You are currently browsing the category archive for the ‘OSLC’ category.

Due to other activities, I could not immediately share the second part of the review related to the PLM Roadmap / PDT Europe conference, held on 23-24 October in Gothenburg. You can read my first post, mainly about Day 1, here: The weekend after PLM Roadmap/PDT Europe 2024.

Due to other activities, I could not immediately share the second part of the review related to the PLM Roadmap / PDT Europe conference, held on 23-24 October in Gothenburg. You can read my first post, mainly about Day 1, here: The weekend after PLM Roadmap/PDT Europe 2024.

There were several interesting sessions which I will not mention here as I want to focus on forward-looking topics with a mix of (federated) data-driven PLM environments and the applicability of AI, staying around 1500 words.

R-evolutionizing PLM and ERP and Heliple

Cristina Paniagua from the Luleå University of Technology closed the first day of the conference, giving us food for thought to discuss over dinner. Her session, describing the Arrowhead fPTN project, fitted nicely with the concepts of the Federated PLM Heliple project presented by Erik Herzog also on Day 2.

They are both research products related to the future state of a digital enterprise. Therefore, it makes sense to treat them together.

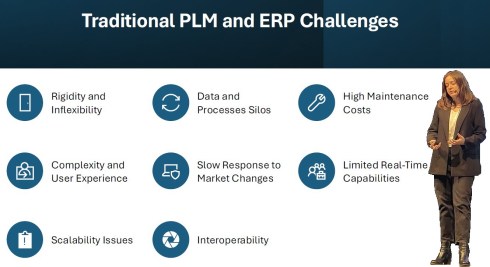

Cristina’s session started with sharing the challenges of traditional PLM and ERP systems:

These statements align with the drivers of the Heliple project. The PLM and ERP systems—Systems of Record—provide baselines and traceability. However, Systems of Record have not historically been designed to support real-time collaboration or to create an attractive user experience.

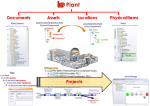

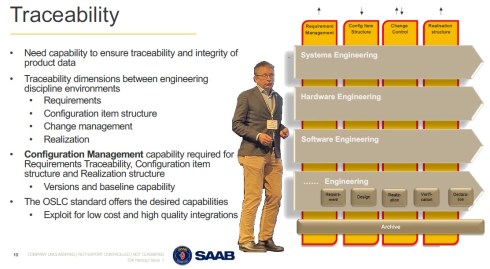

The Heliple project focuses on connecting various modules—the horizontal bars—for systems engineering, hardware engineering, etc., as real-time collaboration environments that can be highly customized and replaceable if needed. The Heliple project explored the usage of OSLC to connect these modules, the Systems of Engagement, with the Systems of Record.

![]() By using Lynxwork as a low-code wrapper to develop the OSLC connections and map them to the needed business scenarios, the team concluded that this approach is affordable for businesses.

By using Lynxwork as a low-code wrapper to develop the OSLC connections and map them to the needed business scenarios, the team concluded that this approach is affordable for businesses.

Now, the Heliple team is aiming to expand their research with industry scale validation through the Demoiple project (Validate that the Heliple-2 technology can be implemented and accredited in Saab Aeronautics’ operational IT) combined with the Nextiple project, where they will investigate the role of heterogeneous information models/ontologies for heterogeneous analysis.

![]() If you are interested in participating in Nextiple, don’t hesitate to contact Erik Herzog.

If you are interested in participating in Nextiple, don’t hesitate to contact Erik Herzog.

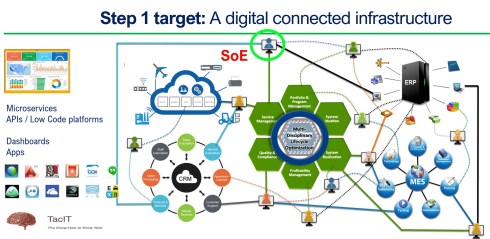

Christina’s Arrowhead flexible Production Value Network(fPVN) project aims to provide autonomous and evolvable information interoperability through machine-interpretable content for fPVN stakeholders. In less academic words, building a digital data-driven infrastructure.

Christina’s Arrowhead flexible Production Value Network(fPVN) project aims to provide autonomous and evolvable information interoperability through machine-interpretable content for fPVN stakeholders. In less academic words, building a digital data-driven infrastructure.

