You are currently browsing the tag archive for the ‘Design Engagement System’ tag.

Those who have been following my blog posts over the past two years may have discovered that I consistently use the terms “System of Engagement” and “System of Record” in the context of a Coordinated and Connected PLM infrastructure.

Understanding the distinction between ‘System of Engagement‘ and ‘System of Record‘ is crucial for comprehending the type of collaboration and business purpose in a PLM infrastructure. When explored in depth, these terms will reveal the underlying technology.

The concept

A year ago, I had an initial discussion with three representatives of a typical system of engagement. I spoke with Andre Wegner from Authentise, MJ Smith from CoLab and Oleg Shilovitsky from OpenBOM. You can read and see the interview here: The new side of PLM? Systems of Engagement!

A year ago, I had an initial discussion with three representatives of a typical system of engagement. I spoke with Andre Wegner from Authentise, MJ Smith from CoLab and Oleg Shilovitsky from OpenBOM. You can read and see the interview here: The new side of PLM? Systems of Engagement!

As a follow-up, I had a more detailed interview with Taylor Young, the Chief Strategy Officer of CoLab, early this year.

CoLab introduced the term Design Engagement System (DES), a new TLA. Based on a survey among 250 global engineering leaders, we discussed the business impact and value of their DES System of Engagement.

CoLab introduced the term Design Engagement System (DES), a new TLA. Based on a survey among 250 global engineering leaders, we discussed the business impact and value of their DES System of Engagement.

You can read the discussion here: Where traditional PLM fails.

The business benefits

I like that CoLab’s external messaging focuses on the business capabilities and opportunities, which reminded me of the old Steve Jobs recording: Don’t talk about the product!

There are so many discussions on LinkedIn about the usage of various technologies and concepts without a connection to the business. I’ll let you explore and decide.

It’s worth noting that while the ‘System of Engagement’ offers significant business benefits, it’s not a standalone solution. The right technology is crucial for translating these benefits into tangible business results.

This was a key takeaway from my follow-up discussion with MJ Smith, CMO at CoLab, about the difference between Configuration and Customization.

Why configurability?

Hello MJ, it has been a while since we spoke, and this time, I am curious to learn how CoLab fits in an enterprise PLM infrastructure, zooming in on the aspects of configuration and customization.

Hello MJ, it has been a while since we spoke, and this time, I am curious to learn how CoLab fits in an enterprise PLM infrastructure, zooming in on the aspects of configuration and customization.

Using configurability, we can make a smaller number of features work for more use cases or business processes. Users do not want to learn and adopt many different features, and a system of engagement should make it easy to participate in a business process, even for infrequent or irregular users.

Using configurability, we can make a smaller number of features work for more use cases or business processes. Users do not want to learn and adopt many different features, and a system of engagement should make it easy to participate in a business process, even for infrequent or irregular users.

In design review, this means cross-functional teams and suppliers who are not the core users of CAD or PLM.

I agree, and for that reason, we see the discussion of Systems of Record (not user-friendly and working in a coordinated mode) and Systems of Engagement (focus on the end-user and working in a connected mode). How do you differentiate with CoLab?

I agree, and for that reason, we see the discussion of Systems of Record (not user-friendly and working in a coordinated mode) and Systems of Engagement (focus on the end-user and working in a connected mode). How do you differentiate with CoLab?

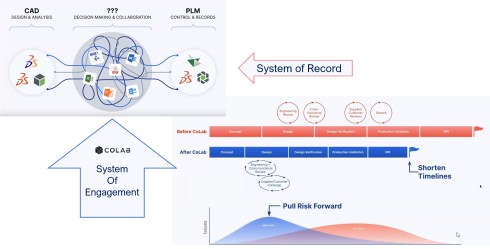

From a technology perspective, as a System of Engagement, CoLab wants to eliminate complex, multi-step workflows that require users to navigate between 5-10+ different point solutions to complete a review.

From a technology perspective, as a System of Engagement, CoLab wants to eliminate complex, multi-step workflows that require users to navigate between 5-10+ different point solutions to complete a review.

