This is almost my last planned post related to the concepts of model-based. After having discussed Model-Based Systems Engineering (needed to develop complex products/systems including hardware and software) and Model-Based Definition (creating an efficient connection between Engineering and Manufacturing), my last post will be related to the most over-hyped topic: The Digital Twin

There are several reasons why the Digital Twin is overhyped. One of the reasons is that the Digital Twin is not necessarily considered as a PLM-related topic. Other vendors like SAP (the network of digital twins), Oracle (Digital Twins for IoT applications) and GE with their Predix platform also contributed to the hype related to the digital twin. The other reason is that the concept of Digital Twin is an excellent idea for marketers to shine above the clouds. Monica Schnitger’s recent comment says it all in her post 5 quick takeaways from Siemens Automation summit. Monica’s takeaway related to Digital Twin:

There are several reasons why the Digital Twin is overhyped. One of the reasons is that the Digital Twin is not necessarily considered as a PLM-related topic. Other vendors like SAP (the network of digital twins), Oracle (Digital Twins for IoT applications) and GE with their Predix platform also contributed to the hype related to the digital twin. The other reason is that the concept of Digital Twin is an excellent idea for marketers to shine above the clouds. Monica Schnitger’s recent comment says it all in her post 5 quick takeaways from Siemens Automation summit. Monica’s takeaway related to Digital Twin:

The whole digital twin concept is just starting to gain traction with automation users. In many cases, they don’t have a digital representation of the equipment on their lines; they may have some data from the equipment OEM or their automation contractors but it’s inconsistent and probably incomplete. The consensus seemed to be that this is a great idea but out of many attendees’ immediate reach. [But it is important to start down this path: model something critical, gather all the data you can, prove benefit then move on to a bigger project.]

Monica is aiming to the same point I have been mentioning several times. There is no digital representation and the existing data is inconsistent. Don’t wait: The importance of accurate data – act now !

What is a digital twin?

I think there are various definitions of the digital twin, and I do not want to go into a definition debate like we had before with the acronyms MBD/MBE (Model Based Definition/Enterprise – the confusion) or even the acronym PLM (classical PLM or digital PLM ?). Let’s agree on the following high-level statements:

- A digital twin is a virtual representation of a physical product

- The virtual part of the digital twin is defined by what you want to analyze, simulate, and predict related to the physical product

- One physical product can have multiple digital twins, but in the ideal world, there is potentially a unique digital twin for every physical product in the world

- When a product interacts with the environment, based on inputs and outputs, we normally call it a system. When I use Product, it will most of the time be a System, in particular in the context of a digital twin

Given the above statements, I will give some examples of digital twin concepts:

As a cyclist, I am active on platforms like Garmin and Strava, using a tracking device, heart monitor and a power meter. During every ride, my device plus the sensors measure my performance, and all the data is uploaded to the platform, providing me with a report where I drove, how fast, my heartbeat, cadence and power during the ride. On Strava, I can see the Flybys (other digital twins that crossed my path and their performances), and I can see per segment how I performed compared to others, and I can filter by age, by level, etc.)

As a cyclist, I am active on platforms like Garmin and Strava, using a tracking device, heart monitor and a power meter. During every ride, my device plus the sensors measure my performance, and all the data is uploaded to the platform, providing me with a report where I drove, how fast, my heartbeat, cadence and power during the ride. On Strava, I can see the Flybys (other digital twins that crossed my path and their performances), and I can see per segment how I performed compared to others, and I can filter by age, by level, etc.)

This is the easiest part of a digital twin. Every individual can monitor and analyze their personal behavior and discover trends. Additionally, the platform owner has all the intelligence about all cyclists worldwide, how they perform and what would be the best performance per location. And based on their Premium offering (where you pay), they can advise you on how to improve. The Strava business model brings value to the individual while learning from the behavior of thousands. Note that in this scenario, there is no 3D involved.

Another known digital twin story is related to plants in operation. In the past 10 years, I have advocated for Plant Lifecycle Management (PLM for Owner/Operators), describing the value of a virtual plant model using PLM capabilities combined with Maintenance, Repair and Overhaul (MRO) to reduce downtime. In a nuclear environment, the usage of 3D verification, simulation and even control software in a virtual environment can bring great benefit due to the fact that the physical twin is not always accessible, and downtime can be up to several million per week.

Another known digital twin story is related to plants in operation. In the past 10 years, I have advocated for Plant Lifecycle Management (PLM for Owner/Operators), describing the value of a virtual plant model using PLM capabilities combined with Maintenance, Repair and Overhaul (MRO) to reduce downtime. In a nuclear environment, the usage of 3D verification, simulation and even control software in a virtual environment can bring great benefit due to the fact that the physical twin is not always accessible, and downtime can be up to several million per week.

The above examples provide two types of digital twins. I will discuss some characteristics in the following paragraphs.

Digital Twin – performance focus

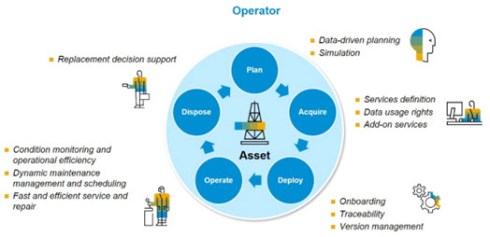

Companies like GE and SAP focus a lot on the digital twin in relation to asset performance. Measuring the performance of assets, comparing their performance with other similar assets and based on performance characteristics the collector of the data can sell predictive maintenance analysis, performance optimization guidance and potentially other value offerings to their customers.

Companies like GE and SAP focus a lot on the digital twin in relation to asset performance. Measuring the performance of assets, comparing their performance with other similar assets and based on performance characteristics the collector of the data can sell predictive maintenance analysis, performance optimization guidance and potentially other value offerings to their customers.

