might be based on an academic approach around a core PLM data model and best practices. Mid-market offerings are around an OOTB (Out-Of-The-Box) quick implementation – the PLM system/implementer leads.

Something the management of likes to hear; quick and with little customization, which would translate in lower costs of implementation and disruption of the organization. But then, the end-users start to complain. There is too much change their standard way of working and they do not see the advantages – keying in more data in a system does not help them.

The introduction of PLM brings more complexity and as the new system has to prove itself, there is not big enthusiasm from the average user. The management can push, like in the ERP situation, but in general also the management is anxious to learn if this OOTB-approach brings the benefits and when it fails they ask the vendor where the estimated ROI can be found.

The introduction of PLM brings more complexity and as the new system has to prove itself, there is not big enthusiasm from the average user. The management can push, like in the ERP situation, but in general also the management is anxious to learn if this OOTB-approach brings the benefits and when it fails they ask the vendor where the estimated ROI can be found.

Concluding you will be lucky if users get excited form the OOTB approach.

In the second and granular approach, the company defines their strategy and vision, not necessary a 100 % PLM vision. This strategy need to be clear and shared with the employees in the company, especially for those who are affected by changes.

In the second and granular approach, the company defines their strategy and vision, not necessary a 100 % PLM vision. This strategy need to be clear and shared with the employees in the company, especially for those who are affected by changes.

Next together with implementation partners, who bring in the know-how and possible software tools, a part of the company’s process is addressed and improved. It can be in any area, changing the CAD engine, automate BOM handling, connect sales to engineering or connect after sales/service to engineering.

Many of these areas of interest have different solutions, some are extensions of the CAD environment, some of them are extensions of the ERP environment and some of them are extensions of the IT-platform used in the company.

This approach is not sold by the PLM vendors, as they want to introduce their system as the IT-platform, wrap around the CAD and even capture the definition of the MBOM and initiation of the Item master.

A step-by-step approach based on different granular components, every time in the direction of the company’s strategy, plus all the time feed-back to the end-users on the positive impact of the change, is for me the key to success. In my previous post I was looking for a global provider for these required components.

With the step by step approach with granular solutions, we get users involved and excited.

And this brings me the to the presentation from Meyn

The first time I got involved with Meyn was in October 2004. At that time they had chosen to move from their BaaN-2D CAD infrastructure to a new environment with BaaN – 3D CAD (CATIA). Simon presented their target strategy and vision: moving away from being an Engineering To Order company to become primarily a Configure To Order company.

The first time I got involved with Meyn was in October 2004. At that time they had chosen to move from their BaaN-2D CAD infrastructure to a new environment with BaaN – 3D CAD (CATIA). Simon presented their target strategy and vision: moving away from being an Engineering To Order company to become primarily a Configure To Order company.

ENOVIA SmarTeam was chosen to manage the 3D CAD and to connect the information to BaaN. Initially Meyn started in the classical PLM approach, but already after a few months, the understanding was there, they need have step-by-step approach, focused on results for the new CATIA users, without communicating around a complete PLM focused project.

So they followed a stepped approach, they called them waves.

Moving from Engineering to Order to Configure to Order is not software implementation. It requires rationalization of your products; convert them into modular, configurable parts. For this you need to be an engineering expert, not a software expert.

But when it comes to implementation of this concept in the software, you need both experts. And through this collaboration, a methodology for skeleton design was established which was driven by Meyn. And the reason the users were excited was, that they were doing real engineering, the benefits were significant visible.

Customer project related engineering time (typical ETO), which was in the beginning their core activity, became around 30 % of the time. More time could be spent on developing new machines in a modular way. With almost the same amount of engineers the turn-over of the company had more than doubled. A win-win environment which makes also the end-users excited.

Customer project related engineering time (typical ETO), which was in the beginning their core activity, became around 30 % of the time. More time could be spent on developing new machines in a modular way. With almost the same amount of engineers the turn-over of the company had more than doubled. A win-win environment which makes also the end-users excited.

Still the backend with ERP at Meyn remained almost the same similar to the time they were working in the 2D environment. And the most interesting conclusion at the end of the presentation was, they are still using the same slide with the vision and they can explain why each step was taken and justify it by measurable benefits.

And this brings me to the answer of the question

“Do you know any specific examples of what some companies have done to get their users ready, excited or more committed to the new PLM system”?