For example:

- SharePoint for sending data

- CAD viewers for interrogating models

- PowerPoint for documenting markups – using screenshots

- Email or Teams meetings for discussing issues

- Spreadsheets for issue tracking

- Traditional PLM systems for consolidation

As mentioned before, the participants can be infrequent or irregular users from different companies. This gap exists today, with only 20% of suppliers and 49% of cross-functional teams providing valuable design feedback (see the 2023 report here). To prevent errors and increase design quality, NPD teams must capture helpful feedback from these SMEs, many of whom only participate in 2 to 3 design reviews each year.

As mentioned before, the participants can be infrequent or irregular users from different companies. This gap exists today, with only 20% of suppliers and 49% of cross-functional teams providing valuable design feedback (see the 2023 report here). To prevent errors and increase design quality, NPD teams must capture helpful feedback from these SMEs, many of whom only participate in 2 to 3 design reviews each year.

Configuration and Customization

Back to the interaction between the System of Engagement (CoLab) and Systems or Records, in this case, probably the traditional PLM system. I think it is important to define the differences between Configuration and Customization first.

Back to the interaction between the System of Engagement (CoLab) and Systems or Records, in this case, probably the traditional PLM system. I think it is important to define the differences between Configuration and Customization first.

These would be my definitions:

- Configuration involves setting up standard options and features in software to meet specific needs without altering the code, such as adjusting settings or using built-in tools.

- Customization involves modifying the software’s code or adding new features to tailor it more precisely to unique requirements, which can include creating custom scripts, plugins, or changes to the user interface.

Both configuration and customization activities can be complex depending on the system we are discussing.

It’s also interesting to consider how configurability and customization can go hand in hand. What starts as a customization for one customer could become a configurable feature later.

It’s also interesting to consider how configurability and customization can go hand in hand. What starts as a customization for one customer could become a configurable feature later.

For software providers like CoLab, the key is to stay close to your customers so that you can understand the difference between a niche use case – where customization may be the best solution – vs. something that could be broadly applicable.

In my definition of customization, I first thought of connecting to the various PLM and CAD systems. Are these interfaces standardized, or are they open to configuration and customization?

In my definition of customization, I first thought of connecting to the various PLM and CAD systems. Are these interfaces standardized, or are they open to configuration and customization?

CoLab offers out-of-the-box integrations with PLM systems, including Windchill, Teamcenter, and 3DX Enovia. By integrating PLM with CoLab, companies can share files straight from PLM to CoLab without having to export or convert to a neutral format like STP.

CoLab offers out-of-the-box integrations with PLM systems, including Windchill, Teamcenter, and 3DX Enovia. By integrating PLM with CoLab, companies can share files straight from PLM to CoLab without having to export or convert to a neutral format like STP.

By sharing CAD from PLM to CoLab, companies make it possible for non-PLM users – inside the company and outside (e.g., suppliers, customers) to participate in design reviews. This use case is an excellent example of how a system of engagement can be used as the connection point between two companies, each with its own system of record.

CoLab can also send data back to PLM. For example, you can see whether there is an open review on a part from within Windchill PLM and how many unresolved comments exist on a file shared with CoLab from PLM. Right now, there are some configurable aspects to our integrations – such as file-sharing controls for Windchill users.

We plan to invest more in the configurability of the PLM to DES interface. We will also invest in our REST API, which customers can use to build custom integrations if they like, instead of using our OOTB integrations.

To get an impression, look at this 90-second demo of CoLab’s Windchill integration for reference.

Talking about IP security is a topic that is always mentioned when companies interact with each other, and in particular in a connected mode. Can you tell us more about how Colab deals with IP protection?

Talking about IP security is a topic that is always mentioned when companies interact with each other, and in particular in a connected mode. Can you tell us more about how Colab deals with IP protection?

CoLab has enterprise customers, like Schaeffler, implementing attribute-based access controls so that users can only access files in CoLab that they would otherwise have access to in Windchill.

CoLab has enterprise customers, like Schaeffler, implementing attribute-based access controls so that users can only access files in CoLab that they would otherwise have access to in Windchill.

We also have customers who integrate CoLab with their ERP system to auto-provision guest accounts for suppliers so they can participate in design reviews.

