Last week, I wrote about the first day of the crowded PLM Roadmap/PDT Europe conference.

Last week, I wrote about the first day of the crowded PLM Roadmap/PDT Europe conference.

You can still read my post here in case you missed it: A very long week after PLM Roadmap / PDT Europe 2025

My conclusion from that post was that day 1 was a challenging day if you are a newbie in the domain of PLM and data-driven practices. We discussed and learned about relevant standards that support a digital enterprise, as well as the need for ontologies and semantic models to give data meaning and serve as a foundation for potential AI tools and use cases.

My conclusion from that post was that day 1 was a challenging day if you are a newbie in the domain of PLM and data-driven practices. We discussed and learned about relevant standards that support a digital enterprise, as well as the need for ontologies and semantic models to give data meaning and serve as a foundation for potential AI tools and use cases.

This post will focus on the other aspects of product lifecycle management – the evolving methodologies and the human side.

Note: I try to avoid the abbreviation PLM, as many of us in the field associate PLM with a system, where, for me, the system is more of an IT solution, where the strategy and practices are best named as product lifecycle management.

Note: I try to avoid the abbreviation PLM, as many of us in the field associate PLM with a system, where, for me, the system is more of an IT solution, where the strategy and practices are best named as product lifecycle management.

And as a reminder, I used the image above in other conversations. Every company does product lifecycle management; only the number of people, their processes, or their tools might differ. As Peter Billelo mentioned in his opening speech, the products are why the company exists.

Unlocking Efficiency with Model-Based Definition

![]() Day 2 started energetically with Dennys Gomes‘ keynote, which introduced model-based definition (MBD) at Vestas, a world-leading OEM for wind turbines.

Day 2 started energetically with Dennys Gomes‘ keynote, which introduced model-based definition (MBD) at Vestas, a world-leading OEM for wind turbines.

Personally, I consider MBD as one of the stepping stones to learning and mastering a model-based enterprise, although do not be confused by the term “model”. In MBD, we use the 3D CAD model as the source to manage and support a data-driven connection among engineering, manufacturing, and suppliers. The business benefits are clear, as reported by companies that follow this approach.

However, it also involves changes in technology, methodology, skills, and even contractual relations.

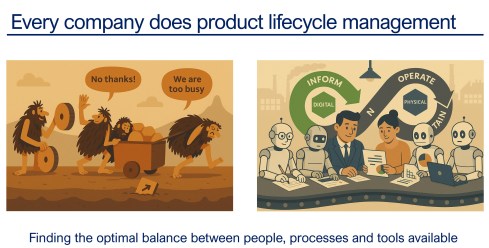

Dennys started sharing the analysis they conducted on the amount of information in current manufacturing drawings. The image below shows that only the green marker information was used, so the time and effort spent creating the drawings were wasted.

It was an opportunity to explore model-based definition, and the team ran several pilots to learn how to handle MBD, improve their skills, methodologies, and tool usage. As mentioned before, it is a profound change to move from coordinated to connected ways of working; it does not happen by simply installing a new tool.

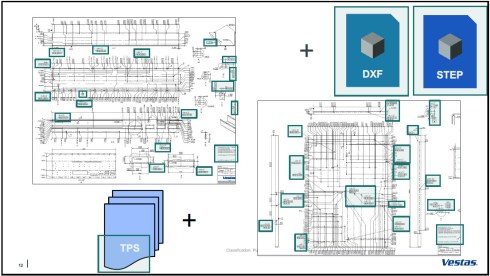

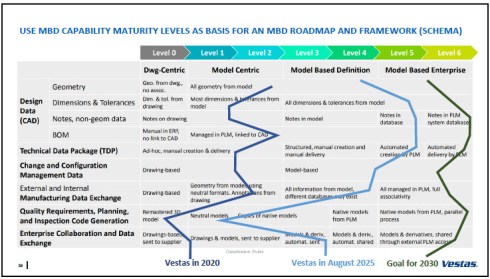

The image above shows the learning phases and the ultimate benefits accomplished. Besides moving to a model-based definition of the information, Dennys mentioned they used the opportunity to simplify and automate the generation of the information.

