One week ago, Yoann Maingon wrote an innocent post with the question: Has FFF killed? The question was raised related to a 2014 problem at GM, where a changed part was causing fatal accidents.

The discussion started by Yoann and here my short extract. Assuming this problem was a configuration management issue and Yoann somehow indicated that the problem might be related to the fact that ERP-systems do not carry a revision on the part number – leading to an unnoticed change. Therefore, he assumes there is a disconnect between the PLM-side (where we have parts with multiple lifecycle states and revisions) and ERP (where we have an industrial lifecycle – prototype/production).

The discussion started by Yoann and here my short extract. Assuming this problem was a configuration management issue and Yoann somehow indicated that the problem might be related to the fact that ERP-systems do not carry a revision on the part number – leading to an unnoticed change. Therefore, he assumes there is a disconnect between the PLM-side (where we have parts with multiple lifecycle states and revisions) and ERP (where we have an industrial lifecycle – prototype/production).

He posted his thoughts, and then LinkedIn exploded (currently 116 comments), which means it is a topic that is of significant concern in our community. Next, if you read the comments, there are different viewpoints:

- What does FFF really imply?

- What about revisions of parts?

- What are the best practices?

Let’s investigate these viewpoints with some comments

What does FFF really imply?

When we talk about FFF in engineering, we mean Form, Fit and Function – the three primary characteristics to describe a part (source Wikipedia)

- Form refers to such characteristics as external dimensions, weight, size, and visual appearance of a part or assembly. This is the element of FFF that is most affected by an engineer’s aesthetic choices, including enclosure, chassis, and control panel, that become the outward “face” of the product.

- Fit refers to the ability of the part or feature to connect to, mate with, or join to another feature or part within an assembly. The “fit” allows the part to meet the required assembly tolerances to be useful.

- Function is a criterion that is met when the part performs its stated purpose effectively and reliably. In an electronics product, for example, a function can depend on the solid-state components used, the software or firmware, and quite often on the features of the electronics enclosure selected.

One of the comments in Yoann’s post referred to Safe/Unsafe as a potential functional characteristic. I think this addition is not needed. Safety should be a requirement for the part, not a characteristic.

One of the comments in Yoann’s post referred to Safe/Unsafe as a potential functional characteristic. I think this addition is not needed. Safety should be a requirement for the part, not a characteristic.

FFF was and still is an approach for engineers to decide if a new, improved version of the part would get a revision or needs a new part number.

I think before we dive deeper into the other viewpoints, it is crucial to define the part number a little more.

In a correct PLM data model, there are two types of part numbers. First, the internal part number that your company uses inside its engineering Bill of Materials to identify a part. This part number can be a meaningless part only to provide uniqueness inside the company.

In 2015 I wrote several posts related to best practices and data modeling for PLM. The most relevant posts to this discussion are here:

The part number can specify a part that needs to be manufactured according to specification, or it can be a part that needs to be purchased from an available supplier/manufacturer. The manufacturer part number is, most of the time, a meaningful number (6 – 7 characters) as these parts need to be ordered by your company. The manufacturer part number is the SKU for the manufacturer. As you can imagine in the manufacturer’s catalog, there isn’t a revision mentioned. In graphics, see the image below:

Your company might sell Product MP-323121 (note: the ID is meaningful to help the customer to order the product).

Internally there is a related EBOM that specifies the product. The EBOM top part is O122 (note: here, we can use a meaningless identifier as all is digitally connected).

For the manufacturing of O122, we need to resolve the EBOM according to its specifications. Therefore, for Part O124, the company needs to decide to purchase from their approved manufacturers either part ABC-21231 or XYZ-88818 (note: again, a meaningful ID as these companies are not digitally connected).

Now coming back to the FFF-discussion. For the orange parts, with a meaningful ID, no revision exists. However, if Assembly O122 is 100% FFF compatible, the Product ID MP-323121 will not change. It allows your company to optimize the EBOM and/or MBOM, meanwhile keeping 100% compatibility to the outside world. (note: the same principle applies to the two manufacturers for Part O124.)