This means that the OEM is responsible for identifying which data is shared within CoLab. I am curious: Are these kinds of IP-sharing activities standardized because you have a configurable interface to the PLM/ERP, or is this still a customization?

This means that the OEM is responsible for identifying which data is shared within CoLab. I am curious: Are these kinds of IP-sharing activities standardized because you have a configurable interface to the PLM/ERP, or is this still a customization?

I am referring to this point in the Federated PLM Interest Group. We discuss using OSLC as one of the connecting interfaces between the System of Record and the System of Engagement (Modules)—it’s still in the early days, as you can read in this article—but we see encouraging similar results. Is this a topic of attention for CoLab, too?

The interface between CoLab and PLM is the same for every customer (not custom) but can be configured with attributes-based access controls. End users who have access must explicitly share files. Further access controls can also be put in place on the CoLab side to protect IP.

The interface between CoLab and PLM is the same for every customer (not custom) but can be configured with attributes-based access controls. End users who have access must explicitly share files. Further access controls can also be put in place on the CoLab side to protect IP.

We are taking a similar approach to integrating as outlined by OSLC. The OSLC concept is interesting to us, as it appears to provide a framework for better-supporting concepts such as versions and variants. The interface delegation concepts are also of interest.

Conclusion

It was great to dive deeper into the complementary value of CoLab as a typical System of Engagement. Their customers are end-users who want to collaborate efficiently during design reviews. By letting their customers work in a dedicated but connected environment, they are released from working in a traditional, more administrative PLM system.

Interfacing between these two environments will be an interesting topic to follow in the future. Will it be, for example, OSLC-based, or do you see other candidates to standardize?

One year ago, I wrote the post: Time to Split PLM, which reflected a noticeable trend in 2022 and 2023.

One year ago, I wrote the post: Time to Split PLM, which reflected a noticeable trend in 2022 and 2023.

If you still pursue the Single Source of Truth or think that PLM should be supported by a single system, the best you can buy, then you are living in the past.

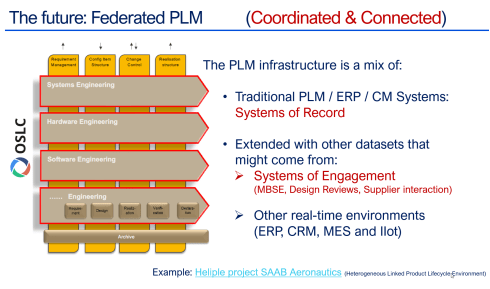

It is now the time to move from a Monolithic PLM Landscape to a Federated Domain and Data Mesh (Yousef Hooshmand) or the Heliple Federated PLM project (Erik Herzog) – you may have read about these concepts.

When moving from a traditional coordinated, document-driven business towards a modern, connected, and data-driven business, there is a paradigm shift. In many situations, we still need the document-driven approach to manage baselines for governance and traceability, where we create the required truth for manufacturing, compliance, and configuration management.

However, we also need an infrastructure for multidisciplinary collaboration nowadays. Working with systems, a combination of hardware and software, requires a model-based approach and multidisciplinary collaboration. This infrastructure needs to be data-driven to remain competitive despite more complexity, connecting stakeholders along value streams.

Traditional PLM vendors still push all functionality into one system, often leading to frustration among the end-users, complaining about lack of usability, bureaucracy, and the challenge of connecting to external stakeholders, like customers, suppliers, design or service partners.

Traditional PLM vendors still push all functionality into one system, often leading to frustration among the end-users, complaining about lack of usability, bureaucracy, and the challenge of connecting to external stakeholders, like customers, suppliers, design or service partners.

Systems of Engagement

It is in modern PLM infrastructures where I started the positioning of Systems or Record (the traditional enterprise siloes – PDM/PLM, ERP, CM) and the Systems of Engagement (modern environments designed for close to real-time collaboration between stakeholders within a domain/value stream). In the Heliple project (image below), the Systems of Record are the vertical bars, and the Systems of Engagement are the horizontal bars.

The power of a System of Engagement is the data-driven connection between stakeholders even when working in different enterprises. Last year, I discussed with Andre Wegner from Authentise, MJ Smith from CoLab, and Oleg Shilovitsky from OpenBOM.