- The management needs to have a clear vision where they want to be as a company in the future. This is not an IT-vision, but a business vision which explain why changes are needed. This vision should be clear to the employees. Communicate!

- Where possible provide metrics!

- Do not talk about a PLM system; it can be also in other tools. Talk about improvement steps in the business processes contributing to the vision. The PLM system is the information backbone, not the front-end. Management and implementers should talk business functionality not IT functions and features. Do not talk in applications!

- Build step by step user scenarios with focus on methodology and user understanding. Implementations with a function-feature focus are hard to accept by the users. Talk business!

- The management should present their vision again and again, supported by metrics what has been accomplished and what has been learned for the future – repeat!

Conclusion

There are thousands of mid-market companies that have a vision to improve their business. The PLM system should never be the topic of discussion with the end users; it is the change in working methods that is important, supported by various systems -CAD/ERP/CRM – and almost invisible …….. PLM

The company Meyn is an example of this approach. Simon and Hessel are working for Meyn as engineers improving their company’s business. Unfortunate it is not their business to explain all around the world, how PLM supports business change in a mid-market company. I was glad to attend their session last week.

In 2008 and 2009 several analysts predicted that the mid-market was now ready for PLM and that most of the PLM vendors were building a targeted offering for the mid-market. I was, and still am, a believer that mid-market companies will benefit from PLM in case ………… they implement it.

In 2008 and 2009 several analysts predicted that the mid-market was now ready for PLM and that most of the PLM vendors were building a targeted offering for the mid-market. I was, and still am, a believer that mid-market companies will benefit from PLM in case ………… they implement it.

When you review my observations in my blog from the past two years, apparently this does not seem to happen. Therefore in the past months, I have been analyzing posts and discussions around the ‘old’ and ‘new’ PLM, I have been talking with representatives from various PLM and PDM vendors, and last but not least analyzed what was the implementation process of a PLM system in companies, where I could get these insights.

This all lead to this post, perhaps too big for a blog, too small for a report.

First the definitions

Before giving my opinion, first my definitions of PLM and mid-market (as everyone has their own definition):

PLM means for me the management of all product related data and processes, from the initial concept phase, through planning, development, production planning and after sales/service. When talking about PLM, I have always a circular process in mind. Experiences from products in the market are again inputs for new product development. Instead of a linear process where every department manages their own data, the challenge is that every discipline contributes and collaborates around the product data. This implies that a PLM implementation always requires a business change process for a customer

PLM means for me the management of all product related data and processes, from the initial concept phase, through planning, development, production planning and after sales/service. When talking about PLM, I have always a circular process in mind. Experiences from products in the market are again inputs for new product development. Instead of a linear process where every department manages their own data, the challenge is that every discipline contributes and collaborates around the product data. This implies that a PLM implementation always requires a business change process for a customer

Mid-market companies are for those companies where there is no strategic layer available plus a minimized investment in IT-resources. This leads to organizations where most changes are happening inside departments and cross-departmental changes are hard to implement. The IT-department might be a facilitator here but usually IT people focus on architecture and infrastructure instead of business change. This implies that a PLM changed should come from external people.

Mid-market companies are for those companies where there is no strategic layer available plus a minimized investment in IT-resources. This leads to organizations where most changes are happening inside departments and cross-departmental changes are hard to implement. The IT-department might be a facilitator here but usually IT people focus on architecture and infrastructure instead of business change. This implies that a PLM changed should come from external people.

And who are doing PLM?

On the enterprise level, there is a battle between the big three (Dassault Systems, Siemens and PTC) and they are challenged mostly by the two big ERP vendors (SAP and Oracle) and on the PLM front by Aras, competing through its Open Source model. Of course there are many other vendors. These observations come from the area where I am active.

There are various ways to group these PLM vendors; one is from the CAD engine point of view: DS-CATIA / Siemens-NX / PTC-Pro/E. Although all claim to support a multi-CAD environment, the main focus in these companies is around the PLM integration with their primary CAD engine.

There are various ways to group these PLM vendors; one is from the CAD engine point of view: DS-CATIA / Siemens-NX / PTC-Pro/E. Although all claim to support a multi-CAD environment, the main focus in these companies is around the PLM integration with their primary CAD engine.