The resulting technology is projected to impact manufacturing productivity and flexibility substantially.

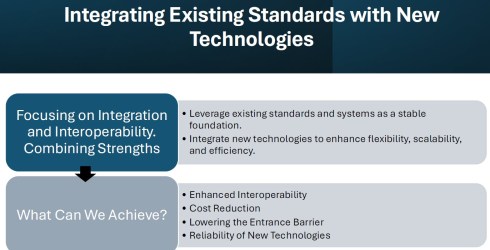

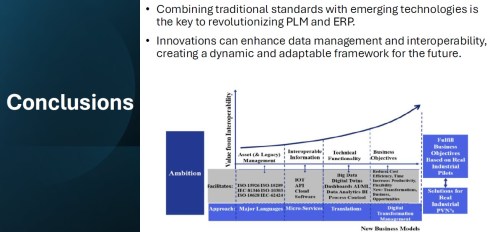

The exciting starting point of the Arrowhead project is that it wants to use existing standards and systems as a foundation and, on top of that, create a business and user-oriented layer, using modern technologies such as micro-services to support real-time processing and semantic technologies, ontologies, system modeling, and AI for data translations and learning—a much broader and ambitious scope than the Heliple project.

I believe that in our PLM domain, this resonates with actual discussions you will find on LinkedIn, too. @Oleg Shilovitsky, @Dr. Yousef Hooshmand, @Prof. Dr. Jörg W. Fischer and Martin Eigner are a few of them steering these discussions. I consider it a perfect match for one of the images I shared about the future the digital enterprise.

I believe that in our PLM domain, this resonates with actual discussions you will find on LinkedIn, too. @Oleg Shilovitsky, @Dr. Yousef Hooshmand, @Prof. Dr. Jörg W. Fischer and Martin Eigner are a few of them steering these discussions. I consider it a perfect match for one of the images I shared about the future the digital enterprise.

Potentially, there are five platforms with their own internal ways of working, a mix of systems of record and systems of engagement, supported by an overlay of several Systems of Engagement environments.

![]() I previously described these dedicated environments, e.g., OpenBOM, Colab, Partful, and Authentise. These solutions could also be dedicated apps supporting a specific ecosystem role.

I previously described these dedicated environments, e.g., OpenBOM, Colab, Partful, and Authentise. These solutions could also be dedicated apps supporting a specific ecosystem role.

See below my artist’s impression of how a Service Engineer would work in its app connected to CRM, PLM and ERP platform datasets:

The exciting part of the Arrowhead fPVN project is that it wants to explore the interactions between systems and user roles based on existing mature standards instead of leaving the connections to software developers.

Christina mentioned some of these standards below:

I greatly support this approach as, historically, much knowledge and effort has been put into developing standards to support interoperability. Maybe not in real-time, but the embedded knowledge in these standards will speed up the broader usage. Therefore, I concur with the concluding slide:

A final comment: Industrial users must push for these standards if they do not want a future vendor lock-in. Vendors will do what the majority of their customers ask for but will also keep their customers’ data in proprietary formats to prevent them from switching to another system.

Accelerated Product Development Enabled by Digitalization

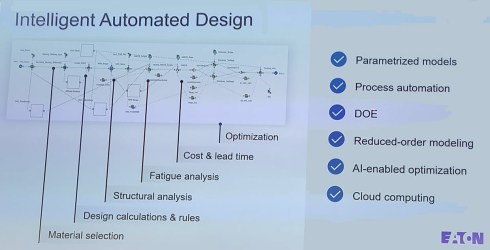

![]() The keynote session on Day 2, delivered by Uyiosa Abusomwan, Ph.D., Senior Global Technology Manager – Digital Engineering at Eaton, was a visionary story about the future of engineering.

The keynote session on Day 2, delivered by Uyiosa Abusomwan, Ph.D., Senior Global Technology Manager – Digital Engineering at Eaton, was a visionary story about the future of engineering.

With its broad range of products, Eaton is exploring new, innovative ways to accelerate product design by modeling the design process and applying AI to narrow design decisions and customer-specific engineering work. The picture below shows the areas of attention needed to model the design processes. Uyiosa mentioned the significant beneficial results that have already been reached.

Together with generative design, Eaton works towards modern digital engineering processes built on models and knowledge. His session was complementary to the Heliple and Arrowhead story. To reach such a contemporary design engineering environment, it must be data-driven and built upon open PLM and software components to fully use AI and automation.