In case Top Assembly O122 has new or changed parts – what should happen there?

At that moment, the definition has changed. The definitions, most of the time described in documents/drawings/models, are related information to the BOM. Therefore the Top Assembly O122 should get a new identifier. There is no need to name it a revision, it is a new data set in the PLM-system, again with a meaningless identifier as we are connected digitally,

At that moment, the definition has changed. The definitions, most of the time described in documents/drawings/models, are related information to the BOM. Therefore the Top Assembly O122 should get a new identifier. There is no need to name it a revision, it is a new data set in the PLM-system, again with a meaningless identifier as we are connected digitally,

What about revisions of parts?

Of course, the management of changes existed long before PLM-systems were introduced.

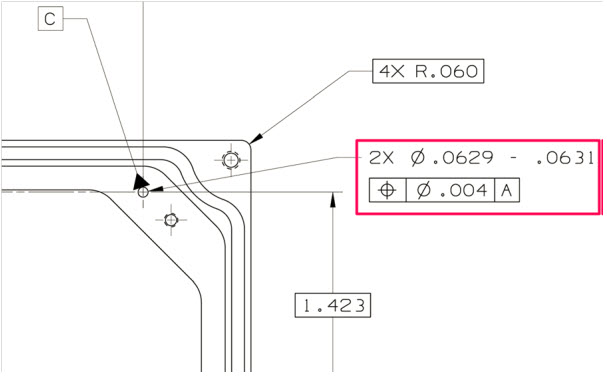

The specifications of a part were defined in drawings. The drawing contained all the information, not only the geometry definitions, but also specifications on how to manufacture the part.

The specifications of a part were defined in drawings. The drawing contained all the information, not only the geometry definitions, but also specifications on how to manufacture the part.

For complex products, a considerable set of consistently related drawings would be released to manufacturing. A release process with physical signatures on it.

At the same time, there was no discussion: the drawing represents the part. And as there was no digital connection, part numbers/drawing numbers were meaningful, often with the format of the drawing as part of the identifier.

In case changes were needed, for example, fixing a dimension or tolerance as discovered during manufacturing, the drawing had to be revised to remain consistent. First, in the original drawing, the issue or change was marked in red (redlining). Then engineering had to create a new version of the drawing.

In case changes were needed, for example, fixing a dimension or tolerance as discovered during manufacturing, the drawing had to be revised to remain consistent. First, in the original drawing, the issue or change was marked in red (redlining). Then engineering had to create a new version of the drawing.

Depending on the impact of change (here comes also the FFF-principle), people decided if a new part number was needed (FFF-change) or that the change only required an update of the drawing(s), meaning a revision. If the difference was small (for example, adding a missing annotation), it could be called a minor change, all to be reflected in the drawing number, which equals the part number in this approach. So, when we talk about revisions of parts, we are talking about a document change.

A lousy practice from that approach is also that often manufacturing just redlines a drawing and keeps the redlined drawing as their source. It is too time-consuming or difficult to update the source drawing(s) through a change process. Engineering is not aware of this change, and when a later change comes through from engineering, these “fixes” might be missed as there is no traceability.

Generic example of a PLM data model and its relationsWhen PLM-systems were introduced, of course, companies did not want to disrupt their existing ways of working. Therefore, they were asking the PLM-editors to enable revisions on parts and so the PLM-editors did (or do).

However, if you want to use the PLM-system in the best manner, you need to “decouple” the concept: part number equals drawing number, combined with the possibility to start using meaningless identifiers, as relations between parts and drawings are managed in the PLM-system through relational links.

Relevant post related to the PLM data model are:

- EBOM and (CAD) Documents

- Intelligent Part or Product numbers

- The impact of Non-Intelligent Part numbers

What are the best practices?

As some people mentioned in their comments to Yoann’s post, why do we have to answer this question as all is already well understood and described in best practices? I agree with that statement: Best Practices exist – so how to obtain them?

First, there is the whole framework of Configuration Management, which existed long before PLM-systems were introduced. If you follow their methodology, you can be (almost) guaranteed your information is consistent and correct. Configuration Management is crucial in areas where the impact of an error is enormous, like the GM-example Yoann referred to. Also, companies in the Aerospace and Defense industry are the ones that have strict configuration management in place.