They all focus on modern, data-driven, multidisciplinary collaboration. You can find the discussion here: The new side of PLM? Systems of Engagement!

Where is the money?

Business leaders usually are not interested in a technology or architectural discussion – too many details and complexity, they look for the business case. Look at this recent post and comments on LinkedIn – “When you try to explain PLM to your C-suite, and they just don’t get it.”

Business leaders usually are not interested in a technology or architectural discussion – too many details and complexity, they look for the business case. Look at this recent post and comments on LinkedIn – “When you try to explain PLM to your C-suite, and they just don’t get it.”

It is hard to build evidence for the need for systems of engagement, as the concepts are relatively new and experiences from the field are bubbling up slowly. With the Heliple team, we are now working on building the business case for Federated PLM in the context of the Heliple project scope.

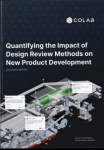

Therefore, I was excited to read the results of this survey: Quantifying the impact of design review methods on NPD, a survey among 250 global engineering leaders initiated by CoLab.

![]() CoLab is one of those companies that focus on providing a System of Engagement, and their scope is design collaboration. In this post, I am discussing the findings of this survey with Taylor Young, Chief Strategy Officer of CoLab.

CoLab is one of those companies that focus on providing a System of Engagement, and their scope is design collaboration. In this post, I am discussing the findings of this survey with Taylor Young, Chief Strategy Officer of CoLab.

CoLab – the company /the mission

Taylor, thanks for helping me explain the complementary value of CoLab based on some of the key findings from the survey. But first of all, can you briefly introduce CoLab as a company and the unique value you are offering to your clients?

Taylor, thanks for helping me explain the complementary value of CoLab based on some of the key findings from the survey. But first of all, can you briefly introduce CoLab as a company and the unique value you are offering to your clients?

Hi Jos, CoLab is a Design Engagement System – we exist to help engineering teams make design decisions.

Hi Jos, CoLab is a Design Engagement System – we exist to help engineering teams make design decisions.

Product decision-making has never been more challenging – or more essential – to get right – that’s why we built CoLab. In today’s world of product complexity, excellent decision-making requires specialized expertise. That means decision-making is no longer just about people engaging with product data – it’s about people engaging with other people.

PLM provides a strong foundation where product data is controlled (and therefore reliable). But PLM has a rigid architecture that’s optimized for data (and for human-to-data interaction). To deal with increased complexity in product design, engineers now need a system that’s built for human-to-human interaction complimentary to PLM.

CoLab allows you to interrogate a rich dataset, even an extended team, outside your company borders in real-time or asynchronously. With CoLab, decisions are made with context, input from the right people, and as early as possible in the process. Reviews and decision-making get tracked automatically and can be synced back to PLM. Engineers can do what they do best, and CoLab will support them by documenting everything in the background.

Design Review Quality

It is known that late-stage design errors are very costly, both impacting product launches and profitability. The report shows design review quality has been rated as the #1 most important factor affecting an engineering team’s ability to deliver projects on time.

It is known that late-stage design errors are very costly, both impacting product launches and profitability. The report shows design review quality has been rated as the #1 most important factor affecting an engineering team’s ability to deliver projects on time.

Is it a severe problem for companies, and what are they trying to do to improve the quality of design reviews? Can you quantify the problem?

Our survey report demonstrated that late-stage design errors delay product launches for 90% of companies. The impact varies significantly from organization to organization, but we know that for large manufacturing companies, just one late-stage design error can be a six to seven-figure problem.

Our survey report demonstrated that late-stage design errors delay product launches for 90% of companies. The impact varies significantly from organization to organization, but we know that for large manufacturing companies, just one late-stage design error can be a six to seven-figure problem.

There are a few factors that lead to a “quality” design review – some of the most important ones we see leading manufacturing companies doing differently are:

- Who they include – the highest performing teams include manufacturing, suppliers, and customers within the proper context.