Next Gen” Life Cycle Management in Next-Gen Nuclear Power and LTO Legacy Plants

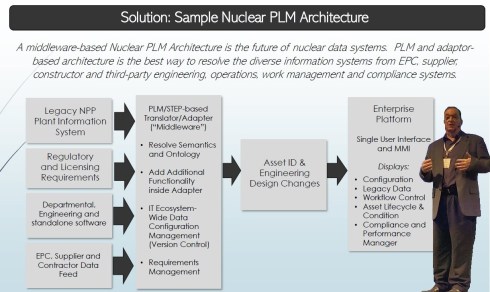

Kent Freeland‘s presentation was a trip into memory land when he discussed the issues with Long Term Operations of legacy nuclear plants.

I spent several years in Ringhals (Sweden) discussing and piloting the setup of a PLM front-end next to the MRO (Maintenance Repair Overhaul) system. As nuclear plants developed in the sixties, they required a longer than anticipated lifecycle, with access to the right design and operational data; maintenance and upgrade changes in the plant needed to be planned and controlled. The design data is often lacking; it resides at the EPC or has been stored in a document management system with limited retrieval capabilities.

I spent several years in Ringhals (Sweden) discussing and piloting the setup of a PLM front-end next to the MRO (Maintenance Repair Overhaul) system. As nuclear plants developed in the sixties, they required a longer than anticipated lifecycle, with access to the right design and operational data; maintenance and upgrade changes in the plant needed to be planned and controlled. The design data is often lacking; it resides at the EPC or has been stored in a document management system with limited retrieval capabilities.

See also my 2019 post: How PLM, ALM, and BIM converge thanks to the digital twin.

Kent described these experienced challenges – we must have worked in parallel universes – that now, for the future, we need a digitally connected infrastructure for both plant design and maintenance artifacts, as envisioned below:

The solution reminded me of a lecture I saw at the PI PLMx 2019 conference, where the Swedish ESS facility demonstrated its Asset Lifecycle Data Management solution based on the 3DEXPERIENCE platform.

The solution reminded me of a lecture I saw at the PI PLMx 2019 conference, where the Swedish ESS facility demonstrated its Asset Lifecycle Data Management solution based on the 3DEXPERIENCE platform.

You can still find the presentation here: Henrik Lindblad Ola Nanzell ESS – Enabling Predictive Maintenance Through PLM & IIOT.

Also, Kent focused on the relevant standards to support a “Single Source of Truth” concept, where I would say after all the federated PLM discussions, I would go for:

“The nearest source of truth and a single source of Change”

assuming this makes more sense in a digitally connected enterprise.

Why do you need to be SMART when contracting for information?

Rob Bodington‘s presentation was complementary to Kent Freeland’s presentation. Ron, a technical fellow at Eurostep, described the challenge of information acquisition when working with large assets that require access to the correct data once the asset is in operation. The large asset could be a nuclear plant or an aircraft carrier.

Rob Bodington‘s presentation was complementary to Kent Freeland’s presentation. Ron, a technical fellow at Eurostep, described the challenge of information acquisition when working with large assets that require access to the correct data once the asset is in operation. The large asset could be a nuclear plant or an aircraft carrier.

In the ideal world, the asset owner wants to have a digital twin of the asset fed by different data sources through a digital thread. Of course, this environment will only be reliable when accurate data is used and presented.

Getting accurate data starts with the information acquisition process, and Rob explained that this needed to be done SMARTly – see the image below:

Rob zoomed in on the SMART keywords and the challenge the various standards provide to make the information SMARTly accessible, like the ISO 10303 / PLCS standard, the CFIHOS exchange standard and more. And then there is the ISO 8000 standard about data quality.

Rob zoomed in on the SMART keywords and the challenge the various standards provide to make the information SMARTly accessible, like the ISO 10303 / PLCS standard, the CFIHOS exchange standard and more. And then there is the ISO 8000 standard about data quality.

Click on the image to get smart.

Rob believes that AI might be the silver bullet as it might help understand the data quality, ontology and context of the data and even improve contracting, generating data clauses for contracting….

And there was a lot of AI ….

![]() There was a dazzling presentation from Gary Langridge, engineering manager at Ocado, explaining their Ocado Smart Platform (OSP), which leverages AI, robotics, and automation to tackle the challenges of online grocery and allow their clients to excel in performance and customer responsiveness.

