I have not been writing much new content recently as I feel that from the conceptual side, so much has already been said and written. A way to confuse people is to overload them with information. We see it in our daily lives and our PLM domain.

I have not been writing much new content recently as I feel that from the conceptual side, so much has already been said and written. A way to confuse people is to overload them with information. We see it in our daily lives and our PLM domain.

With so much information, people become apathetic, and you will hear only the loudest and most straightforward solutions.

One desire may be that we should go back to the past when everything was easier to understand—are you sure about that?

This attitude has often led to companies doing nothing, not taking any risks, and just providing plasters and stitches when things become painful. Strategic decision-making is the key to avoiding this trap.

I just read this article in the Guardian: The German problem? It is an analog country in a digital world.

The article also describes the lessons learned from the UK (quote):

Britain was the dominant economic power in the 19th century on the back of the technologies of the first Industrial Revolution and found it hard to break with the old ways even when it should have been obvious that its coal and textile industries were in long-term decline.

As a result, Britain lagged behind its competitors. One of these was Germany, which excelled in advanced manufacturing and precision engineering.

Many technology concepts originated from Germany in the past and even now we are talking about Industrie 4.0 and Catena-X as advanced concepts. But are they implemented? Did companies change their culture and ways of working required for a connected and digital enterprise?

Technology is not the issue.

The current PLM concepts, which discuss a federated PLM infrastructure based on connected data, have become increasingly stable.

The current PLM concepts, which discuss a federated PLM infrastructure based on connected data, have become increasingly stable.

Perhaps people are using different terminologies and focusing on specific aspects of a business; however, all these (technical) discussions talk about similar business concepts:

- Prof. Dr. Jorg W. Fischer, managing partner at Steinbeis – Reshape Information Management (STZ-RIM), writes a lot about a modern data-driven infrastructure, mainly in the context of PLM and ERP. His recent article: The Freeway from PLM to ERP.

- Oleg Shilovitsky, CEO of OpenBOM, has a never-ending flow of information about data and infrastructure concepts and an understandable focus on BOMs. One of his recent articles, PLM 2030: Challenges and Opportunities of Data Lifecycle Management

- Matthias Ahrens, enterprise architect at Forvia / Hella, often shares interesting concepts related to enterprise architecture relevant to PLM. His latest share: Think PLM beyond a chain of tools!

- Dr. Yousef Hooshmand, PLM lead at NIO, shared his academic white paper and experiences at Daimler and NIO through various presentations. His publication can be found here: From a Monolithic PLM Landscape to a Federated Domain and Data Mesh.

- Erik Herzog, technical fellow at SAAB Aeronautics, has been active for the past two years, sharing the concept of federated PLM applied in the Heliple project. His latest publication post: Heliple Federated PLM at the INCOSE International Symposium in Dublin

![]() Several more people are sharing their knowledge and experience in the domain of modern PLM concepts, and you will see that technology is not the issue. The hype of AI may become an issue.

Several more people are sharing their knowledge and experience in the domain of modern PLM concepts, and you will see that technology is not the issue. The hype of AI may become an issue.

From IT focus to Business focus

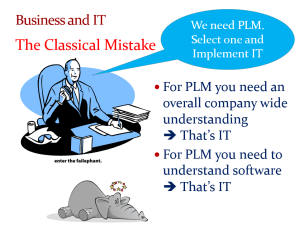

One issue I observed at several companies I worked with is that the PLM’s responsibility is inside the IT organization – click on the image to get the mindset.

One issue I observed at several companies I worked with is that the PLM’s responsibility is inside the IT organization – click on the image to get the mindset.

This situation is a historical one, as in the traditional PLM mode, the focus was on the on-premise installation and maintenance of a PLM system. Topics like stability, performance and security are typical IT topics.

IT departments have often been considered cost centers, and their primary purpose is to keep costs low.

Does the slogan ONE CAD, ONE PLM or ONE ERP resonate in your company?

It is all a result of trying to standardize a company’s tools. It is not deficient in a coordinated enterprise where information is exchanged in documents and BOMs. Although I wrote in 2011 about the tension between business and IT in my post “PLM and IT—love/hate relation?”

It is all a result of trying to standardize a company’s tools. It is not deficient in a coordinated enterprise where information is exchanged in documents and BOMs. Although I wrote in 2011 about the tension between business and IT in my post “PLM and IT—love/hate relation?”

Now, modern PLM is about a connected infrastructure where accurate data is the #1 priority.

Most of the new processes will be implemented in value streams, where the data is created in SaaS solutions running in the cloud. In such environments, business should be leading, and of course, where needed, IT should support the overall architecture concepts.

In this context, I recommend an older but still valid article: The Changing Role of IT: From Gatekeeper to Business Partner.

This changing role for IT should come in parallel to the changing role for the PLM team. The PLM team needs to first focus on enabling the new types of businesses and value streams, not on features and capabilities. This change in focus means they become part of the value creation teams instead of a cost center.

From successful PLM implementations, I have seen that the team directly reported to the CEO, CTO or CIO, no longer as a subdivision of the larger IT organization.