Vestas is on a clear path, and it is interesting to see their ambition in the MBD roadmap below.

An inspirational story, hopefully motivating other companies to make this first step to a model-based enterprise. Perhaps difficult at the beginning from the people’s perspective, but as a business, it is a profitable and required direction.

Bridging The Gap Between IT and Business

It was a great pleasure to listen again to Peter Vind from Siemens Energy, who first explained to the audience how to position the role of an enterprise architect in a company compared to society. He mentioned he has to deal with the unicorns at the C-level, who, like politicians in a city, sometimes have the most “innovative” ideas – can they be realized?

It was a great pleasure to listen again to Peter Vind from Siemens Energy, who first explained to the audience how to position the role of an enterprise architect in a company compared to society. He mentioned he has to deal with the unicorns at the C-level, who, like politicians in a city, sometimes have the most “innovative” ideas – can they be realized?

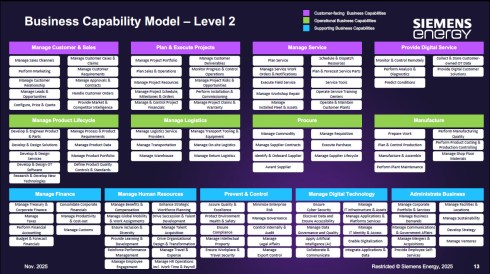

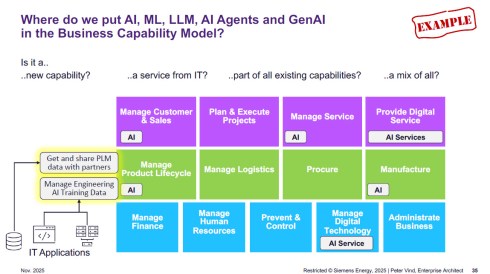

To answer these questions, Peter is referring to the Business Capability Model (BCM) he uses as an Enterprise Architect.

Business Capabilities define ‘what’ a company needs to do to execute its strategy, are structured into logical clusters, and should be the foundation for the enterprise, on which both IT and business can come to a common approach.

The detailed image above is worth studying if you are interested in the levels and the mappings of the capabilities. The BCM approach was beneficial when the company became disconnected from Siemens AG, enabling it to rationalize its application portfolio.

Next, Peter zoomed in on some of the examples of how a BCM and structured application portfolio management can help to rationalize the AI hype/demand – where is it applicable, where does AI have impact – and as he illustrated, it is not that simple. With the BCM, you have a base for further analysis.

Other future-relevant topics he shared included how to address the introduction of the digital product passport and how the BCM methodology supports the shift in business models toward a modern “Power-as-a-Service” model.

He concludes that having a Business Capability Model gives you a stable foundation for managing your enterprise architecture now and into the future. The BCM complements other methodologies that connect business strategy to (IT) execution. See also my 2024 post: Don’t use the P** word! – 5 lessons learned.

He concludes that having a Business Capability Model gives you a stable foundation for managing your enterprise architecture now and into the future. The BCM complements other methodologies that connect business strategy to (IT) execution. See also my 2024 post: Don’t use the P** word! – 5 lessons learned.

Holistic PLM in Action.