- When they happen – the highest performing teams focus on getting CAD to these stakeholders early in the process (during detailed design) and paralleling these processes (i.e., they don’t wait for one group to sign off before getting early info to the next)

- Rethinking the Design Review meeting – the highest performing teams aren’t having issue-generation meetings – they have problem-solving meetings. Feedback is collected from a broad audience upfront, and meetings are used to solve nuanced problems – not to get familiar with the project for the first time.

Multidisciplinary collaboration

An interesting observation is that providing feedback to engineers mainly comes from peers or within the company. Having suppliers or customers involved seems to be very difficult. Why do you think this is happening, and how can we improve their contribution?

An interesting observation is that providing feedback to engineers mainly comes from peers or within the company. Having suppliers or customers involved seems to be very difficult. Why do you think this is happening, and how can we improve their contribution?

When we talk to manufacturing companies about “collaboration” or how engineers engage with other engineers – however good or bad the processes are internally, it almost always is significantly more challenging/less effective when they go external. External teams often use different CAD systems, work in different time zones, speak other first languages, and have varying levels of access to core engineering information.

When we talk to manufacturing companies about “collaboration” or how engineers engage with other engineers – however good or bad the processes are internally, it almost always is significantly more challenging/less effective when they go external. External teams often use different CAD systems, work in different time zones, speak other first languages, and have varying levels of access to core engineering information.

However, as we can read from the HBR article What the Most Productive Companies Do Differently, we know that the most productive manufacturing companies “collaborate with suppliers and customers to form new ecosystems that benefit from agglomeration effects and create shared pools of value”.

They leverage the expertise of their suppliers and customers to do things more effectively. But manufacturing companies struggle to create engaging, high-value, external collaboration and ‘co-design’ without the tools purpose-built for person-to-person external communication.

Traceability and PLM

One of the findings is that keeping track of the feedback and design issues is failing in companies. One of my recommendations from the past was to integrate Issue management into your PLM systems – why is this not working?

One of the findings is that keeping track of the feedback and design issues is failing in companies. One of my recommendations from the past was to integrate Issue management into your PLM systems – why is this not working?

We believe that the task of completing a design review and the task of documenting the output of that review should not be two separate efforts. Suppose we are to reduce the amount of time engineers spend on admin work and decrease the number of issues that are never tracked or documented (43%, according to our survey).

We believe that the task of completing a design review and the task of documenting the output of that review should not be two separate efforts. Suppose we are to reduce the amount of time engineers spend on admin work and decrease the number of issues that are never tracked or documented (43%, according to our survey).

In that case, we need to introduce a purpose-built, engaging design review system that is self-documenting. It is crucial for the quality of design reviews that issues aren’t tracked in a separate system from where they are raised/developed, but that instead, they are automatically tracked just by doing the work.

Learn More?

Below is the recording of a recent webinar, where Taylor said that your PLM alone isn’t enough: Why you need a Design Engagement System during product development.

- A traditional PLM system is the system of record for product data – from ideation through sustaining engineering.

- However one set of critical data never makes it to the PLM. For many manufacturing companies today, design feedback and decisions live almost exclusively in emails, spreadsheets, and PowerPoint decks. At the same time, 90% of engineering teams state that product launches are delayed due to late-stage changes.

- Engineering teams need to implement a true Design Engagement System (DES) for more effective product development and a more holistic digital thread.

Conclusion

Traditional PLM systems have always been used to provide quality and data governance along the product lifecycle. However, most end users dislike the PLM system as it is a bureaucratic overhead to their ways of working. CoLab, with its DES solution, provides a System of Engagement focusing on design reviews, speed, and quality of multidisciplinary collaboration complementary to the PLM System of Record – a modern example of how digitization is transforming the PLM domain.

[…] (The following post from PLM Green Global Alliance cofounder Jos Voskuil first appeared in his European PLM-focused blog HERE.) […]

[…] recent discussions in the PLM ecosystem, including PSC Transition Technologies (EcoPLM), CIMPA PLM services (LCA), and the Design for…

Jos, all interesting and relevant. There are additional elements to be mentioned and Ontologies seem to be one of the…

Jos, as usual, you've provided a buffet of "food for thought". Where do you see AI being trained by a…

Hi Jos. Thanks for getting back to posting! Is is an interesting and ongoing struggle, federation vs one vendor approach.…