Where is your PLM team?

Is it a cost center or a value-creation engine?

The role of business leaders

As mentioned before, with a PLM team reporting to the business, communication should transition from discussing technology and capabilities to focusing on business value.

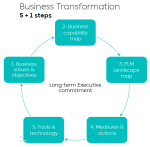

I recently wrote about this need for a change in attitude in my post: PLM business first. The recommended flow is nicely represented in the section “Starting from the business.”

I recently wrote about this need for a change in attitude in my post: PLM business first. The recommended flow is nicely represented in the section “Starting from the business.”

Image: Yousef Hooshmand.

Business leaders must realize that a change is needed due to upcoming regulations, like ESG and CSRD reporting, the Digital Product Passport and the need for product Life Cycle Analysis (LCA), which is more than just a change of tools.

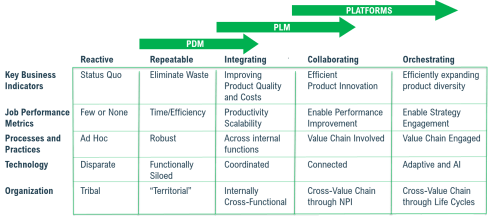

I have often referred to the diagram created by Mark Halpern from Gartner in 2015. Below you can see and adjusted diagram for 2024 including AI.

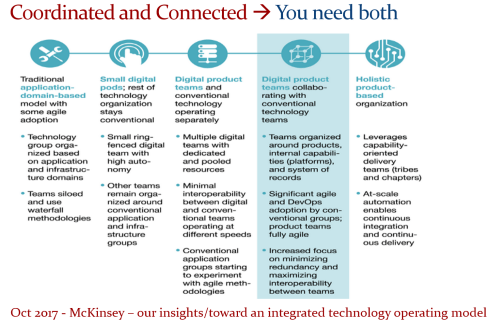

It looks like we are moving from Coordinated technology toward Connected technology. This seems easy to frame. However, my experience discussing this step in the past four to five years has led to the following four lessons learned:

- It is not a transition from Coordinated to Connected.

At this step, a company has to start in a hybrid mode – there will always remain Coordinated ways of working connected to Connected ways of working. This is the current discussion related to Federated PLM and the introduction of the terms System of Record (traditional systems / supporting linear ways of working) and Systems of Engagement (connected environments targeting real-time collaboration in their value chain) - It is not a matter of buying or deploying new tools.

Digital transformation is a change in ways of working and the skills needed. In traditional environments, where people work in a coordinated approach, they can work in their discipline and deliver when needed. People working in the connected approach have different skills. They work data-driven in a multidisciplinary mode. These ways of working require modern skills. Companies that are investing in new tools often hesitate to change their organization, which leads to frustration and failure. - There is no blueprint for your company.

Digital transformation in a company is a learning process, and therefore, the idea of a digital transformation project is a utopia. It will be a learning journey where you have to start small with a Minimum Viable Product approach. Proof of Concepts is a waste of time as they do not commit to implementing the solution. - The time is now!

The role of management is to secure the company’s future, which means having a long-term vision. And as it is a learning journey, the time is now to invest and learn using connected technology to be connected to coordinated technology. Can you avoid waiting to learn?

I have shared the image below several times as it is one of the best blueprints for describing the needed business transition. It originates from a McKinsey article that does not explicitly refer to PLM, again demonstrating it is first about a business strategy.

It is up to the management to master this process and apply it to their business in a timely manner. If not, the company and all its employees will be at risk for a sustainable business. Here, the word Sustainable has a double meaning – for the company and its employees/shareholders and the outside world – the planet.

Want to learn and discuss more?

Currently, I am preparing my session for the upcoming PLM Roadmap/PDT Europe conference on 23 and 24 October in Gothenburg. As I mentioned in previous years, this conference is my preferred event of the year as it is vendor-independent, and all participants are active in the various phases of a PLM implementation.

If you want to attend the conference, look here for the agenda and registration. I look forward to discussing modern PLM and its relation to sustainability with you. More in my upcoming posts till the conference.

Conclusion

Digital transformation in the PLM domain is going slow in many companies as it is complex. It is not an easy next step, as companies have to deal with different types of processes and skills. Therefore, a different organizational structure is needed. A decision to start with a different business structure always begins at the management level, driven by business goals. The technology is there—waiting for the business to lead.

1 comment

Comments feed for this article

September 9, 2024 at 10:56 am

Håkan Kårdén

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach. The one vendor is not possible, we all know this, but of course there are benefits in reducing vendors to a number that is manageable. Including cost of operations and support. But over time, cross disciplines and in the value network one vendor is not possible. Different parts of the world and different industries are sometimes moving also in different directions with PLM looking for the holy grail. It is vital to share ideas across industries and organisations and I believe the PLM Roadmap and PDT Europe conference is a place for that. There will be “one vendor” approaches as well as federation presented and defended. Looking forward to your contribution there.

Fully agree Håkan and that’s why the PLM Roadmap and PDT Europe conference is my favorite event – missing the side theme workshops – see you there!

LikeLike