You are currently browsing the tag archive for the ‘Digital Product Passport’ tag.

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

Now, I want to conclude on what I would call, in my terminology, the connected digital thread. This topic was already addressed when I reported on the federated PLM story from NIO (Yousef Hooshmand) and SAAB Aeronautics (Erik Herzog).

The Need for a Governance Digital Thread

This time, my presentation was a memory refresher related to digital transformation in the PLM domain – moving from coordinated ways of working towards connected ways of working.

A typology that is also valid for the digital thread definition.

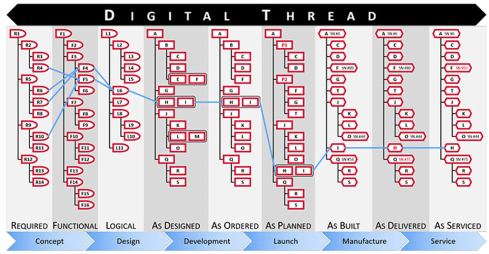

- A Coordinated Digital Thread is a digital thread that connects various artifacts in an enterprise. These relations are created and managed to support traceability and an impact analysis. The coordinated digital thread requires human interpretation to process the information. The image below from Aras is a perfect example of a coordinated digital thread.

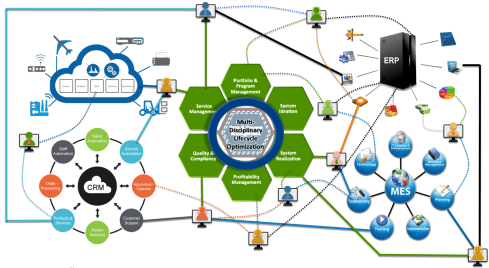

- The Connected Digital Thread is the digital thread where the artifacts are datasets stored in a federated infrastructure of databases. A connected digital thread provides real-time access to data through applications or dashboards for users. The real-time access makes the connected digital thread a solution for real-time, multidisciplinary collaboration activities.

The image above illustrates the connected digital thread as an infrastructure on top of five potential business platforms, i.e., the IoT platform, the CRM platform, the ERP platform, the MES platform and ultimately, the Product Innovation Platform.

Note: These platforms are usually a collection of systems that logically work together efficiently.

The importance of the Connected Digital Thread

When looking at the benefits of the Connected Digital Thread, the most essential feature is that it allows people in an organization to have all relevant data and its context available for making changes, analysis and design choices.

Due to the rich context, people can work proactively and reduce the number of iterations and fixes later.

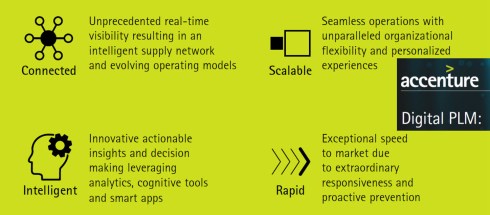

The above image from Accenture (2014) describing the business benefits can be divided into two categories:

- The top, Connected and Scalable describing capabilities

- The bottom, Intelligent and Rapid, describes the business impact

The connected digital thread for governance

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

The PLM system will be one of the sources; other sources can be fragmented in an organization. Bringing them together manually in one report is a significant human effort, time-consuming and not supporting the business.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

According to a recent KPMG report, only a quarter of companies are ready for ESG Reporting Requirements.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

The Connected Digital Thread and the Digital Product Passport

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

The DPP is based on the GS1 infrastructure, originating from the retail industry. Each product will have a unique ID (UID based on ISO/IEC 15459:2015), and this UID will provide digital access to product information, containing information about the product’s used materials, its environmental impact, and recycle/reuse–ability.

It will serve both for regulatory compliance and as an information source for consumers to make informed decisions about the products they buy. The DPP aims to stimulate and enforce a more circular economy.

![]() Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

The Connected Digital Thread and Catena-X

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

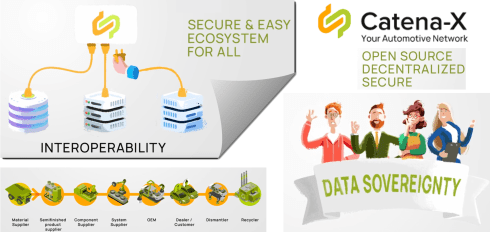

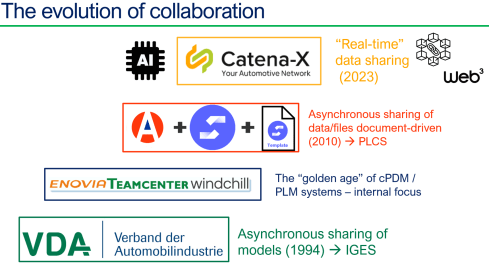

A new exciting trend is the potential rise of not-for-profit infrastructure for a particular industry. Where the GS1-based infrastructure is designed to provide visibility on sustainable targets and decisions, Catena-X is focusing on the automotive industry.