There was a dazzling presentation from Gary Langridge, engineering manager at Ocado, explaining their Ocado Smart Platform (OSP), which leverages AI, robotics, and automation to tackle the challenges of online grocery and allow their clients to excel in performance and customer responsiveness.

There was a significant AI component in his presentation, and if you are tired of reading, watch this video

![]() But here was more AI – from the 25 sessions in this conference, 19 of them mentioned the potential or usage of AI somewhere in their speech – this is more than 75 %!

But here was more AI – from the 25 sessions in this conference, 19 of them mentioned the potential or usage of AI somewhere in their speech – this is more than 75 %!

There was a dedicated closing panel discussion related to the real business value of Artificial Intelligence in the PLM domain, moderated by Peter Bilello and answered by selected speakers from the conference, Sandeep Natu (CIMdata), Lars Fossum (SAP), Diana Goenage (Dassault Systemes) and Uyiosa Abusomwan (Eaton).

The discussion was realistic and helpful for the audience. It is clear that to reap the benefits, companies must explore the technology and use it to create valuable business scenarios. One could argue that many AI tools are already available, but the challenge remains that they have to run on reliable data. The data foundation is crucial for a successful outcome.

An interesting point in the discussion was the statement from Diane Goenage, who repeatedly warned that using LLM-based solutions has an environmental impact due to the amount of energy they consume.

An interesting point in the discussion was the statement from Diane Goenage, who repeatedly warned that using LLM-based solutions has an environmental impact due to the amount of energy they consume.

We have a similar debate in the Netherlands – do we want the wind energy consumed by data centers (the big tech companies with a minimum workforce in the Netherlands), or should the Dutch citizens benefit from renewable energy resources?

Conclusion

There were even more interesting presentations during these two days, and you might have noticed that I did not advertise my content. This is because I have already reached 1600 words, but I also want to spend more time on the content separately.

It was about PLM and Sustainability, a topic often covered in this conference. Unfortunately, only 25 % of the presentations touched on sustainability, and AI over-hypes the topic.

Hopefully, it is not a sign of the time?

Last week, I shared my first impressions from my favorite conference, in the post: The weekend after PLM Roadmap/PDT Europe 2023, where most impressions could be classified as traditional PLM and model-based.

Last week, I shared my first impressions from my favorite conference, in the post: The weekend after PLM Roadmap/PDT Europe 2023, where most impressions could be classified as traditional PLM and model-based.

There is nothing wrong with conventional PLM, as there is still much to do within this scope. A model-based approach for MBSE (Model-Based Systems Engineering) and MBD (Model-Based Definition) and efficient supplier collaboration are not topics you solve by implementing a new system.

Ultimately, to have a business-sustainable PLM infrastructure, you need to structure your company internally and connect to the outside world with a focus on standards to avoid a vendor lock-in or a dead end.

Ultimately, to have a business-sustainable PLM infrastructure, you need to structure your company internally and connect to the outside world with a focus on standards to avoid a vendor lock-in or a dead end.

In short, this is what I described so far in The weekend after ….part 1.

Now, let’s look at the relatively new topics for this audience.

Enabling the Marketing, Engineering & Manufacturing Digital Thread

Cyril Bouillard, the PLM & CAD Tools Referent at the Mersen Electrical Protection (EP) business unit, shared his experience implementing an end-to-end digital backbone from marketing through engineering and manufacturing.

Cyril Bouillard, the PLM & CAD Tools Referent at the Mersen Electrical Protection (EP) business unit, shared his experience implementing an end-to-end digital backbone from marketing through engineering and manufacturing.

Cyril showed the benefits of a modern PLM infrastructure that is not CAD-centric and focused on engineering only. The advantages of this approach are a seamless integrated flow of PLM and PIM (Product Information Management).

I wrote about this topic in 2019: PLM and PIM – the complementary value in a digital enterprise. Combining the concepts of PLM and PIM in an integrated, connected environment could also provide a serious benefit when collaborating with external parties.

Another benefit Cyril demonstrated was the integration of RoHS compliance to the BOM as an integrated environment. In my session, I also addressed integrated RoHS compliance as a stepping stone to efficiency in future compliance needs.

Another benefit Cyril demonstrated was the integration of RoHS compliance to the BOM as an integrated environment. In my session, I also addressed integrated RoHS compliance as a stepping stone to efficiency in future compliance needs.

