You are currently browsing the tag archive for the ‘Catena-X’ tag.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

We, the PLM Green Global Alliance, started our first interviews with PLM-related software vendors two years ago in 2022 with SAP, and recently, we revisited them for a much broader interview.

The initial interview in 2022 focused on companies getting pushed by legislation related to plastic packaging and how they could collect and analyze their product data.

Now, two years later, we discussed a much broader scope, including the Circular Economy and even Circular Manufacturing in the automotive industry. You can read and listen to this interview following this link: The PGGA talking again with SAP on Sustainability.

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

However, as it is claimed that almost eighty percent of the environmental impact of a product is defined and decided during its design phase, we were eager to learn from the primary PLM vendors what they have observed.

PTC

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

We were fortunate to talk again with Dave Duncan, VP Sustainability at PTC, who had just returned from a three-month tour in Europe, talking with 200 manufacturers in 21 different locations and having deep discussions to understand the market and their customer’s needs.

You could follow his movements through Europe on LinkedIn and his posting from the Munich workshop was fascinating. Besides meeting customers, there were also PTC partners like MakerSite, aPriori, and Transition Technologies PSC. All three companies have recently contributed to our PGGA series related to Sustainability.

Together with Dave, we spoke again with James Norman, who is responsible for driving PTC’s solutions and strategy for the digital and Sustainability transformation. He helped us make the connection between what’s happening in the field and what PTC is considering.

When listening to the interview, you will observe that in the PLM domain, so much has changed in the past two years.

Enjoy the 36 minutes of the interview and listen to what Dave has learned from the field, as reflected by James, on how PTC is addressing Sustainability.

Slides shown during the interview combined with additional company information can be found HERE.

What we have learned

- The Corporate Sustainability Reporting Directive (CSRD) has forced companies to address Sustainability and the need for the digitalization of their processes (the digital thread)

- For Sustainability impact, do not focus just on the component properties; identify hot-spots when analyzing analyzing the impact of the product on the product level.

- As the OEM often only assembles the final product, the environmental impact is defined upstream in the supply chain.

- Modularity and Systems Thinking are crucial methodologies for implementing a Circular Economy.

- If you only consider the cradle-to-gate part of a product’s lifecycle, you might miss the big picture entirely. Even worse, you might implement design changes in the name of sustainability that result in outcomes far less sustainable than the original design. It’s crucial to look at the entire Product Service System/lifecycle to truly understand a product’s environmental impact

- We did not talk about Digital Twins and AI this time. Implementing a connected Digital Thread is, at this moment, the highest priority.

Want to learn more?

- There is the PTC Impact Report

- Dave Duncan’s article: Join PTC on Our Sustainability Journey

- A customer story: How Cummins Prioritizes Sustainability for New Product Designs

Conclusion

I enjoyed the dialogue with Dave and James and the progress we all have made towards understanding what is needed to ensure a sustainable future for our planet. So much has changed in two years.

PLM plays a crucial role in the discussion of a circular economy, the need for modularity, and sustainability reporting. All of these elements require a digital infrastructure related to the products we manufacture or use.

In addition, I was impressed by Dave’s pragmatic approach, who was in the hot spots of European manufacturing companies to understand their needs instead of telling them about their should-be dreams.

Our first PGGA interview with PLM-related software vendors was two years ago with SAP. At that time, Sustainability became more visible in corporate strategies, and regulations were imminent.

Our first PGGA interview with PLM-related software vendors was two years ago with SAP. At that time, Sustainability became more visible in corporate strategies, and regulations were imminent.

This time, Klaus Brettschneider and I want to learn what has happened related to Sustainability. Is there visible progress in their organizations and customer base? And what is hot now?

And we were positively surprised by a conversation going in many directions.

SAP

The interview was again with Darren West. Darren is the product expert for SAP’s Circular Economy solutions and this time, Stephan Fester supported him. Stephan is co-leading the SAP Global Circular Manufacturing Practice and, therefore, is well-connected to the field. Last year, in particular, working in discrete manufacturing and discussing circular manufacturing.

The interview was again with Darren West. Darren is the product expert for SAP’s Circular Economy solutions and this time, Stephan Fester supported him. Stephan is co-leading the SAP Global Circular Manufacturing Practice and, therefore, is well-connected to the field. Last year, in particular, working in discrete manufacturing and discussing circular manufacturing.

