![]() In my first discussion with Rob Ferrone, the original Product Data PLuMber, we discussed the necessary foundation for implementing a Digital Thread or leveraging AI capabilities beyond the hype. This is important because all these concepts require data quality and data governance as essential elements.

In my first discussion with Rob Ferrone, the original Product Data PLuMber, we discussed the necessary foundation for implementing a Digital Thread or leveraging AI capabilities beyond the hype. This is important because all these concepts require data quality and data governance as essential elements.

If you missed part 1, here is the link: Data Quality and Data Governance – A hype?

Rob, did you receive any feedback related to part 1? I spoke with a company that emphasized the importance of data quality; however, they were more interested in applying plasters, as they consider a broader approach too disruptive to their current business. Do you see similar situations?

Rob, did you receive any feedback related to part 1? I spoke with a company that emphasized the importance of data quality; however, they were more interested in applying plasters, as they consider a broader approach too disruptive to their current business. Do you see similar situations?

Honestly, not much feedback. Data Governance isn’t as sexy or exciting as discussions on Designing, Engineering, Manufacturing, or PLM Technology. HOWEVER, as the saying goes, all roads lead to Rome, and all Digital Engineering discussions ultimately lead to data.

Honestly, not much feedback. Data Governance isn’t as sexy or exciting as discussions on Designing, Engineering, Manufacturing, or PLM Technology. HOWEVER, as the saying goes, all roads lead to Rome, and all Digital Engineering discussions ultimately lead to data.

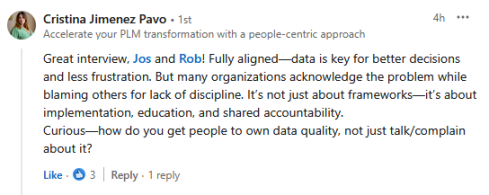

Cristina Jimenez Pavo’s comment illustrates that the question is in the air.:

Everyone knows that it should be better; high-performing businesses have good data governance, but most people don’t know how to systematically and sustainably improve their data quality. It’s hard and not glamorous (for most), so people tend to focus on buying new systems, which they believe will magically resolve their underlying issues.

Data governance as a strategy

Thanks for the clarification. I imagine it is similar to Configuration Management, i.e., with different needs per industry. I have seen ISO 8000 in the aerospace industry, but it has not spread further to other businesses. What about data governance as a strategy, similar to CM?

Thanks for the clarification. I imagine it is similar to Configuration Management, i.e., with different needs per industry. I have seen ISO 8000 in the aerospace industry, but it has not spread further to other businesses. What about data governance as a strategy, similar to CM?

That’s a great idea. Do you mind if I steal it?

That’s a great idea. Do you mind if I steal it?

If you ask any PLM or ERP vendor, they’ll claim to have a master product data governance template for every industry. While the core principles—ownership, control, quality, traceability, and change management, as in Configuration Management—are consistent, their application must vary based on the industry context, data types, and business priorities.

Designing effective data governance involves tailoring foundational elements, including data stewardship, standards, lineage, metadata, glossaries, and quality rules. These elements must reflect the realities of operations, striking a balance between trade-offs such as speed versus rigor or openness versus control.

Designing effective data governance involves tailoring foundational elements, including data stewardship, standards, lineage, metadata, glossaries, and quality rules. These elements must reflect the realities of operations, striking a balance between trade-offs such as speed versus rigor or openness versus control.

The challenge is that both configuration management (CM) and data governance often suffer from a perception problem, being viewed as abstract or compliance-heavy. In truth, they must be practical, embedded in daily workflows, and treated as dynamic systems central to business operations, rather than static documents.

Think of it like the difference between stepping on a scale versus using a smartwatch that tracks your weight, heart rate, and activity, schedules workouts, suggests meals, and aligns with your goals.

![]() Governance should function the same way:

Governance should function the same way:

responsive, integrated, and outcome-driven.

Who is responsible for data quality?

I have seen companies simplifying data quality as an enhancement step for everyone in the organization, like a “You have to be more accurate” message, similar perhaps to configuration management. Here we touch people and organizational change. How do you make improving data quality happen beyond the wish?