Read more later or in this post: Material Compliance – as a stepping-stone towards Life Cycle Assessment (LCA)

Cyril concluded with some lessons learned.

Data quality is essential in such an environment, and there are significant time savings implementing the connected Digital Thread.

Meeting the Challenges of Sustainability in Critical Transport Infrastructures

Etienne Pansart, head of digital engineering for construction at SYSTRA, explained how they address digital continuity with PLM throughout the built assets’ lifecycle.

Etienne Pansart, head of digital engineering for construction at SYSTRA, explained how they address digital continuity with PLM throughout the built assets’ lifecycle.

Etienne’s story was related to the complexity of managing a railway infrastructure, which is a linear and vertical distribution at multiple scales; it needs to be predictable and under constant monitoring; it is a typical system of systems network, and on top of that, maintenance and operational conditions need to be continued up to date.

Regarding railway assets – a railway needs renewal every two years, bridges are designed to last a hundred years, and train stations should support everyday use.

When complaining about disturbances, you might have a little more respect now (depending on your country). However, on top of these challenges, Etienne also talked about the additional difficulties expected due to climate change: floods, fire, earth movements, and droughts, all of which will influence the availability of the rail infrastructure.

In that context, Etienne talked about the MINERVE project – see image below:

As you can see from the main challenges, there is an effort of digitalization for both the assets and a need to provide digital continuity over the entire asset lifecycle. This is not typically done in an environment with many different partners and suppliers delivering a part of the information.

Etienne explained in more detail how they aim to establish digital twins and MBSE practices to build and maintain a data-driven, model-based environment.

Having digital twins allows much more granular monitoring and making accurate design decisions, mainly related to sustainability, without the need to study the physical world.

His presentation was again a proof point that through digitalization and digital twins, the traditional worlds of Product Lifecycle Management and Asset Information Management become part of the same infrastructure.

And it may be clear that in such a collaboration environment, standards are crucial to connect the various stakeholder’s data sources – Etienne mentioned ISO 16739 (IFC), IFC Rail, and ISO 19650 (BIM) as obvious standards but also ISO 10303 (PLCS) to support the digital thread leveraged by OSLC.

And it may be clear that in such a collaboration environment, standards are crucial to connect the various stakeholder’s data sources – Etienne mentioned ISO 16739 (IFC), IFC Rail, and ISO 19650 (BIM) as obvious standards but also ISO 10303 (PLCS) to support the digital thread leveraged by OSLC.

I am curious to learn more about the progress of such a challenging project – having worked with the high-speed railway project in the Netherlands in 1995 – no standards at that time (BIM did not exist) – mainly a location reference structure with documents. Nothing digital.

The connected Digital Thread

The theme of the conference was The Digital Thread in a Heterogeneous, Extended Enterprise Reality, and in the next section, I will zoom in on some of the inspiring sessions for the future, where collaboration or information sharing is all based on a connected Digital Thread – a term I will explain in more depth in my next blog post.

Transforming the PLM Landscape:

The Gateway to Business Transformation

Yousef Hooshmand‘s presentation was the highlight of this conference for me.

Yousef Hooshmand‘s presentation was the highlight of this conference for me.

Yousef is the PLM Architect and Lead for the Modernization of the PLM Landscape at NIO, and he has been active before in the IT-landscape transformation at Daimler, on which he published the paper: From a monolithic PLM landscape to a federated domain and data mesh.

If you read my blog or follow Share PLM, you might seen the reference to Yousef’s work before, or recently, you can hear the full story at the Share PLM Podcast: Episode 6: Revolutionizing PLM: Insights.

If you read my blog or follow Share PLM, you might seen the reference to Yousef’s work before, or recently, you can hear the full story at the Share PLM Podcast: Episode 6: Revolutionizing PLM: Insights.

It was the first time I met Yousef in 3D after several virtual meetings, and his passion for the topic made it hard to fit in the assigned 30 minutes.

There is so much to share on this topic, and part of it we already did before the conference in a half-day workshop related to Federated PLM (more on this in the following review).

First, Yousef started with the five steps of the business transformation at NIO, where long-term executive commitment is a must.

His statement: “If you don’t report directly to the board, your project is not important”, caused some discomfort in the audience.