Catena-X is the establishment of a data-driven value chain for the German automotive industry and is now in the process of expanding to become a global network.

It is a significant building block in what I would call the connected or even adaptive enterprise, using a data-driven infrastructure to let information flow through the whole value chain.

It is one of the best examples of a Connected Digital Thread covering an end-to-end value chain.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

So Sustainability and Digitization go hand in hand.

Why a Digital Thread makes a lot of sense

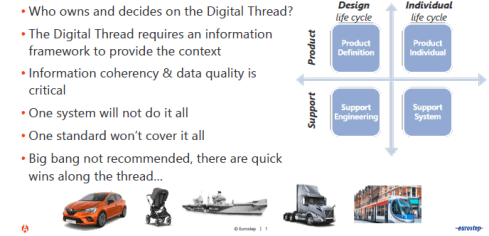

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

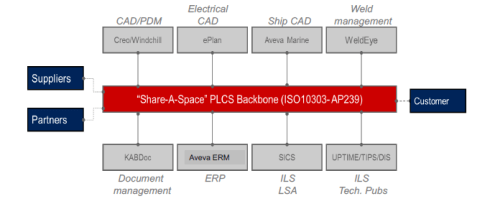

Eurostep, recently acquired by BAE Systems, is known for its collaboration hub or information backbone, ShareAspace. The interesting trend here is switching from a traditional PLM infrastructure to an asset-centric one.

This approach makes a lot of sense for complex assets with a long lifecycle, as the development phase is usually done with a consortium of companies. Still, the owner/operator wants to maintain a digital twin of the asset – for maintenance and upgrades.

A standards-based backbone makes much sense in such an environment due to the various data formats. This setup also means we are looking at a Coordinated Digital Thread at this stage, not a Connected Digital Thread.

Mattias concluded with the question of who owns and who decides on the coordinated digital thread – a discussion also valid in the construction industry when discussing Building Information Management (BIM) and a Common Data Environment(CDE).

I believe software vendors can provide the Coordinated Digital Thread option when they can demonstrate and provide a positive business case for their solution. Still, it will be seen as an overhead to connect the dots.

For a Connected Digital Thread, I think it might be provided as an infrastructure like the World Wide Web (W3C) organization. Here, the business case is much easier to demonstrate as it is really a digital highway.

Such an infrastructure could be provided by not-for-profit organizations like GS1 (Digital Product Passport/Retail), Catena-X (Automotive) and others (Gaia-X).

![]() For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

AI

And then there was AI. During the conference, people spoke more about AI than Sustainability topics, illustrating that our audience is more interested in understanding the next hype instead of feeling the short-term need to address climate change and planet sustainability.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

And we closed the conference with a roundtable discussion: AI, PLM and the Digital Thread: Why should we care about AI?

From the roundtable, I concluded that we are all convinced AI will have a significant impact in the upcoming years and are all in the early phases of the AI hype.

Will AI introduction go faster than digital transformation?

Conclusion

The conference gave me confidence that digital transformation in the PLM domain has reached the next level. Many sessions were related to collaboration concepts outside the traditional engineering domain – coordinated and connected digital threads.

The connected digital thread is the future, and as we saw it, it heralds the downfall of monolithic PLM. The change is needed for business efficiency AND compliance with more and more environmental regulations.

I am looking forward to seeing the pace of progress here next year.

Yes, it is not a typo. Clayton Christensen famous book written in 1995 discussed the Innovator’s Dilemma when new technologies cause great firms to fail. This was the challenge two decades ago. Existing prominent companies could become obsolete quickly as they were bypassed by new technologies.

Yes, it is not a typo. Clayton Christensen famous book written in 1995 discussed the Innovator’s Dilemma when new technologies cause great firms to fail. This was the challenge two decades ago. Existing prominent companies could become obsolete quickly as they were bypassed by new technologies.

The examples are well known. To mention a few: DEC (Digital Equipment Corporation), Kodak, and Nokia.

Why the innovation dilemma?

This decade the challenge has become different. All companies are forced to become more sustainable in the next ten years. Either pushed by global regulations or because of their customer demands. The challenge is this time different. Besides the priority of reducing greenhouse gas emissions, there is also the need to transform our society from a linear, continuous growth economy into a circular doughnut economy.

The circular economy makes the creation, the usage and the reuse of our products more complex as the challenge is to reduce the need for raw materials and avoid landfills.