I have seen companies simplifying data quality as an enhancement step for everyone in the organization, like a “You have to be more accurate” message, similar perhaps to configuration management. Here we touch people and organizational change. How do you make improving data quality happen beyond the wish?

In most companies, managing product data is a responsibility shared among all employees. But increasingly complex systems and processes are not designed around people, making the work challenging, unpleasant, and often poorly executed.

In most companies, managing product data is a responsibility shared among all employees. But increasingly complex systems and processes are not designed around people, making the work challenging, unpleasant, and often poorly executed.

I like to quote Larry English – The Father of Information Quality:

“Information producers will create information only to the quality level for which they are trained, measured and held accountable.”

A common reaction is to add data “police” or transactional administrators, who unintentionally create more noise or burden those generating the data.

The real solution lies in embedding capable, proactive individuals throughout the product lifecycle who care about data quality as much as others care about the product itself – it was the topic I discussed at the 2025 Share PLM summit in Jerez – Rob Ferrone – Bill O-Materials also presented in part 1 of our discussion.

These data professionals collaborate closely with designers, engineers, procurement, manufacturing, supply chain, maintenance, and repair teams. They take ownership of data quality in systems, without relieving engineers of their responsibility for the accuracy of source data.

Some data, like component weight, is best owned by engineers, while others—such as BoM structure—may be better managed by system specialists. The emphasis should be on giving data professionals precise requirements and the authority to deliver.

They not only understand what good data looks like in their domain but also appreciate the needs of adjacent teams. This results in improved data quality across the business, not just within silos. They also work with IT and process teams to manage system changes and lead continuous improvement efforts.

![]() The real challenge is finding leaders with the vision and drive to implement this approach.

The real challenge is finding leaders with the vision and drive to implement this approach.

The costs or benefits associated with good or poor data quality

At the peak of interest in being data-driven, large consulting firms published numerous studies and analyses, proving that data-driven companies achieve better results than their data-averse competitors. Have you seen situations where the business case for improving “product data” quality has led to noticeable business benefits, and if so, in what range? Double digit, single digit?

At the peak of interest in being data-driven, large consulting firms published numerous studies and analyses, proving that data-driven companies achieve better results than their data-averse competitors. Have you seen situations where the business case for improving “product data” quality has led to noticeable business benefits, and if so, in what range? Double digit, single digit?

Improving data quality in isolation delivers limited value. Data quality is a means to an end. To realise real benefits, you must not only know how to improve it, but also how to utilise high-quality data in conjunction with other levers to drive improved business outcomes.

Improving data quality in isolation delivers limited value. Data quality is a means to an end. To realise real benefits, you must not only know how to improve it, but also how to utilise high-quality data in conjunction with other levers to drive improved business outcomes.

I built a company whose premise was that good-quality product data flowing efficiently throughout the business delivered dividends due to improved business performance. We grew because we delivered results that outweighed our fees.

Last year’s turnover was €35M, so even with a conservatively estimated average in-year ROI of 3:1, the company delivered over € 100 M of cost savings or additional revenue per year to clients, with the majority of these benefits being sustainable.

There is also the potential to unlock new value and business models through data-driven innovation.

For example, connecting disparate product data sources into a unified view and taking steps to sustainably improve data quality enables faster, more accurate, and easier collaboration between OEMs, fleet operators, spare parts providers, workshops, and product users, which leads to a new value proposition around minimizing painful operational downtime.

For example, connecting disparate product data sources into a unified view and taking steps to sustainably improve data quality enables faster, more accurate, and easier collaboration between OEMs, fleet operators, spare parts providers, workshops, and product users, which leads to a new value proposition around minimizing painful operational downtime.

AI and Data Quality

Currently, we are seeing numerous concepts emerge where AI, particularly AI agents, can be highly valuable for PLM. However, we also know that in legacy environments, the overall quality of data is poor. How do you envision AI supporting PLM processes, and where should you start? Or has it already started?

Currently, we are seeing numerous concepts emerge where AI, particularly AI agents, can be highly valuable for PLM. However, we also know that in legacy environments, the overall quality of data is poor. How do you envision AI supporting PLM processes, and where should you start? Or has it already started?