Where in the past, CAD independent PDM systems existed (Metaphase, MatrixOne), they could only survive in the major PLM industries by being integrated with CAD tools and were acquired for that reason. It will be interesting to see if Aras can play a major role in the PLM only domain, where others failed in the past due to lack of integration capabilities.

SAP and Oracle took a different path; they have understood that PLM cannot be neglected in an enterprise, so they need to address it. SAP did this by developing a PLM module as a logical extension on their infrastructure. Oracle has chosen to add PLM to their portfolio by the acquisition of two different PLM vendors. Where SAP does not have the challenge to explain to customers a full integrated story, Oracle has to spend more time on marketing to make it look like a single platform, which will come in the future. Big question however for both companies: do they really understand PLM? Is it in their veins and core strategy or does it remain an extension to gain market share, especially as you have no connections to the design world? (Try to find PLM on their corporate website).

SAP and Oracle took a different path; they have understood that PLM cannot be neglected in an enterprise, so they need to address it. SAP did this by developing a PLM module as a logical extension on their infrastructure. Oracle has chosen to add PLM to their portfolio by the acquisition of two different PLM vendors. Where SAP does not have the challenge to explain to customers a full integrated story, Oracle has to spend more time on marketing to make it look like a single platform, which will come in the future. Big question however for both companies: do they really understand PLM? Is it in their veins and core strategy or does it remain an extension to gain market share, especially as you have no connections to the design world? (Try to find PLM on their corporate website).

Interesting to see how Aras will evolve. In their business model, the initial purchase of software is not needed, but once working with Aras you pay also for maintenance like with other PLM vendors. Their advantage is that switching from an existing legacy PLM vendor is less painful, as there are no initial software costs, which can be huge for an enterprise. I believe they have a good chance to succeed in industries where there is less a dependency on the CAD engine.So on the enterprise level the need for PLM is justified. Resources exist and are budgeted both at the customer level as at the supplier level. The PLM suppliers are either the PLM vendors themselves with service teams, or big, global service providers specialized in implementing the PLM software. They can do strategic PLM projects and support the required business change.

Interesting to see how Aras will evolve. In their business model, the initial purchase of software is not needed, but once working with Aras you pay also for maintenance like with other PLM vendors. Their advantage is that switching from an existing legacy PLM vendor is less painful, as there are no initial software costs, which can be huge for an enterprise. I believe they have a good chance to succeed in industries where there is less a dependency on the CAD engine.So on the enterprise level the need for PLM is justified. Resources exist and are budgeted both at the customer level as at the supplier level. The PLM suppliers are either the PLM vendors themselves with service teams, or big, global service providers specialized in implementing the PLM software. They can do strategic PLM projects and support the required business change.

So why does it look like a mission impossible in the mid-market ?

The big enterprise vendors (PLM/ERP) believe that you can just strip down your enterprise software in a kind of prepackaged mode – PLM Out of the Box is a common heard expression. Also the analysts praise in their reports the mid-market approach from some of these vendors.

But do they really address the mid-market or only the high-end mid-market? Again it is all about the definition of where is the mid-market and in this post I stay with my definition of mid-market.

There are two main characteristics for this mid-market:

- Sales and implementation of software is done through Value Added Resellers and not through the vendors or big service companies. The software revenue per customer does not justify high expenses for global consultants with additional high expenses due to travel costs (and sometimes the local language issue). The local VAR is supposed to be the point of contact.

- Mid-market companies do not change their main company processes. Depending on the type of core process, let’s assume ETO or BTO, they have sales and engineering working close together on product/solution definition and they have manufacturing planning and production working close together on product/solution delivery. In term of functionality a PDM focus for sales/engineering and an ERP focus for manufacturing.

A mid-market company can be characterized as a two pillar company :

Who are successful in the mid-market ?

There are two software vendors, touching our PLM prospects , that really understand the mid-market, Autodesk and Microsoft.

Autodesk has a huge range of products and when we focus on the area of manufacturing, Autodesk does not talk about PLM. And I believe for several reasons.

Autodesk has never been a front-runner in making new technology and concepts available for the mainstream. They are more a company providing functionality for mainstream concepts, as compared to a company pushing new concepts and technology for premium pricing.

Autodesk has never been a front-runner in making new technology and concepts available for the mainstream. They are more a company providing functionality for mainstream concepts, as compared to a company pushing new concepts and technology for premium pricing.