In the past few weeks, together with Share PLM, we recorded and prepared a few podcasts to be published soon. As you might have noticed, for Season 2, our target is to discuss the human side of PLM and PLM best practices and less the technology side. Meaning:

In the past few weeks, together with Share PLM, we recorded and prepared a few podcasts to be published soon. As you might have noticed, for Season 2, our target is to discuss the human side of PLM and PLM best practices and less the technology side. Meaning:

- How to align and motivate people around a PLM initiative?

- What are the best practices when running a PLM initiative?

- What are the crucial skills you need to have as a PLM lead?

And as there are always many success stories to learn on the internet, we also challenged our guests to share the moments where they got experienced.

As the famous quote says:

Experience is what you get when you don’t get what you expect!

We recently published our with Antonio Casaschi from Assa Abloy, a Swedish company you might have never noticed, although their products and services are a part of your daily life.

It was a discussion to my heart. We discussed the various aspects of PLM. What makes a person a PLM professional? And if you have no time to listen for these 35 minutes, read and scan the recording transcript on the transcription tab.

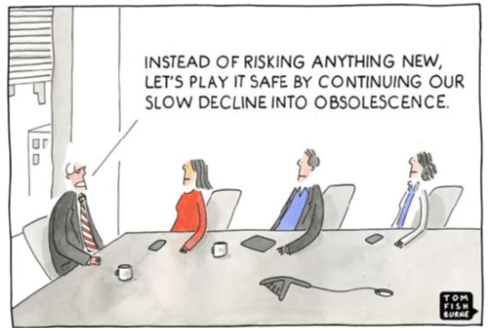

At 0:24:00, Antonio mentioned the concept of Proof of Concept as he had good experiences with them in the past. The remark triggered me to share some observations that a Proof of Concept (POC) is an old-fashioned way to drive change within organizations. Not discussed in this podcast but based on my experience, companies have been using the Proof Of Concepts to win time, as they were afraid to make a decision.

A POC to gain time?

Company A

When working with a well-known company in 2014, I learned they were planning approximately ten POC per year to explore new ways of working or new technologies. As it was a POC based on an annual time scheme, the evaluation at the end of the year was often very discouraging.

When working with a well-known company in 2014, I learned they were planning approximately ten POC per year to explore new ways of working or new technologies. As it was a POC based on an annual time scheme, the evaluation at the end of the year was often very discouraging.

Most of the time, the conclusion was: “Interesting, we should explore this further” /“What are the next POCs for the upcoming year?”

There was no commitment to follow-up; it was more of a learning exercise not connected to any follow-up.

Company B

During one of the PDT events, a company presented that two years POC with the three leading PLM vendors, exploring supplier collaboration. I understood the PLM vendors had invested much time and resources to support this POC, expecting a big deal. However, the team mentioned it was an interesting exercise, and they learned a lot about supplier collaboration.

During one of the PDT events, a company presented that two years POC with the three leading PLM vendors, exploring supplier collaboration. I understood the PLM vendors had invested much time and resources to support this POC, expecting a big deal. However, the team mentioned it was an interesting exercise, and they learned a lot about supplier collaboration.

And nothing happened afterward ………

In 2019

At the 2019 Product Innovation Conference in London, when discussing Digital Transformation within the PLM domain, I shared in my conclusion that the POC was mainly a waste of time as it does not push you to transform; it is an option to win time but is uncommitted.

My main reason for not pushing a POC is that it is more of a limited feasibility study.

- Often to push people and processes into the technical capabilities of the systems used. A focus starting from technology is the opposite of what I have been pushing for longer: First, focus on the value stream – people and processes- and then study which tools and technologies support these demands.

- Second, the POC approach often blocks innovation as the incumbent system providers will claim the desired capabilities will come (soon) within their systems—a safe bet.

The Minimum Viable Product approach (MVP)

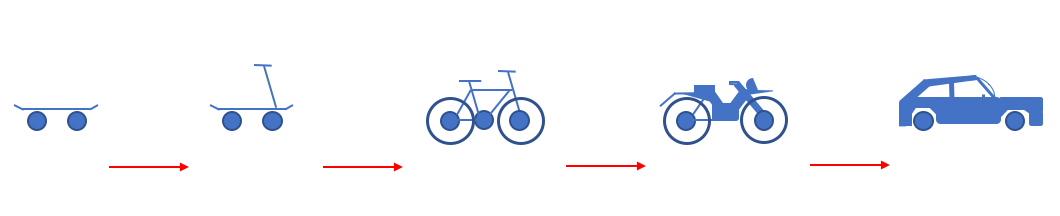

With the awareness that we need to work differently and benefit from digital capabilities also came the term Minimum Viable Product or MVP.