It’s like mining for rare elements—sifting through massive amounts of legacy data to find the diamonds. Is it worth the effort, especially when diamonds can now be manufactured? AI certainly makes the task faster and easier. Interestingly, Elon Musk recently announced plans to use AI to rewrite legacy data and create a new, high-quality knowledge base. This suggests a potential market for trusted, validated, and industry-specific legacy training data.

It’s like mining for rare elements—sifting through massive amounts of legacy data to find the diamonds. Is it worth the effort, especially when diamonds can now be manufactured? AI certainly makes the task faster and easier. Interestingly, Elon Musk recently announced plans to use AI to rewrite legacy data and create a new, high-quality knowledge base. This suggests a potential market for trusted, validated, and industry-specific legacy training data.

Will OEMs sell it as valuable IP, or will it be made open source like Tesla’s patents?

AI also offers enormous potential for data quality and governance. From live monitoring to proactive guidance, adopting this approach will become a much easier business strategy. One can imagine AI forming the core of a company’s Digital Thread—no longer requiring rigidly hardwired systems and data flows, but instead intelligently comparing team data and flagging misalignments.

AI also offers enormous potential for data quality and governance. From live monitoring to proactive guidance, adopting this approach will become a much easier business strategy. One can imagine AI forming the core of a company’s Digital Thread—no longer requiring rigidly hardwired systems and data flows, but instead intelligently comparing team data and flagging misalignments.

That said, data alignment remains complex, as discrepancies can be valid depending on context.

A practical starting point?

Data Quality as a Service. My former company, Quick Release, is piloting an AI-enabled service focused on EBoM to MBoM alignment. It combines a data quality platform with expert knowledge, collecting metadata from PLM, ERP, MES, and other systems to map engineering data models.

Experts define quality rules (completeness, consistency, relationship integrity), and AI enables automated anomaly detection. Initially, humans triage issues, but over time, as trust in AI grows, more of the process can be automated. Eventually, no oversight may be needed; alerts could be sent directly to those empowered to act, whether human or AI.

Experts define quality rules (completeness, consistency, relationship integrity), and AI enables automated anomaly detection. Initially, humans triage issues, but over time, as trust in AI grows, more of the process can be automated. Eventually, no oversight may be needed; alerts could be sent directly to those empowered to act, whether human or AI.

Summary

We hope the discussions in parts 1 and 2 helped you understand where to begin. It doesn’t need to stay theoretical or feel unachievable.

- The first step is simple: recognise product data as an asset that powers performance, not just admin.

Then treat it accordingly. - You don’t need a 5-year roadmap or a board-approved strategy before you begin. Start by identifying the product data that supports your most critical workflows, the stuff that breaks things when it’s wrong or missing. Work out what “good enough” looks like for that data at each phase of the lifecycle.

Then look around your business: who owns it, who touches it, and who cares when it fails? - From there, establish the roles, rules, and routines that help this data improve over time, even if it’s manual and messy to begin with. Add tooling where it helps.

- Use quality KPIs that reflect the business, not the system. Focus your governance efforts where there’s friction, waste, or rework.

- And where are you already getting value? Lock it in. Scale what works.

Conclusion

It’s not about perfection or policies; it’s about momentum and value. Data quality is a lever. Data governance is how you pull it.

Just start pulling- and then get serious with your AI applications!

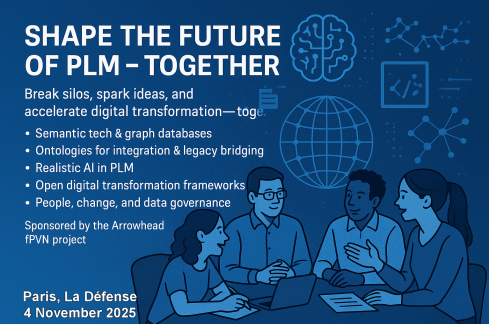

Are you attending the PLM Roadmap/PDT Europe 2025 conference on

November 5th & 6th in Paris, La Defense?

There is an opportunity to discuss the future of PLM in a workshop before the event.

More information will be shared soon; please mark November 4th in the afternoon on your agenda.

Leave a comment

Comments feed for this article