Small improvements in the range of a few percent can significantly impact the overall net results. The digital twin is crucial in this business model to build-up knowledge, analyze and collect it and sell the knowledge again. This type of scenario is the easiest one. You need products with sensors, you need an infrastructure to collect the data and extract and process information in a manner that it can be linked to a behavior model with parameters that influence the model.

This is the model-based part of the digital twin. For a single product, different models can be related to the parameters driving your business. E.g., performance parameters for output, parameters for optimal up-time (preventive maintenance – usage optimization) or parameters related to environmental impact, etc..) Building and selling the results of such a model is an add-on business, creating more value for your customer, combined with creating more loyalty. Using the digital twin in the context of performance focus does not require a company to change the way they are working totally. Yes, you need new skills, data collection and analysis, and more sensor technology, but many product development activities can remain the same (for the moment).

As a conclusion for this type of digital twin, I would state that yes, there is some PLM involved, but the main focus is on business execution.

Due to the fact that I already reach more than 1000 words, I will focus in my next post on the most relevant digital twin for PLM. Here, all disciplines come together. The 3D Mechanical model, the behavior models, the embedded and control software, (manufacturing simulation and more. This is to create an almost perfect virtual copy of a real product or system in the physical world. There, we will see that this is not as easy as concepts depend on accurate data and reliable models, which is not the case currently in most companies in their engineering environment.

Due to the fact that I already reach more than 1000 words, I will focus in my next post on the most relevant digital twin for PLM. Here, all disciplines come together. The 3D Mechanical model, the behavior models, the embedded and control software, (manufacturing simulation and more. This is to create an almost perfect virtual copy of a real product or system in the physical world. There, we will see that this is not as easy as concepts depend on accurate data and reliable models, which is not the case currently in most companies in their engineering environment.

Conclusion

Digital twins are marketing hype. However, when you focus on only performance monitoring and tuning, they become a reality as they do not require a company to align digitally across the whole lifecycle. However, this is just the beginning of a real digital twin.

Where are you in your company with the digital twin journey?

3 comments

Comments feed for this article

July 3, 2018 at 6:55 pm

Chiraag Bhimaraju

Nice blog Jos. I am masters student (TU KL) and in my thesis work I used the concept of Digital twin with Aras plm tool for providing better service process optimization (predictive maintenance condition monitoring was also involved but not under my task).FYI: My thesis was a part of a project called InnoServPro.

Thanks Chiraag, I am curious about your conclusions as to my opinion a PLM-tools can perhaps connect data but I am missing the management or usage of models for example to provide predictive maintenance based on condition monitoring which is to me more an IoT / big data / analytics concept. Can you share your findings ? Best regards, Jos

LikeLike

July 10, 2018 at 8:25 am

Simon Kooij

Hi Jos,

A very good and concise overview about Model-based /The Digital twin.

Recognized a lot of things we have discusses before to get a `picture,` approach and use about this `hype.`

Besides the hype effect, it is clear that OEM-er has to act to create additional Functionality & Business.

Indeed not always is 3D and PLM direct necessary to start.

Depend on the company status an approach and important actions related to the topic are:

1) Create (new or existing) products with a right product structure and store and maintain in it in a PLM environment.

2) Model-Based Definition (creating an efficient connection between Engineering and Manufacturing, reducing the paper load and a step to the digital enterprise).

3) Model-Based Systems Engineering MBSE (needed to develop complex products/systems including hardware, software,).

4) Digital twin: adapt in development of the Smart Product with extra sensors to support the monitoring need and the new business model around this.

This could be a sequence, but some topics (functionality) depending on the business need and platform type can be activated parallel. (when there is enough budget, manpower, learning culture. But a step by step (a growing) approach is a nice way to start)

The remarks and challenges of conserving the digital twin are stated well:

1) Defined first what you as OEM-er and/or your customer want to analyze, simulate, predict related to the physical product.

What and for what purpose collect and provide information is key. Necessary to justify the activity and (future) business models

2) And the awareness that one physical product can have multiple digital twins ……

And this gives the possibility to start and create a type of digital with without the 3D-PLM need.

Conserving the statement:

Measuring the performance of assets, …. the collector of the data can sell predictive maintenance analysis, performance optimization guidance and potentially other value offerings to their customers.

The statement is true but be aware that the customer doesn’t get the feeling in terms of blackmail about his own data.

In some cases the choice is not selling the data, but make your product (by an extra service) interesting for your customer for daily performance (optimization). And this sells your product and increase the customer experience.

And what you mend, this in combination with (predictive) service (maintenance) contracts generate extra business.

In both cases, the product must be suitable for the right monitoring, analysis, and feedback.

And that is the challenging part, to know/define what (information) is needed, and to create the right infrastructure to collect, extract and influence the user and/or the model.

It was a pleasure to read the blog.

Best regards,

Simon.

Thanks Simon for your feedback coming from reality in the field. Best regards, Jos

LikeLike

July 27, 2018 at 4:37 pm

Yannick Prat (@3DS_YPT1)

Hello Jos,

great article. Thank you. I am promoting the value of Digitalization on the shop floor. More and more corporations can see the value of the Digital Continuity and your article helps to increase the awareness.

Dassault Systèmes DELMIA is helping to shorten the time to roll out new production lines by creating the 3D models and simulation before the first sample of the product will be made, before the first tool will be ordered.

This is also a strong contribution in terms of sustainability.

And no, your articles are not too long 😉

Best regards,

Yannick

Thanks Yannick and I agree the message has to come from many directions although the best story is still your competitor enjoy the benefits of digital continuity. The downfall however is that your company might be too late – so keep experimenting and learning towards an efficient digital thread is the message.

Best regards, Jos

LikeLike