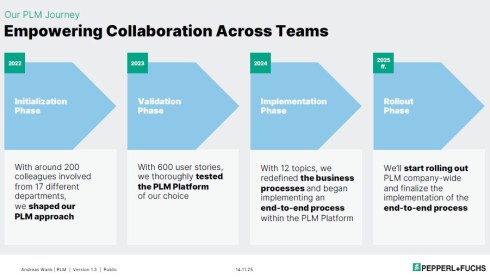

or companies struggling with their digital transformation in the PLM domain, Andreas Wank, Head of Smart Innovation at Pepperl+Fuchs SE, shared his journey so far. All the essential aspects of such a transformation were mentioned. Pepperl+Fuchs has a portfolio of approximately 15,000 products that combine hardware and software.

or companies struggling with their digital transformation in the PLM domain, Andreas Wank, Head of Smart Innovation at Pepperl+Fuchs SE, shared his journey so far. All the essential aspects of such a transformation were mentioned. Pepperl+Fuchs has a portfolio of approximately 15,000 products that combine hardware and software.

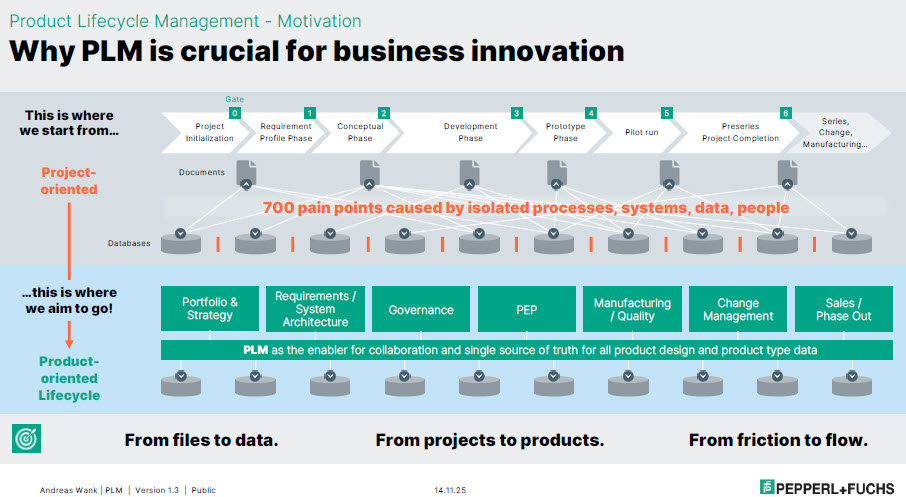

It started with the WHY. With such a massive portfolio, business innovation is under pressure without a PLM infrastructure. Too many changes, fragmented data, no single source of truth, and siloed ways of working lead to much rework, errors, and iterations that keep the company busy while missing the global value drivers.

Next, the journey!

The above image is an excellent way to communicate the why, what, and how to a broader audience. All the main messages are in the image, which helps people align with them.

The first phase of the project, creating digital continuity, is also an excellent example of digital transformation in traditional document-driven enterprises. From files to data align with the From Coordinated To Connected theme.

Next, the focus was to describe these new ways of working with all stakeholders involved before starting the selection and implementation of PLM tools. This approach is so crucial, as one of my big lessons learned from the past is: “Never start a PLM implementation in R&D.”

If you start in R&D, the priority shifts away from the easy flow of data between all stakeholders; it becomes an R&D System that others will have to live with.

You never get a second, first impression!

Pepperl+Fuchs spends a long time validating its PLM selection – something you might only see in privately owned companies that are not driven by shareholder demands, but take the time to prepare and understand their next move.

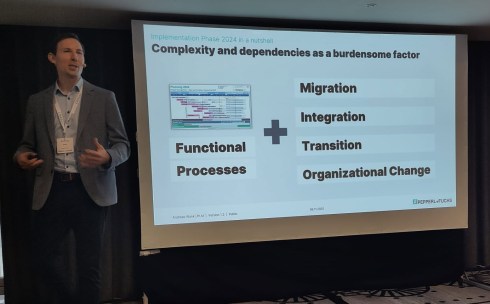

As Andreas also explained, it is not only about the functional processes. As the image shows, migration (often the elephant in the room) and integration with the other enterprise systems also need to be considered. And all of this is combined with managing the transition and the necessary organizational change.