The doughnut economy makes the values of an economy more complex as it is not only about money and growth, human and environmental factors should also be considered.

To manage this complexity, I wrote SYSTEMS THINKING – a must-have skill in the 21st century, focusing on the logical part of the brain. In my follow-up post, Systems Thinking: a second thought, I looked at the human challenge. Our brain is not rational and wants to think fast to solve direct threats. Therefore, we have to overcome our old brains to make progress.

To manage this complexity, I wrote SYSTEMS THINKING – a must-have skill in the 21st century, focusing on the logical part of the brain. In my follow-up post, Systems Thinking: a second thought, I looked at the human challenge. Our brain is not rational and wants to think fast to solve direct threats. Therefore, we have to overcome our old brains to make progress.

An interesting and thought-provoking was shared by Nina Dar in this discussion, sharing the video below. The 17 Sustainability Development Goals (SDGs) describe what needs to be done. However, we also need the Inner Development Goals (IDGs) and the human side to connect. Watch the movie:

Our society needs to change and innovate; however, we cannot. The Innovation Dilemma.The future is data-driven and digital.

What is clear to me is that companies developing products and services have only one way to move forward: becoming data-driven and digital.

Why data-driven and digital?

Let’s look at something companies might already practice, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). This European directive, introduced in 2007, had the aim to protect human health and protect the environment by communicating information on chemicals up and down the supply chain. This would ensure that manufacturers, importers, and their customers are aware of information relating to the health and safety of the products supplied.

Let’s look at something companies might already practice, REACH (Registration, Evaluation, Authorization and Restriction of Chemicals). This European directive, introduced in 2007, had the aim to protect human health and protect the environment by communicating information on chemicals up and down the supply chain. This would ensure that manufacturers, importers, and their customers are aware of information relating to the health and safety of the products supplied.

The regulation is currently still suffering in execution as most of the reporting and evaluation of chemicals is done manually. Suppliers report their chemicals in documents, and companies report the total of chemicals in their summary reports. Then, finally, authorities have to go through these reports.

The regulation is currently still suffering in execution as most of the reporting and evaluation of chemicals is done manually. Suppliers report their chemicals in documents, and companies report the total of chemicals in their summary reports. Then, finally, authorities have to go through these reports.

Where the scale of REACH is limited, the manual effort to have end-to-end reporting is relatively high. In addition, skilled workers are needed to do the job because reporting is done in a document-based manner.

Life Cycle Assessments (LCA)

Where you might think REACH is relatively simple, the real new challenges for companies are the need to perform Life Cycle Assessments for their products. In a Life Cycle Assessment. The Wiki definition of LCA says:

Life cycle assessment or LCA (also known as life cycle analysis) is a methodology for assessing environmental impacts associated with all the stages of the life cycle of a commercial product, process, or service. For instance, in the case of a manufactured product, environmental impacts are assessed from raw material extraction and processing (cradle), through the product’s manufacture, distribution and use, to the recycling or final disposal of the materials composing it (grave)

This will be a shift in the way companies need to define products. Much more thinking and analysis are required in the early design phases. Before committing to a physical solution, engineers and manufacturing engineers need to simulate and calculate the impact of their design decisions in the virtual world.

This is where the digital twin of the design and the digital twin of the manufacturing process becomes relevant. And remember: Digital Twins do not run on documents – you need connected data and various types of models to calculate and estimate the environmental impact.

This is where the digital twin of the design and the digital twin of the manufacturing process becomes relevant. And remember: Digital Twins do not run on documents – you need connected data and various types of models to calculate and estimate the environmental impact.

LCA done in a document-based manner will make your company too slow and expensive.

I described this needed transformation in my series from last year: The road to model-based and connected PLM – nine posts exploring the technology and concept of a model-based, data-driven PLM infrastructure.

Digital Product Passport (DPP)

The European Commission has published an action plan for the circular economy, one of the most important building blocks of the European Green Deal. One of the defined measures is the gradual introduction of a Digital Product Passport (DPP). As the quality of an LCA depends on the quality and trustworthy information about products and materials, the DPP is targeting to ensure circular economy metrics become reliable.

The European Commission has published an action plan for the circular economy, one of the most important building blocks of the European Green Deal. One of the defined measures is the gradual introduction of a Digital Product Passport (DPP). As the quality of an LCA depends on the quality and trustworthy information about products and materials, the DPP is targeting to ensure circular economy metrics become reliable.

This will be a long journey. If you want to catch a glimpse of the complexity, read this Medium article: The digital product passport and its technical implementation related to the DPP for batteries.