Thanks to the expertise of our guests, the discussion went in various directions, with circularity as the central theme.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

We discussed the progress of the Responsible Design & Production module that was just launched two years ago. We discussed the Green Ledger and Carbon Accounting, of course, in the context of circular manufacturing.

But also, we discussed the Digital Product Passport. Catena-X, what is it, and what is it targeting?

We also discussed how to deal with the scarcity of materials and materials harvesting. The interview could not be complete without mentioning AI.

Enjoy the 35-minute interview with Darren and Stephan on our YouTube channel.

The slides shown in this recording can be found here: PGGA talking again with SAP.

What we have learned

- Regulations heavily push SAP customers and require adequate reporting tools, not only for finance and material use but also for sustainability KPIs

- The Responsible Design & Production module launched two years ago is already in use with 60+ customers, showing the importance of having data-driven decision support for plastic packaging – to be extended to the product. Of course, as a PLM community, we are interested in understanding the next steps toward the product.

- The insights from Stephan Fester on circular manufacturing can be a logical evolution of the linear product process, as Stephan’s image shows.

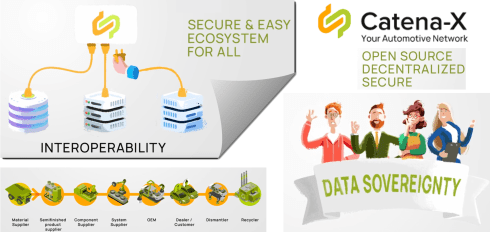

- Great insights on Catena-X as an independent network for data sharing in the global network

Want to learn more?

Events and Shows:

- SAP at Hannover Messe – April 22-26, 2024 – event information

- SAP Sapphire, Orlando, USA – June 3-5, 2024 – event information

- SAP Sapphire, Barcelona, Spain – June 11-13, 2024 – event information

Websites:

- Circular Manufacturing at Scale – Microsite

- SAP Responsible Design and Production – product page

- SAP Circular Economy page

- SAP Sustainability home page

Conclusion

It was a great discussion with a company that is quite active in supporting its customers on a sustainable journey. The journey is complex and has many aspects, as Darren and Stephan shared in this dialogue. The good news is that SAP’s customers are actively implementing measures and processes – going circular is happening!

Join the PDSFORUM next month and join me to get inspired an participate in a Think Thank session on day 2 related to designing more sustainable products. Will we meet there?

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

This is the third and last post related to the PLM Roadmap / PDT Europe conference, held from 15-16 November in Paris. The first post reported more about “traditional” PLM engagements, whereas the second post focused on more data-driven and federated PLM. If you missed them, here they are:

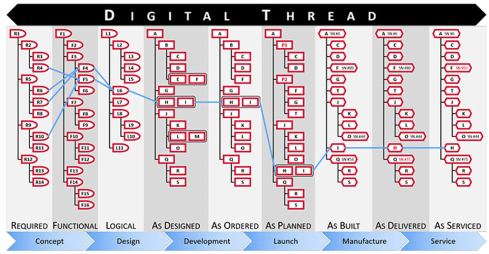

Now, I want to conclude on what I would call, in my terminology, the connected digital thread. This topic was already addressed when I reported on the federated PLM story from NIO (Yousef Hooshmand) and SAAB Aeronautics (Erik Herzog).

The Need for a Governance Digital Thread

This time, my presentation was a memory refresher related to digital transformation in the PLM domain – moving from coordinated ways of working towards connected ways of working.

A typology that is also valid for the digital thread definition.

- A Coordinated Digital Thread is a digital thread that connects various artifacts in an enterprise. These relations are created and managed to support traceability and an impact analysis. The coordinated digital thread requires human interpretation to process the information. The image below from Aras is a perfect example of a coordinated digital thread.

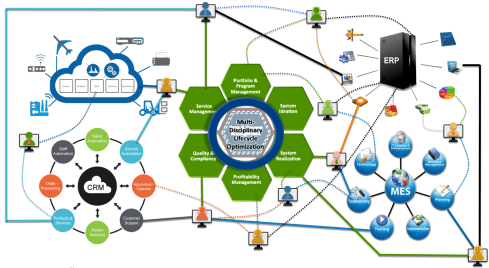

- The Connected Digital Thread is the digital thread where the artifacts are datasets stored in a federated infrastructure of databases. A connected digital thread provides real-time access to data through applications or dashboards for users. The real-time access makes the connected digital thread a solution for real-time, multidisciplinary collaboration activities.