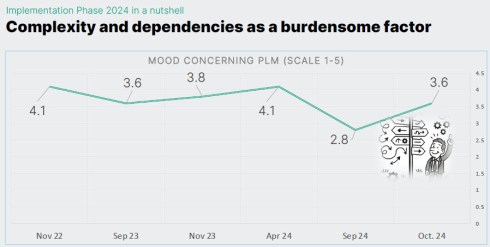

Andreas shared some best practices illustrating the focus on the transition and human aspects. They have implemented a regular survey to measure the PLM mood in the company. And when the mood went radical down on Sept 24, from 4.1 to 2.8 on a scale of 1 to 5, it was time to act.

They used one week at a separate location, where 30 of his colleagues worked on the reported issues in one room, leading to 70 decisions that week. And the result was measurable, as shown in the image below.

Andreas’s story was such a perfect fit for the discussions we have in the Share PLM podcast series that we asked him to tell it in more detail, also for those who have missed it. Subscribe and stay tuned for the podcast, coming soon.

Andreas’s story was such a perfect fit for the discussions we have in the Share PLM podcast series that we asked him to tell it in more detail, also for those who have missed it. Subscribe and stay tuned for the podcast, coming soon.

Trust, Small Changes, and Transformation.

Ashwath Sooriyanarayanan and Sofia Lindgren, both active at the corporate level in the PLM domain at Assa Abloy, came with an interesting story about their PLM lessons learned.

Ashwath Sooriyanarayanan and Sofia Lindgren, both active at the corporate level in the PLM domain at Assa Abloy, came with an interesting story about their PLM lessons learned.

To understand their story, it is essential to comprehend Assa Abloy as a special company, as the image below explains. With over 1000 sites, 200 production facilities, and, last year, on average every two weeks, a new acquisition, it is hard to standardize the company, driven by a corporate organization.

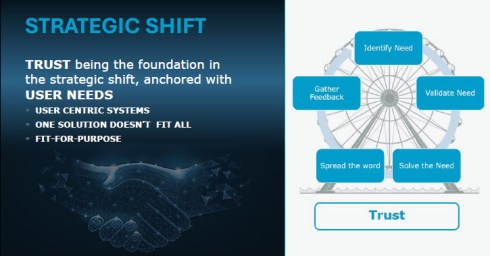

However, this was precisely what Assa Abloy has been trying to do over the past few years. Working towards a single PLM system, with generic processes for all, spending a lot of time integrating and migrating data from the different entities became a mission impossible.

To increase user acceptance, they fell into the trap of customizing the system ever more to meet many user demands. A dead end, as many other companies have probably experienced similarly.

And then they came with a strategic shift. Instead of holding on to the past and the money invested in technology, they shifted to the human side.

The PLM group became a trusted organisation supporting the individual entities. Instead of telling them what to do (Top-Down), they talked with the local business and provided standardized PLM knowledge and capabilities where needed (Bottom-Up).

This “modular” approach made the PLM group the trusted partner of the individual business. A unique approach, making us realize that the human aspect remains part of implementing PLM

Humans cannot be transformed

Given the length of this blog post, I will not spend too much text on my closing presentation at the conference. After a technical start on DAY 1, we gradually moved to broader, human-related topics in the latter part.

Given the length of this blog post, I will not spend too much text on my closing presentation at the conference. After a technical start on DAY 1, we gradually moved to broader, human-related topics in the latter part.

You can find my presentation here on SlideShare as usual, and perhaps the best summary from my session was given in this post from Paul Comis. Enjoy his conclusion.

Conclusion

Two and a half intensive days in Paris again at the PLM Roadmap / PDT Europe conference, where some of the crucial aspects of PLM were shared in detail. The value of the conference lies in the stories and discussions with the participants. Only slides do not provide enough education. You need to be curious and active to discover the best perspective.

For those celebrating: Wishing you a wonderful Thanksgiving!

Leave a comment

Comments feed for this article