The innovation dilemma

Suppose you agree with my conclusion that companies need to change their current product or service development into a data-driven and model-based manner. In that case, the question will come up: where to start?

Becoming data-driven and model-based, of course, is not the business driver. However, this change is needed to be able to perform Life Cycle Assessments and comply with current and future regulations by remaining competitive.

Becoming data-driven and model-based, of course, is not the business driver. However, this change is needed to be able to perform Life Cycle Assessments and comply with current and future regulations by remaining competitive.

A document-driven approach is a dead-end.

Now let’s look at the real dilemmas by comparing a startup (clean sheet / no legacy) and an existing enterprise (experience with the past/legacy). Is there a winning approach?

The Startup

Having lived in Israel – the nation where almost everyone is a startup – and working with startups afterward in the past 10 years, I always get inspired by these people’s energy in startup companies. They have a unique value proposition most of the time, and they want to be visible on the market as soon as possible.

Having lived in Israel – the nation where almost everyone is a startup – and working with startups afterward in the past 10 years, I always get inspired by these people’s energy in startup companies. They have a unique value proposition most of the time, and they want to be visible on the market as soon as possible.

This approach is the opposite of systems thinking. It is often a very linear process to deliver this value proposition without exploring the side effects of such an approach.

For example, the new “green” transportation hype. Many cities now have been flooded with “green” scooters and electric bikes to promote transportation as a service. The idea behind this concept is that citizens do not require to own polluting motorbikes or cars anymore, and transportation means will be shared. Therefore, the city will be cleaner and greener.

For example, the new “green” transportation hype. Many cities now have been flooded with “green” scooters and electric bikes to promote transportation as a service. The idea behind this concept is that citizens do not require to own polluting motorbikes or cars anymore, and transportation means will be shared. Therefore, the city will be cleaner and greener.

However, these “green” vehicles are often designed in the traditional linear way. Is there a repair plan or a plan to recycle the batteries? Reuse of materials used.? Most of the time, not. Please, if you have examples contradicting my observations, let me know. I like to hear good news.

When startup companies start to scale, they need experts to help them grow the company. Often these experts are seasoned people, perhaps close to retirement. They will share their experience and what they know best from the past: traditional linear thinking.

As a result, even though startup companies can start with a clean sheet, their focus on delivering the product or service blocks further thinking. Instead, the seasoned experts will drive the company towards ways of working they know from the past.

Out of curiosity: Do you know or work in a startup that has started with a data-driven and model-based vision from scratch? Please add the name of this company in the comments, and let’s learn how they did it.

Out of curiosity: Do you know or work in a startup that has started with a data-driven and model-based vision from scratch? Please add the name of this company in the comments, and let’s learn how they did it.

The Existing company

Working in an established company is like being on board a big tanker. Changing its direction takes a clear eye on the target and navigation skills to come there. Unfortunately, most of the time, these changes take years as it is impossible to switch the PLM infrastructure and the people skills within a short time.

From the bimodal approach in 2015 to the hybrid approach for companies, inspired by this 2017 McKinsey article: Toward an integrated technology operating model, I discovered that this is probably the best approach to ensure a change will happen. In this approach – see image – the organization keeps running on its document-driven PLM infrastructure. This type of infrastructure becomes the system of record. Nothing different from what PLM currently is in most companies.

In parallel, you have to start with small groups of people who independently focus on a new product, a new service. Using the model-based approach, they work completely independently from the big enterprise in a data-driven approach. Their environment can be considered the future system of engagement.

The data-driven approach allows all disciplines to work in a connected, real-time manner. Mastering the new ways of working is usually the task of younger employees that are digital natives. These teams can be completed by experienced workers who behave as coaches. However, they will not work in the new environment; these coaches bring business knowledge to the team.

People cannot work in two modes, but organizations can. As you can see from the McKinsey chart, the digital teams will get bigger and more important for the core business over time. In parallel, when their data usage grows, more and more data integration will occur between the two operation modes. Therefore, the old PLM infrastructure can remain a System of Record and serve as a support backbone for the new systems of engagement.

The Innovation Dilemma conclusion

The upcoming ten years will push organizations to innovate their ways of working to become sustainable and competitive. As discussed before, they must learn to work in a data-driven, connected manner. Both startups and existing enterprises have challenges – they need to overcome the “thinking fast and acting slow” mindset. Do you see the change in your company?

Note: Before publishing this post, I read this interesting and complementary post from Jan Bosch Boost your digitalization: instrumentation.

Note: Before publishing this post, I read this interesting and complementary post from Jan Bosch Boost your digitalization: instrumentation.

It is in the air – grab it.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…