The image above illustrates the connected digital thread as an infrastructure on top of five potential business platforms, i.e., the IoT platform, the CRM platform, the ERP platform, the MES platform and ultimately, the Product Innovation Platform.

Note: These platforms are usually a collection of systems that logically work together efficiently.

The importance of the Connected Digital Thread

When looking at the benefits of the Connected Digital Thread, the most essential feature is that it allows people in an organization to have all relevant data and its context available for making changes, analysis and design choices.

Due to the rich context, people can work proactively and reduce the number of iterations and fixes later.

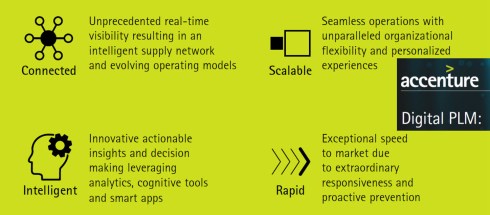

The above image from Accenture (2014) describing the business benefits can be divided into two categories:

- The top, Connected and Scalable describing capabilities

- The bottom, Intelligent and Rapid, describes the business impact

The connected digital thread for governance

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

In my session, I gave examples of why companies must invest in the connected digital thread. If you are interested in the slides from the session you can download them here on SlideShare: The Need for a Governance Digital Thread

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

First of all, as more and more companies need to provide ESG reporting related to the business, either by law or demanded by their customers, this is an area where data needs to be collected from various sources in the organization.

The PLM system will be one of the sources; other sources can be fragmented in an organization. Bringing them together manually in one report is a significant human effort, time-consuming and not supporting the business.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

By creating a connected digital thread between these sources, reporting becomes a push on the button, and the continuous availability of information will help companies assess and improve their products to reduce environmental and social risks.

According to a recent KPMG report, only a quarter of companies are ready for ESG Reporting Requirements.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

Sustaira, a company we reported in the PGGA, provides such an infrastructure based on Mendix, and during the conference, I shared a customer case with the audience. You can find more about Sustaira in our interview with them: PLM and Sustainability: talking with Sustaira.

The Connected Digital Thread and the Digital Product Passport

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

One of the areas where the connected digital thread will become important is the implementation of the Digital Product Passport (DPP), which is an obligation coming from the European Green Deal, affecting all companies that want to sell their product to the European market in 2026 and beyond.

The DPP is based on the GS1 infrastructure, originating from the retail industry. Each product will have a unique ID (UID based on ISO/IEC 15459:2015), and this UID will provide digital access to product information, containing information about the product’s used materials, its environmental impact, and recycle/reuse–ability.

It will serve both for regulatory compliance and as an information source for consumers to make informed decisions about the products they buy. The DPP aims to stimulate and enforce a more circular economy.

![]() Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

Interesting to note is that the infrastructure needed for the DPP is based on the GS1 infrastructure, where GS1 is a not-for-profit organization providing data services.

The Connected Digital Thread and Catena-X

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

So far, I have discussed the connected digital thread as an internal infrastructure in a company. Also, the examples of the connected digital thread at NIO and Saab Aeronautics focused on internal interaction.

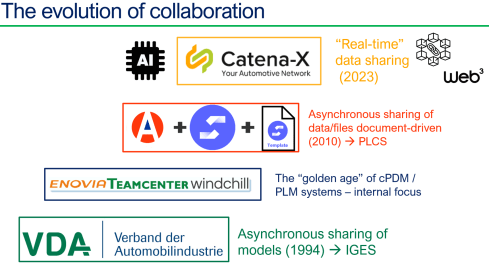

A new exciting trend is the potential rise of not-for-profit infrastructure for a particular industry. Where the GS1-based infrastructure is designed to provide visibility on sustainable targets and decisions, Catena-X is focusing on the automotive industry.

Catena-X is the establishment of a data-driven value chain for the German automotive industry and is now in the process of expanding to become a global network.