First, there is the whole framework of Configuration Management, which existed long before PLM-systems were introduced. If you follow their methodology, you can be (almost) guaranteed your information is consistent and correct. Configuration Management is crucial in areas where the impact of an error is enormous, like the GM-example Yoann referred to. Also, companies in the Aerospace and Defense industry are the ones that have strict configuration management in place.

Configuration management does not come for free. It requires an investment in skills, potentially a change in ways of working, and requires an overhead. Manufacturing companies that are creating less “risky” products often focus more on optimizing (= reducing) the cost of their internal processes instead of investing in proper methodologies to manage consistency.

If you want to learn more about CM, investigate the Institute of Process Excellence (IPX), the founders of the CM2 framework for Enterprise Configuration Management, and much more. Note: Their knowledge does not come for free, which I can understand. However, it also creates a barrier for the company’s further investment in CM as this kind of strategic investments are hard to sell at the management level by individuals in a company.

In the context of CM, I advise you to follow Martijn Dullaart, who is quite active in our social community. His latest blog post related to this thread is: It’s about Interchangeability and Traceability

In the context of CM, I advise you to follow Martijn Dullaart, who is quite active in our social community. His latest blog post related to this thread is: It’s about Interchangeability and Traceability

With the introduction of PLM-system, these companies and the PLM-editors created the opportunity to implement configuration management in their system.

The data inside the system would be the “single version of the truth.” Unfortunately, this was most of the time, just a sales strategy, falsely giving the impression that information is under control now. Last year I wrote several posts related to the relation between PLM and CM, starting from PLM and Configuration Management – a happy marriage?

The data inside the system would be the “single version of the truth.” Unfortunately, this was most of the time, just a sales strategy, falsely giving the impression that information is under control now. Last year I wrote several posts related to the relation between PLM and CM, starting from PLM and Configuration Management – a happy marriage?

If you are interested in another resource for information related to these topics, have a look at the website from Jörg Eisenträger who also collected his best practices for PLM and CM for sharing (thanks Paul van der Ree for the link)

Don’t expect best practices from your PLM-vendors as their role is to sell software. It is the continuous discussion between:

- A PLM-system that forces companies to work according to embedded methodology (hard to sell/implement but idealistically correct)

And

- A flexible PLM-system that allows you to build and configure anything (easy to sell/challenging to implement correctly, depending on “wise” decisions)

The Future

Even though most companies are working drawing-centric, with or without a linked PLM-backbone for BOM-management, the next upcoming challenge is to evolve to model-based practices. The current CM-practices still talk about documents, although documents are already electronic datasets in that context. The future, however, in a model-based enterprise evolves related to connected models, 3D Models, but also simulation and software models, with different lifecycles and pace of change. For the model-based enterprise, we need to develop digital best practices that guarantee the same level of quality, however, executed and/or supported by (AI) Artificial Intelligence. AI is needed as human beings cannot physically analyze and understand all the impact of a change in such an environment.

Even though most companies are working drawing-centric, with or without a linked PLM-backbone for BOM-management, the next upcoming challenge is to evolve to model-based practices. The current CM-practices still talk about documents, although documents are already electronic datasets in that context. The future, however, in a model-based enterprise evolves related to connected models, 3D Models, but also simulation and software models, with different lifecycles and pace of change. For the model-based enterprise, we need to develop digital best practices that guarantee the same level of quality, however, executed and/or supported by (AI) Artificial Intelligence. AI is needed as human beings cannot physically analyze and understand all the impact of a change in such an environment.

Conclusion

The FFF-discussion illustrates that building a consistent framework within PLM is not an easy goal to achieve. My blog buddy Oleg Shilovitsky would claim that we consultants create the complexity. PLM-editors will never solve this complexity, it is up to your company’s mission to invest in knowledge to understand why and how to reduce the complexity. With this post and the related links and discussions, I hope more clarity will help you to make “wise” decisions.

Leave a comment

Comments feed for this article