As the image shows, a business transformation should start with a systematic description and analysis of which business values and objectives should be targeted, where they fit in the business and IT landscape, what are the measures and how they can be tracked or assessed and ultimately, what we need as tools and technology.

In his paper From a Monolithic PLM Landscape to a Federated Domain and Data Mesh, Yousef described the targeted federated landscape in the image below.

And now some vendors might say, we have all these domains in our product portfolio (or we have slides for that) – so buy our software, and you are good.

And here Yousef added his essential message, illustrated by the image below.

Start by delivering the best user-centric solutions (in an MVP manner – days/weeks – not months/years). Next, be data-centric in all your choices and ultimately build an environment ready for change. As Yousef mentioned: “Make sure you own the data – people and tools can leave!”

And to conclude reporting about his passionate plea for Federated PLM:

“Stop talking about the Single Source of Truth, start Thinking of the Nearest Source of Truth based on the Single Source of Change”.

Heliple-2 PLM Federation:

A Call for Action & Contributions

A great follow-up on Yousef’s session was Erik Herzog‘s presentation about the final findings of the Heliple 2 project, where SAAB Aeronautics, together with Volvo, Eurostep, KTH, IBM and Lynxwork, are investigating a new way of federated PLM, by using an OSLC-based, heterogeneous linked product lifecycle environment.

A great follow-up on Yousef’s session was Erik Herzog‘s presentation about the final findings of the Heliple 2 project, where SAAB Aeronautics, together with Volvo, Eurostep, KTH, IBM and Lynxwork, are investigating a new way of federated PLM, by using an OSLC-based, heterogeneous linked product lifecycle environment.

Heliple stands for HEterogeneous LInked Product Lifecycle Environment

The image below, which I shared several times before, illustrates the mindset of the project.

Last year, during the previous conference in Gothenburg, Erik introduced the concept of federated PLM – read more in my post: The week after PLM Roadmap / PDT Europe 2022, mentioning two open issues to be investigated: Operational feasibility (is it maintainable over time) and Realisation effectivity (is it affordable and maintainable at a reasonable cost)

As you can see from the slide below, the results were positive and encouraged SAAB to continue on this path.

One of the points to mention was that during this project, Lynxwork was used to speed up the development of the OSLC adapter, reducing costs, time and needed skills.

After this successful effort, Erik and several others who joined us at the pre-conference workshop agreed that this initiative is valid to be tested, discussed and exposed outside Sweden.

After this successful effort, Erik and several others who joined us at the pre-conference workshop agreed that this initiative is valid to be tested, discussed and exposed outside Sweden.

Therefore, the Federated PLM Interest Group was launched to join people worldwide who want to contribute to this concept with their experiences and tools.

A first webinar from the group is already scheduled for December 12th at 4 PM CET – you can join and register here.

More to come

Given the length of this blog post, I want to stop here.

Topics to share in the next post are related to my contribution at the conference The Need for a Governance Digital Thread, where I addressed the need for federated PLM capabilities with the upcoming regulations and practices related to sustainability, which require a connected Digital.

Topics to share in the next post are related to my contribution at the conference The Need for a Governance Digital Thread, where I addressed the need for federated PLM capabilities with the upcoming regulations and practices related to sustainability, which require a connected Digital.

I want to combine this post with the findings that Mattias Johansson, CEO of Eurostep, shared in his session: Why a Digital Thread makes a lot of sense, goes beyond manufacturing, and should be standards-based.

I want to combine this post with the findings that Mattias Johansson, CEO of Eurostep, shared in his session: Why a Digital Thread makes a lot of sense, goes beyond manufacturing, and should be standards-based.

There are some interesting findings in these two presentations.

And there was the introduction of AI at the conference, with some experts’ talks and thoughts. Perhaps at this stage, it is too high on Gartner’s hype cycle to go into details. It will surely be THE topic of discussion or interest you must have noticed.

And there was the introduction of AI at the conference, with some experts’ talks and thoughts. Perhaps at this stage, it is too high on Gartner’s hype cycle to go into details. It will surely be THE topic of discussion or interest you must have noticed.

The recent turmoil at OpenAI is an example of that. More to come for sure in the future.

Conclusion

The PLM Roadmap/PDT Europe conference was significant for me because I discovered that companies are working on concepts for a data-driven infrastructure for PLM and are (working on) implementing them. The end of monolithic PLM is visible, and companies need to learn to master data using ontologies, standards and connected digital threads.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…