It is a significant building block in what I would call the connected or even adaptive enterprise, using a data-driven infrastructure to let information flow through the whole value chain.

It is one of the best examples of a Connected Digital Thread covering an end-to-end value chain.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

Although sustainability is mentioned in their vision statement, the main business drivers are increased efficiency, improved competitiveness, and cost reduction by removing the overhead and latency of such a network.

So Sustainability and Digitization go hand in hand.

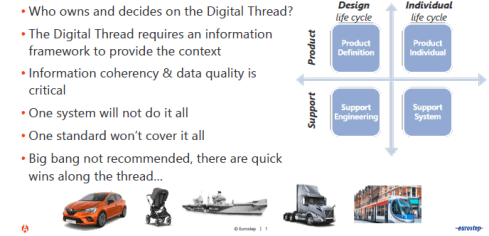

Why a Digital Thread makes a lot of sense

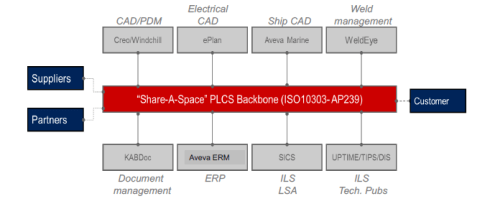

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

Following the inter-company digital thread story, Mattias Johansson‘s presentation was an excellent continuation of this concept. The full title of Mattias’ session was: Why a Digital Thread makes a lot of sense, Why It Goes Beyond Manufacturing, and Why It Should Be Standards-based.

Eurostep, recently acquired by BAE Systems, is known for its collaboration hub or information backbone, ShareAspace. The interesting trend here is switching from a traditional PLM infrastructure to an asset-centric one.

This approach makes a lot of sense for complex assets with a long lifecycle, as the development phase is usually done with a consortium of companies. Still, the owner/operator wants to maintain a digital twin of the asset – for maintenance and upgrades.

A standards-based backbone makes much sense in such an environment due to the various data formats. This setup also means we are looking at a Coordinated Digital Thread at this stage, not a Connected Digital Thread.

Mattias concluded with the question of who owns and who decides on the coordinated digital thread – a discussion also valid in the construction industry when discussing Building Information Management (BIM) and a Common Data Environment(CDE).

I believe software vendors can provide the Coordinated Digital Thread option when they can demonstrate and provide a positive business case for their solution. Still, it will be seen as an overhead to connect the dots.

For a Connected Digital Thread, I think it might be provided as an infrastructure like the World Wide Web (W3C) organization. Here, the business case is much easier to demonstrate as it is really a digital highway.

Such an infrastructure could be provided by not-for-profit organizations like GS1 (Digital Product Passport/Retail), Catena-X (Automotive) and others (Gaia-X).

![]() For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

For sure, these networks will leverage blockchain concepts (affordable now) and data sovereignty concepts now developed for web3, and of course, an aspect of AI will reduce the complexity of maintaining such an environment.

AI

And then there was AI. During the conference, people spoke more about AI than Sustainability topics, illustrating that our audience is more interested in understanding the next hype instead of feeling the short-term need to address climate change and planet sustainability.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

David Henstock, Chief Data Scientist at BAE Systems Digital Intelligence, talked about turning AI into an Operational Reality, sharing some lessons & challenges from Defence. David mentioned that he was not an expert in PLM but shared various viewpoints on the usage (benefits & risks) of implementing AI in an organization.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

Erdal Tekin, Senior Chief Leader for Digital Transformation at Turkish Aerospace, talked about AI-powered collaboration. I am a bit skeptical on this topic as AI always comes with a flavor.

And we closed the conference with a roundtable discussion: AI, PLM and the Digital Thread: Why should we care about AI?

From the roundtable, I concluded that we are all convinced AI will have a significant impact in the upcoming years and are all in the early phases of the AI hype.

Will AI introduction go faster than digital transformation?

Conclusion

The conference gave me confidence that digital transformation in the PLM domain has reached the next level. Many sessions were related to collaboration concepts outside the traditional engineering domain – coordinated and connected digital threads.

The connected digital thread is the future, and as we saw it, it heralds the downfall of monolithic PLM. The change is needed for business efficiency AND compliance with more and more environmental regulations.

I am looking forward to seeing the pace of progress here next year.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…