The abbreviation MVP is not to be confused with the minimum valuable products or most valuable players.

There are two significant differences with the POC approach:

- You admit the solution does not exist anywhere – so it cannot be purchased or copied.

- You commit to the fact that this new approach will be the right direction to take and agree that a perfect fit solution is not blocking you from starting for real.

These two differences highlight the main challenges of digital transformation in the PLM domain. Digital Transformation is a learning process – it takes time for organizations to acquire and master the needed skills. And secondly, it cannot be a big bang, and I have often referred to the 2017 article from McKinsey: Toward an integrated technology operating model. Image below.

We will soon hear more about digital transformation within the PLM domain during the next episode of our SharePLM podcast. We spoke with Yousef Hooshmand, currently working for NIO, a Chinese multinational automobile manufacturer specializing in designing and developing electric vehicles, as their PLM data lead.

You might have discovered Yousef earlier when he published his paper: “From a Monolithic PLM Landscape to a Federated Domain and Data Mesh”. It is highly recommended that to read the paper if you are interested in a potential PLM future infrastructure. I wrote about this whitepaper in 2022: A new PLM paradigm discussing the upcoming Systems of Engagement on top of a Systems or Record infrastructure.

You might have discovered Yousef earlier when he published his paper: “From a Monolithic PLM Landscape to a Federated Domain and Data Mesh”. It is highly recommended that to read the paper if you are interested in a potential PLM future infrastructure. I wrote about this whitepaper in 2022: A new PLM paradigm discussing the upcoming Systems of Engagement on top of a Systems or Record infrastructure.

To align our terminology with Yousef’s wording, his domains align with the Systems of Engagement definition.

As we discovered and discussed with Yousef, technology is not the blocking issue to start. You must understand the target infrastructure well and where each domain’s activities fit. Yousef mentions that there is enough literature about this topic, and I can refer to the SAAB conference paper: Genesis -an Architectural Pattern for Federated PLM.

For a less academic impression, read my blog post, The week after PLM Roadmap / PDT Europe 2022, where I share the highlights of Erik Herzog’s presentation: Heterogeneous and Federated PLM – is it feasible?

For a less academic impression, read my blog post, The week after PLM Roadmap / PDT Europe 2022, where I share the highlights of Erik Herzog’s presentation: Heterogeneous and Federated PLM – is it feasible?

There is much to learn and discover which standards will be relevant, as both Yousef and Erik mention the importance of standards.

The podcast with Yousef (soon to be found HERE) was not so much about organizational change management and people.

However, Yousef mentioned the most crucial success factor for the transformation project he supported at Daimler. It was C-level support, trust and understanding of the approach, knowing it will be many years, an unavoidable journey if you want to remain competitive.

However, Yousef mentioned the most crucial success factor for the transformation project he supported at Daimler. It was C-level support, trust and understanding of the approach, knowing it will be many years, an unavoidable journey if you want to remain competitive.

And with the journey aspect comes the importance of the Minimal Viable Product. You are starting a journey with an end goal in mind (top-of-the-mountain), and step by step (from base camp to base camp), people will be better covered in their day-to-day activities thanks to digitization.

And with the journey aspect comes the importance of the Minimal Viable Product. You are starting a journey with an end goal in mind (top-of-the-mountain), and step by step (from base camp to base camp), people will be better covered in their day-to-day activities thanks to digitization.

A POC would not help you make the journey; perhaps a small POC would understand what it takes to cross a barrier.

Conclusion

The concept of POCs is outdated in a fast-changing environment where technology is not necessary the blocking issue. Developing practices, new architectures and using the best-fit standards is the future. Embrace the Minimal Viable Product approach. Are you?

1 comment

Comments feed for this article

July 11, 2023 at 8:32 am

Bart Willemsen

Another Interesting article, I also see this kind of development in our company where terminology shifts and approach methods change. But what remains in the end: you just have to work and get things done.

Thanks Bart, you have to keep on working (but probably differently) and get things done -first maybe primitive with the MVP but getting better step by step.

Best regards, Jos

LikeLike